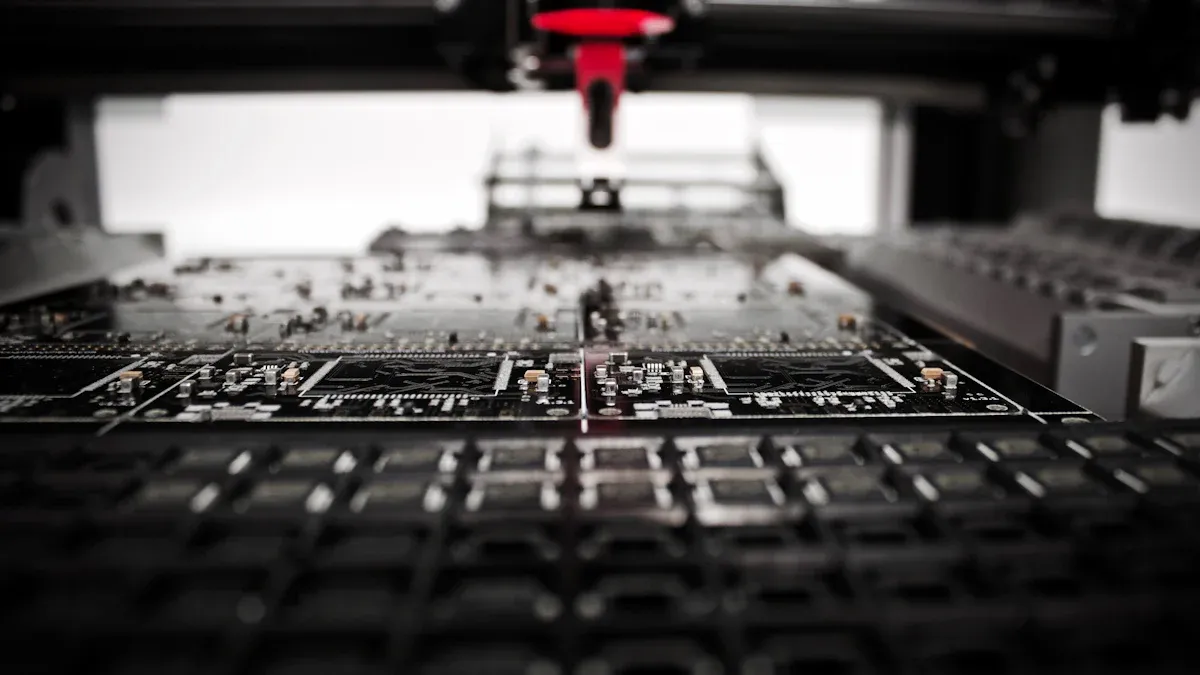

Smart factory monitoring device PCBA is essential for ensuring that smart factory devices operate effectively and reliably. You might wonder how these devices process data so rapidly. The answer lies in the printed circuit board assembly (PCBA). It powers sensors, controllers, and communication tools within factories. The smart factory monitoring device PCBA enables devices to remain compact, conserve energy, and have a long lifespan, even in challenging factory environments. With the integration of PCBA, smart devices enhance factory operations by saving time and increasing efficiency.

Key Takeaways

PCBA is key for smart factory tools, linking sensors and controllers to process data well.

Energy-saving PCBs help batteries last longer and cut waste, making them important for IoT use.

Strong PCBs handle hard factory conditions, staying reliable and lasting a long time.

Flexible PCB designs let factories adjust to new production needs without big expenses.

Using trends like AI and green materials in PCBA design improves performance and helps the planet.

What is PCBA and Why is it Important in Smart Factory Monitoring Devices?

What is PCBA?

Printed Circuit Board Assembly (PCBA) means putting electronic parts on a board. This board, called a PCB, makes devices work. It connects parts like resistors, capacitors, and microcontrollers. These connections help devices run smoothly. For factories, PCBA must be strong, reliable, and work well.

Here are some important features and methods used in PCBA:

Feature/Method | What It Does |

|---|---|

Uses thick copper for better heat control and power flow. | |

Conformal Coating | Adds a protective layer to keep moisture out and improve safety. |

Press-Fit Technology | Pushes pins into the board to handle shaking and heat changes. |

Peel-Off Test | Checks how well coatings stick to the board. |

Drop Test | Tests if the board stays strong after being dropped. |

Thermal Aging | Heats the board over time to check its durability. |

Pressure Test | Tests how the board works under high pressure, like at high altitudes. |

These features make PCBA tough enough for factory use. That’s why it’s so important in smart factory monitoring devices.

