Finding trustworthy and affordable PCB assembly services USA can be challenging. Balancing price, quality, and speed is often difficult. Choosing the right company is crucial for success, as poor decisions can lead to delays, subpar boards, or additional expenses. Prioritizing high-quality services ensures your project runs smoothly and achieves its objectives. By selecting reliable PCB assembly services USA, you can save money while obtaining excellent results. Always prioritize transparency, quality materials, and responsive support for long-term success.

Key Takeaways

Know what your project needs early. Write down things like assembly type to stay organized and clear.

Plan a budget that works. Learn the costs for different assembly types and think about buying in bulk to save money.

Pick a company with good experience. Find one with a strong history in your field for better results.

Focus on quality checks. Choose companies that test well to make sure PCBs work and last long.

Talk clearly about costs. Ask for full pricing details and avoid companies that hide fees or are not honest.

Identifying Your Needs for PCB Assembly Services

Know What Your Project Needs

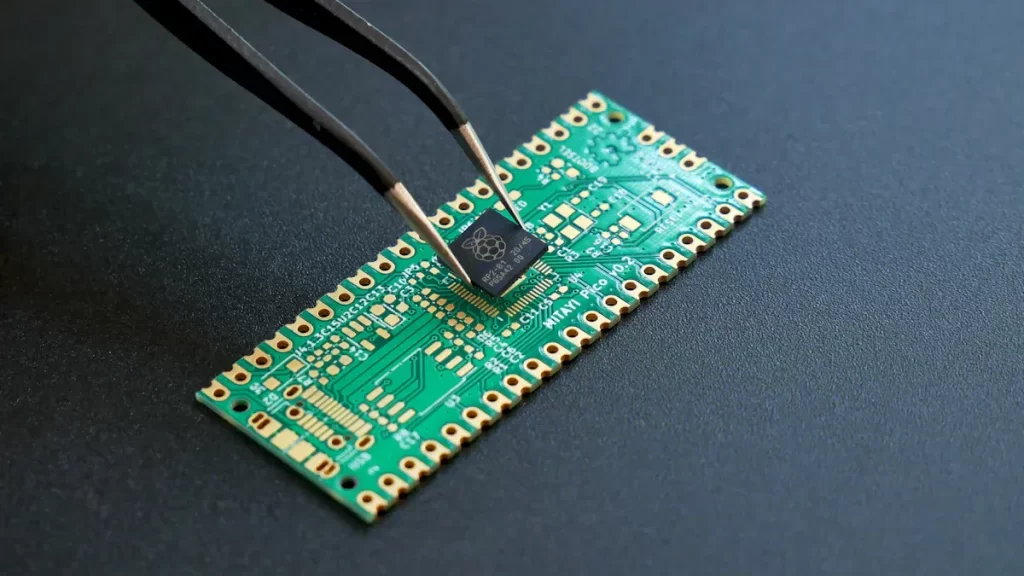

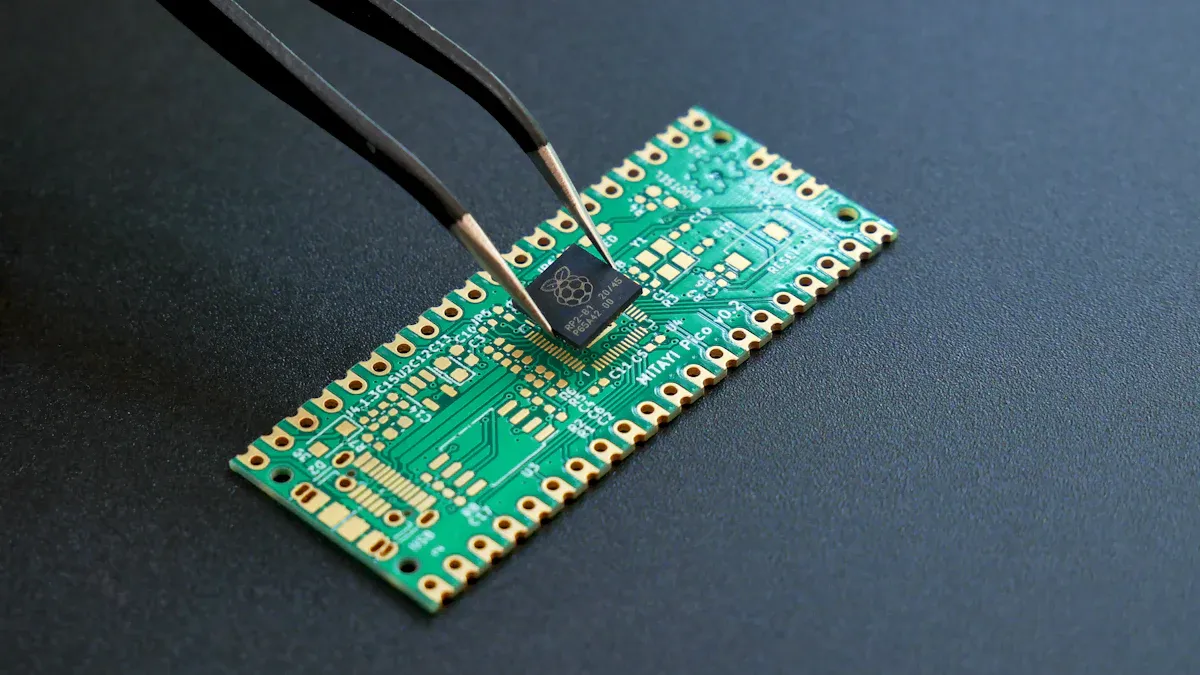

The first step is to understand your project needs. Start by listing what your project requires. Decide if you need surface-mount (SMT), through-hole, or mixed assembly. Work with manufacturers early to avoid confusion and improve results. Regular talks help answer questions and solve problems quickly. Involving manufacturers in design reviews can give helpful tips, like where to place parts or how to assemble them.

A strong review process is very important. It keeps your design goals clear and avoids expensive changes later. Make a detailed list of needs and their purposes. Get input from different teams early to gather ideas. This helps create clear goals and ensures everyone knows what to expect.

