Choosing the right PCBA conformal coating services is very important. These coatings protect electronic parts from damage caused by the environment. Good coatings help devices work better and last longer. The market for conformal coatings is growing fast. It is expected to increase from $14.44 billion in 2024 to $15.51 billion in 2025, growing at 7.4% each year. This growth is due to new technology in electric cars, medical tools, and space equipment. To pick the best coating, check the provider’s skills, certifications, and if they can meet your needs. By doing this, your electronics will stay safe and work well.

Key Takeaways

Pick a coating company with the right skills and knowledge. Find one that knows about coatings like silicone and acrylic.

Look for certifications like ISO9001. These prove they follow quality and safety rules.

Ask how they check their work. Good companies carefully check to make sure coatings are done right.

See if they can handle special projects. A good company can adjust to your needs and problems.

Ask how long the project will take. Knowing the time helps you plan and avoid waiting too long.

Understanding PCBA Conformal Coating Services

What is conformal coating for PCBs?

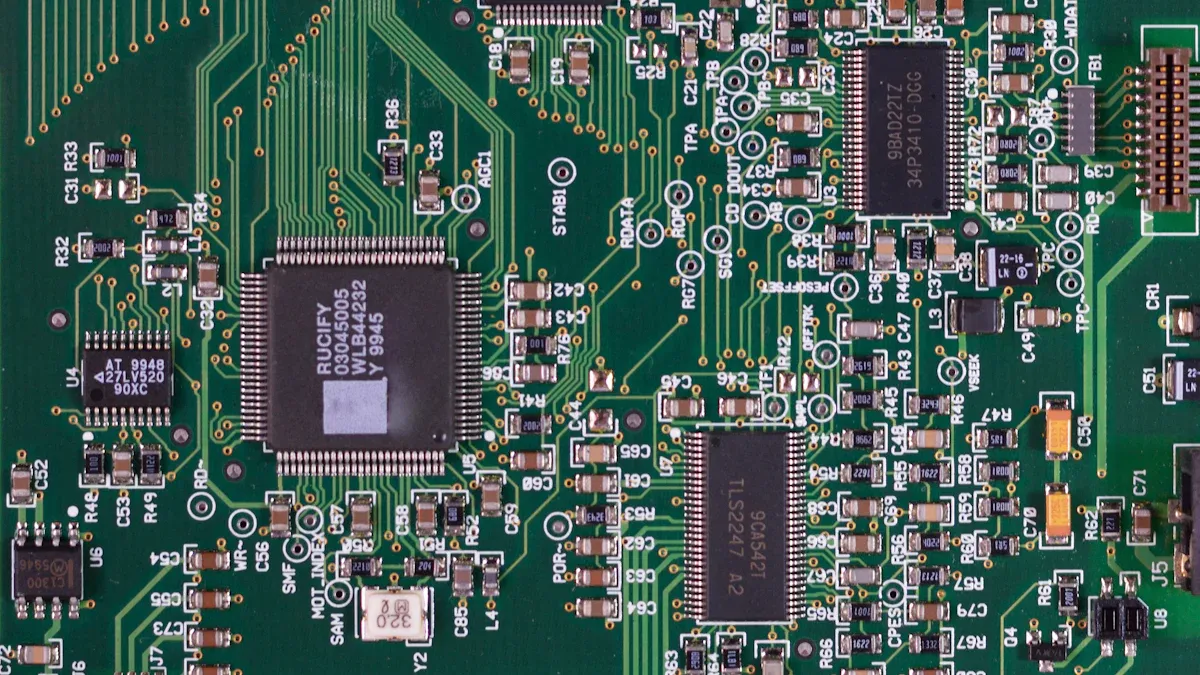

Conformal coating is a thin layer that protects PCBs. It keeps the board and its parts safe from harm. This clear film blocks moisture, dust, and chemicals. Coatings are applied by spraying, dipping, or brushing. Each method affects how strong and reliable the coating is.

There are different coating types like silicone, acrylic, and epoxy. Silicone handles high heat well, while acrylic sticks better. Certifications like IPC-CC-830B and UL746E prove the coating’s quality. IPC-CC-830B checks flexibility and resistance to the environment. UL746E ensures safety from electricity and fire.

