Bringing reshoring PCB assembly services back to the U.S. helps businesses in many ways. It lowers your total cost of ownership (TCO), even if overseas factory prices seem cheaper at first. For instance, studies show U.S. factories do better than China’s in 32% of cases when TCO is included, compared to only 8% based on factory price alone. You also get more control over your supply chain, reducing problems like delays and disruptions. Additionally, reshoring PCB assembly services uses cleaner energy and cuts down on shipping pollution, helping your business meet environmental goals.

Key Takeaways

Moving PCB assembly back home can save money by cutting hidden costs and skipping tariffs.

Making products locally improves quality checks and solves problems faster.

Manufacturing in the U.S. keeps your ideas safe with strong laws.

Reshoring makes supply chains better by speeding up delivery and lowering overseas risks.

It also helps the environment by using cleaner energy and cutting shipping pollution.

Cost Advantages of Reshoring PCB Assembly Services

Lower Transportation and Logistics Costs

Making PCBs closer to your customers saves on shipping costs. Products travel shorter distances, which lowers expenses and speeds up delivery. Local production uses nearby warehouses, making shipping faster and simpler.

Reshoring avoids delays from overseas shipping and customs checks. Working with local suppliers makes production smoother and reduces problems. These savings help businesses spend money on other important needs.

Avoidance of Tariffs and Import Fees

Producing PCBs in the U.S. means no tariffs or import fees. These extra costs can grow quickly with changing trade rules. Domestic production keeps expenses steady and easier to manage.

Making products locally avoids surprises from international trade changes. This helps businesses plan better and save money long-term. Reshoring lets companies focus on improving their work without worrying about added costs.

Reduction of Hidden Offshore Expenses

Making PCBs overseas often has hidden costs like poor quality and delays. Reshoring fixes these problems by working with nearby suppliers. Being in the same time zone makes communication faster and clearer.

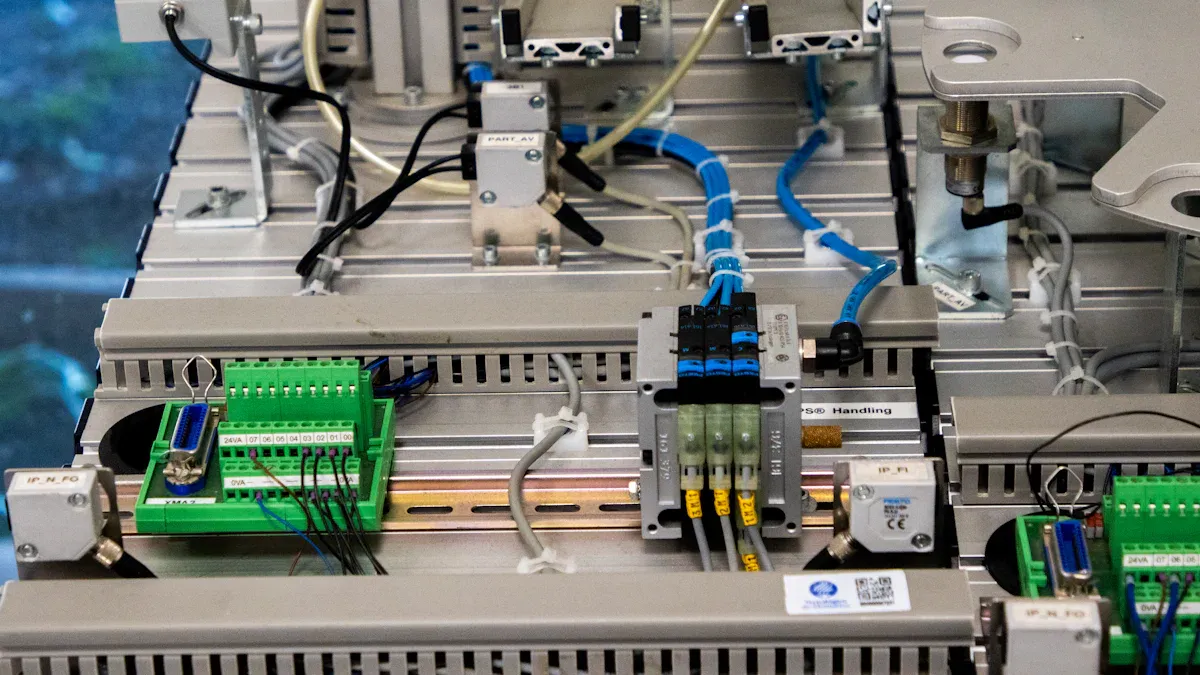

Reshoring also allows upgrades like smart factories and automated machines. These tools reduce labor needs and improve efficiency. Local PCB makers help cut wait times and lower storage costs. These changes save money and make production better overall.

