Choosing the right main PCBA is very important for success. A good PCBA improves performance, works reliably, and keeps costs low. For instance, using CEM materials can cut costs by 20–30%. Automated production also lowers labor costs by 40%. Quality checks have reduced rework from 8% to 1.2%. This saves over $18,000 for every 1,000 units made. Watching key factors like cost, quality, and speed helps meet your goals. It can also make delivery times faster by about 20%. Smart decisions lead to better results and long-term success.

Key Takeaways

Picking the right main PCBA improves performance and saves money. Good choices can help you save a lot.

Know what your PCBA will do. Understanding its job helps you pick the best materials and design for your needs.

Quality checks are very important. Choose manufacturers with good certifications and testing to make sure your PCBA is high quality.

Testing is key. Try out your designs before making many to find problems early and make them better.

Work closely with your manufacturer. Their knowledge can improve your design and make production easier.

Understanding the Role of the Main PCBA

What Is a Main PCBA?

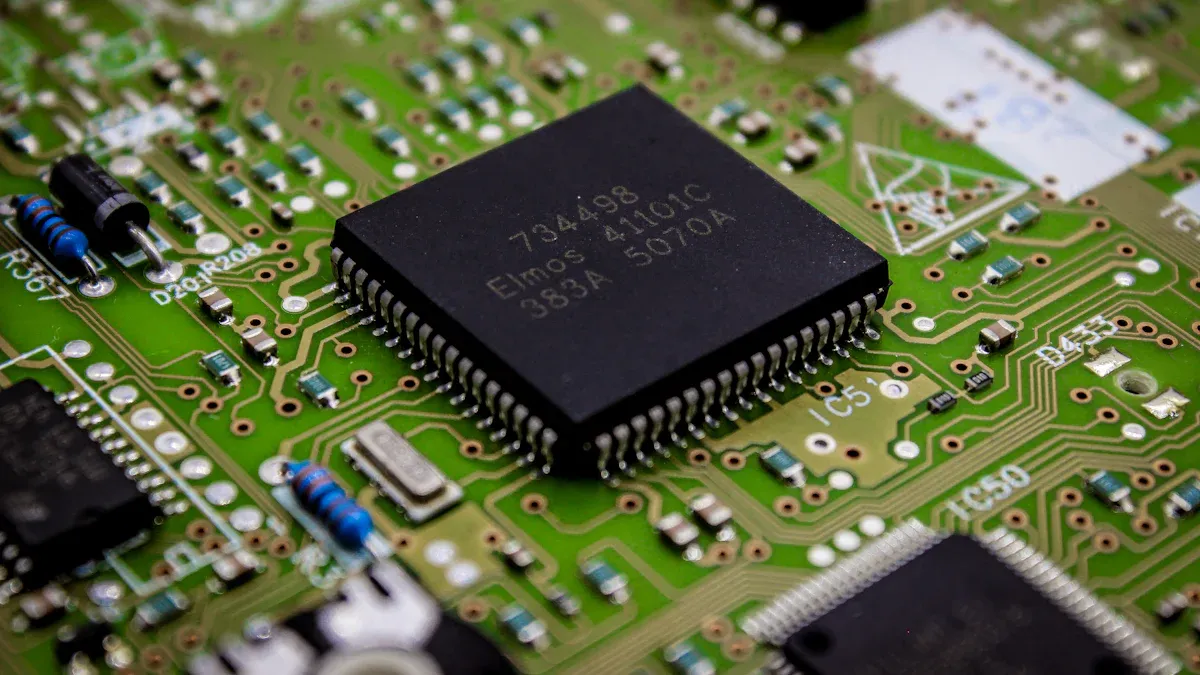

A main PCBA, or Printed Circuit Board Assembly, is key to electronics. It includes a circuit board with parts like resistors and microchips. These parts work together to make the device function. The board has copper tracks and pads on a non-conductive base. This setup connects and supports the parts. Without a well-made PCBA, devices won’t work properly.

