Supply chain problems can slow down your business and production. Parts shortages, rule issues, and global problems make overseas work tricky. Reducing supply chain risk with US PCBA offers a safer choice. Local PCBA solutions focus on stability and less need for foreign parts. You get quicker shipping, better quality checks, and easier rule-following. Using U.S. PCBA helps your business stay strong in a tough market.

Key Takeaways

Choosing US-based PCBA solutions helps avoid supply chain problems. It ensures faster delivery and better quality control.

Getting materials locally prevents issues like tariffs and shipping delays. This makes production more dependable.

Working with US manufacturers helps follow local rules. This lowers the chance of fines or product recalls.

Talking often with nearby suppliers solves problems quickly. It also improves teamwork.

Using domestic solutions saves money in the long run. It increases efficiency and profits.

Understanding Supply Chain Problems in PCBA Manufacturing

Part Shortages and Buying Challenges

Missing parts are a big problem for PCBA companies. Important items like chips, resistors, and capacitors often run out. This stops or slows down making products, causing trouble for businesses. Waiting a long time to get these parts makes things worse. High demand, limited suppliers, and shipping issues cause these delays.

Problem Type | Details |

|---|---|

Missing Parts | PCBA companies often lack key items like chips, resistors, and capacitors, stopping or slowing production. |

Long Wait Times | Getting parts takes a long time due to high demand, few suppliers, and shipping problems. |

To keep parts ready and avoid delays, plan ahead. Work with trusted suppliers and use different sources to solve these problems.

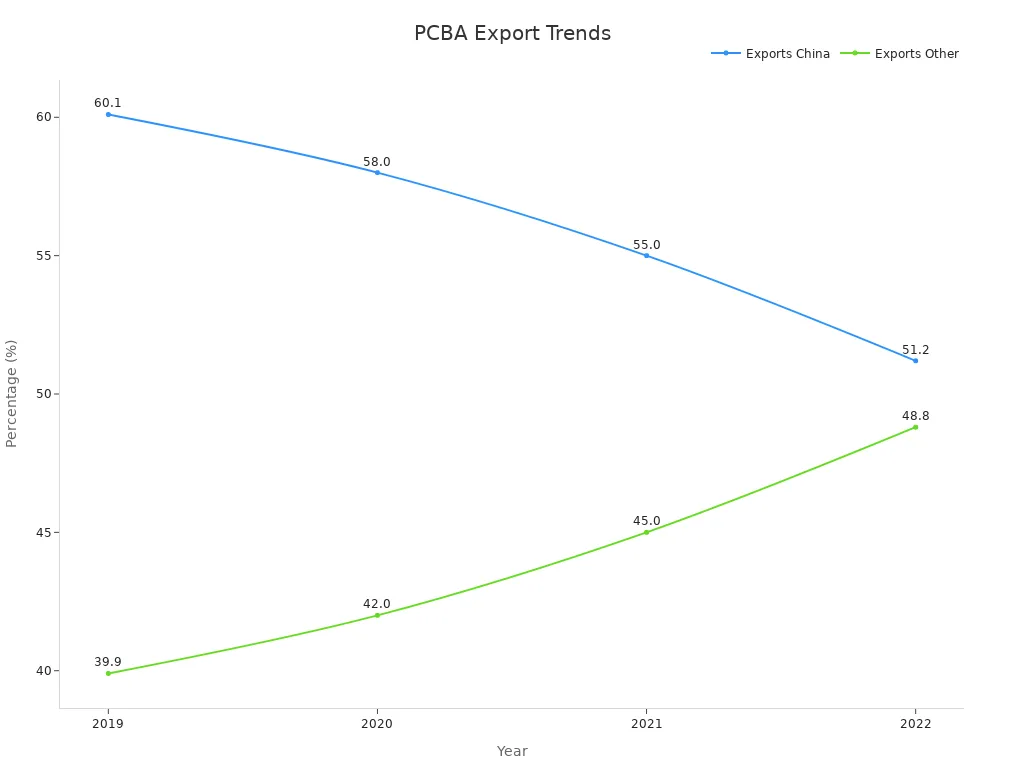

Trade and Political Problems

Politics and trade rules affect PCBA production a lot. Taxes, export limits, and unstable governments mess up global supply chains. For example, fewer exports go to China now, but more go to other places. This shows businesses must adjust to new trade rules.

These problems show why using local markets and parts is smart. Doing this can cut delays and make supply chains more steady.

Rules and Compliance Problems

Following rules is hard for PCBA companies. They must meet many global rules like RoHS, REACH, and FCC. Rules about the environment, product safety, and data privacy add more challenges.

Global Rules: Companies must follow rules like RoHS and REACH.