Quality Benefits of Reshoring Manufacturing

Better Control and Communication

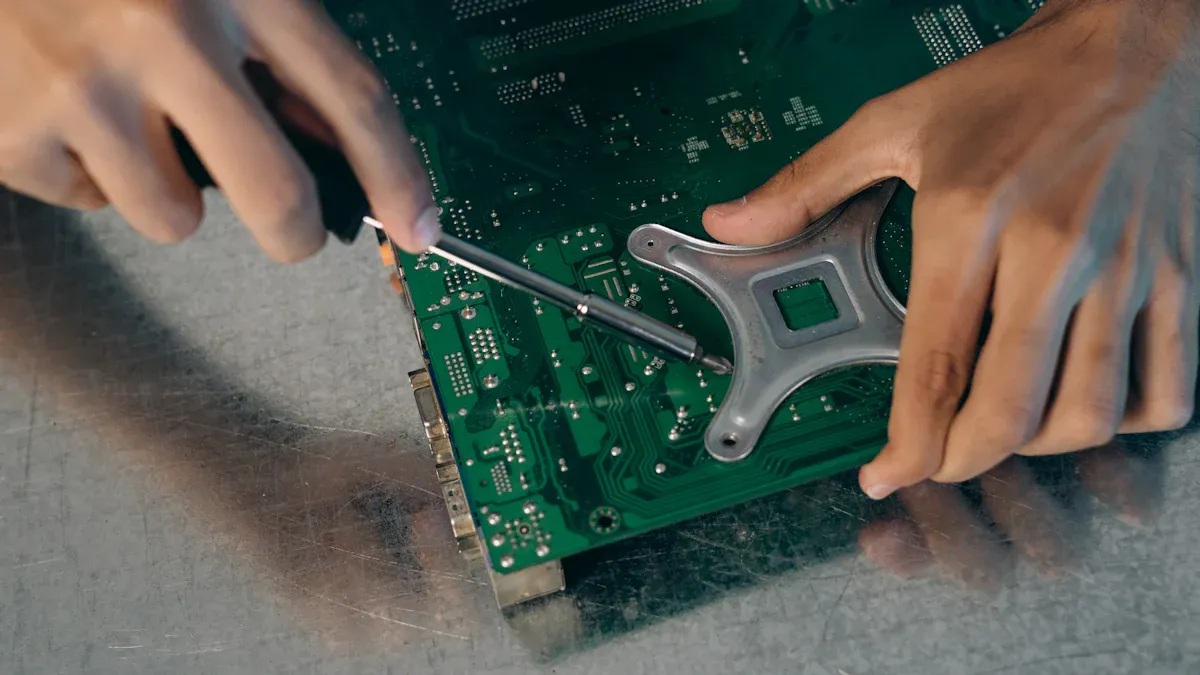

Reshoring gives you more control over making products. When PCB assembly is done nearby, you can visit often. This helps you check the work and make sure it’s done right.

Local production makes talking to suppliers easier. Being in the same time zone avoids delays. You won’t face problems like language issues or time gaps. Quick chats help fix problems fast, so products stay high quality.

Following U.S. Quality Rules

Reshoring ensures products meet strict U.S. quality rules. Factories in the U.S. follow important certifications for great results. For example, PCB assembly follows IPC rules for perfect part placement and soldering.

Here’s a list of key certifications reshored factories meet:

Certification/Standard | What It Ensures |

|---|---|

IPC Standards | High-quality part placement and soldering in PCBA processes. |

ISO 9001 | Consistent quality in products and services. |

AS9100 | Safety and reliability for aerospace products. |

ISO 13485 | Compliance with rules for medical devices. |

ITAR Compliance | Strict quality and security for defense-related products. |

By reshoring, your products meet these rules, giving customers reliable and top-quality items.

Fixing Problems Faster

When problems happen, reshoring helps fix them quickly. Local factories can solve issues right away, cutting downtime. You don’t have to wait days for overseas replies.

Reshored factories often use smart tools like robots and automated systems. These tools find and fix mistakes faster. This keeps production smooth and avoids delays. Reshoring helps you deliver great products on time without interruptions.

Supply Chain Efficiency Through Reshoring

Shorter Lead Times and Faster Delivery

Reshoring PCB assembly makes delivery faster and lead times shorter. Producing closer to customers removes long shipping and customs delays. This helps your products reach buyers quickly, giving you an advantage.

