Turnkey PCB assembly solutions provide everything needed for electronics manufacturing. They combine all steps, from design to delivery, into one process. This makes things easier and lowers costs by using automation and reducing shipping fees. It also boosts efficiency by organizing supply chains and improving teamwork. Turnkey services let you focus on new ideas while speeding up production and ensuring better quality. These advantages make turnkey PCB assembly important in today’s competitive manufacturing world.

Key Takeaways

Turnkey PCB assembly makes electronics easier by combining all steps. This saves time and lowers costs.

A turnkey provider improves product quality with expert checks and testing. This ensures high standards are kept.

Businesses can focus on new ideas while the provider handles design, parts, and assembly. This makes the process faster and simpler.

Turnkey solutions can adjust to small or big companies. They work well for startups and large businesses with different needs.

Picking a good turnkey manufacturer improves teamwork and support. This helps projects run smoothly and finish on time.

Understanding Turnkey PCB Assembly Solutions

What Is Turnkey PCB Assembly?

Turnkey PCB assembly is a complete solution for making PCBs. It covers everything, from design to delivery, in one service. This means you don’t need to manage many vendors or handle tricky logistics. It’s a simpler and cheaper way to manufacture electronics.

Tip: Turnkey PCB assembly works well for both small and large projects.

This method gives you expert help at every step. It includes better designs, supply chain planning, and strict quality checks. These steps reduce mistakes and speed up production, so your products are ready faster.

Differences Between Turnkey and Partial PCB Services

Choosing between turnkey and partial services depends on your needs. Turnkey services handle everything, while partial services leave some tasks to you. Here’s a quick look:

Aspect | Turnkey Services | Partial Services |

|---|---|---|

Cost | Cheaper but needs more effort | |

Time | Longer because of testing | Faster if done in-house |

Output Quality | Better with professional checks | Depends on your skills |

Turnkey services combine all steps into one package. This makes the process easier and ensures good quality. Partial services might save money but need more work and knowledge from you.

Note: If you don’t have the tools or skills for PCB assembly, turnkey services can save time and avoid errors.

Why Turnkey PCB Assembly Is Essential for Electronics Manufacturing

Turnkey PCB assembly is very important in today’s electronics industry. It makes things faster, cheaper, and better. Here’s why it matters:

Cost Reduction: You save money by letting experts handle everything. They buy parts in bulk to cut costs.

Faster Time-to-Market: Turnkey services avoid delays and help you meet deadlines.

Improved Quality Control: One team checks everything to meet high standards like IPC-610.

Simplified Supply Chain Management: You only deal with one company, avoiding confusion.

Flexibility and Scalability: Turnkey services adjust to your needs, whether small or big projects.

Did You Know? Many industries, like IoT and medical devices, use turnkey PCB assembly for its reliability.

By choosing turnkey services, you get a simple and reliable way to make PCBs. This improves efficiency and ensures top-quality products.

Benefits of Turnkey PCB Assembly Solutions

Cost Savings and Efficiency

Turnkey PCB assembly helps save money and work faster. It combines all production steps in one place. Instead of managing many vendors, you work with just one. This cuts hidden costs like extra shipping and admin fees. You also avoid redoing design files or changing testing methods when switching vendors.

Here’s how turnkey services save money and improve operations:

Benefit | Description |

|---|---|

One manufacturer lowers hidden costs from using multiple vendors. | |

Faster Turnaround | Quick quotes and feedback speed up production. |

Reduced Delays | No need to redo designs or adjust testing between vendors. |

Smoother Operations | Clear communication makes the process easier and more organized. |

Better Product Quality | One vendor ensures quality stays the same throughout production. |

Turnkey PCB assembly simplifies the process so you can focus on creating new ideas. It keeps things running smoothly and saves money, making it great for electronics manufacturing.

Tip: Choosing a trusted turnkey provider can cut problems and save money.

Faster Time-to-Market

In electronics, getting products out fast is very important. Turnkey PCB assembly speeds this up by combining design, testing, and production. Early testing checks if designs work, avoiding delays and fixing problems quickly.

Here’s how turnkey services help launch products faster:

Prototyping speeds up testing and improves development cycles.

Quick checks find issues early, allowing fast fixes and retests.

This shortens the time from idea to finished product, ready for the market.

