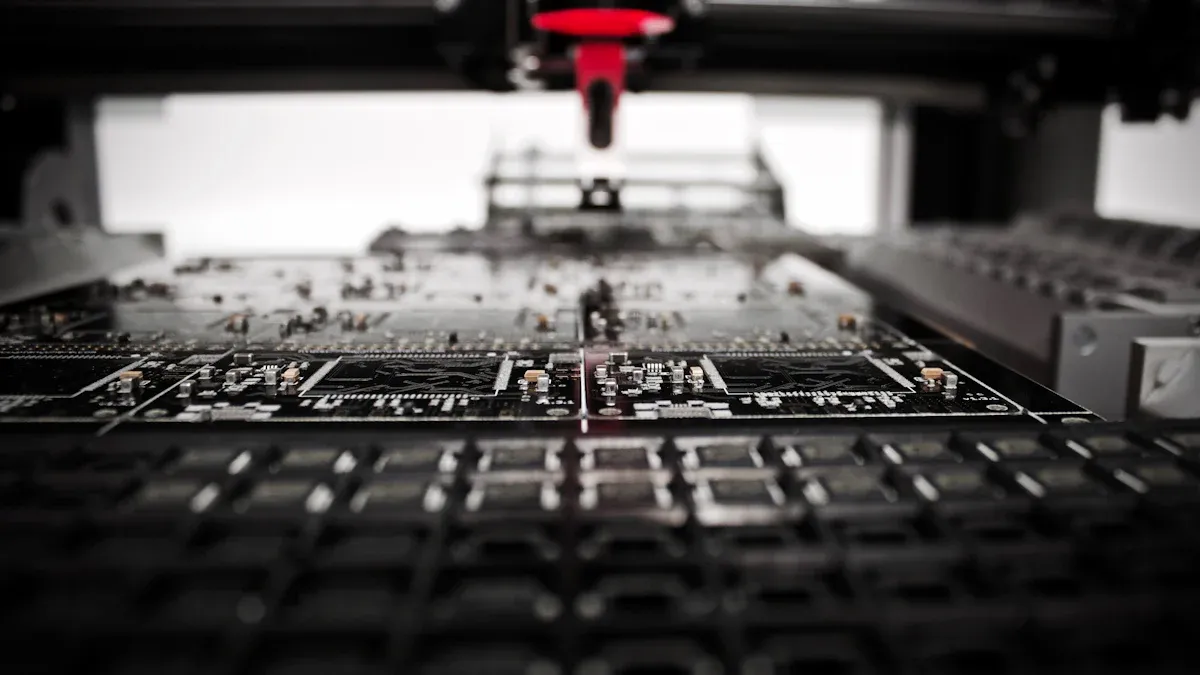

Quick turn industrial automation PCBA changes how factories make products. It speeds up production, so automation systems are ready faster. For example, inspection now takes 80% less time than manual checks. Production output has also increased by up to 20%. Automated systems can spot problems early, avoiding sudden breakdowns. This keeps work running smoothly without stops. Quick turn industrial automation PCBA also helps with fast prototyping and custom designs. Factories can now make prototypes in 1-2 days. This helps businesses adjust quickly and test new ideas easily.

Key Takeaways

Quick turn PCBA makes production faster, cutting wait times to days. This helps factories meet market needs quickly.

Faster prototyping with quick turn PCBA saves up to 60% of time. This lets businesses test and improve designs easily.

Quick turn PCBA reduces delays by providing needed parts on time. This keeps machines working and avoids expensive stops.

Customization matters; quick turn PCBA allows flexible designs for specific needs. This improves how systems work overall.

Careful testing ensures quick turn PCBA gives reliable parts. This boosts the reliability and efficiency of automation systems.

Understanding Quick Turn Industrial Automation PCBA

Definition and Key Features

Quick turn industrial automation PCBA means making printed circuit boards quickly for automation systems. It helps reduce waiting times while keeping quality high. This allows faster production and quicker use of automation tools.

Key features include:

Rapid turnaround times: Boards are ready in days, not weeks.

Flexibility in design modifications: Designs can be changed easily after testing.

Small batch feasibility: Small amounts of complex boards can be made cheaply.

The PCB market is growing fast. Experts predict it will grow by USD 19.05 billion between 2022 and 2027. This shows more industries need advanced parts like quick turn industrial automation PCBA to improve automation.

Role in Modern Industrial Automation

Quick turn industrial automation PCBA helps make factories smarter. It speeds up testing and creating new ideas. Design changes can be made quickly, so systems stay updated.