Aspect | Description |

|---|---|

Definition | A thin, clear layer that protects circuit boards. |

Application Methods | Spraying, dipping, or brushing affects coating quality. |

Types of Coatings | Silicone, acrylic, and epoxy offer unique benefits. |

Certifications | IPC-CC-830B and UL746E ensure coating quality and safety. |

IPC-CC-830B | Tests flexibility, flammability, and environmental resistance. |

UL746E | Ensures electrical and fire safety for coated electronics. |

Benefits of conformal coating for electronic components

Conformal coatings help electronic parts last longer and work better. These are the main benefits:

Environmental Protection: Blocks moisture, dust, and chemicals to stop damage.

Insulation: Prevents electrical leaks and short circuits.

Mechanical Protection: Reduces harm from vibrations and shocks.

Chemical Resistance: Protects against oils and solvents.

UV Protection: Stops damage from sunlight in outdoor use.

Ease of Application: Can be applied evenly with different methods.

Enhanced Reliability: Makes devices work better and last longer.

Compliance with Standards: Meets safety rules for reliable use.

Using conformal coating keeps your devices safe, even in tough conditions.

Industries and applications that rely on PCBA conformal coating services

Many industries use PCBA conformal coatings to protect electronics. These coatings are crucial where durability matters most. Here are some examples:

Industry Sector | Key Reasons for Reliance on Conformal Coatings |

|---|---|

Consumer Electronics | Protects gadgets like phones and tablets from damage. |

Automotive | Keeps car electronics safe from moisture and dust. |

Aerospace & Defense | Protects sensitive parts in planes and defense systems. |

Industrial | Shields control systems and sensors in tough environments. |

Medical | Ensures medical devices stay reliable in harsh conditions. |

If you work in these fields, protecting electronics is essential. PCBA conformal coatings keep devices working, even in extreme situations.

Key Things to Check When Choosing a Coating Company

Picking the right coating company means checking important details. These checks help ensure they meet your needs and provide good quality. Below are the main points to review.

Coating Skills and Application Methods

A company’s skills show if they can meet your needs. Look at how they handle different coatings like acrylic, silicone, or epoxy. Each type works differently, so they must offer the right one for your project.

