Turnkey industrial IoT device assembly makes building devices easier. It manages everything, from designing to setting up the devices. Turnkey solutions remove the need to work with many vendors. This method helps make products faster and use resources better. It also ensures dependable results every time. Using turnkey methods lets you focus on new ideas instead of problems. In industries needing accuracy and speed, turnkey solutions are very helpful.

Key Takeaways

Turnkey industrial IoT assembly makes things easier by using one provider for design to setup.

These solutions make production faster and cheaper by skipping extra vendors.

Careful testing and support make sure IoT devices work well and follow rules.

Turnkey manufacturing lets businesses focus on new ideas by doing hard tasks, helping products launch quicker.

Picking the right turnkey provider is important; find one with skill, full services, and good communication.

Understanding Turnkey Industrial IoT Device Assembly

Definition and Key Features

Turnkey industrial IoT device assembly is a simple process. One provider handles everything to create IoT devices. This includes design, making, testing, and setting up the devices. You don’t need to work with many vendors or manage different steps. Turnkey manufacturing makes things easier, faster, and more reliable.

Some key features are full service, quicker production, and great quality. It also smoothly combines IoT parts like sensors, processors, and communication tools into systems. With turnkey solutions, you can focus on new ideas while experts handle the hard parts.

Tip: Turnkey manufacturing works well for industries needing accuracy, like automation and IoT systems.

Components of Turnkey Manufacturing

Turnkey manufacturing has important steps that create a complete solution:

Design and Engineering: Experts plan IoT devices to meet your needs.

Prototyping: A sample is made to check how it works.

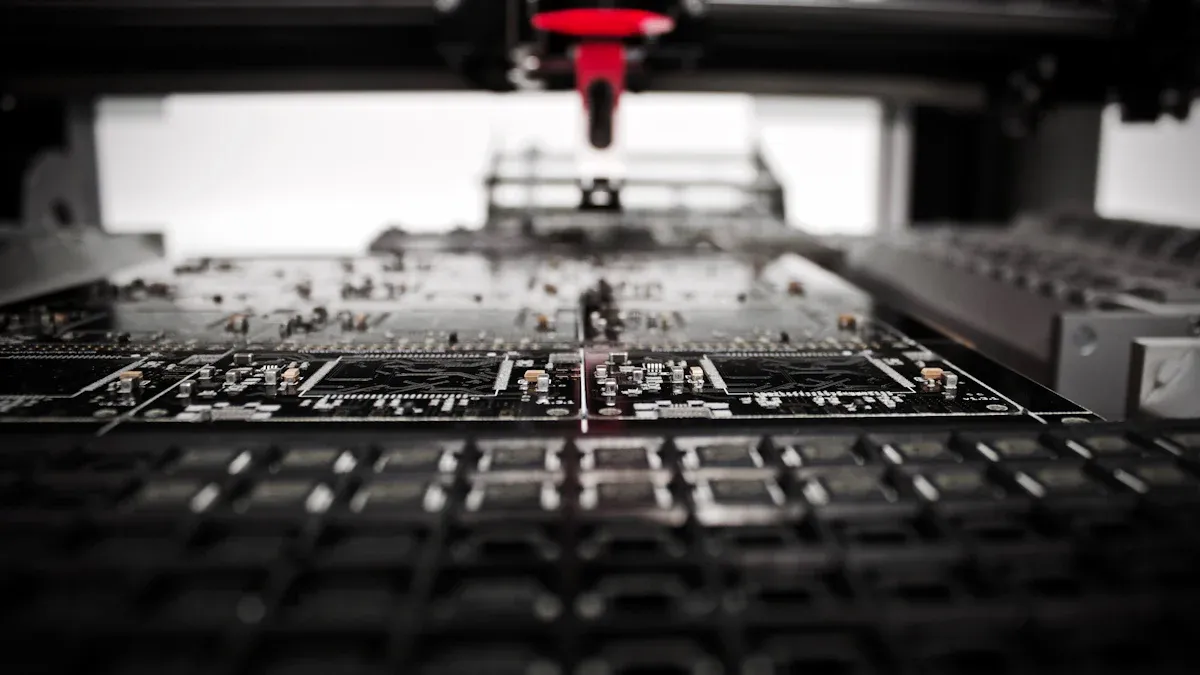

IoT PCB Assembly: Circuit boards, the device’s base, are put together.

