You need systems to work without stopping. Redundant control system PCB assembly helps make them reliable. It acts as a backup to prevent unexpected failures. This keeps your work running without problems. In industries where even short downtime causes big losses, this is very important. It improves safety and keeps important tasks running. By lowering risks, it saves money on repairs and delays.

Downtime isn’t just annoying; it can cause big problems. Redundant systems help you avoid these issues.

Key Takeaways

Backup control systems keep things running during failures.

Adding backups costs more at first but saves money later.

Fields like healthcare and aviation use backups for safety.

Simple systems without backups can stop working for a long time.

Using backups with maintenance makes systems work better and longer.

Understanding Redundant and Non-Redundant Control Systems

What Is a Redundant Control System?

A redundant control system uses backups to keep things running. If one part breaks, another takes over right away. This design reduces downtime and makes systems more reliable. Common types include Standby Redundancy, Cold Standby, and Hot Standby. Standby Redundancy keeps backups off until needed. Hot Standby keeps backups ready to work instantly.

Active redundancy means all parts work at the same time. For example, n+1 redundancy adds one extra part to handle failures. 2n redundancy doubles every important part for maximum safety. These setups help systems recover faster and fail less often. They are crucial for industries needing high reliability.

What Is a Non-Redundant Control System?

Non-redundant systems use only one set of parts. If something breaks, the system stops until fixed. This design is simpler and cheaper but less reliable. Failures happen more often, making downtime a bigger problem.

Non-redundant systems work for tasks where downtime isn’t a big deal. But they aren’t good for critical jobs where interruptions cause big losses. Without backups, systems are less dependable and take longer to recover.

The Role of Redundancy in System Dependability

Redundancy makes systems more dependable by adding backups. It keeps systems running even when parts fail. Studies show redundancy improves reliability by giving alternate ways to succeed. For example, n+1 redundancy lets systems keep working if one part fails.

Evidence Description | Explanation |

|---|---|

Backups improve reliability by duplicating important parts. | |

Redundancy increases availability | Extra parts make systems available even during failures. |

Backup systems as a smart choice | Redundancy gives alternate paths when reliability is uncertain. |

Redundancy also improves dependability using math. For example, three backups show how redundancy increases reliability. This setup helps systems recover faster and stay running longer.

Tip: Redundancy costs more at first but saves money later by avoiding failures and reducing downtime.

Comparing Redundant and Non-Redundant Systems

Reliability and Fault Tolerance

Redundant systems are built to be dependable. They use backups to keep working if something breaks. For example, redundant ultrasonic sensors in AGVs overlap functions to improve reliability. Extra actuators in designs help fix faults by adding more parts. This setup avoids single points of failure, making systems stronger.

Non-redundant systems don’t have these protections. One fault can stop everything, causing downtime and losses. These systems are simpler and cheaper but less reliable. In industries needing constant work, redundancy is key to avoid big problems.

Evidence Description | Key Findings |

|---|---|

Better reliability from overlapping sensor functions. | |

Over-actuation in system design | Uses extra actuators to handle faults and improve dependability. |

Multiple engines in airplanes | Shows how redundancy boosts reliability in critical systems. |

Downtime and Operational Continuity

Downtime slows work and lowers productivity. Redundant systems reduce this risk by staying available during failures. For example, n+1 redundancy lets one part take over if another fails. This quick switch keeps things running smoothly and avoids delays.

Non-redundant systems can’t do this. One fault stops everything until repairs are made. This downtime costs money, especially in industries where time matters. Investing in redundancy ensures work continues without interruptions, which is vital for reliability.

Tip: Spending on redundancy may seem high, but it saves money by avoiding downtime and lost work.

Cost Implications and Long-Term Efficiency

Redundancy costs more upfront because of extra parts and complexity. But it saves money later by preventing failures and downtime. Managing these systems well means balancing redundancy with other methods to control costs.