Plan a Budget That Works

Making a good budget is key to balancing cost and quality. PCB assembly prices in the USA depend on assembly type, board design, and order size. SMT assembly costs $50–$500 per panel, while through-hole costs $100–$1,000. Mixed assembly costs $150–$1,500 per panel. Knowing these ranges helps you plan better.

To save money, think about your design and order size. Ordering in bulk often lowers costs per unit. Talk to service providers about pricing to avoid surprises.

Set a Timeline and Delivery Goals

Having a clear timeline is as important as knowing your needs and budget. Fast PCB assembly can deliver prototypes in 24 hours but costs more. For slower projects, standard delivery times are cheaper. Choose companies with a 98% or higher on-time delivery rate to stay on schedule.

Regular check-ins during assembly help track progress and fix problems fast. This prevents delays and keeps your project on time.

Evaluating PCB Assembly Companies and Their Capabilities

Check PCB and PCBA Skills

Start by checking what the company can do. Not all companies offer the same services. Match their skills to your project needs. Some focus on simple PCBs, while others handle advanced ones like multi-layer or flexible PCBs.

PCB Type | Description | Uses |

|---|---|---|

Single-sided | One layer of conductive material. | Toys, home gadgets |

Double-sided | Conductive material on both sides for complex work. | Car dashboards, lighting systems |

Multi-layer | Many layers for dense, tricky circuits. | Phones, computers, medical devices |

Rigid | Hard and strong for tough use. | Cars, planes, factory machines |

Flexible | Can bend for tight spaces. | Wearables, medical implants, foldable phones |

Rigid-flex | Mix of rigid and flexible for special uses. | High-tech devices |

Also, check how they test their boards for quality. Companies using advanced tests like AOI, electrical checks, and stress tests often deliver better results.