Environment Rules: Picking safe materials and keeping records is key.

Product Safety: Testing makes sure products are safe to use.

Data Privacy: Rules like GDPR and CCPA need strong data protection.

Supplier Rules: Suppliers must follow ethical and legal standards.

Training and checking risks help companies follow rules. Staying updated and careful avoids fines and problems.

Quality Control Problems with Overseas Manufacturing

Quality issues happen a lot with overseas factories. It’s hard to check standards when factories are far away. Different time zones and unclear processes make it even tougher. Cheaper labor may sound good, but it often means less training. This can cause bad product quality and slow production, hurting your business.

U.S. factories focus on training workers and strict quality checks. This leads to better products and fewer mistakes. Overseas factories might not follow such strict rules. Problems like poor testing, bad materials, and weak oversight are common.

Here are some problems with overseas manufacturing:

Hard to track quality due to unclear processes.

Weak testing can result in faulty products.

Delays happen more due to poor communication and shipping issues.

Using U.S.-based PCBA solutions gives you better testing and quality checks. Local factories use advanced tools to meet high standards. They also provide faster updates and fewer delays. Choosing local suppliers helps avoid overseas problems and keeps your supply chain steady.

Reducing Supply Chain Risk with US PCBA Solutions

Shorter Lead Times and Faster Turnaround

Using overseas factories can cause long wait times. Shipping delays, customs checks, and world events make things slower. Choosing US-based PCBA solutions helps avoid these problems. Local factories skip long shipping, so projects finish faster.

Making PCBA closer to home improves supply chain strength. It lowers risks from global issues and weather problems. This also cuts shipping costs and pollution, helping the planet. With quicker delivery, you can meet market needs and stay ahead.

Enhanced Compliance with U.S. Regulations

Following global rules can be confusing and hard. Overseas factories might not meet strict U.S. standards. This can lead to fines, recalls, or legal trouble. US-based PCBA solutions follow local rules like RoHS, REACH, and FCC.

Local factories focus on safety, privacy, and eco-friendly laws. They use safe materials, test carefully, and keep good records. Working with U.S. PCBA makers ensures your products meet all rules without extra stress.

Superior Quality Assurance and Testing Standards

Good quality is key for making reliable PCBA products. Overseas factories often have less skilled workers and fewer checks. U.S. factories use advanced tools to ensure top quality.

Here are some tests used in U.S. PCBA production:

Solder Paste Inspection (SPI): Checks solder paste is applied correctly.

Automated Optical Inspection (AOI): Finds problems in solder and parts.

X-ray Inspection: Spots hidden issues like gaps or misaligned parts.

Functional Circuit Testing (FCT): Makes sure the PCB works properly.

In-Circuit Testing (ICT): Tests each part to see if it works.

These tests catch problems early, saving time and money. Fixing issues before shipping avoids recalls or repairs. You can trust your products will work well and last long. This strong quality control keeps your supply chain steady.

By choosing US-based PCBA, you get faster delivery, better rule-following, and higher quality. These benefits make your business stronger and ready for the future.

Mitigating Geopolitical Risks with Domestic Sourcing

Problems in other countries can slow down global supply chains. This can lead to delays, higher costs, and uncertainty. Using local suppliers helps avoid these risks. It keeps materials flowing for your PCBA production without interruptions. Domestic sourcing avoids issues like trade limits, tariffs, or political problems. This makes your business stronger and more reliable.

A smart idea is to use many suppliers. Depending on one overseas supplier can be risky. Political or money problems in one country can cause big delays. Working with several local suppliers lowers this risk. It ensures you always have the parts you need. For example, companies like Bosch and Cisco use digital tools to manage suppliers better. This helps them stay ready for supply chain problems.

Keeping extra stock is another helpful plan. Having extra inventory means you can keep working during short-term supply issues. Also, having backup plans helps your business adjust quickly. This is useful for sudden changes like new trade rules or natural disasters.

Making products locally has become more popular. Tariffs on goods from China make local production cheaper. The COVID-19 pandemic showed the problems of relying on faraway suppliers. Local sourcing avoids high import fees and gives you more control. It also reduces delays and makes operations smoother.

Strategy | Description |

|---|---|

Diversify Suppliers | Use many suppliers to avoid risks from one country. |

Maintain Safety Stock | Keep extra inventory to handle supply chain problems. |

Contingency Plans | Prepare for surprises like trade changes or disasters. |

Using local suppliers reduces global risks and keeps your supply chain steady. It lets you focus on making great PCBA products without worrying about outside problems.

Improved Communication and Collaboration with Local Partners

Good communication is key for making PCBA products. Working with local suppliers makes teamwork easier. Problems like time zones, language, and culture can make talking to overseas suppliers hard. Local sourcing removes these issues and helps things run smoothly.