Non-redundant systems are cheaper at first but cost more over time. Frequent breakdowns and long downtime lead to big financial losses. While redundancy adds complexity, it makes systems more reliable and efficient. For industries focused on smooth operations, investing in redundancy pays off.

Redundancy costs more but saves money in the long run.

Good management balances redundancy with other resiliency methods.

Redundancy improves reliability but adds complexity and upfront costs.

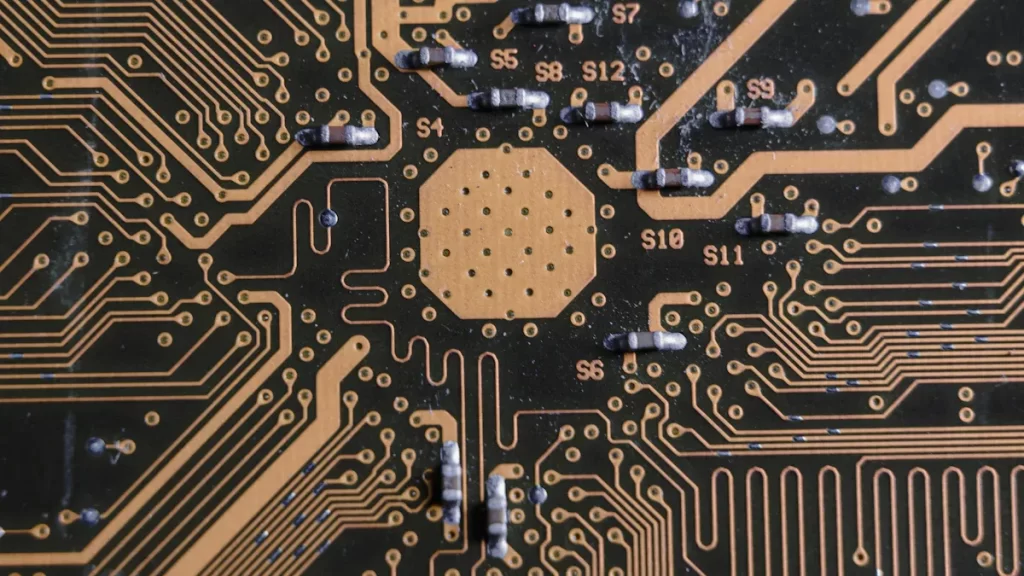

Importance of Redundant Control System PCB Assembly

Enhancing Safety in Critical Applications

In industries where safety is crucial, redundant control system PCB assembly is very important. Adding backup parts ensures critical systems keep working if something fails. This design lowers the chance of service interruptions from unexpected problems. For example, airplanes use dual engines as backups to avoid dangerous situations if one engine stops working.

Redundancy also makes systems more reliable by preventing total breakdowns. When key parts are duplicated, systems can still work during partial failures. This is especially vital in healthcare, where life-support machines depend on redundant systems to stay functional without stopping.

Tip: Always use redundancy in safety-critical systems to protect lives and property.

Ensuring Operational Continuity in Industrial Processes

Industries that can’t afford downtime need systems that keep running. Redundant control system PCB assembly helps processes stay active even when problems happen. Backup parts create a safety net to keep operations smooth.

Studies show how redundancy improves performance. For example:

Metric | Improvement |

|---|---|

Average unplanned downtime | |

Mean time between failures (MTBF) | Increased by 40% |

Predictive maintenance interventions | Boosted by 60% |

These results prove redundancy reduces downtime and improves reliability. Combining predictive maintenance with redundant systems lets you fix issues early before they cause bigger problems. This method keeps businesses running and improves efficiency.

Note: Spending on redundancy now avoids costly repairs and downtime later.

Achieving Long-Term Cost Efficiency Through Redundancy

At first, redundancy may seem expensive, but it saves money over time. Redundant control system PCB assembly stops failures that lead to costly repairs or long downtime. Fewer service interruptions mean saving money on emergency fixes and lost work.

