Selecting a good PCB maker in 2025 is very important for your project’s success, especially when considering the top pc board manufacturers. The right maker can greatly affect how well your product works and how reliable it is. When looking at possible partners, think about these important things:

Certifications and Standards

Advanced Manufacturing Skills

Quality Control

Customization and Flexibility

Lead Times and Scalability

Cost-Effectiveness

Customer Support

These points will help you make a smart choice. Now, let’s look at the best pc board manufacturers in the USA that can help you.

Key Takeaways

Picking the right PCB maker is very important for your project. Check their skills and certifications to make sure they are good.

Keep up with the latest trends in PCB making, like smaller sizes and AI use, to help you decide better.

Choose makers with strong quality checks. Look for certifications like ISO 9001 and IPC standards to ensure they are reliable.

Check their production abilities closely. Make sure they can handle your order size and have fast delivery options.

Good customer service is very important. Pick a maker that has different ways to contact them and responds quickly to problems.

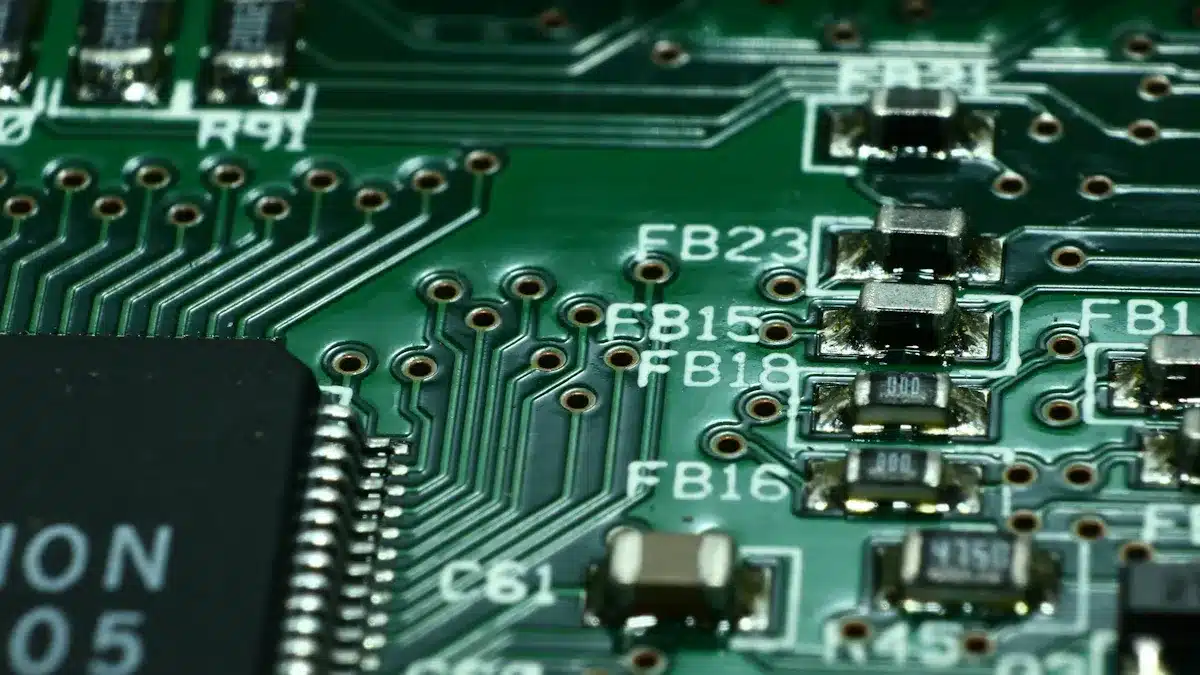

Overview of PCB Manufacturing

Current Trends

The PCB manufacturing industry is changing quickly. In 2023, the U.S. had a 71.4% share of the North American PCB manufacturing equipment market. This growth comes from many areas like defense, aerospace, cars, and electronics. Here are some important trends for 2025:

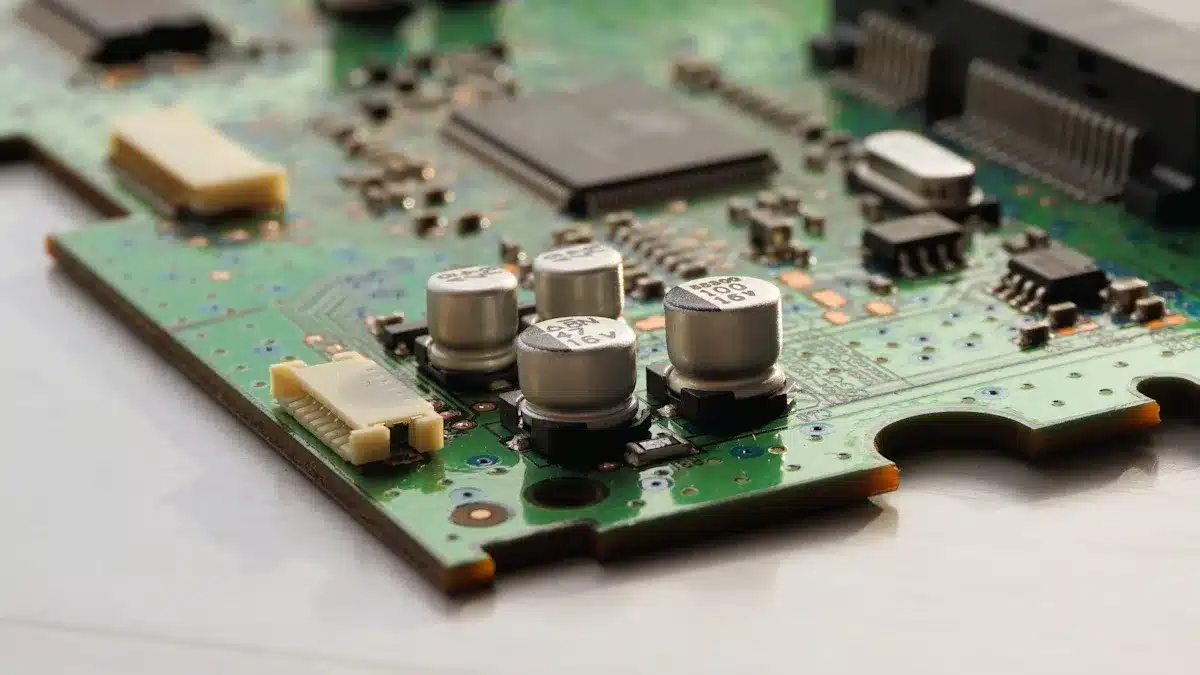

Miniaturization and High-Density Interconnects (HDI): More functions will fit into smaller spaces. This is important for modern portable devices.

Flexible and Stretchable PCBs: These designs help electronics change shapes. This is key for wearables and medical sensors.

Advanced Materials for High-Frequency Applications: Materials like PTFE help support 5G networks and high-frequency uses.

Embedded Component Technology: This trend puts parts inside the PCB layers. It improves performance and makes things smaller.

3D-Printed Electronics (3DPE): This new method allows direct printing of circuits. It promises quick prototyping and customization.

AI and Machine Learning in PCB Design and Manufacturing: These tools help make designs better and improve how things are made.

Quality and Reliability

Quality and reliability matter a lot when picking pc board manufacturers. High-quality PCBs make sure your products work well and last longer. You should check industry standards that show PCB quality, like IPC-TM-650 and MIL-STD-202. These standards look at thermal cycling, mechanical shock, and other reliability factors.

