Smart factory tools improve PCB assembly by using smart tech like IoT, AI, and robots. These tools make production faster and better. For example, factories see a 30% rise in speed and 95% success in making products. Smart factories use live data to find and fix problems quickly. This helps deliver 98% of orders on time. It also cuts costs by 20% and improves accuracy. Smart factory PCB assembly is changing how things are made today.

Key Takeaways

Smart factory tools make PCB assembly 30% faster and 95% more accurate. This helps production become quicker and more dependable.

IoT and AI help factories find and fix issues fast. This ensures 98% of orders arrive on time.

Automation in smart factories lowers costs by 20% and reduces mistakes. This creates better-quality products.

Using smart factory technology gets businesses ready for future changes. It also improves how well they work overall.

Eco-friendly PCB manufacturing helps the planet and follows today’s rules.

Understanding Smart Factory PCB Assembly

What Are Smart Factory Solutions?

Smart factories are the future of making things. They use advanced tools like IoT, AI, and robots to connect machines and make them work on their own. These systems collect and study live data to improve work with little help from people.

Industry 4.0 has changed how factories work by using smart tools like IoT and AI.

Machines in smart factories learn, check data, and fix themselves to work better.

We can explain smart factory solutions in two ways:

Perspective | Meaning |

|---|---|

Business Practices | Smart factories gather data, connect machines, and work with little human help. |

Research Studies | Fully connected systems that use data to handle production tasks. |

Using these tools, smart factory PCB assembly connects processes smoothly, reduces mistakes, and boosts productivity.

Why Are Smart Factories Important for PCB Assembly?

Smart factories are changing how PCBs are made. They help meet the need for faster, cheaper, and more accurate production. Tools like 3D SPI (Solder Paste Inspection) and AOI (Automated Optical Inspection) check quality and give useful data. This data helps improve work as it happens.

Some key benefits of smart factories in PCB assembly are:

Better decisions with AI, leading to higher success rates and faster work.

Trusted data from machines to quickly find and fix problems.

Smarter use of resources, cutting waste and saving time.

By using smart factory methods, you can make PCB assembly more accurate and reliable. These tools not only improve your work now but also prepare you for future tech upgrades.

Technologies Powering Automated PCB Assembly

IoT Applications in PCB Assembly

IoT helps improve how PCBs are made. It connects machines, sensors, and systems to share live data. This lets factories track steps, spot problems, and make better choices. For example, Boeing uses IoT to manage production smoothly and get better results.

IoT also helps prevent equipment breakdowns. Sensors check machines and warn about issues early. This stops delays and keeps machines working longer. IoT systems, like those at Sanmina Corp., improve solder paste use. This reduces mistakes and increases production success.

Adding IoT to your PCB assembly line makes work smarter. It cuts waste and boosts productivity. IoT is a key part of smart factories, helping businesses stay ahead in a fast-moving industry.

AI for Process Optimization

AI makes PCB assembly faster and smarter. It studies lots of data to find patterns and suggest fixes. AI can spot problems early, cutting human mistakes by up to 96%.

AI tools like Advanced Process Control (APC) improve production quality. They adjust parts placement and assembly steps as needed. The table below shows how AI improves PCB assembly:

Metric | Improvement |

|---|---|

Fewer human mistakes | 94-96% |

Better conversion rates | 4.44% |

Higher production success | 4.25% |

AI also helps save resources. It uses data to reduce waste and energy use. This lowers costs and supports eco-friendly manufacturing. Adding AI to PCB assembly improves accuracy, quality, and efficiency.