How PCBs Help in Industrial IoT

Printed circuit boards (PCBs) are key in the Internet of Things (IoT) for factories. They connect sensors, controllers, and other parts. PCBs collect, process, and send data quickly. This helps factories monitor and improve their work.

Here are examples of how PCBs help in different industries:

Industry | How It Helps |

|---|---|

PCBs control robots and track production steps. | |

Food Factories | PCBs manage temperature and mix ingredients for safe food. |

Medicine Factories | PCBs measure doses and check packaging with sensors. |

With smart PCB designs, factories can work faster, safer, and make better products.

How PCBA Helps Smart Factory Monitoring Devices Work

PCBA is the main part of smart factory monitoring devices. It helps these devices do hard tasks accurately. Here’s how PCBA improves their work:

Real-Time Monitoring: Tracks how machines and production lines are working.

Custom Reports: Makes special reports for checking quality and managing tools.

Traceability: Saves inspection records so data is easy to find later.

Analytics: Analyzes data to find trends and improve operations.

PCBA also connects data, predicts problems, and gives tips to avoid downtime. It helps factories work better and make higher-quality products. This makes PCBA a must-have for smart factories and automation systems.

Key Features and Benefits of Smart Factory Monitoring Device PCBA

Miniaturization and Compact Design for Industrial Applications

Making devices smaller is important for modern industries. Advanced PCB designs create small, efficient devices that fit tight spaces. Better layouts make production faster and less complicated. Materials that handle heat well keep devices working in tough conditions.

Here’s how smaller designs help industries:

Simpler Layouts: Easy designs save time and boost efficiency.

Better Heat Control: Special materials help remove heat quickly.

Faster Assembly: Automated processes make building devices quicker and more accurate.

Small PCBs also improve electronic scales by quickly turning weight into signals. They reduce signal problems, making them great for automation and IoT systems.

Energy Efficiency and Power Optimization

Saving energy is key for smart factory devices. PCBs designed to use less power make batteries last longer. This is vital for IoT devices that need to work for a long time. Automated PCB production also reduces waste, helping the environment.

Benefits of energy-saving PCBs include:

Energy Control: Smart designs use power wisely for better performance.

Longer Battery Life: Devices last longer with efficient power use.

Less Waste: Automation cuts down on wasted materials.

For example, energy-smart PCBs help sensors run nonstop without much upkeep. This ensures accurate data and smooth factory operations.

Reliability and Durability in Challenging Factory Environments

Smart factory PCBA must work well in tough conditions. Tests check if PCBs can handle heat, cold, and stress. These tests ensure PCBs stay strong and reliable.

Here’s a table of key tests and their uses:

Testing Method | Purpose | Application |

|---|---|---|

Thermal Cycling Testing | Handles big temperature changes | Car or airplane electronics |

High-Temperature Operating Life | Works well in high heat | Consumer and industrial devices |

Temperature-Humidity Bias | Handles heat and moisture together | Marine or high-altitude products |

Vibration Testing | Resists shaking and shocks | Car, airplane, and home electronics |

Mechanical Shock Testing | Stays strong after sudden impacts | Portable devices that might be dropped |

Electromagnetic Interference Testing | Follows rules for electromagnetic safety | Devices in areas with high interference |

Salt Fog Testing | Resists damage from salty air | Marine or corrosive environment products |

These tests make sure PCBs last in factories. For instance, vibration tests prove PCBs can handle factory stress. This strength makes PCBs essential for smart manufacturing and automation.

Scalability for Different Smart Factory Needs

Scalability is a key feature of smart factory PCBA. It helps devices adjust to changes in automation and manufacturing. Whether your factory is big or small, scalable PCBs let systems grow without major changes.

Why Scalability is Important in Factories

Factories often need to change how much they produce. Some times need more output, while others need special tasks. Scalable PCB designs let you add sensors or upgrade parts easily. This saves money and time by avoiding full system replacements.

Tip: Pick PCBs with modular designs. These allow easy upgrades as your factory grows.

