Improving through-hole PCB assembly techniques not only saves time and money but also enhances the overall quality of the process. By implementing effective assembly methods, we can significantly reduce errors and achieve consistent results. For instance:

The error rate decreased from 8.7% to 0.9% with the adoption of better techniques.

This demonstrates how refined processes can elevate product quality.

Additionally, utilizing these through-hole PCB assembly techniques minimizes waste and strengthens the final product. Therefore, every aspect of the assembly process becomes crucial.

Key Takeaways

Begin your PCB assembly with good planning. Make a clear parts list and set goals to avoid errors and save time.

Use a detailed Bill of Materials (BOM) to track all parts. This avoids delays and keeps the assembly process easy.

Use jigs and fixtures to hold parts steady while soldering. This lowers mistakes and makes your assembly better.

Train your team often on how to assemble. Skilled workers make fewer errors and improve product quality.

Test your boards carefully after assembly. Finding problems early saves money and ensures they work well.

Preparation and Planning for Through-Hole PCB Assembly

Good preparation and planning are key to smooth PCB assembly. Starting early, making a clear parts list (BOM), and having proper instructions help avoid mistakes and make work easier.

Early Project Planning for PCB Assembly

Planning early saves time and cuts down on errors. It helps spot problems and fix them before they grow. For example, using machines for assembly can lower mistakes and speed up work. Testing during planning ensures the PCBs work well, saving money later.

To plan well:

Set clear goals and deadlines.

List tools and materials you’ll need.

Test designs early to save money and improve quality.

Check your design for mistakes to avoid costly fixes later.

Spending time on planning helps make PCB assembly cheaper and better.

Creating a Detailed Bill of Materials (BOM)

A good BOM is like a map for your project. It lists all the parts needed so nothing is missed. A clear BOM helps manufacturers know exactly what to do. For example, adding details like capacitor voltage avoids missing parts.

When making your BOM:

Write down all parts with exact details.

Add part numbers, amounts, and descriptions.

Double-check everything to avoid mistakes.

A strong BOM keeps the assembly process smooth and on track.

Ensuring Proper Documentation and Instructions

Clear instructions and documents are important for successful PCB assembly. They help your team and manufacturers work correctly. Without them, mistakes and delays can happen.

To make good documentation:

Write step-by-step assembly instructions.

Use pictures or diagrams to explain better.

Point out important details like where to solder parts.

Good instructions make sure everyone works together for a smooth PCB assembly.

Getting Tools and Materials Ready Before Starting

Getting tools and materials ready before starting is very important. It helps avoid delays, mistakes, and keeps work smooth. This way, your team can focus on building the boards without stopping.

Put tools and equipment in order before you begin. Keep items like soldering irons, tweezers, and cutters close by. Label bins and shelves to find parts quickly. For example, sorting resistors, capacitors, and connectors by size and type saves time.

Set up your workspace to make assembly easier. A clean, bright area helps you see better and avoid errors. Use anti-static mats and wrist straps to protect parts from static electricity. Make sure your table has enough room for tools and PCB panels.

Here are some tips to make assembly faster:

Add fiducials on the PCB for better alignment.

Make sure markers and labels are easy to see.

Leave space between parts to prevent damage.

Group small boards together to save time.

Give accurate BOM and CAD data to help the process.

These tips help you skip extra steps and build better boards. Being organized saves time, lowers mistakes, and makes the product more reliable.

Lastly, check your inventory before starting. Make sure all parts in the BOM are there and correct. Missing or wrong parts can slow down work. A well-prepared setup helps you finish the assembly quickly and confidently.

Design for Assembly (DFA) in Through-Hole PCB Assembly

Making PCB Layouts Simple for Easy Assembly

Keeping PCB layouts simple makes assembly faster and easier. Using fewer parts and a clean design helps avoid mistakes. This method saves time and reduces errors during assembly.

Fewer parts mean fewer steps, so work is quicker.

Correct part placement avoids costly mistakes and rework.

For example, putting similar parts together helps workers or machines place them faster. Avoiding messy wiring also makes the board easier to build. A simple design follows smart rules for better through-hole PCB assembly.

Placing Components for Easy Access

Putting parts in easy-to-reach spots makes assembly smoother. Good placement helps workers solder and check parts without trouble. This lowers mistakes and speeds up the process.