Importance of the Main PCBA in Your Application

The main PCBA is vital for your electronic product’s success. Its quality affects how well and how long your device works. For example, tests like MIL-STD-810G check if the PCBA handles heat and stress. Stress testing finds weak spots to ensure only strong PCBAs are used. These tests stop failures and keep customers happy.

Evidence Type | Description |

|---|---|

Physics of Failure Analysis | Focuses on reliability and why PCBAs fail. |

Thermal and Thermomechanical Tests | Tests heat resistance using MIL-STD-810G standards. |

Accelerated Stress Testing | Finds weak design areas and reasons for failure. |

Empirical Models | Uses past data to predict failure rates in new designs. |

How the Main PCBA Impacts Performance and Reliability

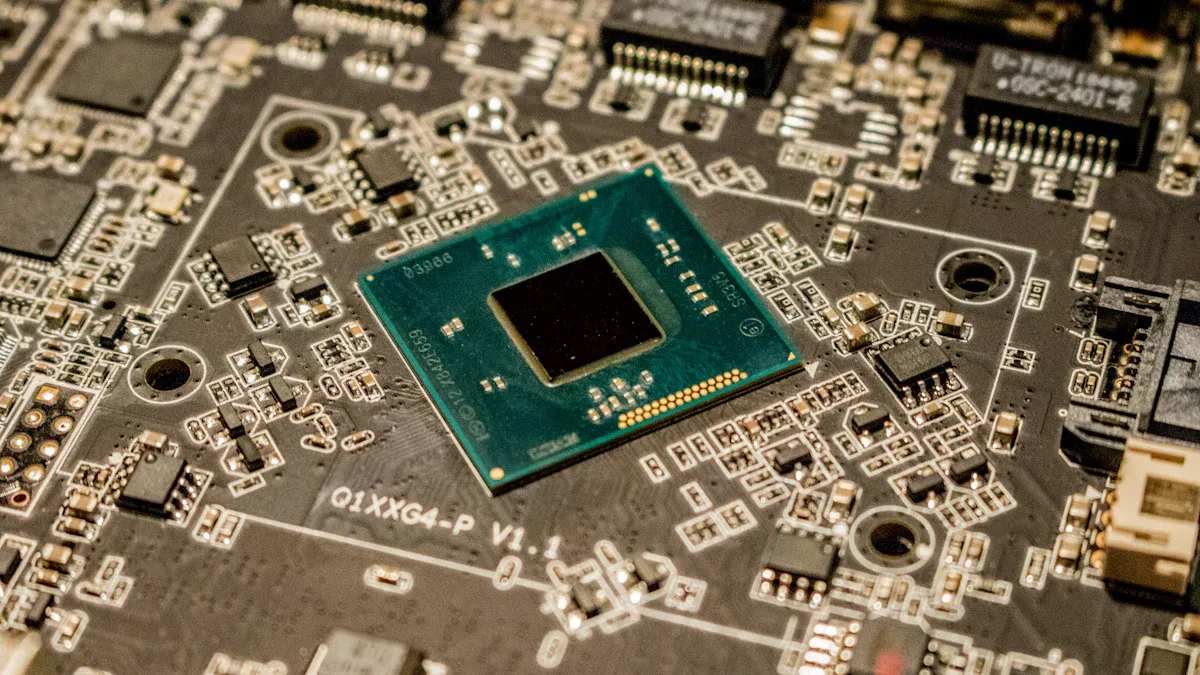

The quality of the main PCBA affects how well your device works. Inspections like automated optical checks find cracks or flaws in solder joints. These checks ensure the PCBA is ready to use. Pre-production tests confirm the design and materials. In-process checks catch problems early. Functional tests make sure the PCBA works as planned. Post-production checks confirm the final product is solid.

Pre-Production Testing: Checks design and materials before making the PCBA.

In-Process Inspection: Finds assembly issues during production.

Functional Testing: Confirms the PCBA works correctly.

Post-Production Analysis: Ensures solder joints are strong and reliable.

Reliability tests, like Monte Carlo simulations, improve the PCBA’s performance. These tests mimic real-world use to find and fix problems. By doing these steps, you can make sure your PCBA is dependable and works well.