Manufacturing: Devices are made in large amounts with steady quality.

Testing and Quality Assurance: Devices are tested to ensure they work well.

Deployment and Support: Finished devices are set up and supported as needed.

These steps make turnkey manufacturing a full solution for IoT devices. It handles all stages, so you don’t need to manage many suppliers or tasks.

Differences from Traditional IoT Production

Turnkey manufacturing is very different from traditional IoT production. In traditional methods, you work with separate vendors for each step. This can cause delays, mistakes, and uneven quality.

With turnkey manufacturing, one provider does everything. This makes the process simpler and ensures all parts fit together well. It also speeds up production, so your devices are ready faster. Turnkey solutions often include advanced steps like IoT PCB assembly, which improves device performance.

Note: Turnkey projects are great for industrial IoT, where precision matters.

By using turnkey manufacturing, you avoid problems with traditional methods. It helps you get better results for your IoT projects.

The Process of Turnkey Manufacturing

Design and Prototyping

Turnkey manufacturing starts with designing and making a prototype. Experts help create a plan for your IoT device. They make sure the design fits your needs and works well. After designing, a sample device is built to test how it works. This step finds problems early, saving time and effort later.

Prototyping also helps improve the device’s features to match your goals. Fixing issues now lowers risks and makes the final product better. This step prepares for smooth manufacturing and assembly.

Manufacturing and Integration

Making and combining parts are key steps in turnkey manufacturing. Devices are made in large amounts while keeping good quality. Integration ensures all parts, like sensors and processors, work together perfectly.

Studies show how these steps meet production goals:

Phase | What Happens |

|---|---|

Analysis | Decide what to measure and set clear goals for tasks. |

Measurement | Record how long each task takes, including extra time needed. |

Synthesis | Study the data to find ways to improve and set goals. |

These goals help make the process faster and more accurate. By combining making and integration, you get high-quality IoT devices quickly.

Testing and Quality Assurance

Testing and checking quality are important to ensure devices work well. This step uses strict tests to check how the device performs and stays secure.

Quality checks include these tests:

Test Type | What It Does |

|---|---|

Usability testing | Checks if the device is easy to use and has needed features. |

Load testing | Tests how well it works under heavy use and data sharing. |

Compatibility testing | Makes sure it works with different devices and systems. |

Scalability testing | Tests if it can handle more users or data over time. |

Data consistency check | Ensures data stays correct during and after setup. |

Security testing | Checks if user data is safe and private. |

Connectivity testing | Makes sure it stays connected even if the network has issues. |

These tests make sure devices meet standards and work well in real life. By focusing on quality, you create reliable IoT devices.

Deployment and Support

The last step in turnkey manufacturing is deployment and support. This ensures your IoT devices are ready to use and work well over time.

During deployment, experts set up and install your devices. They make sure all parts fit with your current systems. This reduces delays and keeps your work running smoothly. Experts configure the devices properly so they perform their best from the start.

Support services are important to keep your devices working efficiently. Providers help fix problems, update software, and monitor systems. These services solve issues early, preventing bigger problems later. Updates also protect your devices and keep them up-to-date with new technology.

One big benefit of turnkey manufacturing is how smoothly it moves from making to deployment. With one provider handling everything, you avoid managing many vendors. This saves time and lowers the chance of mistakes during setup.

Tip: Pick a provider that offers full support services. This keeps your devices working well for a long time.

By focusing on deployment and support, turnkey manufacturing gives a complete solution. You can trust your devices are well-made and cared for by experts.

Benefits of Turnkey Industrial IoT Device Assembly

Improved Efficiency and Faster Time to Market

Turnkey industrial IoT device assembly makes production faster and simpler. Using one provider means you don’t need to manage many vendors. This avoids delays and gets your IoT systems ready quickly. The turnkey model removes complicated steps, letting you focus on creating new ideas.

