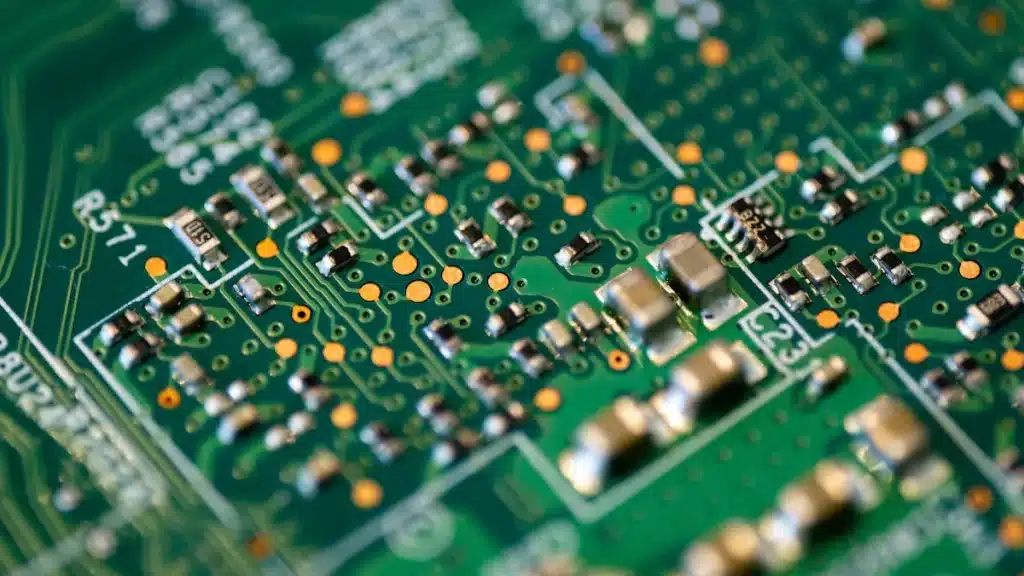

Efficient electronics production needs the right tools to work well. SMT operators use special machines to make tasks easier and better. Tools like pick-and-place machines, reflow ovens, and solder paste printers are important for pcb assembly. These machines help put parts in the right spots, solder neatly, and move materials easily. They also make sure every pcb is high quality and works reliably. Using better tools makes work faster, lowers mistakes, and saves time and money over time.

Key Takeaways

Pick-and-place machines make work faster and more accurate. They can place up to 120,000 parts each hour with few mistakes.

Reflow ovens help solder parts evenly. They use temperature control to lower defects and make products more reliable.

Solder paste printers spread paste smoothly. This stops problems like solder bridging and makes strong connections.

AOI systems check for mistakes quickly. They reduce waste and keep production quality high.

Cleaning SMT equipment often is very important. It keeps machines working well and stops problems from dirt or residue.