Turnkey solutions also allow quick design changes. Problems are fixed fast, so products meet market needs without delays. Early testing ensures PCBs work, letting you do other tasks at the same time, saving even more time.

Did You Know? Companies using turnkey services often finish faster, staying ahead in the market.

Enhanced Quality Control

Turnkey PCB assembly keeps quality high during production. One team handles everything, avoiding mistakes from working with multiple vendors. This ensures your product meets top standards like IPC-610.

Key benefits of turnkey quality control include:

Centralized Oversight: One team checks every step for consistent quality.

Rigorous Testing: Careful tests catch problems early, avoiding bad products.

Standardized Processes: Using one provider keeps quality the same in all steps.

Turnkey solutions reduce errors and make products more reliable. This improves customer trust and avoids costly fixes or recalls.

Note: High-quality PCBs are crucial for industries like medical devices and IoT, where reliability is key.

Simplified Supply Chain Management

Handling a supply chain for electronics can be tricky. Turnkey PCB assembly makes it easier by combining all steps in one place. You don’t have to work with many vendors or manage different schedules. Instead, one company takes care of everything, from getting parts to delivering the final product.

This organized method reduces confusion and saves time. For example, you get regular updates about your project, so it’s easy to track progress. If changes are needed, the provider quickly reviews and makes them. This teamwork helps keep your project on time.

Here’s how turnkey solutions make supply chain management simpler:

Metric | Description |

|---|---|

Project Planning | Careful planning ensures smooth and easy project handling. |

Production Coordination | Updates and quick changes keep production running smoothly. |

Cost Reduction | One bill and combined delivery lower extra costs. |

Quality Assurance | Regular checks improve quality and catch problems early. |

Demand Analysis | Helps balance production and predict future needs. |

Design Revisions | Suggestions make designs easier to build and assemble. |

By combining these tasks, turnkey PCB assembly reduces paperwork and improves communication. You can focus on creating new ideas while the provider handles the rest. This saves time and improves the quality of your products.

Tip: Working with a turnkey provider means fewer contracts and easier supply chain management.

Scalability for Businesses of All Sizes

Turnkey PCB assembly works for all businesses, big or small. It lets you adjust production based on what you need. Start with small test runs and move to full production when ready.

For small businesses, turnkey services provide tools and help that might be too expensive otherwise. You don’t need to buy costly machines or hire experts. The provider does it all, helping you compete with bigger companies.

Big businesses can handle large orders without losing quality. Turnkey providers are set up to manage big projects efficiently. They also offer custom options to meet specific needs.

Here’s how turnkey solutions help businesses grow:

Flexible Production Volumes: Change production levels to fit market needs.

Cost-Effective Prototyping: Test new ideas without making big orders.

Streamlined Expansion: Grow quickly without making your supply chain harder to manage.

Consistent Quality: Keep high standards, no matter the order size.

Turnkey PCB assembly helps your business grow at its own speed. Whether launching a new product or entering new markets, this method gives you the support you need.

Did You Know? Many small businesses use turnkey services to bring ideas to life without high costs.

The Turnkey PCB Assembly Process

Design Review and Optimization

The first step in turnkey PCB assembly is reviewing the design. This step checks for mistakes and improves the design for manufacturing. Experts use Design for Manufacturing (DFM) and Design for Assembly (DFA) checks. These checks find problems like bad part placement or signal issues that could cause delays or failures.

For example, a consumer electronics project had overheating and signal issues. After testing, the design was fixed, making it work better and last longer. Similarly, industrial systems had part placement problems. Reviews fixed these, making designs error-free and easier to maintain.

Case Study | Initial Problems | Review Steps | Results |

|---|---|---|---|

Consumer Electronics | Overheating, Signal Issues | Thermal and Signal Testing | Better Performance, Reliability |

Industrial Systems | Part Placement, Electrical Errors | Placement Review, Circuit Checks | No Errors, Easier Maintenance |

Fixing these problems early saves time and avoids costly changes later.

Component Sourcing and Procurement

Getting good parts is key for turnkey PCB assembly. This step finds needed parts, picks trusted suppliers, and gets good deals. A smooth process ensures high-quality parts at fair prices.

Here’s how sourcing and buying parts works:

List needed parts and send a purchase request.

Choose reliable suppliers with good quality.

Check delivered parts to meet standards.

Approve payments after confirming the order.