Automation systems need reliable electronic parts. Quick turn PCB assembly ensures these parts work well. Faster production means solutions are ready sooner, boosting efficiency and output.

Advantages Over Traditional PCB Assembly

Quick turn PCB assembly is better than older methods. It saves time, lowers costs, and improves quality.

Feature/Benefit | Quick Turn PCBA | Traditional PCB Manufacturing |

|---|---|---|

Average Lead Time | 24 hours to a few days | Weeks to months |

Flexibility in Design Modifications | High | Low |

Batch Size | Small batches feasible | Larger batches required |

Importance in R&D Cycle | Speeds up innovation | Slower due to longer lead times |

Quick turn PCB assembly also reduces hidden costs and finds errors early. Designs move to production faster, making changes easier to apply. These benefits help industries stay ahead in automation.

Benefits of Quick Turn PCB Assembly for Industrial Automation

Faster Prototyping and Development Cycles

Quick turn PCB assembly helps make prototypes faster. This speeds up the process of turning ideas into real products. Working with skilled local manufacturers can save a lot of time. These experts use advanced tools to make development quicker. Studies show using good PCB prototypes can cut engineering time by 60%. This means you can test and improve designs more easily, ensuring systems work well.

Quick prototyping also finds problems early, avoiding costly fixes later. Faulty designs are fixed before production starts, saving time and money. This faster process helps businesses launch products sooner and stay competitive.

Benefit | What It Means |

|---|---|

Lower Costs | Faster cycles mean less waste and lower costs per product. |

Increased Capacity | Shorter cycles allow more products to be made with the same resources. |

Improved Service Levels | Quicker production leads to faster delivery and happier customers. |

Competitive Advantage | Companies can create and sell products faster than their rivals. |

Using quick turn PCB assembly for prototyping helps businesses innovate and stay ahead in the market.

Minimizing Downtime and Maintenance Delays

Downtime can stop work and cause big losses. Quick turn PCB assembly helps by making sure important parts are ready when needed. Keeping spare parts organized, as suggested by MaintainX, reduces repair time and keeps systems running.

Source | Key Idea |

|---|---|

MaintainX | Organized spare parts reduce delays and improve system availability. |

IBM | Tracking repair times helps find ways to fix systems faster. |

MachineMetrics | Monitoring machines helps reduce unplanned downtime and delays. |

Quick turn PCB assembly also cuts production time by over 25%, according to industry data. A 15% drop in defect rates makes systems more reliable and competitive.

Metric | How It Helps Reduce Downtime |

|---|---|

Production lead time | Speeds up work by over 25%. |

Defect rate reduction | Fewer defects improve reliability. |

Yield rate | Higher yield means less waste. |

Using quick PCB assembly keeps systems running smoothly with fewer interruptions, boosting productivity.

Supporting Customization and Adaptability

Factories often need special solutions for their unique needs. Quick turn PCB assembly allows custom designs to fit these needs. Over 60% of customers prefer systems they can adjust to their operations.

Evidence Type | What It Shows |

|---|---|

Customization Preference | Most customers want systems they can change to fit their needs. |

Pricing Impact | Custom designs can affect costs based on materials and complexity. |

Cost Increase | Adding advanced features can raise costs by up to 25%. |

Custom designs also cut rework time by 30% and reduce manual data entry by 85%. These changes make work faster and more efficient.

Quick turn PCB assembly helps create flexible systems that meet specific goals. This flexibility keeps automation systems competitive in a fast-changing industry.