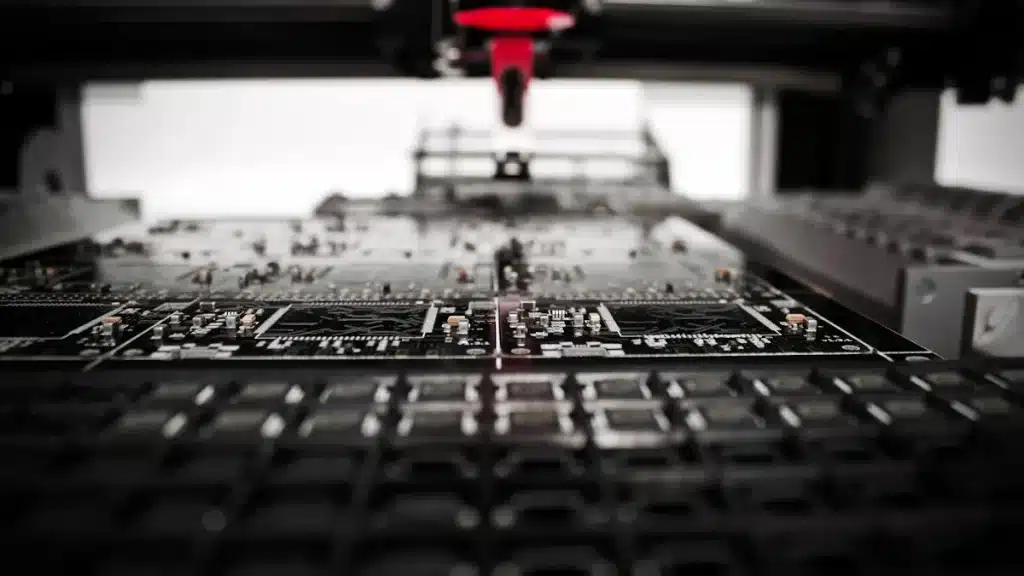

Pick-and-Place Machines for PCB Assembly

Key Features of Pick-and-Place Machines

Pick-and-place machines are important for building circuit boards. They place parts exactly where they need to go. Cameras help check placement to keep it accurate. These machines work fast, placing up to 120,000 parts per hour. This makes them great for making many boards quickly.

Modern machines can adjust to different board sizes easily. They switch between projects without much delay. Touchscreens make them simple to program and use. They work with tiny chips and bigger parts, making them useful for many tasks.

Benefits for Efficient Manufacturing

Pick-and-place machines make production faster and easier. They work on their own most of the time, giving steady results. They place parts with accuracy of ±0.015mm, lowering mistakes and improving quality. Automating placement saves time and cuts labor costs.

These machines help operators work better and avoid delays. They can handle changing production needs, like making electronics or car parts. Their speed and accuracy help meet deadlines while keeping quality high.

Top Brands and Models for SMT Operators

Choosing the right machine means looking at top brands. FUJI NXT III is a favorite with its modular design and accuracy of ±0.03mm. It places tiny chips and works at 40,000 parts per hour.

ASM SIPLACE TX is another great choice for fast and precise work. It places parts with accuracy of ±0.025mm and handles small components like 0201. Both models have dual lanes, making them good for making lots of boards quickly.

Reflow Ovens for Printed Circuit Board Soldering

Types of Reflow Ovens

Reflow ovens come in various types for different pcb needs. Convection ovens are common and use hot air to heat pcbs evenly. Vapor phase ovens use a special liquid that turns into vapor for heating. These are great for jobs needing exact temperature control.

Batch ovens are good for small projects, while inline ovens suit large-scale production. Long ovens with 8-10 heating zones control heat better for big jobs. Short ovens with 4-6 zones work well for smaller or medium tasks.

Features for Consistent Soldering Quality

Reflow ovens have features to ensure soldering is done right. Many models keep temperatures steady within ±5°C to avoid overheating. They use temperature curves to match the soldering process to the pcb’s needs.

Some ovens use nitrogen to create a controlled space, improving solder joints. Heat spreads evenly across the board, reducing mistakes. These features make products more reliable and lower defects.

Metric | Description |

|---|---|

Temperature uniformity | Checks heat differences in the oven, staying within ±5°C. |

Temperature curve | Matches actual heat profiles to set ones for proper soldering. |

Heat transfer efficiency | Measures how evenly heat spreads on the pcb. |

Use of nitrogen | Ensures nitrogen flow for better solder joints in a controlled space. |

Benefits for High-Volume Assembly

Reflow ovens are key for making many pcbs quickly. Long ovens with more zones and faster belts speed up production. For instance, an 8-zone oven can run belts at 20 inches per minute, perfect for big jobs.

Short ovens are better for smaller or mixed projects. They balance speed and quality, ensuring good soldering without delays. By cutting down on errors, these ovens save time and money, helping smt operators work efficiently.

Long ovens with 8-10 zones are best for big jobs.

Short ovens with 4-6 zones are great for smaller tasks.

Faster belts help finish work quicker, saving time.

Tip: Pick a reflow oven based on your production size and pcb design. This helps you get the right tool for your work.

Solder Paste Printers for Accurate PCB Assembly

High-Precision Features of Solder Paste Printers

Solder paste printers are crucial for pcb assembly. They apply solder paste with great precision. Modern printers have advanced features for better accuracy. For example, they achieve repeat position accuracy of ±12.5um@6 σ, CPK≥2.0. Their print accuracy is ±22um@6 σ, CPK≥2.0. This ensures even tiny parts get the right amount of paste.

Large pcbs need special printers because they are more complex. These printers prevent warping by providing strong support. Warping can cause problems like solder bridging. Custom bases and regular stencil cleaning improve their performance. These features help printers handle high-density pcb tasks with ease.