Turnkey providers often buy parts in bulk to save money. This also ensures parts arrive on time, keeping projects on track. By letting the provider handle this, you avoid dealing with many suppliers and can focus on your main work.

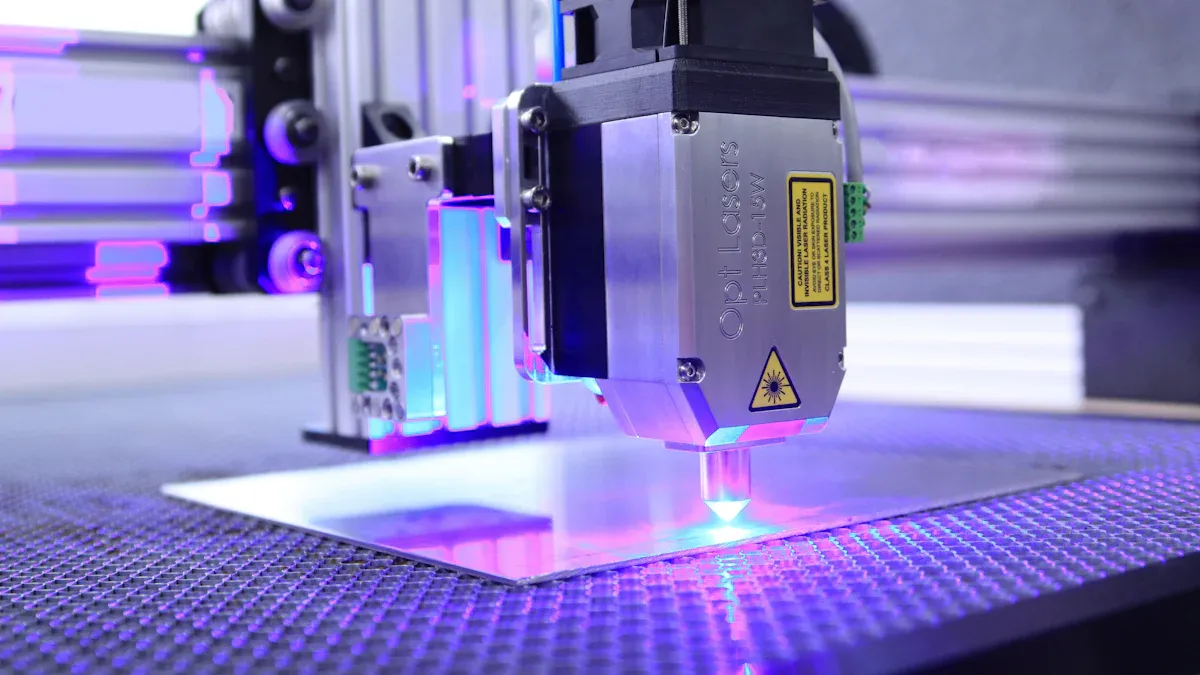

PCB Fabrication and Assembly

Making and assembling PCBs is the core of the turnkey process. Fabrication creates the bare PCB using steps like drilling and etching. Then, assembly starts with applying solder paste, placing parts, and soldering them.

Quality checks ensure everything is done right:

DFM/DFA Check: Finds and fixes design mistakes.

Material Inspection: Makes sure materials are high quality.

Solder Paste Screening: Applies paste accurately with stencils.

Machine Placement: Places parts precisely on the PCB.

Reflow Soldering: Secures parts while keeping the layout flexible.

Step | Description |

|---|---|

DFM / DFA Check | Checks designs to fix errors before production. |

Makes the bare PCB using drilling and etching. | |

Material Inspection | Checks all materials to ensure they meet standards. |

Solder Paste Screening | Applies solder paste to the PCB using stencils. |

Machine Placement | Places parts on the PCB with high accuracy. |

Reflow Soldering | Soldering process that secures parts in place. |

Turnkey providers work fast. For example, making a PCB can take one day, and full assembly can be done in five days. Advanced tools and skilled teams ensure great results, making turnkey PCB assembly a smart choice for manufacturing.

Testing and Quality Assurance

Testing and quality checks make sure your PCB works well. These steps find and fix problems before products are sold. Suppliers use smart testing tools to keep high standards. This helps avoid product recalls and saves money.

Testing checks how strong and reliable your PCB is. For example:

Solder Mask Resistance Test: Tests if the solder mask can handle heat and chemicals.