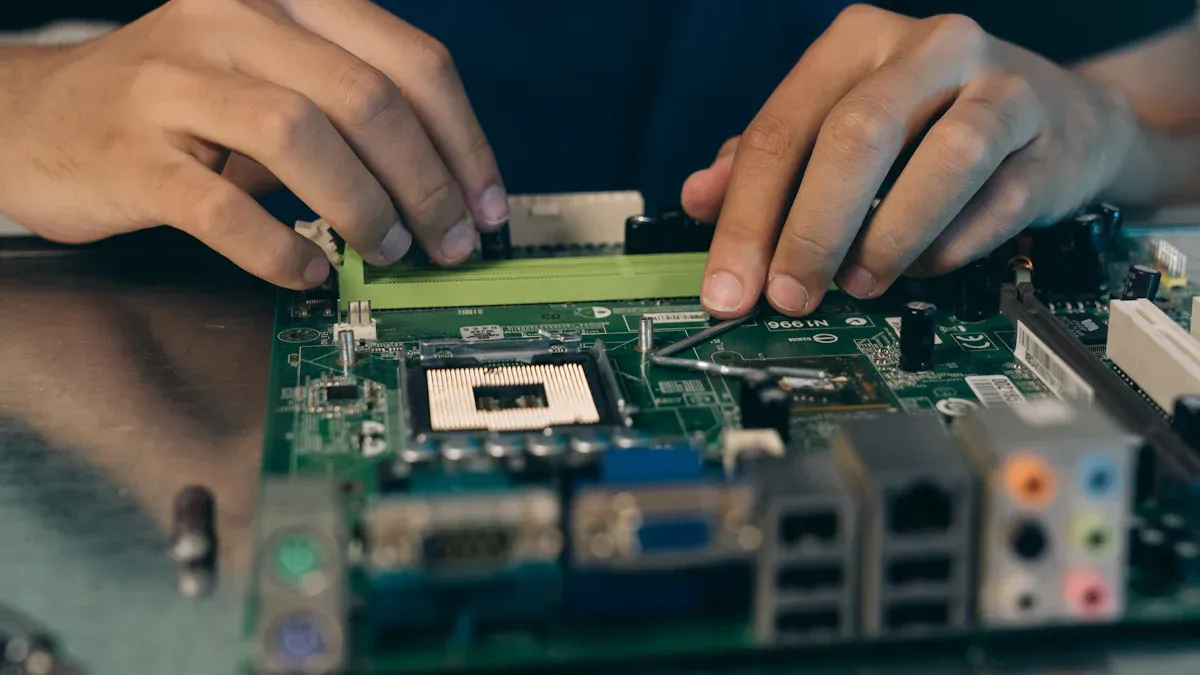

The way coatings are applied also matters. Methods like spraying, dipping, or brushing affect how smooth and strong the coating is. A good company will follow careful steps to ensure quality, such as:

Cleaning surfaces before applying the coating.

Mixing and thinning materials correctly.

Checking the thickness of the coating layers.

These steps help the coating stick well and protect better. Companies that follow rules like SSPC for cleaning and OSHA for safety show they care about quality.

Certifications and Following Industry Rules

Certifications prove a company is trustworthy. They show the company follows important safety and quality rules. For example:

Certification | What It Means |

|---|---|

Ensures good quality management | |

IATF16949 | Needed for car industry quality systems |

ISO13485:2016 | Needed for medical device quality systems |

These certifications mean the company can deliver good results in many industries. Also, following eco-friendly rules like RoHS and WEEE shows they care about the environment. This is important as more industries want green solutions.

Experience with Similar Projects

Experience is key when picking a coating company. A company with a history in your field knows your needs better. For example, industries like electronics and aerospace need advanced coatings. Experienced companies can offer smart solutions for these needs.

Ask for case studies or client reviews to see their past work. These examples show they can handle tough or custom projects. A company with this experience is more likely to meet your expectations.

Quality checks and keeping things clean

Good quality checks are very important when picking a coating company. These checks make sure your electronics get strong and reliable protection. A company with good quality control will follow strict rules to keep things clean and precise during coating. Cleanliness matters because dirt or oils can weaken the coating’s grip on the PCB, making it less effective.

Look for companies that use smart tools like automated optical inspection (AOI) systems. These tools find problems early, ensuring every coated PCB is high quality. Companies with certifications like ISO9001 show they care about doing a good job. Regular checks and reviews also prove they are reliable.

Some companies use special tests like ion chromatography to check for tiny contaminants. These tests help prevent corrosion or electrical problems. Picking a company with these steps means your PCBs will work well, even in tough conditions.

Fixing and reworking coatings

Fixing and reworking coatings is important for solving problems. A good coating company should fix mistakes or make changes without harming the PCB. This saves time and money, especially for tricky projects.

Some companies share examples of how they use low-VOC/HAP coatings. These coatings meet eco-friendly rules and make fixing easier. For instance, one company worked with a client to improve zinc phosphate coatings. This made the coating stronger and reduced the need for fixes, showing the company’s skill.

Another example showed a company switching to low-VOC/HAP coatings in many places. This change proved they could handle different needs while keeping quality high. These stories show why choosing a company with fixing skills is smart.

Saving money and handling big projects

Saving money and managing big projects is key. A good coating company should offer fair prices and still do great work. They should also handle large orders quickly and well.

Big projects need companies with strong systems and tools. Automated coating machines help finish big batches faster, cutting down waiting times. This is helpful for industries like cars or electronics, where demand changes often.

Also, check if the company can adjust to your needs. Some companies create custom coating plans for specific projects. This way, you only pay for what you need, saving money. Picking a company with flexible and affordable options helps you stay on budget and finish on time.

Questions to Ask When Picking the Best Conformal Coating Provider

Choosing the right conformal coating provider means asking smart questions. These questions help you check their skills, quality, and if they fit your project. Below are some important questions to guide your choice.

What coatings and materials do you offer?

Knowing the coatings and materials a provider offers is important. Different coatings work for different needs. Acrylic coatings block moisture well, while silicone handles heat better. A good provider should offer many options and help you pick the best one.

