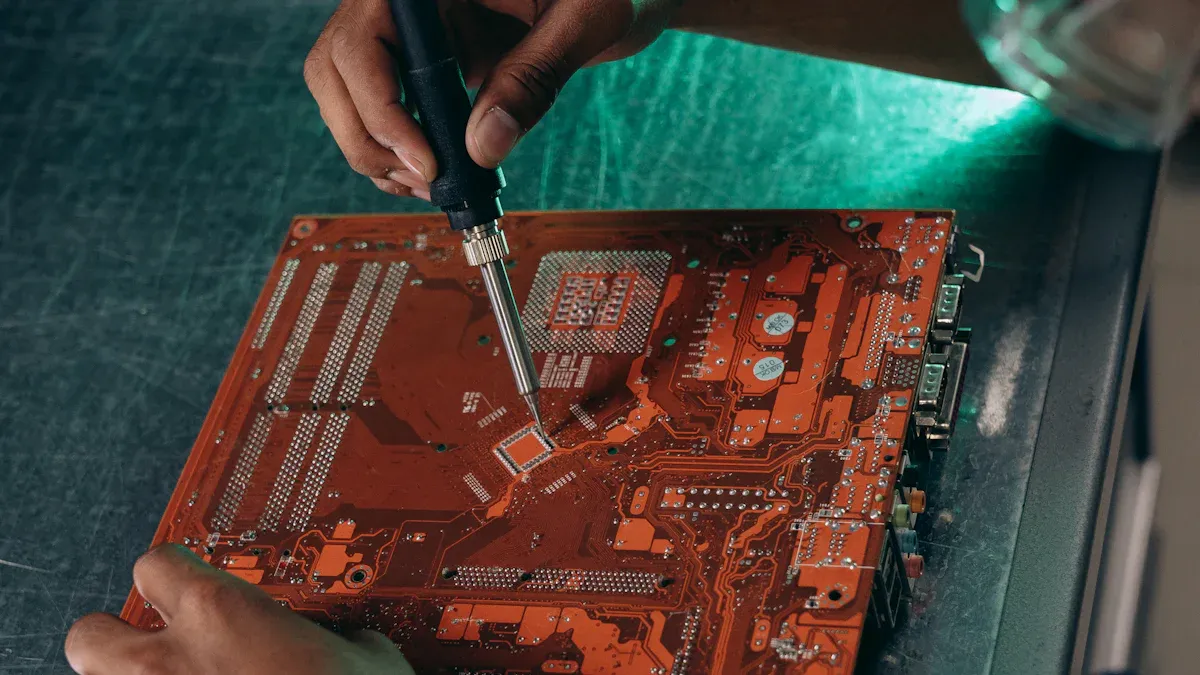

Reliability and efficiency are key in through-hole PCB assembly techniques. These traits help circuits work well in tough conditions. Military and aerospace fields use through-hole parts for their strength. They handle strong vibrations and big temperature changes. These assemblies follow strict rules, making them vital for important tasks. New methods like automated machines and wave soldering add accuracy to through-hole PCB assembly techniques. They also make the process faster and easier. Using these tools gets your designs ready for 2025 standards. This ensures they work great and stay up-to-date.

Key Takeaways

Through-hole PCB assembly creates strong links, perfect for harsh places like military and space use.

Good soldering habits and frequent checks make PCBs work better and last longer.

Following Design for Assembly (DFA) rules makes building faster and cheaper.

Using machines in assembly speeds up work and reduces errors, making better products.

Learning new tech and green methods helps build smart and eco-friendly PCBs.

Basics of Through-Hole PCB Assembly

Benefits of Through-Hole PCB Assembly

Through-hole PCB assembly has many good points. One big benefit is its strong connections. Parts are soldered through the board, making them great for tough jobs. They work well in places like military and space industries. These parts stay strong even with heavy shaking or big temperature changes.