Testing Method | What It Does |

|---|---|

Automated Optical Inspection (AOI) | Finds problems like bad solder or cracks. |

Electrical Testing | Includes checks like continuity and in-circuit tests. |

PCB Stress Tests | Tests how boards handle stress over time. |

Look at metrics like FPY, defect rate, and cycle time. High FPY and low defect rates mean better work.

First Pass Yield (FPY): Shows how many products pass checks the first time.

Defect Rate: Percentage of faulty items made during assembly.

Cycle Time: Time taken to finish making a product.

Find Experienced Companies

Experience matters when picking a PCB assembly partner. Companies with more years in business know how to solve problems better. Choose those who have worked in industries like cars, healthcare, or electronics.

The U.S. PCB market is growing fast. By 2030, it may reach $106.85 billion, growing 4.87% yearly from 2025. This growth comes from new tech like HDI, flexible PCBs, and trends like 5G and IoT. Companies investing in research are better prepared for future needs.

Metric | Value |

|---|---|

Market Size 2025 | USD 84.24 billion |

Market Size 2030 | USD 106.85 billion |

CAGR (2025-2030) | 4.87% |

Key Segments | Multilayer, Rigid, HDI, Flexible, Rigid-Flex |

End-User Industries | Healthcare, Aerospace, Cars, Electronics |

Pick a company skilled in your field. For example, if you need rigid-flex PCBs for planes, choose one with experience in aerospace.

Check Certifications and Standards

Certifications show a company cares about quality. Look for standards like IPC-A-610 and IPC-J-STD-001. These ensure good soldering and proper assembly.

IPC-A-610: Focuses on final product checks like soldering and placement.

IPC-J-STD-001: Covers the whole assembly process for reliability.

Companies doing strict tests like AOI and FAI often deliver better boards. These tests confirm the product meets your needs.

Good quality checks are key to reliable results. Companies that follow these checks meet customer needs better. Always confirm the company follows these rules to avoid problems later.

Ensuring Quality Standards in PCB Assembly Services

Look at Testing and Inspection Steps

Testing and checking are key for keeping good quality. Find companies that use advanced tools to get reliable results. Automated Optical Inspection (AOI) is a popular method. It uses cameras and software to spot solder gaps or faulty parts. Burn-in testing checks PCBs under heat or electrical stress to find early problems. X-ray inspection is also helpful. It looks at hidden connections and solder joints, especially in tight spaces.

Testing Method | What It Does | Why It Helps |

|---|---|---|

Automated Optical Inspection | Uses cameras and software for visual checks. | Finds solder gaps and faulty parts during production. |

Burn-In Testing | Tests PCBs under heat or electrical stress. | Spots weak parts and checks how much load they can handle. |

X-Ray Inspection | Uses X-rays to check hidden connections and solder joints. | Finds problems in tight spaces and high-density designs. |

These tests make sure PCBs work well and have fewer problems. Companies that focus on testing often make better products.

Check Material Quality and Where It Comes From

The materials used in PCBs affect how good they are. Make sure the company gets parts from trusted suppliers. Good materials make PCBs last longer and work better. For example, using strong solder paste and good substrates avoids issues like peeling or bad connections.

Ask about their sourcing methods. Do they buy from certified suppliers? Are the materials following rules like RoHS? These questions show if they care about quality. Trusted sourcing also lowers the chance of fake parts, which can cause big problems.

Read Customer Reviews and Feedback

Customer reviews can tell you a lot about a company. Look for comments about quality, delivery times, and service. Good reviews often mention things like meeting deadlines or having strict quality checks.

Check independent review sites for honest opinions. A company with many good reviews is more likely to do a great job. See how they handle complaints too. If they respond quickly and honestly, it shows they care about their customers.