Figuring Out What You Need for a Circuit Board

Decide Why You Need the PCBA

First, think about why you need the circuit board. Its purpose decides how it works and looks. For example, a smartwatch needs a small, powerful board. But car parts need boards that handle heat and shaking. Knowing the purpose helps pick the right materials and design.

List What the PCBA Must Do

After deciding the purpose, write down what it must do. This includes speed, power use, and strength. For example, a company made a better smartwatch by fixing heat issues. This made it work faster and meet all goals. A car control board was improved to handle stress and heat. This made it strong enough for tough conditions.

Industry | Problem | Fix | Outcome |

|---|---|---|---|

Consumer Electronics | Used better layout, placed parts well, and fixed heat issues. | Made a strong, fast smartwatch that cost less. | |

Automotive | Needed a board for a car part to handle tough conditions. | Improved heat control and checked for stress problems. | Created a strong board that worked well in cars. |

This table shows how knowing what you need makes better boards.

Think About Rules and the Environment

Rules and the environment are important when picking a board. Make sure it follows rules like RoHS or IPC standards. Also, think about where it will be used. Will it face heat, wetness, or shaking? For example, car boards need good heat control for hot engines. Solving these problems keeps the board safe and working well.

Determine Budget and Cost Constraints

Planning your budget is key to picking the right printed circuit board. You should check costs early to avoid overspending. This also helps your design stay within your financial limits. Follow these simple steps to manage your budget well:

Define Project Scope and Complexity

List what your PCB needs to do, its size, and performance. Knowing this helps you guess costs better and avoid extra spending.Identify Key Design Factors

Look at things like part count, board size, and design difficulty. These directly affect how much your PCB will cost.Estimate Design Time

Figure out how many hours the design will take. More time means higher costs, so plan wisely.Consider Software Licensing and Tools

Don’t forget the cost of design software. Tools like Altium’s ActiveBOM show prices and stock, helping you decide smartly.Factor in Designer Expertise

Skilled designers may cost more but can prevent expensive mistakes. Balance their cost with their experience.Research and Compare Pricing Models

Check different pricing options and get quotes. Comparing prices helps you find the best deal for your budget.Add Contingency Costs

Set aside 10–20% extra for unexpected problems. This safety net keeps your project on track.Total All Estimated Costs

Add up all the costs to see your total budget. This shows you how much you can spend.

Tip: Use tools like BOM managers to track early costs and part prices. Keeping an eye on price trends helps you plan better and avoid surprises.

By using these steps, you can make a smart budget for your PCB project. Good planning keeps costs under control and helps you meet your design goals.

Key Factors When Choosing a PCB Manufacturer

Quality Assurance and Reliability Standards

When picking a PCB manufacturer, focus on quality and reliability. A good manufacturer ensures every printed circuit board meets strict safety rules. For example, the UL 796 standard requires using strong materials that resist fire and have good electrical properties. This standard also demands precise spacing and trace width to avoid short circuits and keep signals clear.

Reliable manufacturers check materials, watch production, and test finished boards. These steps help ensure high quality and fewer defects. Below are key quality control processes:

Quality Control Process | Description |

|---|---|

Quality Reports & Certifications | Show proof of product quality with detailed documents. |

Manufacturing Standards | Follow IPC Class 2, IPC Class 3, and auto industry rules. |

PCB Assembly Standards | Use IPC-A-610E standards for assembly work. |

CNC Machining Standards | Keep tolerances within +/-0.2 mm (+/-0.01″) as per ISO 2768. |

Tip: Choose manufacturers with UL certification. This ensures safety and reduces risks like fires or electric shocks.

By focusing on quality, you can trust your PCB will work well in its application.

Certifications and Compliance with Industry Standards

Certifications and following industry rules are very important when choosing a PCB maker. These certifications prove the manufacturer can make high-quality PCBs that meet specific needs. For instance, ISO 13485 ensures quality for medical devices, and FDA registration shows they follow U.S. laws.