Experts handle design and prototyping faster with turnkey methods. They manage everything, from IoT PCB assembly to deployment. This speeds up production, helping industries like automation launch products quickly to stay ahead.

Tip: Working with a turnkey provider helps avoid delays in production.

Cost Savings and Resource Optimization

Turnkey solutions save money by combining all production steps in one place. This lowers extra costs and avoids mistakes common in contract manufacturing. Fewer errors mean less rework, saving time and money.

Turnkey providers use smart methods like turnkey PCB assembly to make quality products at lower costs. This reduces waste and uses resources better. For example, combining IoT PCB assembly into the process removes the need for extra vendors, saving both time and money.

Note: Picking a skilled turnkey provider gives you the best value for your money.

Enhanced Product Quality and Reliability

Turnkey manufacturing focuses on making high-quality products. Strict testing ensures IoT devices meet top standards. Reliable products are important for industrial IoT systems.

Studies show turnkey methods improve reliability and lower repair costs. IoT can cut repair costs by 12% and maintenance costs by 30%. This leads to 70% fewer equipment breakdowns, improving performance.

Evidence Description | Impact |

|---|---|

IoT can cut repair costs by 12% and lower maintenance costs by 30% | Leads to 70% fewer equipment breakdowns, improving reliability |

Companies like LG Electronics show how IoT boosts quality control. LG used IoT edge computing to raise fault detection rates from 50% to 99.9%, saving $20 million yearly.

LG Electronics used IoT edge computing to improve fault detection from 50% to 99.9%, saving $20 million each year.

Turnkey manufacturing helps create reliable, high-quality products for industrial IoT and automation needs.

Simplified Supply Chain Management

Handling a supply chain can be tricky with many vendors. Turnkey manufacturing makes it easier by letting one provider do everything. This removes the need to work with different suppliers. It cuts down on delays and avoids miscommunication. The process becomes smooth, from design to final setup.

A big advantage of turnkey manufacturing is combining steps like IoT PCB assembly into production. This means no need to hire outside help, which can cost more and lower quality. By keeping everything in one place, you save money and have better control.

Turnkey solutions also lower risks that come with using many vendors. Working with several suppliers can cause uneven quality and missed deadlines. A turnkey provider keeps high standards at every step. This makes products more reliable and gets them ready faster, helping you stay ahead.

Another benefit is easier inventory management. Turnkey providers often handle buying, storing, and delivering materials. This saves you time and money. Instead of worrying about IoT PCB assembly logistics, you can focus on growing your business.

Tip: Choose a turnkey provider offering complete solutions for better efficiency.

By making supply chain management simpler, turnkey manufacturing offers many benefits. You save time, spend less, and get high-quality products. This method uses resources wisely and helps your business succeed in the long run.

Challenges and Considerations

Vendor Dependence and Risk Management

Using one turnkey provider makes things easier but has risks. You rely on them to deliver on time and meet quality. If they fail, your production could stop or slow down. To avoid this, plan well and talk often with your provider.

Getting raw materials is another challenge. Turnkey providers depend on many suppliers for parts. If one supplier has issues, your project might face delays. Managing supplier relationships is key to keeping things running smoothly.

Risk/Dependency Type | Description |

|---|---|

Full responsibility for production means meeting high standards. | |

Dependence on Suppliers in Sourcing Raw Materials | Needs good supplier management and a steady supply chain. |

To lower these risks, check your provider’s history and problem-solving skills. Building trust with your provider can help reduce surprises.

Balancing Customization with Standardization

IoT systems need a mix of customization and standardization. Customization lets you make devices fit your needs but costs more. Standardization is cheaper and simpler but less flexible.

Your choice depends on your goals. For example, automation industries may prefer standard designs for easy system compatibility. Unique industries might need more custom features for better performance.

Work with your provider to decide what needs customizing and what can stay standard. This helps you save money while meeting your needs.

Scalability and Future-Proofing

Scalability and future-proofing are important for IoT systems. As your business grows, devices must handle more work and new tech. Turnkey providers help make sure your devices can grow and stay useful.

For example, flexible carrier options and partnerships with mobile networks support global use. Providers like Zipit offer data plans and eSIMs to cut costs and simplify management. These tools let you expand without changing hardware.

