“I always want clear answers, quick work, and results I can trust when I pick a pcb assembly service. Good help really matters to me.”

Most people say they are happy with printed circuit board assembly. Recent surveys show that over 99.6% of customers have good experiences with their pcb orders. Reviews talk about good quality, helpful support, and clear prices. Many people say great instructions and fast shipping make them trust the pcb company. Both hobbyists and experts use real experiences to pick the best printed circuit board assembly partner.

Key Takeaways

Pick PCB assembly services that use quality rules and test each board. This helps make sure the boards work well and last long.

Find companies that work fast and talk clearly. This helps your projects finish on time.

Good customer support fixes problems fast. It also makes ordering simple, even for new or hard designs.

Look at prices closely and ask for full quotes. This helps you avoid surprise costs like setup or rush fees.

Check your design files before you order. Choose a service that matches your project size, money, and time needs for the best deal.

What Users Value

Quality

You want your pcbs to work well every time. Most people look for safety and rules like UL and RoHS. You care about how the boards are made. You check for no mistakes, right parts, and strong solder. Many trust a pcb assembly service that checks boards with machines and X-rays. You want your boards to pass tests like power-on and stress tests. Good boards do not have scratches or missing parts. You need every batch to be just as good as the first one.

Key quality metrics users mention:

No scratches, cracks, or solder mistakes

Works well and lasts long

Tested with AOI, X-ray, and other checks

Same good build every time

Turnaround Time

You want your boards fast, especially for a prototype. Many pcb assembly companies can finish small orders in 24 hours. Local companies like Avanti Circuits Inc. and Sunstone Circuits are fast but may cost more. Overseas companies like JLCPCB and PCBWay are also quick, sometimes in one day, but shipping can slow things down. You think about speed, quality, and price. Fast service helps you finish on time, but you still want good boards.

Support

You want good help when you order pcb assembly. People talk about staff who answer fast and help with questions. You want to know what is happening with your order. You want quick help if there is a problem. Good support makes you feel sure, even with new designs or prototypes.

Pricing

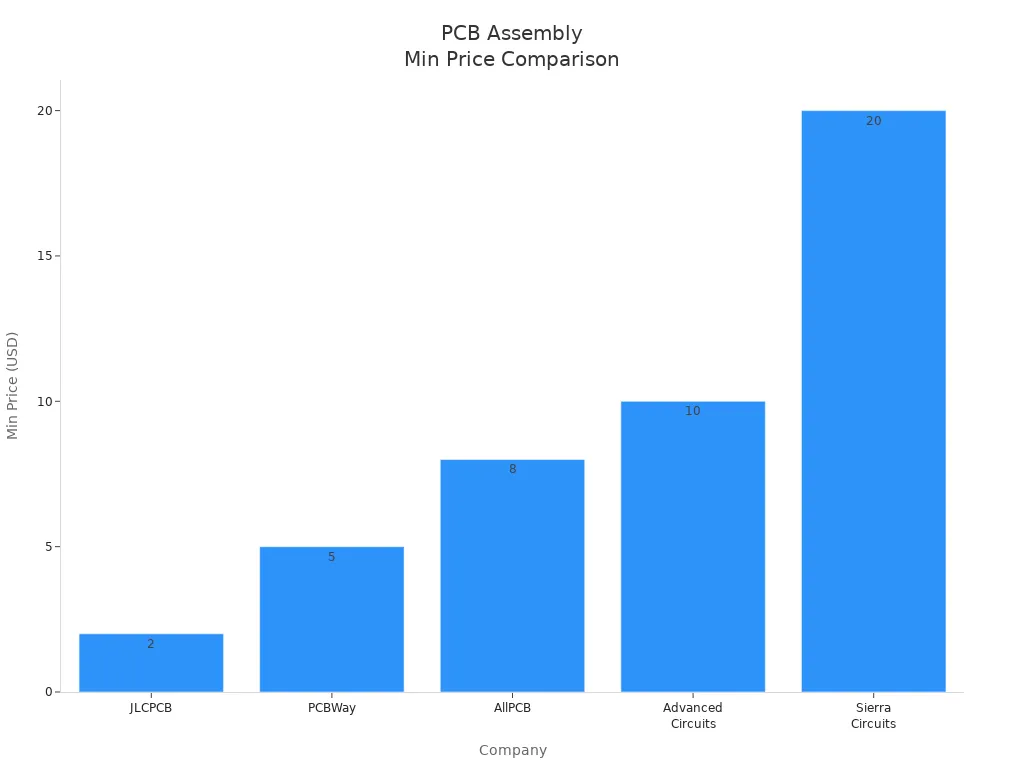

You see that prices for pcb assembly can be very different. Some companies like JLCPCB have low prices for small orders. Others like Sierra Circuits cost more for special features and fast work. Many European companies do not show prices online, so you must ask. Prices change with order size, board type, and extra help. The table below shows how prices and times compare:

Company | Approximate Price Range (USD for 10 boards) | Lead Time (Days) | Specialization / User Perception Highlights |

|---|---|---|---|

JLCPCB | $2 – $5 | 3 – 7 | Cheap, fast for new ideas |

PCBWay | $5 – $10 | 5 – 10 | Flexible, good for more boards |

AllPCB | $8 – $12 | 7 – 12 | One-stop, fair price |

Advanced Circuits | $10 – $20 | 5 – 10 | Premium, good for hard designs |

Sierra Circuits | $20 – $50 | 7 – 15 | Premium, advanced boards |

Ordering Process

You want ordering to be easy and simple. Many people like instant quote tools like InstantDFM™. You like uploading files in many formats and getting answers fast. A clean website helps you order without trouble. You also like services that do design, making, and assembly together. Good help during ordering makes you feel safe. Some people want more features, but most say the process is easy.