Local suppliers answer questions faster. If you need to change schedules or fix quality problems, they respond quickly. Being close by allows real-time communication. This keeps your projects on track and helps meet deadlines.

Meeting in person is another benefit of local suppliers. You can visit their factories to check how things are made. You can talk about your needs and build trust. These visits help create strong partnerships for the future.

Local suppliers also understand U.S. rules and market needs better. They can guide you through laws and industry changes. This ensures your PCBA products meet high standards and stay competitive.

Choosing local suppliers improves teamwork and reduces mistakes. This partnership makes your supply chain stronger and helps you create reliable PCBA products.

Strategies for Using U.S. Supply Chain Benefits

Working with Reliable U.S.-Based PCBA Makers

Teaming up with trusted U.S. PCBA makers is smart. They use advanced tools, skilled workers, and follow strict quality rules. This gives you steady production and on-time deliveries.

Local suppliers make communication easier and solve problems faster. You can visit their factories, talk face-to-face, and check product quality. This teamwork avoids confusion and ensures your needs are met.

U.S. manufacturers often use new tech like automated SMT lines and robots. These tools boost efficiency and cut labor costs. For example, AI-driven SMT lines can improve speed and reduce labor by 70%. Partnering with them strengthens your supply chain and helps your business grow.

Using Real-Time Supply Chain Data

Real-time data helps manage supply chains better. It tracks production, machine health, and shipping. This lets you fix problems quickly and keep things running smoothly.

Benefits of real-time data include:

Predictive maintenance cuts downtime by 50%.

Process optimization boosts production by 15-20%.

Defect detection lowers waste by 30-40%.

For example, if a machine shows wear, data alerts you early. Fixing it fast avoids delays. Real-time data also helps adjust to demand changes or challenges. Using this tech improves efficiency and keeps you competitive.

Having Multiple Suppliers for Key Parts

Relying on one supplier is risky. Using several suppliers ensures steady materials and smooth production. This was helpful during COVID-19 when supply chains faced big problems.

Multiple suppliers reduce risks from politics, disasters, or money issues. They also offer new ideas and better materials. Comparing options improves product quality and speeds up production.

Keep extra stock of key parts as a backup. This helps during supplier issues. Building strong ties with many suppliers makes your supply chain stronger and your business more reliable.

Investing in Scalable and Flexible Production Models

Investing in flexible production helps your business handle market changes. Using advanced tools and smart strategies saves money and improves operations.

One way is upgrading to smart factory systems. For example, AI-powered SMT lines can place 120,000 parts per hour. This cuts labor needs by 70% and speeds up production. Robots can also help with tasks like placing parts and checking quality. These robots make work easier and lower costs.

Working closely with local suppliers is also important. Partnering with PCB makers to create fast production lines can cut wait times to under four weeks. Setting up local hubs for parts can save 30% on inventory costs. These ideas keep costs low and ensure steady supplies.

Training workers is another smart move. Teaming up with schools to offer quick courses can train workers in three months. This lowers labor costs by 20% and builds a skilled team. Using AR tools can make assembly jobs simpler, so less experience is needed.

These flexible production methods prepare your business for the future. They save money and help you adapt to market changes quickly.

Building Long-Term Relationships with Domestic Suppliers

Strong partnerships with local suppliers make your supply chain reliable. These relationships build trust and teamwork, which are key for success.

Long-term supplier ties have many benefits. They ensure steady delivery of good-quality parts. Working closely with suppliers improves communication and keeps things running smoothly. This teamwork gives your business an edge in a changing market.

To build these relationships, focus on clear communication and shared goals. Visiting suppliers’ factories helps you understand their work and build trust. Talking face-to-face solves problems faster and strengthens connections. Working together also ensures suppliers meet your quality and rule standards.

Another helpful idea is teaming up on projects. You can work on saving costs or creating new tools to improve production. These efforts help both your business and your suppliers grow.

Studies show strong supplier partnerships lead to lasting success. They highlight the importance of teamwork and shared commitment. By focusing on these relationships, you can create a strong supply chain that supports your goals.

Building long-term ties with local suppliers ensures stability and growth. This approach makes your supply chain stronger and helps your business succeed.

Long-Term Benefits of US-Based PCBA Solutions

Stronger and More Reliable Supply Chains

Using U.S.-based PCBA solutions makes your supply chain stronger. Making products locally avoids tariffs, keeping costs steady. Shorter delivery times mean fewer delays compared to overseas shipping. Local sourcing avoids global problems, helping you adjust to demand changes faster.