For example, n+1 redundancy uses one backup part to take over instantly when something breaks. This setup reduces downtime and helps equipment last longer. Using strong industrial-grade parts in redundant systems also lowers maintenance costs and keeps systems stable.

To save even more, try remote monitoring and predictive maintenance. These tools find problems early and fix them before they stop operations. Over time, the money saved from fewer failures and less downtime outweighs the upfront cost of redundancy.

Tip: Combine redundancy with other strategies to save money without making systems too complex.

Practical Applications of Redundant Systems

Data Center Redundancy and Redundant Data Centers

Data centers are vital for storing and managing digital data. If they fail, businesses lose access to important services and information. Redundancy in data centers adds backups for power, cooling, and networks. A redundant data center goes further by creating a second location. This backup site mirrors the main one and takes over if problems occur.

Standards show why redundancy is key for data centers. For example:

Standard | Description |

|---|---|

Rates data center reliability using four levels of redundancy. | |

Telecommunication Infrastructure Standard (ANSI/TIA 942-A 2014) | Focuses on cables and networks, stressing redundancy. |

European standard (EN 50,600) | Covers building, power, and systems for reliable data centers. |

These rules help design dependable data centers that work during failures. Adding redundancy protects businesses from downtime and keeps customers happy.

Tip: Use redundant data centers to avoid service interruptions and build trust.

Redundancy in Manufacturing and Process Control

Factories need systems that work without stopping. A single failure can delay production and cost money. Redundancy solves this by adding backups for sensors, controllers, and other parts.

For example, redundant PLCs (Programmable Logic Controllers) keep assembly lines running. If one fails, the backup starts working right away. Similarly, redundant power supplies prevent shutdowns during power issues. These backups make systems more reliable and reduce downtime.

Redundancy also helps with predictive maintenance. It tracks performance to find problems early. Fixing issues before they grow avoids breakdowns and extends equipment life.

Note: Adding redundancy improves reliability and makes factories more efficient.

Real-World Examples of Redundant Systems Preventing Failures

Real-life examples show how redundant systems save the day. In aviation, airplanes use multiple engines for safety. If one engine stops, others keep the plane flying. This setup has saved lives and avoided disasters.

In healthcare, life-support machines use redundant systems to stay running. Even if one part fails, the machine keeps working to protect patients.

In IT, redundant data centers prevent service outages. During disasters, businesses with backups kept running while others shut down. These examples prove redundancy is essential for safety, assets, and business success.

Callout: Redundant systems are not optional—they are critical for reliability.

Redundant control system PCB assembly helps keep things running smoothly. It reduces downtime by keeping systems working even if something breaks. This makes critical tasks safer and avoids big losses from interruptions. Less downtime means saving money on repairs and staying productive. Redundant systems are better than non-redundant ones, especially when time is important. Spending on redundancy ensures systems work well for a long time. It’s a smart choice for industries that can’t afford to stop.

FAQ

1. What is the main purpose of redundant control system PCB assembly?

Redundant control system PCB assembly helps systems keep working during failures. It adds backup parts to important systems. This reduces downtime and makes them more reliable. It is very useful in industries where interruptions cause big losses or safety issues.

2. How does redundancy improve system reliability?

Redundancy makes systems more reliable by adding extra parts. If one part breaks, the backup starts working right away. This stops the whole system from failing and keeps it running. It is very helpful for important tasks that need to work all the time.

3. Is redundancy worth the extra cost?

Yes, redundancy saves money over time. It costs more at first but lowers downtime, avoids expensive repairs, and makes equipment last longer. For industries needing reliable systems, spending on redundancy is a smart choice.

4. Can redundancy be applied to all systems?

Not every system needs redundancy. It works best for important tasks where failures cause big problems. For less important jobs, non-redundant systems might be cheaper and good enough.

5. What industries benefit the most from redundant systems?

Industries like healthcare, aviation, factories, and IT benefit a lot. These fields need systems that work without stopping. Redundant systems make sure they stay safe, reliable, and running smoothly.

Tip: Think about how important your system is before choosing redundancy.