Here’s a table of key certifications and their importance:

Certification/Standard | Description | Significance |

|---|---|---|

ISO 13485 | Quality system for medical devices. | Ensures safe and effective medical device production. |

FDA Registration | Needed for selling in the U.S. | Proves compliance with FDA rules and allows tracking products. |

IPC Standards | Rules for making and checking PCBs. | Ensures reliable and consistent PCB production. |

UL Compliance | Confirms safety for critical devices. | Often required for product approval. |

IEC Standards | Global safety rules for medical equipment. | Ensures safety and performance of medical PCBs. |

Note: Manufacturers with these certifications show they care about quality and rules. This ensures your PCB meets all requirements.

By checking certifications, you can pick a manufacturer that fits your project’s needs.

Manufacturing Capabilities and Technology

A manufacturer’s skills and tools are key to making great PCBs. Advanced tools help with accuracy, speed, and efficiency. For example, companies like MacroFab offer fast PCB prototypes and advanced bonding methods, speeding up production without losing quality.

Here are important things to check about manufacturing capabilities:

Scalability: Make sure the manufacturer can handle both small and big orders. This helps if your project grows.

Prototyping: Find manufacturers that offer quick prototypes to test your design before full production.

Advanced Techniques: Look for techniques like gold wire bonding or reflow soldering for stronger PCBs.

Equipment: Modern machines ensure precise work, meeting tight design needs.

Tip: Work with manufacturers that offer design help. They can improve your PCB design, saving time and money.

By choosing a manufacturer with advanced tools and strong skills, you can ensure your PCB is high-quality and reliable.

Cost, Lead Times, and Scalability

When picking a pcb maker, think about cost, speed, and growth. These factors affect your project’s success and future potential. Planning well helps you balance price, efficiency, and expansion.

Cost Considerations

Cost isn’t just about the price you pay. It also includes how efficient production is, custom features, and long-term expenses. Better processes can lower labor costs and save time, but they might need more money upfront. For example, using automated machines reduces mistakes and saves money later. However, special designs may cost more because they need skilled workers.

Where the manufacturer is located matters too. Companies in areas with cheaper labor may charge less, but shipping costs could cancel out savings. Always consider the total cost, including repairs and delays, to understand long-term expenses.

Factor | Description |

|---|---|

Production Efficiency | Faster processes cut labor costs but may need upfront spending. |

Expertise and Specialization | Unique designs may cost more due to skilled labor needs. |

Manufacturing Location | Costs vary by location, but shipping can add extra expenses. |

Lifecycle Costs | Think about repairs and downtime for a full cost picture. |

Lead Times and Quick Turnaround

Lead times show how fast your product gets made. Shorter times often cost more but help you sell sooner. A manufacturer with quick delivery can keep you ahead of others. Check if they meet deadlines without lowering quality. Good pcb makers balance speed and accuracy.

Scalability for Future Growth

Scalability means the manufacturer can grow with your needs. It might cost more at first, but it saves money later. For example, a company with advanced tools can adjust to your changing demands. This flexibility avoids switching manufacturers, which can cause delays.

Tip: Pick a manufacturer that offers both small test runs and large orders. This helps your project at every stage.

Material Sourcing and Supply Chain Transparency

Getting good materials and having a clear supply chain are key for making reliable pcbs. A clear supply chain lets you track materials, avoid delays, and follow environmental rules.

Importance of Material Sourcing

The materials in your pcb affect how well it works and lasts. Strong materials like FR4 or polyimide handle stress better. But it’s also important to get these materials from trusted suppliers. Manufacturers with good supplier connections ensure steady quality and avoid running out of materials.

Supply Chain Transparency

A clear supply chain builds trust and lowers risks. A good manufacturer will share where their materials come from and show certifications. This ensures they follow rules like RoHS and avoid fake parts.

Factor | Description |

|---|---|

Quality and Reliability | Cheaper materials may fail, costing more in the long run. |

Environmental Compliance | Following rules can save money on waste and energy. |

Material Traceability | Knowing material sources avoids fake parts and meets standards. |

Benefits of Transparent Practices

Clear supply chains improve teamwork and solve problems early. You can fix issues like delays or shortages before they get worse. This keeps your project on time and within budget.