Being near Original Equipment Manufacturers (OEMs) cuts transport costs.

Reshoring boosts delivery speed, like in German car-making industries.

Same time zones with local suppliers mean quicker communication and fixes.

Smart factories also speed up production and delivery. A study found 62% of global leaders plan to use smart tech. These tools make production faster and more efficient. Reshoring electronics lets you use these tools to meet customer needs quickly.

Reduced Supply Chain Risks

Reshoring lowers risks in your supply chain, keeping work steady. Overseas production faces problems like unstable politics, trade fights, or disasters. Moving production closer gives you more control and fewer risks.

Local production means less need for international shipping, which can be tricky. You avoid delays from crowded ports or customs issues. Reshoring also builds stronger ties with local suppliers, making your supply chain more reliable.

Tip: A local supply chain lowers risks and helps handle surprises better. This strength is key in today’s fast-changing markets.

Enhanced Flexibility to Meet Market Demands

Reshoring helps you adjust quickly to market changes. Faster production and delivery let you meet customer needs on time. This is vital for industries with fast-changing tech or seasonal demands.

Benefit | Description |

|---|---|

Faster production and delivery for quicker responses. | |

Better manufacturing standards for higher-quality products. | |

Adaptability | Easier adjustments to market and customer needs. |

Reshoring PCB assembly lets you scale production up or down as needed. This keeps you ahead of competitors and satisfies customers. It also updates your supply chain to be more modern, flexible, and efficient.

Intellectual Property and Regulatory Advantages of Reshoring

Stronger Protection Against IP Theft

Reshoring keeps your intellectual property safer than making products overseas. U.S. factories follow strict laws to protect your ideas and designs. Producing locally lowers the chance of someone stealing or copying your work.

Foreign factories may not enforce IP laws well. This puts your ideas at risk. By reshoring, you make sure your important information stays safe.

Tip: Working with U.S. manufacturers helps protect your intellectual property under strong legal rules.

Simplified Compliance with Domestic Regulations

Reshoring makes following U.S. rules easier. Local factories already meet safety and industry laws. You don’t have to deal with confusing foreign regulations.

Producing nearby ensures your products follow environmental and labor laws. This avoids fines or delays from breaking rules. Reshoring also helps you keep up with new laws without relying on overseas updates.

Alignment with Industry Standards and Certifications

Reshoring ensures your products meet top industry standards. U.S. factories follow certifications like ISO, IPC, and ITAR for high-quality results. These certifications show your products are reliable and trustworthy.

Making products locally helps your brand look better. U.S. factories keep quality steady, so your products work as expected. Reshoring builds customer trust by delivering great results every time.

Note: Meeting certifications improves product quality and boosts customer trust in your business.

Reshoring PCB assembly services helps businesses in many ways. It cuts costs, makes products better, and improves supply chains. Small companies can check quality more closely. Big companies avoid huge risks by working with local partners. Reshoring also solves supply chain problems and uses the growing PCB market, expected to hit $130 billion by 2030. By reshoring, businesses grow stronger and help local economies by creating jobs. This keeps businesses successful in tough markets.

FAQ

1. What is reshoring, and why does it matter for PCB assembly?

Reshoring means making products in your own country again. It helps businesses control their supply chain better and save money. For PCB assembly, reshoring also ensures high-quality products and protects your ideas.

2. How does reshoring save money for businesses?

Reshoring removes extra costs like tariffs and shipping fees. It avoids problems like delays and poor quality from overseas factories. Making products locally is simpler and saves money over time.

3. Can reshoring make products better?

Yes, reshoring follows strict U.S. rules like IPC and ISO standards. Local factories let you check work often and fix issues fast. This leads to better products with fewer mistakes.

4. Does reshoring keep intellectual property safe?

Definitely! U.S. factories follow strong laws to protect your ideas. Reshoring lowers the chance of someone stealing or copying your designs.

5. How does reshoring improve supply chains?

Reshoring makes delivery faster and reduces shipping risks. It avoids problems like trade fights or customs delays. Local production also helps businesses adjust quickly to market changes.

Tip: Reshoring makes your business stronger by improving reliability and flexibility.

See Also

Effective Strategies for Choosing Quality PCB Assembly Services

Essential Advice for Enhancing PCB Assembly Productivity

Understanding PCBA Services and Their Importance in Electronics Production

Uncover the Advantages of PCBA Surface Mount Technology

Why PCBA Manufacturing Skills Are Crucial for Electronics Design