Naprotek shows how U.S. manufacturing brings stability. They work closely with suppliers and manage inventory well. This simple supply chain allows quick changes when markets shift. It also saves resources for new technology, giving you an advantage.

Here’s how local production helps your supply chain:

Avoids tariffs, keeping costs steady.

Cuts delays from long shipping times.

Skips global supply chain problems.

Choosing U.S.-based PCBA solutions makes your business stronger. It keeps things running smoothly, even during tough times.

Better Business Continuity and Risk Management

Keeping your business running during problems is very important. U.S.-based PCBA solutions help by finding and fixing risks quickly. They also recover faster after disruptions, keeping your operations steady.

What It Means | |

|---|---|

Risk Detection | Finds problems early before they grow. |

Recovery Speed | Shows how fast operations return to normal. |

Business Continuity | Keeps important work going during and after issues. |

Local suppliers spot risks sooner and solve problems faster. Being nearby helps with quick communication and fixes. This ensures your business keeps running with little downtime, even during challenges.

Staying Ahead in a Competitive Market

U.S.-based PCBA solutions help you compete better worldwide. The North American PCB market is growing with demand for electronics in cars, healthcare, and more. Strict rules push companies to improve quality and safety.

U.S. manufacturers adapt well to new tech like IoT and 5G. Partnering with them helps you meet market needs and beat competitors. Their focus on quality and rules makes your products stand out.

Choosing U.S.-based PCBA solutions gives you access to the latest tools and reliable production. This keeps your business ready for market changes and ahead of the competition.

Reduced Total Cost of Ownership Over Time

Lowering the total cost of ownership (TCO) helps businesses succeed long-term. Picking U.S.-based solutions saves money and boosts efficiency and reliability.

Making products locally avoids hidden costs from overseas production. Shipping fees, tariffs, and customs charges add up fast. Domestic sourcing skips these extra costs, keeping budgets steady and easy to manage.

Quality checks are key to cutting TCO. U.S.-based PCBA manufacturers focus on strict testing and inspections. This means fewer broken products and less need for fixes. High-quality items last longer, saving money on repairs and warranties.

Better operations also lower ownership costs. Local factories use smart tools like automated machines and real-time data. These tools speed up production, cut waste, and use resources wisely. For example, fixing machines early avoids expensive downtime and keeps work moving.

Strong ties with local suppliers save even more money. Long-term deals bring better prices and steady deliveries. Reliable suppliers prevent delays, keeping production smooth and avoiding surprise costs.

Tip: Flexible production systems with U.S.-based manufacturers help you adjust to market changes without spending too much. These systems meet demand while avoiding waste.

Choosing U.S.-based PCBA solutions gives you control over spending and boosts profits. Quality, efficiency, and reliability combine to lower TCO, making your business stronger and more competitive.

US-based PCBA solutions offer a dependable way to lower supply chain risks. Making products locally means quicker delivery, stronger quality checks, and following strict rules. These benefits help prevent delays and expensive errors.

Tip: Picking nearby suppliers improves your business and protects it from worldwide problems.

Using U.S.-based PCBA brings lasting benefits like smoother production and better efficiency. This choice keeps your business strong and prepared for future challenges. Rely on domestic solutions to build a steady and successful supply chain.

FAQ

What is PCBA, and why does it matter for electronics?

PCBA means Printed Circuit Board Assembly. It connects parts to a circuit board to make it work. Devices like phones, computers, and medical tools need PCBA. It helps them run well and use advanced technology.

How do U.S.-based PCBA solutions lower supply chain risks?

Local PCBA solutions deliver faster, check quality better, and follow rules. They avoid problems like shipping delays and global issues. Using local suppliers keeps production steady and communication easy.

Are U.S.-based PCBA solutions costlier than overseas ones?

They may cost more at first, but save money later. You skip tariffs, shipping costs, and fixing bad products. Reliable production lowers repair and warranty expenses. Domestic options reduce overall costs over time.

Which industries gain the most from U.S.-based PCBA solutions?

Industries like cars, healthcare, aerospace, and electronics benefit a lot. They get strong, safe parts that meet strict rules. These fields need precise and long-lasting components.

How can I pick the best U.S.-based PCBA maker?

Choose makers with good quality checks, modern tools, and experience. Visit their factories to see how they work. Build strong partnerships for steady supplies and custom solutions for your needs.

See Also

Essential Strategies for Overcoming PCBA Manufacturing Challenges

Best Practices for Selecting a Trustworthy PCBA Manufacturer in China

Crucial Steps to Identify a Reliable PCBA Supplier

Ways to Choose the Ideal PCBA Manufacturer for Success

Guidelines for Picking the Perfect PCBA Manufacturer for You