Measurement Type | Value |

|---|---|

Repeat position accuracy | ±12.5um@6 σ, CPK≥2.0 |

Print accuracy | ±22um@6 σ, CPK≥2.0 |

Benefits for Consistent Paste Application

Applying solder paste evenly is very important for pcb assembly. Advanced inspection systems check paste application for uniformity. This reduces errors and makes products more reliable. These systems give instant feedback to adjust settings when needed.

Modern technologies like 3D imaging check paste deposits carefully. This ensures the paste is applied correctly, improving solder joint quality. Fully automatic printers also reduce common issues like too much or too little paste. By cutting down on waste and rework, these printers save time and money.

Note: Even paste application is key for high-density SMT work. It affects how well the final product performs.

Use Cases in SMT Manufacturing

Solder paste printers are essential in smt manufacturing. Studies show that 50% to 70% of soldering problems come from stencil printing. Factors like stencil design and paste type affect how well the paste is applied.

In one study, a defect detection model reached 96.97% accuracy. It used data from multiple sources to find errors. This shows how important precise solder paste printing is for quality control. These printers are also great for large-scale production. They ensure consistent results across many pcbs.

Aspect | Details |

|---|---|

Study Focus | Finding defects in solder paste printing |

Methodology | Using data from multiple sources |

Key Findings | Model had 96.97% accuracy in finding defects |

Implication | Improves quality control in SMT production |

AOI Systems for Quality Control in PCB Assembly

Advanced Features of AOI Systems

AOI systems use smart technology for pcb assembly. They don’t rely on human checks but use data to improve inspections. This helps lower false alarms while keeping defect detection high. For example, a study showed an 18% drop in false calls at the 80th percentile. This proves AOI systems are reliable and efficient for finding problems.

Modern AOI systems have fast cameras and smart software. These tools inspect shiny surfaces, like aluminum parts, with great accuracy. They also work well in different factory setups, making them flexible for many tasks. With these features, AOI systems keep production quality steady every time.

Benefits for Detecting Defects

AOI systems make finding defects easier and faster. They catch problems like misplaced parts or bad soldering with 84.71% accuracy. They also work quickly, making them good for live inspections during production.

Another benefit is reducing waste. Faulty parts can often be reused, helping the environment. By spotting issues early, AOI systems save time and stop bad pcbs from moving forward. This ensures products are high-quality and production runs smoothly.

Aspect | Details |

|---|---|

Inspection Capability | Checks shiny aluminum parts with smart tools. |

Performance Metrics | Finds defects with 84.71% accuracy using advanced methods. |

Operational Feasibility | Works fast enough for live inspections during production. |

Environmental Adaptability | Fits into different factory setups easily. |

Sustainability Benefits | Reuses faulty parts to cut waste and help the planet. |

Applications in SMT Production Lines

AOI systems are important for SMT production lines. They find small mistakes in part placement and soldering. Fast cameras let workers fix problems right away, reducing delays.

In DIP lines, AOI systems check through-hole parts for alignment and soldering. Special tools inspect before and after soldering to ensure quality. In PCBA coating lines, they check for even coatings and spot issues like bubbles or cracks. This improves efficiency and lowers coating errors.

Application Area | Key Metrics and Advantages |

|---|---|

SMT Production Line | - Finds small mistakes in part placement or soldering. |

- Fast cameras help fix problems quickly. | |

- Early checks reduce waste and faulty pcbs. | |

DIP Production Line | - Checks alignment and soldering of through-hole parts. |

- Special tools inspect before and after soldering. | |

- Ensures accurate checks without slowing production. | |

PCBA Coating Line | - Makes sure coatings protect against damage. |

- Spots problems like bubbles or cracks. | |

- Improves efficiency and lowers coating mistakes. |

Tip: Adding AOI systems to your production line keeps quality high and reduces wasted time and materials.

SPI Systems for Pre-Reflow Inspection

Features of SPI Systems

SPI systems check solder paste quality during pcb assembly. They use 3D technology to measure paste deposits. Unlike 2D checks, 3D systems look at paste volume, height, and shape. This helps find small problems early.

You can pick off-line or in-line SPI systems based on your needs. Off-line systems are accurate and flexible, good for detailed checks. In-line systems work directly in the production line for live monitoring. They reduce mistakes and save money over time.