Improving System Dependability and Efficiency

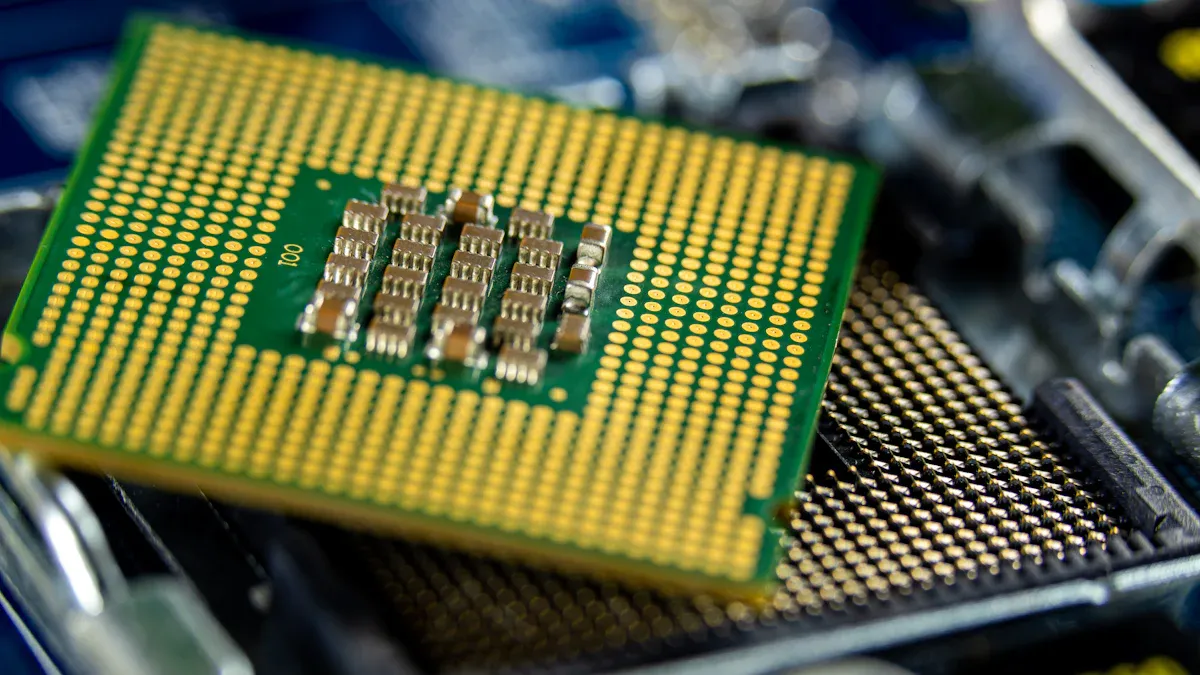

Dependability and efficiency are very important for factory systems. Quick turn PCB assembly helps these systems work well and reliably. By following global rules and using strict tests, makers create high-quality PCBs that fit tough factory needs.

Quick turn PCB assembly focuses on quality while staying fast. This means your systems get reliable parts quickly, even for urgent jobs.

Steps to Make PCBs Reliable

Makers use many steps to ensure PCBs are dependable for factories:

They follow global rules like IPC-A-610 for top-quality work.

Multiple checks make sure PCBs work in real-life situations.

Services include making, finding parts, and testing for factory needs.

PCBs are built to handle tough conditions like heat or shaking.

Testing to Boost Performance

Testing is key to making sure PCBs work well. Makers use different tests to check performance:

Test Type | What It Checks |

|---|---|

Makes sure PCBs work as they should | |

Burn-in Testing | Tests how PCBs handle stress |

Environmental Testing | Checks strength in tough conditions |

In Circuit Testing | Tests each part for dependability |

These tests prove PCBs can handle factory demands. For example, burn-in testing puts PCBs under stress to check strength. Environmental testing sees how they handle heat, cold, or shaking. Functional testing ensures PCBs do their job, and in-circuit testing checks each part works well.

Real-Life Benefits for Factory Systems

Factory PCBs go through tough tests, like chemical and mechanical checks. This ensures only the best PCBs are used in your systems. Strong PCBs lower the chance of breakdowns, reduce downtime, and improve system performance. Using quick turn PCB assembly makes your systems more reliable and efficient.

Quick turn PCB assembly not only gives you strong parts but also customizes them for your needs. This flexibility helps your systems stay efficient, even in hard factory conditions. With these improvements, your systems can work better and succeed for a long time.

Real-World Applications of Quick Turn Industrial Automation PCBA

Manufacturing and Assembly Line Optimization

Quick turn PCB assembly helps factories work faster and better. It shortens production times and boosts efficiency. By cutting changeover times, it allows assembly lines to handle different products quickly. This is very useful in places where changes happen often.

Evidence Description | Key Insight |

|---|---|

PCB makers need efficient lines to earn more money. | Better line efficiency means higher productivity and profits. |

Long changeover times slow down production in busy factories. | Quick turn PCBA reduces these times, improving line efficiency. |

OEE checks how well machines work based on time, speed, and quality. | Using quick turn PCBA improves OEE for better results. |

Quick turn PCB assembly also increases the number of products made. This helps meet tight deadlines without lowering quality. Better production leads to higher profits and smoother operations.

Tip: Focus on cutting changeover times and improving OEE. Quick turn PCBA can help you reach these goals.