Features That Make Scalability Possible

Advanced PCB designs include features that support scalability. These features help devices fit into bigger systems or adapt to new needs. Key features include:

Modular Design: Add or remove parts based on factory needs.

Standardized Interfaces: Work smoothly with other devices and systems.

High Data Processing Capacity: Handle more data as factories expand.

Durable Materials: Stay strong in tough factory conditions.

These features make scalable PCBs perfect for IoT and automation. They help factories stay ahead in a fast-changing world.

Examples of Scalable PCBs in Use

Scalable PCBs are used in many industries to grow and improve. For example, car factories use them to add systems for electric cars. Food factories use them to add sensors for better quality checks. These examples show how scalability boosts efficiency and innovation.

Benefits of Scalability in Smart Factories

Scalability has many benefits for smart factories. It helps devices keep up with new technology and market changes. Key benefits include:

Cost Savings: Avoids frequent replacements or upgrades.

Future-Ready: Prepares factories for IoT and automation.

Better Integration: Connects devices easily to current systems.

Higher Productivity: Handles more work and manages data better.

By focusing on scalability, factories can stay flexible and efficient. Scalable PCBs are essential for modern industrial success.

Design and Assembly Considerations for PCBA in Smart Manufacturing

Component Integration for Smooth Functioning

Making sure all parts work together is very important. In smart factory PCBA, smooth integration keeps automation systems running well. Parts like sensors, controllers, and communication tools must work together. This helps process data quickly and correctly.

Engineers use tests to check if parts work well together. These tests measure how components interact. Here’s a table of key tests:

Metric Type | What It Checks |

|---|---|

Causality | Makes sure signals don’t create errors in time responses. |

Reciprocity | Checks if signal paths behave the same in both directions. |

Passivity | Ensures signals are not affected by their strength, keeping behavior steady. |

2x-thru Configuration | Helps with accurate measurements during testing. |

Line Structure | Uses ABCD parameters to measure signal performance. |

Beatty Standard | Helps calibrate tools by checking signal loss and reflection. |

These tests ensure parts work well together, which is crucial for IoT devices in factories.

Quality Control and Testing for Strong Performance

Quality checks make sure PCBs can handle factory challenges. Testing finds problems early, saving money and improving safety. These methods help ensure PCBs are reliable.

Here are some common quality checks:

Quality Checks: Make sure PCBs meet required standards.

Cost Savings: Find problems early to avoid expensive fixes.

Safety: Prevent failures in important systems.

Specific tests also check reliability. The table below shows these tests:

Testing Method | What It Does |

|---|---|

In-Circuit Testing (ICT) | Checks for shorts, opens, and correct part placement. |

Flying Probe Testing | Tests circuits without needing special tools, great for small batches. |

Functional Testing | Simulates real use to ensure everything works as designed. |

Environmental Stress Screening | Tests PCBs under heat, vibration, and moisture to find weak spots. |

Reliability Testing | Includes heat and vibration tests to check long-term strength. |

These tests make sure PCBs stay strong and reliable in tough factory conditions.

Customization for Special Needs

Custom PCBs are made to fit specific jobs in different industries. In factories, custom designs help devices do special tasks, like monitoring certain processes or handling unique conditions.

Here are examples of custom PCB uses:

Industry Area | Example Task | Benefits |

|---|---|---|

Military Radar Systems | Used special PCBs for better target detection. | Improved range and accuracy. |

Satellite Communications | Used lightweight PCBs for better communication systems. | Smaller size with high performance. |

Telecommunications | Redesigned PCBs for faster 5G networks. | Better speed and coverage. |

Aerospace | Created compact PCBs for radar altimeters. | Better heat control and landing accuracy. |

Medical Devices | Used custom PCBs in imaging machines. | Clearer images with less interference. |

Custom PCBs make devices work better for specific tasks. This improves performance and efficiency in factory automation.

Solving Problems in Making PCBA for Tough Conditions

Making PCBAs for tough factory conditions is not easy. These places often have high heat, shaking, and wetness. To make sure PCBAs work well, these problems need fixing during design and production.

One big problem is shaking and sudden hits. Machines in factories shake a lot, which can harm PCBAs. If the shaking matches the board’s natural vibration, it might break. Engineers study how PCBAs handle these forces. They use smart methods to make boards stronger and safer.