Start by organizing parts logically. Place connectors near edges for quick access. Keep hot parts away from sensitive ones to avoid damage. Line up through-hole parts in rows to make soldering easier. These small changes can greatly improve assembly speed.

Easy-to-reach designs also help with repairs and testing later. This is an important rule for making boards easier to build.

Using Standard Parts to Keep Things Simple

Using standard parts makes PCB assembly simpler. Common parts work across many designs, cutting costs and saving time.

For example, picking resistors and capacitors with common values makes them easy to find. Using the same type of connector on different boards also reduces confusion. Standard parts keep things consistent, which is key for smooth assembly.

By following these tips, you can make boards that are cheaper and easier to build. Standardizing parts is a smart way to save time and improve your workflow.

Reducing Unique Parts in PCB Assembly

Using fewer unique parts makes PCB assembly easier and faster. It also helps avoid mistakes and keeps the process simple.

First, check your design for parts you can standardize. For example, instead of many resistor types, pick a few common ones. This reduces the number of parts you need to buy and manage. Standard parts are also easier to reorder later, saving time.

Fewer unique parts can save money too. Buying standard parts in bulk often costs less. It also avoids delays from finding rare or custom parts. Using common parts makes the assembly process smoother.

Having fewer unique parts also speeds up assembly. Workers or machines can work faster with fewer part types. For instance, using the same connector on different boards makes soldering quicker.

Here are some tips to follow:

Group similar parts together in your design.

Use common sizes and values for parts.

Avoid rare or custom parts unless necessary.

By doing this, you make your boards easier to build and save time. It also helps keep the quality of your PCB assembly consistent.

Tip: Work with your suppliers to find standard parts that are cheap and easy to get. This can make your process even better.

Streamlining the Through-Hole PCB Assembly Process

Making the through-hole PCB assembly process smoother helps save time and avoid mistakes. Using tools like jigs, grouping tasks in batches, and adding automation can make work faster and more reliable.

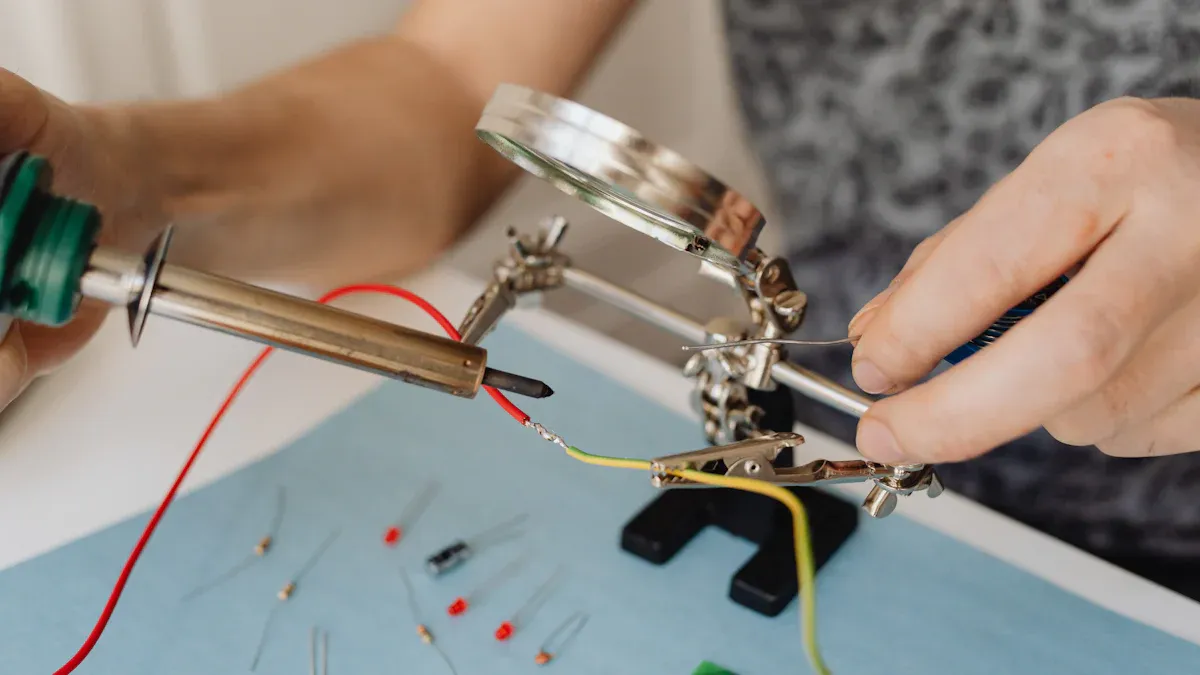

Using Jigs and Fixtures for Consistency

Jigs and fixtures are important for keeping the assembly process steady. They hold parts in place, align them properly, and stop errors. For example, jigs can fix problems like uneven solder or misplaced parts by keeping everything stable during soldering.