Another plus is that through-hole parts last longer. Research shows they handle 2.8 times more heat cycles than unfilled vias. This makes them a good pick for products that need to last a long time. Capped vias also lower short-circuit risks by 14%. They allow for 6.2% more circuit density, which improves your design’s performance.

Fixing through-hole parts is easier too. You can check and replace parts quickly. This saves time during repairs. It’s a top choice for projects where fixing things is important.

Problems in Through-Hole Assembly

Even with its benefits, through-hole assembly has some issues. It takes extra steps like drilling holes and adding leads. This makes the process slower than other methods. Drilling holes in all layers also limits design choices, especially for multi-layer boards.

Cost is another problem. Through-hole assembly uses more materials, so it costs more than surface-mount technology. For big production runs, this can lower profits. To solve these problems, you need to plan the process carefully. This helps balance strength and speed.

Comparing Through-Hole and Surface-Mount Technologies

Through-hole and surface-mount technologies (SMT) each have their own strengths. Through-hole parts make stronger connections, perfect for reliable products. SMT is better for smaller designs, cutting costs and fitting more circuits.

Feature | Through-Hole Technology (THT) | Surface-Mount Technology (SMT) |

|---|---|---|

Mechanical Strength | Stronger connections, good for tough conditions | Weaker bonds, stays on the surface |

Reliability | Very reliable, used in military and space fields | Less reliable in extreme situations |

Size and Compactness | Bigger parts, less compact | Smaller parts, fits more circuits |

Repairability | Easier to fix and replace parts | Harder to fix layouts |

Cost | Some parts cost less | Cheaper to make and assemble |

Through-hole is best for strength and repairs. SMT is great for saving space and money. Pick the one that fits your project’s needs.

Techniques to Enhance Reliability in Through-Hole PCB Assembly

Soldering Best Practices for Reliability

Soldering is very important in through-hole PCB assembly. To make it reliable, follow steps that improve solder joint quality. Always keep tools, materials, and surfaces clean. Dirt can cause problems and make soldering less effective.

Follow the heating and cooling rules from the manufacturer. This stops thermal shock, which can harm delicate parts. When soldering wires, keep strands together and solder the tinned area well. This makes the connection stronger and less likely to fail.

Check your work carefully. Use tools like automated optical inspection (AOI) or X-ray inspection (AXI). These tools find mistakes early and ensure solder joints are good. Before adding coatings, inspect for defects and fix or replace bad parts.

Use advanced tests to improve reliability:

Continuity tests find open or short circuits in boards.

Hi-pot tests check isolation on high-voltage PCBs.

In-circuit testing measures shorts, opens, and voltage/current levels.

ROSE tests detect leftover flux residues.

Time domain reflectometry (TDR) checks trace impedance for better performance.

By following these steps, you can make soldering better and improve through-hole PCB reliability.

Thermal Management Strategies

Good thermal management keeps through-hole PCB assemblies working well. Too much heat can weaken solder joints and hurt your design. Use methods to remove heat effectively.

Pick materials that spread heat well, like copper. Add thermal vias to move heat from hot parts to cooler areas. This protects sensitive parts and spreads heat evenly.

Place components wisely. Keep hot parts away from those sensitive to heat. This setup avoids damage and keeps performance steady.

Use heat sinks and thermal pads to manage heat. Heat sinks pull heat away, and thermal pads improve contact with the heat sink. These tools help protect your assembly from overheating.

Drilling and board design also affect heat management. Bad drilling can cause plating to spread into glass fibers, which hurts heat flow. Fix drilling processes to avoid this and improve heat control.

Ensuring IPC Compliance in Through-Hole Assembly

Following IPC standards is key to making reliable through-hole PCB assemblies. These rules guide soldering, heat management, and overall assembly quality.

Choose good materials that meet industry rules. Avoid materials that can get dirty, as they can cause problems. For example, lead-indium solder with contamination caused big defects. Picking clean materials prevents issues and meets standards.