Note: Ask your manufacturer about their material sources and certifications. A trustworthy partner will share this information.

By focusing on good materials and clear supply chains, you make sure your pcb is high-quality and works well.

Questions to Ask When Choosing a PCB Manufacturer

How Experienced Are They in Your Industry?

When picking a PCB manufacturer, check their experience in your field. Manufacturers with industry knowledge understand your specific needs and challenges. For example, car makers need PCBs that handle heat and shaking. Medical devices require reliable PCBs that meet strict rules.

You can judge their experience by reviewing their testing and production methods. For instance, Calumet Electronics tested over 1,000 panels for strength and heat resistance. This shows they focus on quality and meeting industry needs.

Company | Location | Specialization | Key Strengths |

|---|---|---|---|

Company A | USA | Military and Aerospace | Strong materials, strict quality checks |

Company B | USA | Quick-turn PCBs, Prototyping | Fast delivery, design help |

Company C | Canada | Medical Devices, Automotive | ISO 13485 certified, material tracking |

Choosing a manufacturer with the right experience ensures your project benefits from their skills and proven methods.

Do They Communicate Clearly and Offer Good Support?

Clear communication and good support are key when working with a PCB maker. You need updates on progress and quick answers to your questions. Reliable manufacturers often provide 24/7 support to fix issues fast.

Find manufacturers who share clear timelines, costs, and challenges. Reviews and case studies can show how well they work with clients. Some manufacturers are known for solving problems quickly and giving helpful design feedback. This ensures your project stays on track.

Check how fast they reply to questions.

Ask if they offer warranties or rework services.

Learn about their return policies for faulty products.

Tip: A manufacturer with clear communication and strong support helps avoid delays and costly mistakes.

Can They Share References or Case Studies?

References and case studies help you judge a PCB manufacturer’s skills and reliability. These examples show how they solve problems and meet client needs. Look for details about how they handled challenges and delivered quality work.

For example, a case study might explain how they improved a PCB design to lower costs and boost performance. Client references can also reveal their professionalism and ability to meet deadlines. Don’t hesitate to ask for these materials when deciding.

Look for projects similar to yours.

Ask for client reviews that show successful results.

Confirm they can handle tough tasks and tight schedules.

By reviewing references and case studies, you can feel confident in choosing a PCB manufacturer that fits your project needs.

What Testing and Quality Assurance Processes Do They Use?

Testing and quality assurance (QA) make sure your PCB works well. A good manufacturer uses smart tests to find and fix problems early. These steps save money, time, and improve product quality.

Here are common testing and QA methods top manufacturers use:

Functional Testing: They test PCBs in normal and tough conditions. This checks if the board works in different environments.

Test Fixtures: Special tools copy how the PCB will be used. This helps find any issues before production.

Comprehensive Assembly Testing: Instead of testing parts alone, they test the whole PCB. This ensures the board works as one unit and saves resources.

Automated Testing Systems: For example, a system tested car gauge controllers using LabVIEW. It had flexible tools to adjust for future changes.

Tip: Ask your manufacturer about their testing steps. A good one will explain their methods and share reports to prove quality.

Choosing a manufacturer with strong QA processes ensures your PCB is reliable and meets high standards.

Are They Flexible with Customization and Prototyping?

Being flexible with custom designs and prototypes is very important. Your project might need special changes, and a good manufacturer can handle these without losing quality.

Top manufacturers offer many custom options for different needs. Here are some key features they provide:

Feature | Details |

|---|---|

Line Widths and Spacing | 0.035 mm for small and detailed designs. |

Customization Options | Special solutions for unique applications. |

Layer Options | Multiple layers for various industries. |

High-Density Interconnect (HDI) | Skilled in complex designs. |

Prototyping is also very important. Good manufacturers make quick prototypes to test your design before full production. This helps find and fix problems early, saving time and money. For example, advanced tools can create HDI prototypes or custom layouts to fit your needs.