Here’s a simple guide to what to ask about:

Aspect | Details |

|---|---|

Coating Purpose | Protects against moisture, dust, and corrosion. |

Application Methods | Uses methods that fit your project for strong protection. |

Industry Standards | |

Security Certifications | FIPS-certified to keep electronics safe from theft. |

Military Specifications | MIL-SPEC coatings for defense and military electronics. |

Material Properties | Resists moisture, fungus, fire, and keeps electrical parts working. |

By asking these questions, you can check if the provider has the right tools and knowledge for your needs.

Can you share case studies or client reviews?

Case studies and reviews show how experienced and reliable a provider is. They prove the provider can handle projects like yours and deliver good results. Look for examples showing problem-solving, meeting rules, and finishing on time.

Ask about their work in industries like cars, planes, or medical devices. Providers with experience in your field will understand your needs better. Reviews from past clients can also confirm their skills and give you confidence.

How do you ensure quality and consistency?

Quality control is very important when picking a coating provider. Good checks make sure every coated PCB works well and meets standards. Ask how they keep their work consistent and avoid mistakes.

Here are some key practices to ask about:

Regular Checks and Audits: Frequent reviews to meet coating rules.

Detailed Records: Keeping track of processes to maintain quality.

Staff Training: Making sure workers know their jobs well.

Equipment Maintenance: Fixing tools regularly to prevent problems.

Problem-Solving Plans: Steps to fix issues and improve processes.

These steps show the provider cares about doing a good job. Providers who follow these practices are more likely to deliver reliable results.

Tip: Always ask, “What standards does your process follow?” This helps you check if the provider meets rules like ISO or industry-specific needs. Also, ask how they stay updated with new ideas and technology to keep their coatings top-notch.

How do you handle custom or complex coating requirements?

Special coating needs require skilled and flexible providers. When choosing a provider, ask how they solve tough challenges. A good provider will have clear steps to meet your needs.

Here’s what to check:

Material Selection Expertise: They should help pick the best coating. For instance, silicone works for heat, and parylene blocks moisture well.

Tailored Application Methods: They must adjust techniques like spraying or brushing for your project. This ensures accuracy and reduces waste.

Prototyping and Testing: A reliable provider offers small-scale tests before full production. Testing confirms the coating works as expected.

Collaboration and Communication: Providers should work closely with you. They need to share updates and involve you in decisions.

Tip: Ask if they’ve handled similar projects before. This shows they can manage your specific needs.

What is your typical turnaround time for projects?

Project speed is important when picking a coating provider. Delays can mess up schedules and raise costs. Ask about their usual timelines and how they meet deadlines.

Key factors affecting time include:

Project Complexity: Harder designs take more time for prep and testing.

Batch Size: Big orders may take longer, but automated tools help.

Material Curing Time: Some coatings, like epoxy, need extra time to dry.

Quality Assurance Processes: Careful checks take time but ensure better results.

A good provider gives clear timelines upfront. They should also have backup plans for delays.

Note: Providers with advanced tools and smooth processes often finish faster without losing quality.

Common Types of Conformal Coatings and Their Applications

Acrylic coatings: Features and ideal use cases

Acrylic coatings are popular because they protect well and are easy to use. They create a clear layer that keeps moisture, dust, and dirt away from electronics. These coatings are strong and work great outdoors because they resist damage from sunlight and alkali.

In gadgets like smartphones, acrylic coatings protect parts from sweat, water, and bumps. This helps the devices last longer and work better. They also dry quickly and are easy to fix, saving time and money for manufacturers.

Tip: Use acrylic coatings for fast projects needing strong protection from the environment.

Silicone coatings: Features and ideal use cases

Silicone coatings are flexible and handle very hot or cold temperatures. They stay strong in conditions from -40°F to 350°F. This makes them perfect for delicate parts like LEDs and small devices. They also fill tiny cracks, improving waterproofing and strength.

Silicone coatings are great for tough weather. For example, they stop water damage in hurricane areas. They last long in extreme climates and block harmful sunlight. These features make them a smart pick for aerospace and outdoor uses.