Also, automation and smart manufacturing have changed PCB production a lot. Automation makes things more efficient by allowing real-time monitoring and data analysis. It cuts labor costs and improves product quality by finding defects faster. For example, using Failure Mode and Effects Analysis (FMEA) has lowered the lot reject rate from 5500 parts per million (PPM) to 900 PPM.

By focusing on quality and reliability, you can make sure your custom circuit boards meet high standards. This leads to better performance and happier customers.

Top PCB Manufacturers in the USA

If you need reliable partners for your PCB needs, check out these top manufacturers in the USA for 2025:

TTM Technologies

TTM Technologies is a leader in PCB manufacturing. They work in many areas like aerospace and healthcare. TTM is the biggest printed circuit board supplier in North America. They are great in high-speed and high-reliability markets. Their services include:

Service/Capability | Description |

|---|---|

Prototype and Quick-Turn Services | They are experts in quick-turn services and new product introduction, making it fast to ramp up. |

Medium to High Volume Manufacturing | They can meet different needs with their global PCB fabrication facilities. |

Advanced Technology Solutions | They provide technologies like HDI, rigid-flex, RF components, and substrate-like PCBs. |

Thermal Management Solutions | They offer heavy copper and thermal vias for good thermal management in high-density uses. |

RF/Microwave Expertise | They create custom solutions for mm-Wave applications, tested for different end markets. |

In 2025, TTM Technologies has about 16,400 employees, showing their big role in the industry.

Sanmina

Sanmina is known for its full electronics design and manufacturing services. They are good at making complex PCBs for many sectors. Sanmina follows high standards and certifications, such as:

Certification/Standard | Industry/Application |

|---|---|

TL 9000 | Telecommunications |

ISO 13485 | Medical |

AS 9100 | Aerospace |

IATF 16949 | Automotive |

ESD 20.20 | Electrostatic Discharge |

ISO 14001 | Environmental |

MIL-PRF-31032 | Military Performance Specs |

Jabil Inc.

Jabil Inc. is one of the largest electronic manufacturing companies. They serve many sectors like automotive, healthcare, and telecommunications. Their PCB assembly services are made to fit customer needs. Jabil’s skills ensure high-quality PCBs that meet strict industry standards.

Industry | Description |

|---|---|

Automotive | Solutions for automotive electronics |

Healthcare | Services for medical devices and systems |

Telecommunications | Support for communication technologies |

FLEX LTD.

FLEX LTD. focuses on product design and manufacturing. They help many industries with advanced technologies. Their focus on innovation helps them provide high-tech PCB assembly solutions that meet market needs.

Plexus

Plexus gives complete manufacturing solutions for PCBs. They serve many industries, making sure clients get high-quality products. Their focus on quality and customer service makes them stand out in the market.

VictoryPCB

VictoryPCB offers different types of printed circuit boards, including:

Product Type | Description |

|---|---|

14-Layer High-Density HDI Immersion Gold PCB | Great for high-performance electronic devices needing durability and precision. |

2-Layer Rogers RO4003 PCB for Communication | Provides excellent performance in wireless networks and data transmission. |

6-Layer Black High-Density Holes PCB | Helps with detailed electronic designs with a density of 300,000 holes/m². |

2-Layer Yellow PCB Board | Offers reliable and affordable solutions for many uses. |

Epec Engineered Technologies

Epec has over 70 years of experience in PCB manufacturing. They provide special engineering solutions, such as:

Power integrity solutions for reliable power distribution.

Reverse engineering services to copy or change existing PCBs.

Advanced thermal management solutions to stop overheating.

Design for manufacturability (DFM) to improve PCB designs.

Their skilled team solves complex design problems, ensuring high-quality materials and great service.

Advanced Circuits

Advanced Circuits can make multilayer PCBs with up to 40 layers. They offer many advanced PCB manufacturing options for different materials and needs. Their focus on quality means you get reliable custom circuit boards.