Feature | Off-line SPI Systems | In-line SPI Systems |

|---|---|---|

Inspection Type | Separate inspection stations | Built into production line |

Accuracy | Very precise and detailed | Real-time checks |

Flexibility | Handles complex tasks | Improves efficiency with constant monitoring |

Production Impact | May slow work due to manual steps | Cuts errors and lowers costs |

Cost | Lower upfront cost | Higher upfront cost but saves money later |

Benefits for Ensuring Paste Consistency

SPI systems help keep solder paste application steady. They spot paste problems early, avoiding defects later. Early fixes save time and money during production.

Modern SPI systems miss less than 0.1% of defects. They also cut first-check times from two hours to 15 minutes. Finding issues early stops expensive mistakes in later steps.

Fixing defects early costs $0.40, but $45 if found later.

Early detection saves time and improves production speed.

Use Cases in PCB Assembly

SPI systems are common in pcb assembly to improve quality. For example, one company tested different pastes using a Koh Young SPI system. They measured paste transfer and process capability to pick the best option.

These systems are great for large-scale production. They ensure consistent results across many pcbs. SPI systems are especially helpful for high-density boards where accuracy matters. Adding SPI systems improves quality control and reduces waste.

Technology | Resolution | Inspection Speed | Applicable Defects |

|---|---|---|---|

2D AOI | 10μm | 0.5s/board | Surface/visual defects |

3D AOI | 5μm | 1.2s/board | Height and coplanarity defects |

3D SPI | 3μm | 0.8s/board | Solder Paste volume/deformation |

Tip: Using SPI systems keeps solder paste application consistent. This lowers defects and improves assembly quality.

Conveyors and Handling Systems for Smooth Manufacturing

Features of SMT Conveyors

SMT conveyors help move PCBs safely and quickly during assembly. They are built to handle fragile parts carefully while keeping materials flowing smoothly. Many have adjustable speeds to match your production pace. Some also use sensors to check PCB placement, ensuring proper alignment and fewer mistakes.

Motorized roller conveyors save energy by running motors only when needed. This lowers power use a lot. Modern conveyors also work well with other SMT tools, creating a connected production line. This setup helps your assembly process run without stops.

Benefits for Better Workflow

SMT conveyors improve how work gets done. They automate moving materials, cutting down on delays from manual handling. Workers can focus on more important tasks, boosting productivity. Automation also reduces mistakes, keeping PCB quality steady.

Research shows key benefits:

Conveyors reduce downtime and keep things running smoothly.

Sensors check products in real time to meet standards.

They save money by lowering labor costs and preventing injuries.

Benefit | What It Does |

|---|---|

Automated print accuracy | Makes printing more precise and efficient. |

Tracks and improves placement | Ensures parts are placed correctly, reducing errors. |

Faster new product launches | Speeds up introducing new items to production. |

Pre-print optimization | Cuts waste and improves first-run quality. |

Works with other equipment | Easily connects with existing systems. |

Boosts productivity and cuts costs | Improves efficiency and saves money overall. |

Uses in Material Handling

Conveyors are key for moving PCBs during assembly. They carry boards between steps like solder paste printing, part placement, and reflow soldering. This keeps production moving without delays.

In large factories, conveyors move PCBs quickly to keep up with demand. In smaller setups, they adjust to fit different PCB sizes and designs. Advanced software makes them even better by standardizing tasks and helping workers be more productive.

Tip: Pick conveyors that fit your production needs. This keeps things running smoothly and boosts efficiency.