Note: Pick manufacturers that offer both standard and custom prototypes. This ensures they can meet your project’s specific needs while keeping quality high.

Working with a flexible manufacturer lets you customize and test your PCB fully. This ensures your final product works well and meets all your goals.

Tips for Choosing the Best Main PCBA

Test Prototypes Before Full Production

Testing prototypes is very important before making many PCBAs. It helps find problems early and ensures the PCBA works well. New technology, like Industry 4.0, makes testing better with real-time checks. These systems can spot small or big issues during tests. Alerts are sent right away if something is wrong. This lets workers fix problems quickly, improving quality and avoiding costly mistakes.

Prototyping also lets you compare new designs with old test results. This shows patterns of failures and keeps quality steady. By testing prototypes, you can improve your design, check parts work together, and avoid delays in production.

Work Closely with Your Manufacturer

Working with your manufacturer during design and production helps a lot. Skilled manufacturers can give tips to make your design better. For example, a company making wearable devices used prototypes to test and improve their designs. This teamwork helped them launch their product faster and with confidence.

Another company making automation systems worked with a manufacturer to upgrade their designs. Through testing and prototyping, they fixed problems and improved their systems. This teamwork made sure their new systems worked well. By partnering with your manufacturer, you can use their tools and knowledge to make better PCBAs.

Plan for Future Support and Maintenance

Pick a manufacturer who offers long-term help and repairs. Good manufacturers provide testing, fixing, and updates to keep your PCBA working well. This is very important for industries like cars or medical devices, where safety and durability matter a lot.

Choose a manufacturer with clear communication and a history of making good PCBAs. Look for one that can grow with your needs. Planning for future support protects your investment and ensures your PCBA stays reliable for a long time.

Get Feedback from Stakeholders and Users

Getting feedback from stakeholders and users is very important. It helps make sure your PCB works well and meets needs. Their ideas can show problems and improve the design before production.

Involve stakeholders early in the process. Share designs and prototypes with them to hear their thoughts. Ask clear questions about the design, assembly, and performance. For example, check if the PCB fits the product or if assembly is easy. Their answers help you make changes.

Users give helpful feedback on how the product works in real life. Let them test the prototype and watch how they use it. Take notes if they face problems like overheating or hard installation. Fix these issues in the next design round.

Tip: Use surveys or interviews to collect detailed feedback. This helps you cover all important parts of the PCB design.

After collecting feedback, look for common problems. Focus on fixing the most mentioned issues first. Work with your manufacturer to make these changes. Their skills in prototyping and assembly can help match updates with production needs.

By using feedback wisely, you can create a PCB that works well for everyone. This step improves quality and builds trust in your design.

Picking the right main PCBA begins with knowing your needs. Check important things like quality, cost, and if the manufacturer is trustworthy. These steps help your project work well and stay on budget. Testing prototypes and working with your manufacturer can improve the design and production process. Planning for future support keeps your PCBA reliable and protects your money.

Remember: Smart choices bring better results. Use these tips to pick the best PCBA and succeed with confidence.

FAQ

What’s the difference between a PCB and a PCBA?

A PCB is just the empty board. A PCBA has all the parts attached. The PCBA is ready to use in devices.

How can I tell if a manufacturer is trustworthy?

Look for certifications like ISO or IPC standards. Read customer reviews and case studies. Ask about their testing and where they get materials. Good manufacturers are clear and focus on quality.

Can one PCBA work for different uses?

Not always. Each use needs specific features like size or strength. Pick or design a PCBA that fits your project’s needs for the best results.

Why is prototyping important before making many PCBAs?

Prototyping lets you test your PCBA’s design and function. It finds problems early, saving time and money. You can improve the design to make sure it works well.

How can I lower the cost of my PCBA project?

Simplify your design to use fewer parts. Pick affordable materials that still work well. Choose manufacturers with fair prices and efficient processes. Plan your budget and save extra for surprises.

See Also

Essential Advice for Selecting a PCBA Contract Manufacturer

Guidelines for Finding the Ideal PCBA Manufacturer for You

Steps to Identify the Right PCBA Factory for You