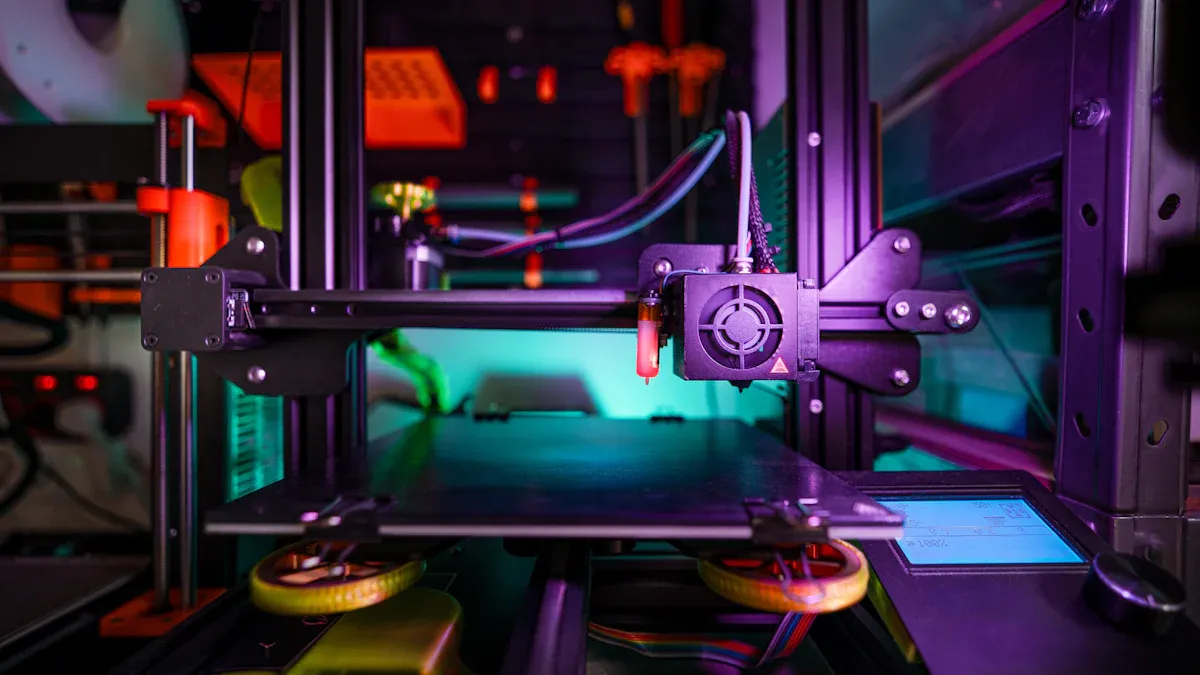

Robotics in PCB Manufacturing

Robots are changing how PCBs are made. They handle tasks like soldering and inspecting with great accuracy. This lowers mistakes and keeps quality high.

Robots are great for repetitive or tricky jobs. Workers can focus on bigger tasks while robots do the detailed work. For example, Sierra Circuits uses robots to make PCBs for surgical tools. These meet strict requirements easily. Another example shows robots improving design checks and production speed.

Case Study | Description | Benefits |

|---|---|---|

Org A | Used Sierra Circuits’ PCBs for surgical tools. | Made complex PCBs that meet strict needs efficiently. |

Org B | Used robots for development boards and equipment. | Saved money and improved design checks automatically. |

Using robots speeds up production, lowers costs, and keeps quality high. Robotics is a big part of smart factories, helping PCB manufacturing become faster and better.

Benefits of Smart Factory Solutions in PCB Assembly Process

Better Efficiency and Faster Production

Smart factory tools make PCB assembly faster and more efficient. They use automation and advanced systems to simplify tasks and avoid delays. Machines can quickly adjust to new designs, speeding up production. For example, closed-loop systems fix problems instantly. This stops slowdowns and keeps work running smoothly.

Aspect | Evidence |

|---|---|

Automation helps assembly lines adapt to new designs easily. | |

Lower Costs | Real-time data reduces waste and improves machine use. |

Faster Lead Times | Closed-loop systems prevent delays and handle changes quickly. |

Better Quality | Standardized instructions ensure consistent results in every step. |

Real-time data helps track and improve production. This keeps assembly lines working their best, meeting deadlines without losing quality.