Positive Reviews

High-Quality Assembly

You want your pcbs to be made well. Many people say they get great quality from printed circuit board assembly services. They see that the boards are strong and put together with care. Companies that check every board and follow rules get more good reviews. When you get a board with no problems, you feel ready to use it right away. Good quality helps your project work as it should.

“The boards looked perfect and worked the first time. I trust this company for every order.”

Fast Delivery

You need your boards to arrive quickly. Many people say fast delivery is a big reason they pick a service. Users talk about companies like Mermar Electronics for always sending orders on time. You can get your boards in as little as 24 hours with quick turn pcb assembly. Fast delivery lets you finish your projects on time.

Customers say, “100% on time delivery for the past 6 months.”

Quick Turn PCB Assembly ships in one day to one week.

People say fast shipping helps with new ideas and urgent jobs.

Many workers, like engineers and managers, like on-time shipping.

Helpful Service

You want good help when you order pcbs. Many people say customer service is easy and friendly. You can ask questions and get answers that are clear. Some people say the staff helped fix design issues before making the boards. People from many countries say good support is important everywhere.

ALLPCB gets good reviews for great service and helpful staff.

Customers like how easy it is from start to finish.

Many people feel thankful for the help they get.

Easy Ordering

You want ordering to be simple and quick. Many people say it is easy to upload files and get quotes right away. A clear website and simple steps help you not make mistakes. You can watch your order and see updates at each step. When ordering is easy, you save time and feel sure about your order.

Tip: Always check your files before you send them to get the right boards.

Printed Circuit Board Assembly Issues

Defects

Defects are a big problem in printed circuit board assembly. These problems can make your pcb not work well or break early. Here are some defects people often see:

Component placement issues: parts not lined up, missing or extra parts, polarity reversal, offset

Physical damage: pads that are lifted or missing, bent boards, bent parts, cracked solder

Other defects: oxidation, contamination, solder resist defects

You might find parts in the wrong place or missing. Sometimes, there are extra parts or parts put on sideways. You may see too much solder, wrong polarity, or wrong parts. Oxidation, cracked solder, and dirt can show up too. Bent boards and other defects can make your board stop working. These problems can make your project look bad and not work right.

Tip: Check your boards for defects as soon as you get them. Early checks help you find problems before you use the boards.

Communication Problems

You want clear updates and answers about your order. Sometimes, companies reply slowly or give confusing messages. Bad communication makes it hard to fix problems or get feedback. Some companies, like Bittele Electronics, give good updates and manage projects well. Others, like Seeed Studio, sometimes help but can be slow or sound like robots. Delays in talking often happen during holidays or busy times. Good customer service helps you feel sure and keeps your project moving.

Extra Costs

You might find extra costs when you order assembly. These costs can surprise you if you do not check first. The table below shows common extra charges you might see:

Extra Cost Category | Description | Cost Details / Notes |

|---|---|---|

Component Sourcing | Buying parts for your board | Prices change with supplier and part rarity |

Inventory Management | Storing and tracking parts | Extra costs for rare or hard-to-find parts |

SMT Processing Cost | Soldering small parts onto the board | $0.0015–$0.002 per patch point, more for complex parts |

DIP Post-Welding Cost | Soldering larger or special parts by hand | Higher cost for more pins or complex parts |

Testing Cost | Checking if your board works | About $0.30 per pcb, discounts for big orders |

Engineering and Stencil Fees | Setup fees for small orders | $300–$1000 for engineering, $50–$100 for stencils |

Turnaround Time Premium | Rush fees for faster delivery | Extra charges for overtime or quick part sourcing |

You can avoid extra costs by asking for a full quote. Always check for hidden fees before you order.

Delays

You may have delays with your pcb order. Over 60% of new designs get delayed because companies need more info or must fix files. Delays can happen if your files are missing details or have mistakes. Flexible and rigid-flex boards often take longer to make. Other reasons are hard designs, missing parts, or changes to your order. Shipping, quality checks, or rules can also slow things down. You can help by checking your files and giving clear instructions.

Note: Clear and full paperwork helps your order go faster.

Company Responses

You want to know how companies fix problems. Some companies answer fast and try to help you. Bittele Electronics has a team that manages projects and gives updates. They care about customers and want good relationships. Seeed Studio sometimes gives friendly help and may give coupons or refunds for lost packages. But some people say replies are slow or not helpful, especially on holidays. You may get sorry messages and offers to help, but company rules can limit what they do. Good customer service makes you feel important and helps fix problems quickly.