Cost-Saving Tips for Affordable PCB Assembly Services

Make Your PCB Design Cost-Friendly

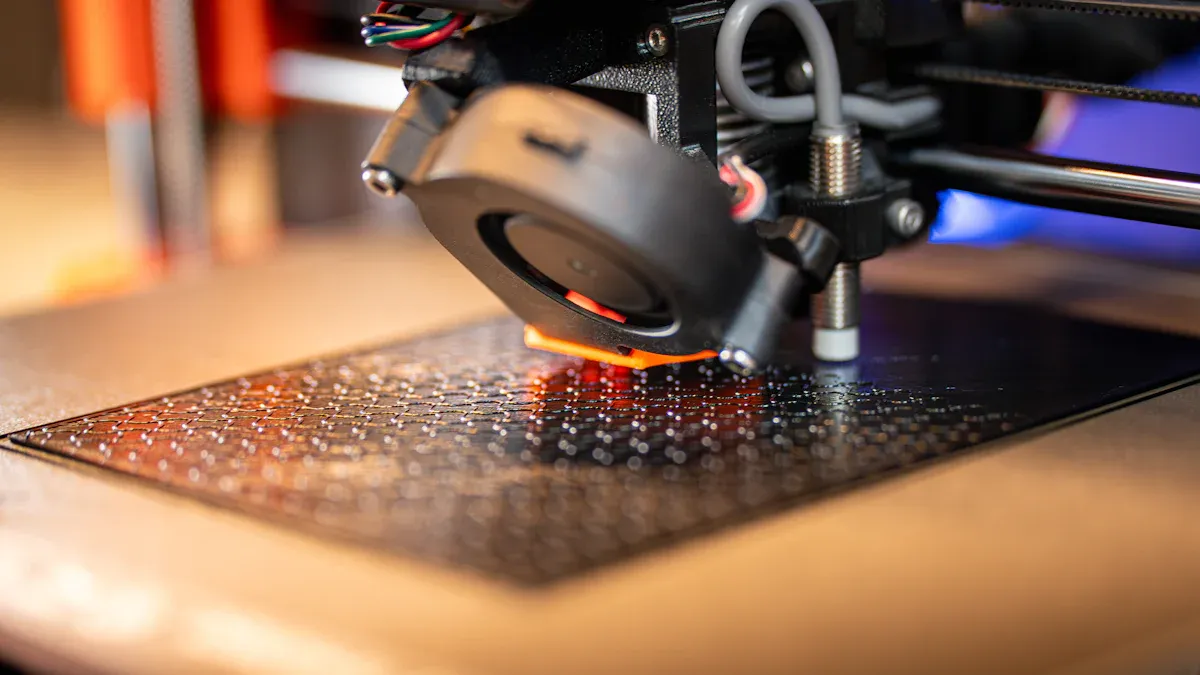

Changing your PCB design can help save money. Keep the design simple to lower costs without losing quality. For example, using fewer layers in your PCB can cut production costs. A company making electronics reduced their PCB layers from six to four. They also grouped boards together and used cheaper parts. These changes saved them 22% on production costs while keeping the product reliable.

Example Company | Changes Made | Results |

|---|---|---|

Electronics Maker | 1. Cut layers from 6 to 4 | |

2. Grouped boards (panelization) | ||

3. Used cheaper parts | 22% lower production costs | |

Kept product reliable | ||

Faster production time | ||

Industrial Systems | 1. Used hybrid materials | |

2. Improved design for easier making | ||

3. Custom testing | 18% lower material costs | |

15% better manufacturing success | ||

Kept performance standards |

Placing parts smartly on the PCB also saves money. Good placement lowers assembly costs and speeds up production. Avoid making the design too complex. Focus on the most expensive parts and find ways to make them cheaper. Using affordable materials and better assembly methods can save a lot.

Buy in Bulk or Build Long-Term Partnerships

Buying in bulk or working with the same manufacturer for a long time can save money. Ordering more items at once lowers the cost per piece. You can also ask for discounts based on how much you order. For example, buying many parts together often means cheaper shipping and lower prices. Sticking with one supplier can increase these savings.

Benefit | What It Means |

|---|---|

Bigger orders | |

Discounts for large orders | Save money by ordering more |

Plan for future needs | Save by preparing for upcoming projects |

Before ordering in bulk, make sure your design is final. This avoids wasting money on changes later. Talk to your manufacturer about discounts for large orders. Find out how many items you need to buy to get the best price. Long-term deals with manufacturers can also give you steady prices for future projects.