Robotics and Automated Machinery Advancements

Robots and automated machines need accurate and strong electronic parts. Quick turn PCB assembly makes these parts fast and ensures they are high quality. This helps add new technology to systems, making them smarter and quicker.

The industrial automation market is growing fast. Systems like SCADA, PLC, and DCS are very important. SCADA systems help analyze data and make decisions in real time. Quick turn PCB assembly supports these systems by providing the needed parts quickly.

Quick turn PCB assembly speeds up production in busy factories.

It helps create prototypes fast, which is key for tight schedules.

Using quick turn PCBA improves assembly line efficiency greatly.

With quick turn PCB assembly, you can stay ahead in robotics. It helps deliver new ideas that meet modern industry needs.

Energy Sector Efficiency Improvements

The energy sector needs to save money and work better. Quick turn PCB assembly helps by making important parts faster. These parts are used in renewable energy systems and power grids. Quick turn PCBA ensures these systems have reliable and strong components.

The energy market is growing quickly. New technologies that improve efficiency are leading this growth. Quick turn PCB assembly helps by reducing the time it takes to make new energy solutions. This lets companies meet market needs faster and use new ideas.

Note: SCADA systems are key in energy for real-time control. Quick turn PCB assembly ensures these systems work well and reliably.

Using quick turn PCB assembly improves energy systems. It reduces downtime, boosts performance, and supports a greener future.

Logistics and Supply Chain Automation Enhancements

Quick turn PCBA helps improve logistics and supply chain systems. It makes sure electronic parts are made and delivered quickly. This keeps operations smooth and avoids delays that can cause problems.

Boosting Supply Chain Efficiency

Supply chains need fast deliveries and accurate tracking to work well. Quick turn PCBA provides quality parts faster, reducing delays and keeping systems running.

Fast deliveries mean less waiting for important parts.

Better product availability avoids running out of stock.

Custom strategies make customers happier with better service.

When your supply chain works smoothly, you can grow your business. It also helps meet customer needs without interruptions.

Key Benefits for Logistics Performance

Quick turn PCBA improves logistics by speeding up deliveries and cutting delays. This saves money and makes operations more efficient.

Key Benefits | What It Does |

|---|---|

Finds better delivery routes to save money. | |

Improves delivery accuracy | Ensures parts arrive on time for working systems. |

Reduces delays | Speeds up production and delivery cycles for better efficiency. |

Using these benefits, you can make logistics smoother and save money.

Tip: Use data to check delivery routes and find ways to improve. This helps make deliveries faster and more accurate.

Supporting Automation in Logistics

Logistics automation needs reliable electronic parts to work well. Quick turn PCBA ensures these parts are ready when needed. This helps with real-time tracking and better inventory management.

For example, automated warehouses use quick turn PCBA for advanced sensors and controllers. These tools improve inventory tracking and reduce mistakes. This makes logistics faster and saves money.

Quick turn PCBA not only improves current systems but also helps create new solutions. By using this technology, you can make your logistics and supply chain more efficient and seamless.

Quick turn PCBA helps factories work faster and avoid delays. It lets you change systems quickly to match new needs. This keeps your business competitive. PCB production is moving to places like Thailand and Vietnam. These areas focus on making things faster and smarter. Experts say the PCB market will grow by USD 19.05 billion by 2027. Better automation and smart tools are making this happen. Using quick turn PCBA gives you strong and flexible solutions. These improve how well your systems work and make them more reliable.

FAQ

What is quick turn PCBA?

Quick turn PCBA means making printed circuit board assemblies very fast. It helps deliver high-quality PCBs quickly for testing and use in automation systems.

How does quick turn PCBA reduce downtime?

It quickly provides parts for repairs or upgrades. This reduces waiting time during fixes, keeping your systems running smoothly.

Can quick turn PCBA support custom designs?

Yes, it lets you create special PCB designs. This helps your systems work better by meeting specific needs.

Is quick turn PCBA cost-effective?

Quick turn PCBA saves time and reduces mistakes. Faster testing and fewer errors lower costs, making it a smart choice for automation.

What industries benefit most from quick turn PCBA?

Industries like factories, robotics, energy, and shipping benefit the most. Quick turn PCBA improves how these industries work by making them faster and more reliable.

Tip: Work with skilled PCB makers to get the most out of quick turn PCBA for your systems.

See Also

Enhancing Workflow Efficiency in PCBA Production Processes

The Role of PCBA in Advancing Modern Electronics

Significance of PCBA Manufacturing Skills in Electronics Design

Elevating Electronics Performance Through Advanced PCBA Techniques