Heat changes are another issue. High heat makes PCB materials expand differently, causing stress. Over time, this stress can weaken the board. Using heat sinks and special holes helps manage heat. These tricks keep PCBAs working even in very hot places.

Wetness is also a big challenge. In damp or wet areas, water can get into the PCB and cause problems. Adding a protective coating keeps water and chemicals out. This step is key to making PCBAs last longer in hard conditions.

The table below shows these problems and their fixes:

Problem | What Happens | Fixes |

|---|---|---|

Shaking and Hits | Shaking at certain frequencies can break PCBAs. | Study and strengthen boards to handle shaking and hits. |

Heat Changes | High heat causes stress from uneven material expansion. | Use heat sinks and special holes to control heat. |

Wetness | Water can damage PCBAs in damp or wet places. | Add protective coatings to block water and chemicals. |

By solving these problems, PCBAs can stay strong and reliable in tough factory settings. Good design and testing help them work well, even in extreme conditions.

Real-World Uses of PCBs in Smart Factory Devices

Sensors for Collecting Data in Real-Time

PCBs are key to making IoT sensors work. These sensors collect real-time data in smart factories. They check machines, inventory, and the environment. This helps improve how factories run. For example, sensors can spot temperature changes or track machine health. They can even predict repairs before something breaks. This reduces downtime and keeps things running smoothly.

Here are some facts about IoT sensors with PCBs:

Fact Description | Key Takeaway |

|---|---|

IoT improves factory efficiency, safety, and sustainability. | Sensors monitor inventory, machines, and environmental factors in real-time. |

Data from sensors helps reduce downtime and costs. | Factories can optimize workflows and reduce machine stress. |

Sensors predict repairs before breakdowns happen. | Monitoring inventory digitally prevents supply problems that delay production. |

Sensors create a lot of data. | One sensor can make over 500,000 data points in a week. |

Inventory tracking cuts down on waste. | Sensors calculate extra materials to use resources better. |

These facts show how PCBs help IoT devices improve factories with real-time data.

Predicting Maintenance with PCBA

PCBA is crucial for systems that predict equipment problems. These systems watch machine health and warn about issues early. This helps fix problems before they get worse. It also reduces downtime and keeps production steady.

Benefits of predictive maintenance include:

Watching machines for early signs of wear or trouble.

Fixing problems early to keep production smooth.

Planning maintenance better to save time and money.

Extending machine life with timely upgrades and fixes.

With PCBA, these systems give accurate data and useful tips. This helps factories stay ahead in automation.

PCBA’s Role in Automation and Better Processes

PCBA is vital for automation and improving factory processes. It powers systems that make work faster and more accurate. For example, robots and AI inspection tools need PCBA to work well.

Here’s how PCBA helps factories improve:

Company | Problem | Solution | Results |

|---|---|---|---|

Slow manual assembly | Robots and automated machines | Faster assembly, better accuracy, higher output | |

Company B | Quality issues | AI tools to find defects | Fewer defects, better product quality |

Company C | Environmental concerns | Eco-friendly materials and energy-saving methods | Smaller environmental impact, better reputation |

Company D | Design challenges | Teamwork on design for easier production | Faster production, quicker market delivery |

Company E | Need for constant improvement | Data tools to monitor and improve processes | Faster work, fewer errors, better efficiency |

These examples show how PCBA boosts automation and helps factories work smarter.

Future Trends in PCBA Technology for Smart Manufacturing

AI and Machine Learning in PCBA Design

AI and machine learning are changing how PCBs are made. These tools make work faster, fix mistakes, and save money. For example, AI helps plan PCB layouts better, cutting costs and saving time. It also spots signal problems early and suggests fixes before production.

AI systems are great at finding PCB flaws. They use heat images and smart programs to detect issues quickly. This ensures only good PCBs are used in factories. Companies like PCBAIR use AI to catch problems early, making manufacturing more reliable.

Use Case | What It Does |

|---|---|

Layout Planning | AI saves time and money by improving PCB layouts. |

Signal Problem Fixing | AI predicts and solves signal issues before production starts. |

Flaw Detection | AI finds defects early, ensuring high-quality PCBs. |

Faster Design | AI speeds up design work, making it more accurate and reliable. |

Adding AI to PCBA design fills knowledge gaps and boosts efficiency for IoT and automation.