Here’s how jigs and fixtures help during soldering:

Problem Solved | How It Helps |

|---|---|

Ensures solder is applied correctly, avoiding weak connections. | |

Solder Bridges | Keeps parts aligned to prevent solder from connecting wrong areas. |

Misaligned Components | Holds parts in the right position during soldering. |

Not Enough Solder | Stabilizes parts to ensure enough solder is used. |

Too Much Solder | Prevents overuse of solder by keeping parts steady. |

Lifted Pads and Tracks | Stops parts from moving, avoiding damage to pads or tracks. |

Solder Splashes | Controls solder flow to reduce messy splashes. |

Using jigs improves assembly quality, reduces waste, and avoids doing extra work. This makes the process faster and cheaper.

Implementing Batch Processing for Efficiency

Batch processing groups similar tasks together to save time and make work easier. For example, assembling many boards with the same design at once lets you repeat steps, cutting setup time and mistakes.

Batch processing also improves results like First Pass Yield (FPY) and lowers defects. Look at these numbers:

Metric | Typical Range |

|---|---|

First Pass Yield (FPY) | |

Defects Per Million (DPMO) | 500 to 1000 |

Customer Return Rate | Less than 1% |

These stats show how batch processing makes assembly better and faster. To use this method, organize tasks so similar boards or parts are handled together. This reduces delays and keeps production smooth.

Leveraging Automation Tools in PCB Assembly

Automation tools make through-hole PCB assembly quicker and more accurate. Machines like automated soldering tools, pick-and-place systems, and inspection devices reduce human effort and improve precision. For instance, an automated soldering machine applies solder evenly, avoiding mistakes from manual work.

Automation also speeds up repetitive tasks like placing parts or soldering. Machines work faster than people and make fewer errors. Inspection tools can quickly find problems, ensuring only good boards move forward.

Start automating simple, repetitive tasks first. As you get used to the tools, expand to other areas. Automation helps you work faster and keeps quality consistent.

Tip: Combine automation with batch processing for the best results. This lets you handle many boards quickly while keeping high standards.

Training Staff on Through-Hole PCB Assembly Techniques

Training helps your team work confidently on through-hole PCB assembly. Skilled workers make fewer mistakes, work faster, and keep quality steady. Teaching new tools and methods also keeps your process up-to-date and competitive.

Why Training is Important

Without training, workers may struggle with soldering or placing parts. Mistakes like weak solder joints or damaged parts can happen. Training teaches your team how to avoid these problems and follow the best steps.

Tip: Hold regular training to teach new skills and updates.

Key Training Areas

Focus on these areas to help your team improve:

Learning PCB Assembly Basics

Teach the basics of through-hole PCB assembly. Show how to place, solder, and check parts. Use pictures or videos to make it simple.Practicing Soldering Skills

Show how to solder correctly. Teach how much solder to use and how to avoid problems like cold joints. Practice helps workers get better and more confident.Using Tools Properly

Train workers to use tools like soldering irons and tweezers. Show them how to care for tools so they last longer and work well.Following Safety Rules

Teach safety steps like handling parts carefully and using anti-static tools. A clean workspace also helps protect parts from damage.

Best Ways to Train

Use these methods to make training fun and useful:

Hands-On Practice

Let workers practice soldering and assembly with guidance. Real tasks help them learn faster.Step-by-Step Demos

Show each step clearly. Break hard tasks into small, easy parts.Mentor Programs

Pair new workers with experienced ones to learn together. This builds teamwork and shares knowledge.Online Learning

Share videos, courses, or guides about through-hole PCB assembly. Workers can learn at their own speed.

Checking Training Success

Check if training works by watching how your team improves. Look for faster work, fewer mistakes, and better products. Feedback helps find areas to improve more.

Note: A trained team makes better products and feels happier at work.

By focusing on training, you build a strong team ready for through-hole PCB assembly. This effort leads to faster work, fewer errors, and great results.