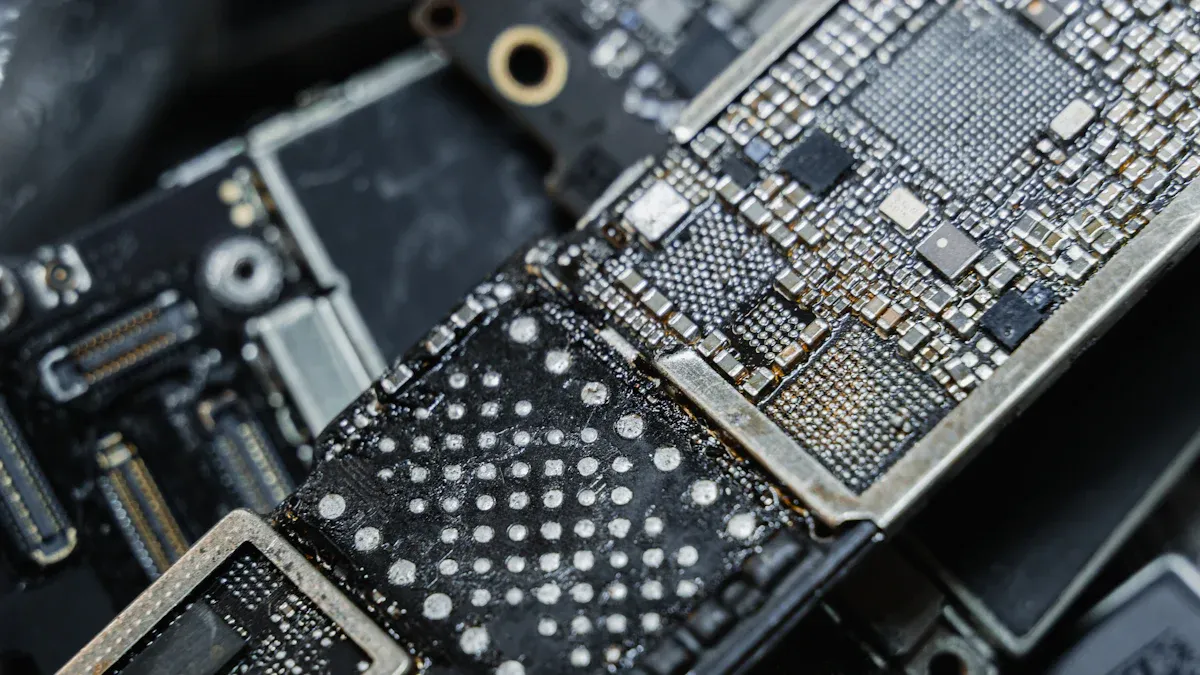

Improved Quality and Fewer Errors

Smart factories improve quality checks in PCB assembly. They use advanced tools and automation to meet high standards. This reduces mistakes and makes better products. Tools like SPI and AOI catch problems early, saving time and money. For example, SPI checks solder paste, and AOI finds missing or misplaced parts.

Quality Control Metric | Description |

|---|---|

Checks solder paste is applied correctly to avoid mistakes. | |

Automated Optical Inspection (AOI) | Uses cameras to find missing parts or wrong placements. |

X-ray Inspection | Looks inside to check hidden connections like BGA components. |

Functional Circuit Testing (FCT) | Tests if the PCB works properly in real-world conditions. |

In-Circuit Testing (ICT) | Checks each circuit on the PCB to ensure it works. |

These tools help make PCB assembly more accurate and reliable. They improve product quality and build trust by delivering dependable items.

Saving Money and Using Resources Wisely

Smart factory solutions save money by using resources better and cutting waste. Automation helps predict problems, reducing machine breakdowns and repairs. For example, one car company cut downtime by 45% and improved machine use by 25% with predictive maintenance.

A global company saved 30% on inventory costs and improved delivery times by 20% using AI tools.

Predictive maintenance reduced downtime by 45% and boosted machine efficiency by 25% for a car maker.

Digital twins helped cut production times and improved resource use for many manufacturers.

Using these tools lowers costs and boosts efficiency. It also supports eco-friendly practices by reducing waste and saving energy.

Challenges in Using Smart Factory Solutions

Combining with Current Systems

Adding smart factory tools to old systems can be tricky. You might need to change how your work is done. This could mean updating machines and changing workflows. For smaller companies, the high cost of setup can be tough. In big factories, making machines talk to each other is also hard. If you don’t plan well, these problems can slow down your switch to smart factories.