Buying more items at once lowers costs per piece.

Working with one supplier can increase savings over time.

Finalize your design before ordering in bulk to avoid extra costs.

Ask your manufacturer about discounts for large orders.

Talk About Prices and Payment Options

Discussing prices and payment terms can help you save. Compare quotes from different PCB assembly companies to find the best deal. Look for a company that offers good prices, quality, and delivery times. When negotiating, aim for a balance between cost and quality. For example, ask for discounts on big orders or long-term contracts.

Flexible payment plans can also help manage your budget. Some companies let you pay in parts or delay payments, which can ease financial stress. Talk to your manufacturer about these options to find what works best.

Using automation and better quality checks can also save money. Automation can cut labor costs by 40%. Improved quality checks can reduce rework rates from 8% to 1.2%. These methods save money and ensure good results.

Method | Savings Achieved |

|---|---|

Choosing cheaper materials | |

Better quality checks | Rework rates drop from 8% to 1.2% |

Monthly savings from quality checks | $12,400 saved on rework labor |

Monthly savings from material change | $8,700 saved for a startup |

Savings on 1,000-unit orders | Over $18,000 saved |

By using these tips, you can save a lot of money while keeping your PCB assembly high-quality and reliable.

Red Flags to Watch for When Picking PCB Assembly Companies

Bad Communication or Customer Service

Good communication is very important when working with pcb assembly companies. If a company takes too long to reply or gives unclear answers, it shows poor customer service. Be cautious of companies that avoid talking about project details or skip giving updates. These actions can cause mistakes, delays, and confusion in your project.

Tip: Pick a company with easy ways to communicate, like email or phone. A quick and helpful team will answer your questions and solve problems fast.

Hidden Costs or Unclear Processes

Being open about costs and steps builds trust with pcb assembly companies. If a company hides prices or won’t explain their process, it’s a bad sign. Surprise fees or unclear pricing can make your project more expensive. Not knowing their steps can also lead to bad-quality boards.

To prevent this, ask for a full cost breakdown, including materials and labor. Also, request details about their assembly process. A trustworthy company will share this information to make you feel confident.

Using Cheap or Bad Materials

The materials used affect how well your PCBs work and last. Some companies use low-quality parts to save money. This can cause your boards to fail often, need repairs, or cost more over time.

Check where the company gets its parts. Ask if they buy from certified suppliers and follow rules like RoHS. Using good materials ensures your PCBs work well and last longer.

Note: Always choose quality over saving money. Spending more on good parts now can help you avoid costly fixes later.

Choosing a good PCB assembly company takes thoughtful planning. First, figure out what your project needs. Then, check what the company can do and how they ensure quality. Saving money is possible by improving designs or discussing better prices. It’s important to pick services that are both affordable and dependable. Look for companies that are honest, use strong materials, and offer great support. Following these tips will help you get good results without overspending.

FAQ

How long does PCB assembly usually take?

The time depends on the order size and complexity. Prototypes are ready in 1–2 days. Bigger orders might take 1–2 weeks. Always check with your provider to match your project timeline.

How can I make sure my PCB design works for assembly?

Share your design files, like Gerber files, with the manufacturer. They will check your design and suggest changes if needed. This helps avoid mistakes and makes assembly easier.

Do PCB assembly companies have minimum order rules?

Some companies need a minimum order, but others take small jobs. Ask your provider about their rules to find the best fit for your project.

What certifications should a good PCB assembly company have?

Look for certifications like IPC-A-610 and ISO 9001. These show the company follows quality and industry standards. Certified companies are more likely to make reliable PCBs.

Can I send my own parts for PCB assembly?

Yes, many companies let you send your own parts. This is called consignment assembly. Make sure your parts meet the specs and arrive on time to avoid delays.

See Also

10 Essential Strategies for Cost-Effective PCBA Assembly

Reliable Advice for Choosing Quality PCB Assembly Services

Key Considerations for Selecting a Trustworthy PCBA Manufacturer