Quality Checks and Testing in Through-Hole PCB Assembly

Making sure your through-hole PCB assembly is good needs strong checks. By looking at parts, watching the process, and testing boards, you can avoid mistakes and get reliable results.

Checking Parts Before Assembly

Checking parts before starting is key to good quality. Broken or bad parts can cause problems later. Look for cracks, bent pins, or strange colors. Make sure each part matches your design needs.

Sort parts by type and size to spot issues fast. For example, putting resistors and capacitors in labeled boxes helps find mistakes quickly. Catching problems early stops bad parts from ruining the final board.

Watching the Process for Mistakes

Watching the process helps find mistakes while building. Check after big steps like soldering or placing parts. This way, you can fix errors before they get worse.

Studies show checking during work makes better boards. It stops bad boards from moving forward, saving time and materials. For instance, checking solder joints right after soldering finds weak spots or bridges. This careful checking makes the whole process smoother.

Testing Boards to Make Sure They Work

Testing boards makes sure they work as planned. Turn on the board and check how it performs. Testing like this avoids problems later and saves money.

Data shows testing is very important. Boards tested this way fail only 0.0003% of the time. Without testing, failure jumps to 0.03%. This proves testing reduces mistakes and ensures good performance.

Use tools like multimeters to check voltage and signals. Test every board to make sure only good ones go to customers. Testing also helps find repeated problems to fix in future designs.

Tip: Write down test results to see patterns and improve designs later.

Setting Up Feedback Loops for Better Assembly

Feedback loops help improve through-hole PCB assembly. They make the process better and raise quality. By listening to your team and checking results, you can find problems and fix them. This keeps your methods improving over time.

Start by asking workers for feedback. Let them share problems they see, like soldering mistakes or parts not lining up. Use their input to find where things slow down or go wrong. For example, if soldering errors happen a lot, you might need better tools or techniques.

Next, study data from testing and quality checks. Look for repeated issues. If some parts fail often, check how they are placed or where they come from. This helps solve the main problem, not just the surface issue.

Hold regular team meetings to talk about feedback. Share ideas and solutions during these meetings. For instance, if a new tool makes soldering easier, tell the team and use it on other projects too.

Keep a record of feedback and fixes. Write down problems, what you did to solve them, and the results. This log helps with future projects and stops old mistakes from happening again.

Using feedback loops makes your process better over time. It improves product quality and helps your team work faster and feel more confident.

Good through-hole PCB assembly needs planning, smart designs, and strict checks. These steps help improve important measures like First Pass Yield (FPY) and Cycle Time. Look at the table below:

KPI | What It Means |

|---|---|

First Pass Yield (FPY) | Percent of boards passing checks the first time, no fixes. |

Cycle Time | Time it takes to finish one board from start to end. |

Defect Rate | Number of mistakes found per board, showing quality level. |

Using IPC rules and good parts makes boards work better and last longer. These methods lower mistakes and make production faster. Try these tips now for better results!

FAQ

What is the main advantage of through-hole PCB assembly?

Through-hole assembly creates stronger bonds for parts. This makes it great for products facing stress or tough conditions. It’s trusted for durability in critical uses like aerospace or industrial machines.

How can you reduce errors during through-hole PCB assembly?

Set up your workspace and tools before starting. Use jigs to align parts and batch tasks for faster work. Teach your team proper soldering skills. Check for mistakes during assembly to fix them early.

Tip: Always review your Bill of Materials (BOM) to avoid missing parts.

Why is Design for Assembly (DFA) important in through-hole PCB assembly?

DFA makes assembly easier by improving layouts and using standard parts. It lowers errors, speeds up work, and saves resources. This ensures better quality and faster production.

What tools are essential for through-hole PCB assembly?

You’ll need soldering irons, tweezers, and cutters. Anti-static mats protect parts from damage. Automated tools like soldering machines help with speed and accuracy. Organizing tools ahead of time keeps work smooth.

How do you ensure quality in through-hole PCB assembly?

Check parts before starting and inspect during assembly. Test finished boards to make sure they work well. Use feedback to find and fix repeated problems, improving quality over time.

Note: Keep records of test results to improve future designs.

See Also

Essential Strategies to Enhance PCB Assembly Productivity

10 Professional Insights for Cost-Effective PCBA Assembly

Best Practices for Achieving Quality and Efficiency in PCBA