Training Workers and Building Skills

Smart factories need workers who know new tech. Employees must learn to use tools like IoT devices and smart systems. This means lots of training to teach new skills. Some workers may feel stressed by these changes. To help, create a friendly learning space. Give hands-on lessons and clear instructions to make the switch easier.

Solving Cybersecurity Problems

Smart factories use connected systems, which can face cyber risks. These include hacking, phishing, and weak IoT device security. You can protect your factory by using safety measures. For example, split networks to stop DDoS attacks. AI tools can also find threats quickly. The table below shows more risks and how to fix them:

Cybersecurity Risks | How to Fix Them |

|---|---|

DDoS attacks | Split networks |

Weak IoT device security | Use AI to spot threats |

Phishing tricks | Use zero trust systems |

Old system weaknesses | Do regular updates |

Cyber-Physical System risks | Use strong encryption |

By fixing these issues, your smart factory can stay safe and work well.

Future Trends in Smart Factory PCB Assembly

Role of 5G and Edge Computing

5G and edge computing are changing smart factories. 5G makes networks faster and more reliable. This helps PCB assembly work better. With 5G, factories can connect more devices and sensors. This allows real-time tracking and quicker decisions. For example, 5G reduces delays, letting machines run smoothly.

Key Aspect | Description |

|---|---|

Speed and Capacity | 5G boosts network speed and reliability, helping PCB assembly. |

Connectivity | Connects more devices, making smart manufacturing easier. |

Operational Efficiency | Reduces delays and supports many devices, improving factory work. |

Edge computing works with 5G to process data nearby. This speeds up how factories use information. Together, these tools make smart factories faster and more efficient.

Sustainability in PCB Manufacturing

PCB factories are focusing on eco-friendly methods. Using biodegradable materials like cellulose instead of fiberglass helps the planet. Lead-free solder is safer and avoids pollution.

Other green practices include:

Water-based inks and coatings to lower harmful fumes.

Recycling metals like copper to reduce mining needs.

Halogen-free materials to stop toxic gas during disposal.

These steps protect the environment and meet modern eco rules.

Advancements in Automation Technologies

Automation tools are improving PCB assembly. Systems that move materials continuously make handling and testing easier. Automated tracking lets factories follow parts during production. These tools speed up work and reduce mistakes.

Technology/Methodology | Benefits |

|---|---|

Advanced Automation | Faster production, fewer errors, better consistency, easier miniaturization. |

Software Automation | Tracks materials, packs efficiently, and stores for large-scale production. |

Additively Manufactured PCBs | New ways to design and make PCBs. |

Tools like AOI (Automated Optical Inspection) and AOS (Automated Optical Soldering) improve quality checks. These upgrades help smart factories meet industry needs while staying efficient.

Smart factories are changing how PCBs are made. They make work faster and more efficient. These systems help improve accuracy and product quality. They also save money by cutting costs. There are challenges like connecting old systems and stopping cyber threats. But the benefits are much bigger than the problems. Using these tools helps businesses stay strong in tough markets. As technology grows, smart factories will create greener and better ways to make things.

FAQ

What are smart factories, and how do they work?

Smart factories use tools like IoT, AI, and robots. These tools help automate and improve how things are made. They collect live data, study it, and make changes to work better.

How do smart factories improve PCB assembly efficiency?

Smart factories make PCB assembly faster and easier. They use machines to do repeated tasks and fix problems quickly. This saves time, reduces waste, and keeps quality steady.

Are smart factory solutions expensive to implement?

Setting up smart factories can cost a lot at first. Small businesses may find it harder to afford. But over time, they save money by working faster and using fewer resources.

What challenges might you face when adopting smart factory solutions?

You might have trouble adding new tools to old systems. Workers need training to use the new technology. Cybersecurity risks can also be a problem. Good planning can solve these issues.

Can smart factories adapt to changing production needs?

Yes, smart factories can change quickly. They use smart systems to handle new designs or bigger orders. This makes them flexible and ready for new challenges.

See Also

Essential Strategies to Enhance PCB Assembly Productivity

Ways to Optimize Workflow Efficiency in PCBA Production

Ten Professional Insights for Cost-Effective PCBA Assembly

Best Practices for Maintaining Quality and Efficiency in PCBA

Comprehending the Processes of PCBA Manufacturing and Assembly