Sierra Circuits

Sierra Circuits provides quick turnaround times for prototype PCB orders. Their services include:

Service Type | Turnaround Time |

|---|---|

Quick Turn PCB Assembly | 1-day, 2-day, 5 or 10 days |

Turnkey PCBs | As fast as 5 days |

Standard PCBs | 24-hour turn-times available |

RUSH PCB Inc.

RUSH PCB Inc. works with many industries, including:

Industry |

|---|

Semiconductors |

Military and Defense |

Aerospace |

Medical Devices |

Commercial Enterprises |

Drone Technology |

Autonomous Vehicles |

Consumer Electronics |

Telecommunication |

Automotive |

Industrial Applications |

OSH Park

OSH Park has good prices for PCB prototyping services. Their pricing includes:

Board Type | Price per Square Inch | Minimum Order Requirement |

|---|---|---|

2-layer boards | $5.00 | Multiple of 3 |

4-layer boards | $10.00 | Multiple of 3 |

Medium Run 2-layer | $1.00 | 100 square inches |

Medium Run 4-layer | $2.00 | 100 square inches |

These manufacturers are at the top of PCB technology in the USA. They provide many services and skills to meet your needs.

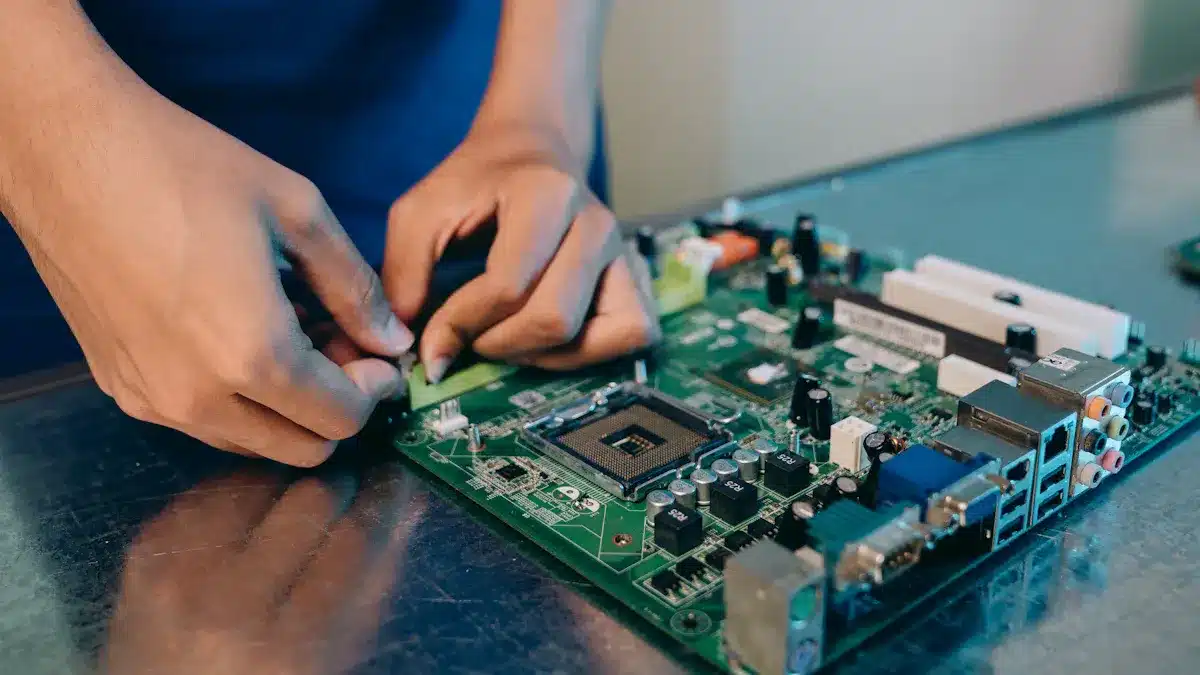

Choosing a PCB Manufacturer

Picking the right PCB manufacturer is very important. You need to think about several things carefully. Make sure your partner can meet your project’s needs. Here are some key points to focus on:

Quality Assurance

Quality assurance is very important in PCB manufacturing. You should choose manufacturers that have high-quality standards. Look for certifications that show they follow industry rules. Here are some important certifications to check:

Certification | Importance | Benefits |

|---|---|---|

High | Ensures quality, consistency, and reliability | |

IPC Standards | High | Guarantees following industry standards |

Nadcap | High | Involves strict audits and meeting tough standards |

These certifications help make sure the manufacturer keeps high-quality production. They also improve performance and reliability in your final product. For high-reliability uses, think about these factors:

Quality Certifications: Check for IPC, ISO, and other industry certifications to ensure quality.

Technical Capabilities: Look at the manufacturer’s ability to handle complex designs, like layer count and special boards.

Delivery Reliability: Make sure on-time delivery rates are over 95% and ask about past performance.

Communication & Collaboration: Good communication and dedicated account management help reduce mistakes.

Cost vs. Value: Think about the overall value, not just the upfront cost, and consider long-term effects.

Production Capabilities

Production capabilities are very important in your decision. You need to know if the manufacturer can meet your volume and complexity needs. The usual lead time for high-volume PCB orders in the USA is about 20 working days. But quick-turn options can cut this time to as little as 1 day, depending on the details. Factors that affect lead time include design complexity, material availability, and production methods.

When looking at production capabilities, consider these points:

Flexibility: Can the manufacturer change to meet your project needs?

Technology: Do they use advanced manufacturing methods for precision and efficiency?

Capacity: Can they handle your order size without losing quality?

Customer Support

Good customer support is key for a successful partnership. You want a manufacturer that gives real-time feedback and technical help. Here are some important parts of customer support to think about:

Multiple Communication Channels: Look for manufacturers that offer phone, email, or live chat for quick help.

Early Engagement: Getting customer support involved early can stop costly mistakes.

Responsiveness: Make sure the manufacturer responds quickly to questions and problems.

Common reasons for customer dissatisfaction often come from manufacturing defects, burnt components, and soldering problems. By choosing a manufacturer with strong customer support, you can reduce these risks and have a smoother production process.

In short, picking a good PCB manufacturer is very important for your project’s success in 2025. The PCB manufacturing world is changing with new ways to make things and better materials. Good manufacturers focus on automation, quality checks, and being eco-friendly.

Think about these main points when choosing a partner:

Picking the right manufacturing partner is key for project success.

This guide shows the strengths and skills of top PCB manufacturers.

Knowing these factors helps you make smart choices.

Take time to look into these manufacturers based on what your project needs. This will help you find the best match for your needs. 🌟

FAQ

What is a PCB?

A PCB, or printed circuit board, is a board that connects electronic parts. It gives electrical paths and support for devices like smartphones, computers, and appliances.

How do I choose the right PCB manufacturer?

To pick the right PCB maker, think about their quality checks, production skills, and customer help. Look at their certifications and past work to make sure they fit your project needs.

What are the common types of PCBs?

Common types of PCBs are single-sided, double-sided, and multilayer boards. Each type is used for different tasks based on how complex and functional they are.

What is the typical lead time for PCB production?

The usual lead time for making PCBs is 20 working days for large orders. For quick-turn services, it can be as fast as 1 day, depending on how complex and what materials are used.

Why is quality assurance important in PCB manufacturing?

Quality assurance makes sure that PCBs meet industry rules and work well. It helps stop defects, lowers costs, and improves customer happiness by providing high-quality products.

See Also

Choosing The Right PCB Prototype Manufacturer For Your Needs

Finding The Ideal PCBA Manufacturer For Your Business Goals

Identifying The Perfect PCBA Manufacturer For Business Growth

Selecting PCBA Manufacturing Services With Superior Features

Essential Advice For Picking A Trustworthy PCBA Manufacturer