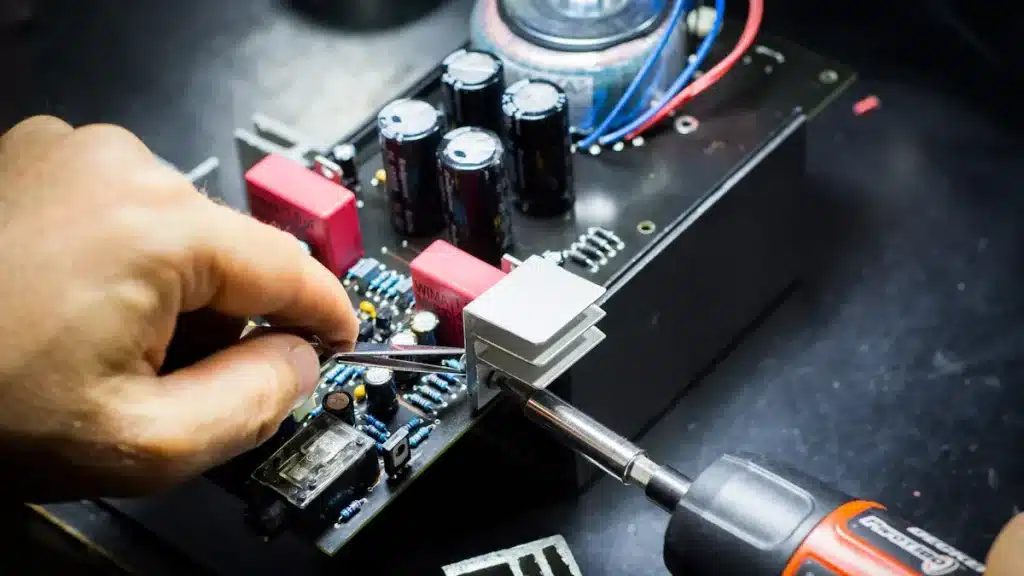

Cleaning Equipment for PCB and SMT Maintenance

Features of SMT Cleaning Systems

SMT cleaning systems help keep PCB assembly clean and working well. They remove dirt like solder paste and flux residues using smart technology. For example, the InJet® 388 CRD uses vertical spray-in-air cleaning to save water and chemicals. The PSE LH7 cleans up to 540 boards in just 12 seconds, making it great for busy factories.

Modern systems focus on safety and being eco-friendly. They use detergents without harmful chemicals or metals. The Trident ZDO system has zero-discharge cleaning, checks cleanliness in real time, and recycles water to save energy. These features make it perfect for industries with strict rules about the environment.

Tip: Pick cleaning systems with water recycling to cut waste and help the planet.

Benefits for Equipment Longevity and PCB Quality

Cleaning regularly keeps machines working longer and improves PCB quality. Dust and dirt can cause problems like corrosion or bad connections. Cleaning stops these issues and keeps production smooth.

The demand for PCB cleaning machines is growing fast worldwide. This shows how important they are for high-quality work, especially in fields like medicine and aerospace. Regular checks like calibration and lubrication also make machines more reliable.

Cleanliness: Stops dust buildup for better inspection results.

Lubrication: Protects parts from damage with regular care.

Scheduled Calibration: Keeps machines accurate by following guidelines.

Using advanced cleaning systems reduces repairs and keeps equipment running longer.

Applications in Post-Production Cleaning

Post-production cleaning makes sure PCBs meet strict quality rules. These systems clean off residues, dirt, and germs that could cause problems. Tests and inspections check for leftover issues after cleaning.

High-tech systems like Trident ZDO and PSE LH7 are great for post-production cleaning. They offer flexible cleaning cycles and monitor results in real time. In industries like pharmaceuticals, cleaning methods are tested to meet safety standards.

Check cleaning for bioreactors and cell systems.

Test tanks and systems for leftover dirt.

Do safety tests like bioburden and endotoxin checks.

Note: Good post-production cleaning makes PCBs more reliable and lowers the chance of defects.

Picking the right tools is key for making PCBs efficiently. Machines like pick-and-place, reflow ovens, and AOI systems help speed up assembly. They make sure parts are placed correctly and work faster. Good tools lower mistakes and improve how long products last. For example, ENIG finishes cost more but work better than HASL or OSP in tough jobs. This shows why spending on advanced tools is worth it for big projects.

Think about your production size and budget when choosing tools. Pick equipment that fits your needs and can grow with you. As an SMT operator, using quality tools makes work easier and results better. Investing in good tools now helps save time and keeps production reliable later.

FAQ

What is the most important SMT equipment for beginners?

Pick-and-place machines are key for new users. They place parts automatically, making work faster and more accurate. Choose a machine that fits your budget and production needs.

How do you choose the right reflow oven?

Think about how many PCBs you make and their design. Long ovens with many zones are good for big jobs. Short ovens work better for smaller tasks. Look for features like steady heat control and nitrogen use.

Why is solder paste printing accuracy critical?

Good solder paste printing makes strong connections between parts and the PCB. Bad printing can cause problems like bridges or weak joints, which hurt product performance.

How can AOI systems improve production quality?

AOI systems find mistakes early, cutting waste and fixing errors fast. They check soldering, part placement, and coatings carefully, keeping quality steady during production.

Are cleaning systems necessary for SMT equipment?

Yes, cleaning systems keep machines working well and lasting longer. They clean off things like solder paste and flux, stopping damage and helping make high-quality PCBs.

Tip: Clean and maintain your SMT tools often to keep them running smoothly and reliably.