PCB Assembly Service Comparison

Provider Strengths

There are many good things about top pcb assembly providers. PCBWay is known for fast and clear answers. You can pay in different ways and watch your order. People say the boards are high quality with no mistakes. Bittele Electronics helps with small and big orders. They use advanced SMT and check boards with AOI and X-ray. Seeed Studio works with all project sizes and gives open-source hardware. ALLPCB is good for saving money and has helpful support.

Boards work well because of careful soldering.

Providers follow rules like ISO 9001 and UL.

You get your boards on time and get good help.

Some companies have special features, like different solder colors or flexible pcb shapes.

Weaknesses

There are some problems with these companies. Sometimes, boards have burnt spots or loose parts from bad heat control. Bad soldering can make weak spots or break parts. Some people say orders come late and slow down projects. You might see plating voids or slivers that break the path. Dust or water can also hurt your boards. Talking with overseas companies can be hard and slow to fix problems.

Some companies do not keep your data safe enough.

Slow delivery can mess up your project plans.

User Preferences

You have lots of choices for pcb assembly services. Local companies give fast service and easy talking. You get quick answers and can change things fast. Local services test boards well, so they work right. They let you order custom or small amounts. Big companies, often far away, cost less for big orders. But you might pay extra, wait longer, or get boards that are not as good. Many people pick local companies for small jobs and fast needs. They use big companies for lots of boards.

Factor | Local Assemblers | Large PCB Companies |

|---|---|---|

Cost | Higher for small runs | Lower for big orders |

Lead Time | Faster | Slower |

Communication | Direct and quick | Can be slow or unclear |

Flexibility | High | More standard |

Quality Assurance | Very strict | Varies by provider |

Note: Pick a company based on your project size, time, and support needs. Always read reviews and ratings before you choose.

User Tips

Choosing a Service

When you choose a pcb assembly service, you want your boards to work well. You also want them to arrive on time. Pick companies that use the best machines. Make sure they have certifications like ISO 9001:2015. See if they offer tests like automated optical inspection or in-circuit verification. Read what other customers say about their experience. Check if the company can do special requests or pcb prototyping customization. Good customer support and clear updates help you feel sure during the pcb assembly process.

Look at the company’s machines and certifications.

Ask about their testing and inspection steps.

Read reviews and what customers say.

See if they can customize your prototype.

Questions to Ask

Before you order, ask questions to stop problems:

Can you work with my design, file types, and materials?

How do you make sure the boards are good and correct?

What does your pricing look like?

Can you deliver when I need the boards?

How do you talk with customers and give support?

Where do you get parts, and do they follow safety rules?

Can you make both small and big orders?

Tip: Always ask if the pcb prototype service has a Design for Manufacturing (DFM) team.

Avoiding Mistakes

Many people make easy mistakes when ordering pcb assembly. The table below lists common problems and how to stop them:

Mistake | How to Avoid |

|---|---|

Incorrect layer assignment | Double-check and use standard names |

Missing drill files | Include all files and verify formats |

Wrong board outline | Keep outline clear and check size |

Solder mask/silkscreen issues | Review layers and text for clarity |

Incorrect scale or units | Confirm settings before sending |

Missing aperture definitions | Define all apertures and review list |

Not enough copper-edge clearance | Follow clearance rules and check |

You should always check your design with software and by looking at it before you send it to the manufacturer.

Getting the Best Value

To get the most from your pcb order, plan ahead. Design your board with fewer layers and use standard sizes. Make a full Bill of Materials (BOM) and add backup parts. Order more boards at once if you can, since bigger orders cost less for each board. Work with suppliers who know how to find good, low-cost parts. This helps you save money and avoid waiting.

Note: Good planning and clear updates help you get the best value from your pcb assembly service.

You will usually get good quality and fair prices from most pcb assembly services. Most people say they like clear updates and fast help.

Pick companies that have lots of experience and good testing tools. Choose ones that work with both hobbyists and experts.

Real reviews can show you which companies help customers well and fix problems fast.

Tell us about your own pcb assembly service experience in the comments. Your story can help others pick the right company.

FAQ

What files do you need to order PCB assembly?

You need to send Gerber files, a Bill of Materials (BOM), and a pick-and-place file. These files show the board layout, parts list, and where to put each part.

How can you check the quality of your assembled boards?

You can inspect your boards by looking for clean solder joints, correct part placement, and no missing parts. Many companies also test boards with machines like AOI or X-ray.

What should you do if you find a defect in your order?

Contact customer support right away. Take clear photos of the problem. Most companies will review your case and offer a solution, such as a replacement or refund.

How do you avoid extra costs in PCB assembly?

Always ask for a full quote before you order. Check for hidden fees like setup, testing, or rush charges. Read the price list and ask questions if you see anything unclear.

Can you order just one or two boards for a prototype?

Yes, many PCB assembly services accept small orders. You can order just one or two boards to test your design before making more.

See Also

A Comprehensive Guide To PCBA Manufacturing And Assembly

Effective Strategies For Choosing Top PCB Assembly Services

Ten Professional Tips To Achieve Cost-Effective PCBA Assembly