Green Manufacturing and Eco-Friendly Materials

Making PCBs eco-friendly is now a big focus. Companies use energy-saving methods to cut pollution. 3D printing reduces waste by up to 86%. Modular designs let you fix or upgrade devices instead of replacing them.

New rules, like the ESPR, push factories to be greener. Water-saving ideas and safer materials are becoming popular. These changes help the planet and meet global eco-goals.

Focus Area | What It Covers |

|---|---|

Green Ideas | New ways to make PCBs and chips eco-friendly. |

Pollution Problems | Explains how old methods harm the environment. |

Water Saving | Talks about using less water in making chips. |

New Rules | Discusses laws like ESPR for greener production. |

By going green, companies help the Earth and stay ahead in the market.

Flexible and Wearable PCBs for Industry

Flexible PCBs are changing how devices are built. They handle heat and moisture well, making them tough for hard jobs. These PCBs bend and stretch, perfect for small IoT gadgets and wearable tech.

For example, flexible PCBs fit into tiny spaces while staying powerful. They use special materials to manage heat in high-power devices. Roll-to-roll printing with copper inks lowers costs, making them affordable.

Flexible PCBs resist heat and moisture, lasting longer.

Special materials keep devices cool and working well.

Copper inks make PCBs cheaper and more flexible.

Strong materials handle bending, great for wearables like smart patches.

These advances help create smaller, stronger, and smarter devices for industries.

The impact of 5G and edge computing on PCBA functionality.

5G and edge computing have changed how PCBs work in technology. These new advancements need faster data handling, less delay, and better efficiency. This directly affects how PCBs are designed and perform. These changes are very important for industries using IoT and automation.

5G networks send data much faster. This helps PCBs manage real-time tasks better. For example, in smart factories, PCBs in IoT devices quickly process large amounts of sensor data. This keeps machines running smoothly and avoids delays. Less delay also helps with predictive maintenance. Quick actions stop costly machine breakdowns.

Edge computing improves PCB use by processing data near its source. Instead of using faraway cloud servers, edge devices with advanced PCBs handle data locally. This reduces pressure on main systems and boosts efficiency. Strong memory and processors are needed for this, making PCBs more complex but also more powerful.

Here’s how 5G and edge computing improve PCBs:

Faster Data Handling: PCBs support quick communication for real-time tasks.

Stronger Materials: Special materials help PCBs work in tough 5G and edge setups.

Easy Upgrades: Modular designs let PCBs grow with data needs.

These upgrades make PCBs vital for healthcare, cars, and factories. As 5G and edge computing grow, PCBs will become even better and more useful.

Tip: Choose PCBs made for 5G and edge computing to keep your systems ready for the future.

The circuit board is key to smart factory devices. It links sensors, controllers, and parts for smooth operation. Its smart designs save energy and boost productivity. These boards make small, strong devices that work in tough places. In factories, PCBA helps with automation and remote monitoring. Learning about new tech like IoT, AI, and green methods keeps you ahead. Using these tools opens doors to better work and success in Industry 4.0.

FAQ

1. Why is PCBA important for smart factory devices?

PCBA links and powers parts in smart devices. It helps sensors, controllers, and tools work together smoothly. This teamwork lets devices gather, process, and share data quickly. This is key for checking and improving factory work.

2. How does PCBA save energy in factories?

PCBA uses smart designs to lower power use. It helps sensors and devices use less energy, making batteries last longer. This saves money and cuts waste, helping factories meet green goals.

3. Can PCBA survive tough factory conditions?

Yes, PCBA is built for hard environments. Special coatings, strong materials, and strict tests make it resist heat, water, and shaking. These features keep it working well in rough places.

4. How does PCBA help with machine maintenance?

PCBA powers IoT sensors that check machines in real time. These sensors collect data to spot problems early. Fixing issues before they get worse avoids downtime and keeps machines running longer.

5. What new ideas are shaping PCBA for factories?

New trends include AI designs, eco-friendly materials, and bendable PCBs. These ideas improve performance, cut pollution, and support tech like 5G and edge computing. Learning about these trends helps factories stay ahead.

Tip: Use scalable PCBA designs to prepare your factory for the future.

See Also

Why PCBA Manufacturing Skills Are Crucial for Electronics Design

Understanding PCBA Manufacturing and Its Significance in Industry

Exploring PCBA Services and Their Role in Electronics Production

Key Applications and Advantages of PCBA in Today’s Electronics