Inspect and test often. Look for problems like conductive anodic filamentation (CAF). CAF creates faults in PCBs and lowers reliability. Fixing these problems helps future designs work better.

Drilling and board design must also follow IPC rules. Bad drilling can harm solder joints. Improve these processes to meet standards and boost assembly quality.

By following IPC rules, you can make better through-hole PCB assemblies. This ensures your designs meet industry needs and work reliably.

Optimization Strategies for Efficiency in Through-Hole PCB Assembly

Design for Assembly (DFA) Principles

Design for Assembly (DFA) makes building easier and faster. It focuses on simple designs that save time and money. By removing extra steps, parts fit together smoothly during assembly.

Good PCB layouts help avoid mistakes while making products. For example, lining up parts evenly and using fewer pieces makes assembly quicker. This also makes products stronger and more reliable. Companies using DFA often see big improvements, as shown below:

Evidence Type | Description |

|---|---|

Cost Reduction | Companies using DFA cut manufacturing costs by 25% on average. |

Time Savings | DFA reduces production time and lowers error risks. |

Quality Improvement | Efficient designs build better products, making customers happier. |

Using DFA helps speed up assembly, improve quality, and make reliable products.

Component Placement Optimization

Placing parts in the right spots makes assembly easier. It helps with soldering, fixing, and replacing parts. Checking part positions before starting saves time and avoids problems.

Good placement also controls heat better. Keeping hot parts away from sensitive ones stops damage. Spacing parts well makes soldering stronger and more reliable. Lining up special parts neatly helps machines work faster.

Smart PCB designs prevent signal problems and reduce interference. Fixing these issues early makes production faster and extends product life.

Automation in Through-Hole Assembly Processes

Automation makes through-hole assembly faster and more accurate. Machines do repeated tasks perfectly, cutting mistakes and saving time. For example, one company cut production time by 30% using automation.

Monitoring systems check work in real-time. They catch problems early and reduce delays. Lean practices, like those used by another company, improve processes and increase output.

Wave soldering is an automated method that makes soldering easier. It creates strong solder joints quickly across many boards. Adding automation to your process boosts speed and reliability.

Tip: Start small with tools like pick-and-place machines or inspection systems. Add more automation as you find ways to improve.

Quality Control Measures for Through-Hole PCB Assembly

Inspection Techniques for Reliability

Inspection is key to making reliable through-hole PCB assemblies. Different methods help find problems early and improve quality:

Flying Probe Test: Great for small batches, it skips custom fixtures. It directly checks component pins for issues.

Automated Optical Inspection (AOI): Cameras spot errors like bad soldering or misaligned parts. It gives instant feedback to improve the process.

Burn-In Testing: This test pushes the PCB hard to find weak spots. It’s useful for tough jobs but needs care to avoid damage.

X-Ray Inspection (AXI): Finds hidden problems in solder joints and traces. It takes time and skill but ensures thorough checks.

Functional Testing: Confirms the PCB powers on and works correctly. It’s affordable and fits many PCB types.

Using these methods together helps catch problems early. This ensures your assembly meets top-quality standards.

Documentation and Traceability Practices

Good records and tracking keep through-hole PCB assembly consistent. Detailed logs of materials, steps, and checks help trace problems back to their source.

Label each PCB with serial numbers or barcodes. This makes it easy to track parts and steps. Store this data in one system for quick access during checks or repairs.

Recording inspection results shows patterns and helps improve designs. For example, tracking solder issues can guide better assembly methods.

Traceability also ensures you follow industry rules. It helps you make reliable products that customers trust.

Testing Protocols for Defect Mitigation

Testing is crucial to reduce defects and boost reliability. Advanced methods can check your PCB assembly:

In-Circuit Testing (ICT): Tests electrical performance for shorts, opens, and wrong values. It ensures the assembly matches the design.

Functional Testing: Mimics real-world use to check if the PCB works well. This includes power tests and signal checks.