Feature/Benefit | Description |

|---|---|

Temperature Resistance | Works well in very hot or cold conditions. |

Flexibility | Bends with surfaces to avoid cracks and keep protection. |

UV Protection | Protects surfaces from sunlight, making them last longer. |

Polyurethane coatings: Features and ideal use cases

Polyurethane coatings are strong and protect against wear, heat changes, and chemicals. They are tough, making them great for car electronics like sensors and control systems. These coatings help parts work well, even in hard conditions.

In cars, polyurethane coatings guard electronics from shaking and fuel vapors. They also resist scratches and chemicals, which is helpful in factories. These coatings keep machines working in places where damage happens often.

Note: Choose polyurethane coatings for projects needing toughness and resistance to rough conditions.

Epoxy coatings: Features and ideal use cases

Epoxy coatings give strong protection to PCBs. They guard against moisture, chemicals, and temperature changes. This helps devices stay reliable and last longer, even in tough conditions. These coatings are great for industries where harsh chemicals or extreme environments are common.

Choosing the right epoxy resin is very important. Not all epoxy coatings protect the same way. Some may not resist moisture or chemicals well. You need to pick the right coating for your project. Cleaning the surface before coating is also key. A clean surface helps the coating stick better to the PCB. The curing process must also be done correctly. If the coating doesn’t cure at the right time or temperature, it may not be strong or durable.

Epoxy coatings are perfect for projects needing high strength and chemical resistance. For example, they protect car electronics like sensors from fuel vapors and shaking. They also work well in machines that face constant wear. While epoxy coatings are strong, they can have limits, like heat problems. Think about these limits when choosing them for your project.

Tip: Talk to your coating provider to make sure the epoxy resin fits your project’s needs.

Parylene coatings: Features and ideal use cases

Parylene coatings are great for covering complex surfaces evenly. They are applied using a chemical vapor process. This process turns the coating into a vapor, which settles as a thin layer. The result is a smooth, even coating that protects electronic parts well.

One big advantage of parylene coatings is their ability to cover tricky shapes. They can coat sharp edges and small spaces perfectly. This makes them ideal for thin-film protection in medical tools and aerospace electronics. Unlike liquid coatings, parylene coatings are much thinner. This keeps delicate parts working properly.

Parylene coatings are also very resistant to moisture, chemicals, and extreme temperatures. This makes them perfect for critical environments. For example, they protect medical implants from body fluids. In aerospace, they shield electronics from tough weather conditions.

Note: The vapor process ensures parylene coatings are even and precise, even at tiny scales. This makes them a top choice for advanced electronics.

Picking the right PCBA conformal coating services keeps electronics safe. A good provider knows all five coating types well. They should have experience and offer many coating options. Certifications and quality checks ensure they do a great job. Ask about materials, methods, and timelines to choose wisely. Research providers that match your project needs carefully. This way, you protect your devices and get great results.

FAQ

How can I pick the right conformal coating provider?

Check their certifications, skills, and coating options first. Make sure they follow rules like ISO9001 and IPC-CC-830C. Ask about their quality checks and if they handle custom needs. Request examples of past work or client reviews for trust.

How do I choose the best conformal coating for my project?

Think about your project’s needs and environment. Silicone is great for heat, while acrylic blocks moisture. Parylene works well on tricky shapes. Talk to the provider to find the best material and method for your project.

Can conformal coatings be fixed or changed?

Yes, coatings like acrylic and silicone can be repaired. Providers use special tools to fix coatings without harming the PCB. Always ask if the provider can repair coatings before starting your project.

Are conformal coatings safe for the environment?

Some coatings meet eco-friendly rules like RoHS and WEEE. Low-VOC or low-HAP coatings are better for the planet. Ask your provider about their green practices and materials to ensure they follow these standards.

How long does a conformal coating project take?

The time depends on the project’s size and details. Simple jobs might take a few days, while bigger ones could take weeks. Providers with advanced tools often finish faster. Always ask for a timeline before starting.

See Also

Choosing The Ideal Fusion PCBA Service For Your Requirements

Finding PCBA Manufacturing Services With Superior Capabilities

Identifying The Top PCBA Manufacturer For Your Business

Selecting The Optimal PCBA Factory For Your Custom Needs

Effective Strategies To Choose The Best PCB Assembly Services