Evidence | Explanation |

|---|---|

Carrier profiles need strong network partnerships and billing systems. | Flexible carriers help businesses grow and adapt to new markets. |

Zipit works with top mobile networks for global connections. | Strong partnerships ensure reliable and scalable IoT systems. |

Zipit offers custom data plans for different needs. | Tailored plans help businesses run efficiently and grow easily. |

Devices that support new cellular tech stay compatible as networks change. | This future-proofs devices, keeping them useful longer. |

eSIMs lower costs and allow remote updates for scalability. | eSIMs make managing devices easier and support market expansion. |

eSIMs adjust to new networks without hardware changes. | This extends device life and reduces upgrade needs. |

Future-proofing also means staying ready for new tech. Devices that work with updated networks and allow remote updates last longer. Picking a provider focused on scalability and future-proofing helps your IoT systems succeed over time.

Choosing the Right Turnkey Provider

Checking Expertise in Industrial IoT

When picking a turnkey provider, check their IoT knowledge. A good provider knows how to handle IoT challenges. These include combining sensors, processors, and communication tools. They should also know advanced steps like IoT PCB assembly. This ensures your devices work well and last long. Look for providers with experience in industries like automation and manufacturing.

You can learn about their skills by reading case studies or reviews. These show how they’ve helped other businesses solve problems. Also, see if they use the latest IoT technology. Providers who focus on new ideas often deliver better solutions for your needs.

Important Things to Consider

Choosing the right provider means looking at key factors. First, check if they manage all steps, from design to setup. Providers offering full services make the process easier and safer. This ensures steady quality throughout the project.

Next, review their performance using trusted measures. For example:

ISS ESG EVA Leaders Index tracks companies with strong results.

ISS ESG Governance QualityScore checks board structure and governance.

ISS ESG US Diversity Index looks at leadership diversity.

ISS ESG US Cyber Risk Index finds companies with low cyber risks.

These tools help you find providers with good practices and ethics. Lastly, check their IoT PCB assembly experience. This is key for making reliable IoT devices.

Why Transparency and Communication Matter

Clear communication is important for a good partnership. A reliable provider keeps you updated on every step. They share progress on design, making, and setup. This keeps you involved and avoids problems.

Being open builds trust. Providers who are honest about costs, timelines, and challenges are dependable. This matters in manufacturing, where hidden costs or delays can cause trouble. Regular updates and clear talks keep your project on track.

By focusing on these points, you can pick a provider who delivers great IoT solutions and works well with you.

Turnkey industrial IoT device assembly brings many benefits to businesses. It makes production easier, lowers costs, and creates better products. By simplifying steps, it helps launch products faster and stay ahead. Turnkey methods also encourage new ideas, letting you build smarter devices.

The future of turnkey manufacturing is bright. By 2025, IoT connections may reach 30 billion, changing industries everywhere. IoT spending could go over $1 trillion by 2023, showing its growing importance. As technology improves, turnkey solutions will help create efficient and expandable IoT systems.

FAQ

What is turnkey industrial IoT device assembly?

Turnkey industrial IoT device assembly means one company does everything. They handle design, making, testing, and setup. This makes production easier and ensures great quality.

How does turnkey manufacturing save time?

Turnkey manufacturing removes the need for many vendors. One company manages all steps, cutting delays and speeding up work. This makes production and delivery faster.

Can turnkey solutions handle custom IoT designs?

Yes, turnkey companies can make IoT devices fit your needs. They mix custom features with standard ones to save money and ensure everything works well.

Are turnkey solutions cost-effective?

Turnkey solutions save money by doing all steps in one place. This lowers mistakes, avoids extra work, and uses resources wisely, making it a smart choice.

How do I choose the right turnkey provider?

Pick a company with IoT experience and a good history. Make sure they handle all steps, from design to setup, and meet your quality needs. Clear communication is also important.

See Also

Essential Strategies to Enhance PCB Assembly Productivity

The Role of PCBA in Advancing Today’s Electronics

Ten Professional Insights for Cost-Effective PCBA Production