Statistical Process Control (SPC): Tracks production data to find and fix problems early.

Root Cause Analysis (RCA): Studies failures to stop them from happening again.

Studies show these methods work well. Predictive models find defects with over 82% accuracy. Data trends prove these tools are effective across different setups.

By using these tests, you can make reliable assemblies and keep high-quality standards.

Future Trends in Through-Hole PCB Assembly

Emerging Technologies and Materials

New tools and materials are changing through-hole PCB assembly. These updates make the process faster and eco-friendly.

Rules like RoHS replaced lead solder with safer alloys. This needs better soldering skills for precise work.

Recycling is growing due to EU waste recovery rules. Companies now reuse 85% of leftover non-metal parts.

Energy-saving laws, like California’s Title 24, promote convection soldering. These systems cut energy use by 30–40%.

Selective wave soldering is gaining popularity. It speeds up production and gets 95% success on the first try.

These changes help make strong PCBs while saving money and protecting the planet.

AI and Machine Learning Applications

AI and machine learning are improving through-hole PCB assembly. They make the process smarter and more reliable.

AI spots problems early, so you can fix them fast. This keeps quality high and reduces mistakes.

Machine learning helps design better paths for circuits. It saves time and lowers costs by avoiding crowded routes.

AI checks layouts to meet performance needs. This ensures your PCBs are high-quality and work well.

Using AI tools makes assembly easier and designs more dependable.

Sustainability in Through-Hole PCB Manufacturing

Making PCBs is focusing more on being eco-friendly. You can track and improve your impact with these measures:

What It Measures | |

|---|---|

Substrate Selection | Checks how materials affect the environment. |

Integrated Circuit Recycling | Looks at how recycling chips helps the planet. |

Energy Consumption | Tracks energy used in cleaning and other steps. |

Water Consumption | Measures water use, considering local needs. |

Environmental Impact Categories | Includes effects like global warming and acid rain. |

By using these ideas, you can cut waste and save resources. Green practices help the Earth and make your work more efficient.

Making through-hole PCB assembly reliable and efficient needs good methods. Using soldering tips, heat control, and following IPC rules helps reliability. Better designs, smart part placement, and using machines make the process faster and easier.

Keeping up with new ideas ensures your designs meet modern needs. New tools, AI, and eco-friendly ways are changing PCB assembly. Using these ideas helps you stay ahead and ready for the future.

To improve your process, follow these steps:

Look at PCBs closely and test for broken connections early.

Use a stencil to place solder paste neatly and correctly.

Arrange parts to keep signals clear and manage heat well.

Get tools ready to make assembly smooth and problem-free.

By using these tips, you can build strong, efficient, and future-proof PCB assemblies.

FAQ

What makes through-hole PCB assembly more reliable than other methods?

Through-hole PCB assembly connects parts by soldering them through the board. This method makes it strong for tough conditions like shaking and heat changes. It’s perfect for important uses in fields like space and defense.

How can you streamline the assembly process for through-hole PCBs?

You can make the process faster by using machines like pick-and-place tools. These machines reduce mistakes and save time during production. They also help large factories work better and faster.

How does component placement affect signal integrity?

Placing parts correctly stops interference and keeps signals clear. Keeping heat-sensitive parts away from hot ones helps too. This is important for making reliable and high-performing PCBs.

Why is automation important in through-hole assembly?

Automation reduces mistakes, speeds up work, and keeps quality steady. Tools like wave soldering and monitoring systems improve assembly and save time. They are key for modern PCB production.

What testing methods ensure high-reliability PCBA?

Tests like in-circuit and functional testing check if circuits work well. These tests find problems early to make designs reliable. X-ray tests also find hidden issues in solder joints and wires.

See Also

Essential Strategies for Improving PCB Assembly Productivity

Innovative Testing Methods for Enhanced PCBA Production

Ways to Improve Quality Assurance in PCBA Operations