Acid and Alkali Resistance Test: Checks if the PCB resists damage from harsh chemicals.

These tests make sure your PCB works in tough conditions. Suppliers also use advanced tools to improve product quality.

Quality checks happen during every step of assembly. One team oversees everything to keep it consistent. Standard rules help catch mistakes early. This ensures your PCB meets industry rules and customer needs.

Tip: Good quality control builds trust and keeps customers happy.

Test Type | Purpose |

|---|---|

Solder Mask Resistance Test | Tests if the solder mask can handle heat and chemicals. |

Acid and Alkali Resistance Test | Checks if the PCB resists damage from harsh chemicals. |

Strong testing and quality checks give you confidence in your product. By focusing on these steps, you ensure your PCB works well every time.

Packaging and Delivery

Packaging and delivery are key parts of turnkey PCB assembly. Good packaging keeps your PCB safe during shipping. Fast delivery gets it to you on time. Suppliers work hard to make these steps better and save money.

Packaging uses materials that protect your PCB from harm. Providers also track material use to cut waste and costs. Eco-friendly options protect the environment while keeping your PCB safe.

Delivery depends on important measures of efficiency, such as:

Lead Time: Measures how long it takes from order to delivery.

Delivery Time: Tracks how fast shipments arrive.

Order Accuracy Rate: Checks how many orders are correct.

Pick and Pack Cycle Time: Measures how quickly orders are packed for shipping.

Metric | Description |

|---|---|

Lead Time | Time from order to delivery, showing any delays. |

Delivery Time | How fast shipments arrive, ensuring customer satisfaction. |

Order Accuracy Rate | Percentage of correct orders, reducing mistakes and costs. |

Use of Packing Material | Tracks material use to save money and reduce waste. |

Pick and Pack Cycle Time | Time to pack orders, showing how efficient the process is. |

Good packaging and delivery make sure your PCB arrives safely. By improving these steps, suppliers help avoid delays and keep quality high.

Note: Reliable delivery builds trust and keeps your projects on track.

Choosing the Right Turnkey PCB Manufacturer

Checking Experience and Skills

Picking the right turnkey PCB maker starts with checking their skills. Companies with lots of experience often do better work. Find manufacturers who know your industry or have done similar projects. This helps them understand your needs and solve problems easily.

Experienced makers also have strong technical knowledge. They can help improve designs, choose materials, and guide production. This lowers mistakes and makes your PCB better. Always ask for examples of their past work or customer reviews to confirm their abilities.

Looking at Quality Standards and Certifications

Certifications show a manufacturer’s focus on quality. Look for ones like ISO 9001, which follows global quality rules. Another key certification is IPC-A-610, which checks electronic assembly standards.

Certified manufacturers follow strict steps to keep quality high. They focus on leadership, planning, and improving processes. This ensures your PCB meets industry rules and works well.

Component | Description |

|---|---|

Organization Context | Looks at factors affecting quality results. |

Leadership | Highlights leaders’ role in keeping quality systems strong. |

Planning | Includes steps to meet quality goals and improve systems. |

Support | Covers resources, skills, communication, and documentation. |

Operation | Plans and controls processes to meet customer needs. |

Performance Check | Tracks and reviews how well the quality system works. |

Improvement | Focuses on making the quality system better over time. |

Choosing a certified maker ensures your PCB is made with care and accuracy.

Comparing Prices and Delivery Times

Price and delivery time are key when picking a turnkey PCB maker. A good provider offers fair prices without lowering quality. Check their costs, including materials, labor, and other fees. Makers who buy parts in bulk often have lower prices.

Fast delivery is also important, especially for urgent projects. Quick service helps you meet deadlines and launch products on time. Compare makers based on how fast they can deliver prototypes and full orders.

Cost Part | Revenue Share | Details |

|---|---|---|

Profits | Expected earnings before taxes in manufacturing. | |

Wages | 12.1% | Part of revenue spent on worker pay, varies by sector. |

Material Costs | 54.1% | Biggest cost, includes raw materials and packaging. |

Rent & Utilities | 2.2% | Revenue share for rent and utilities. |

Depreciation | 3.1% | Revenue share for equipment wear and tear, depends on tools used. |

By comparing prices and delivery times, you can find a maker who is both affordable and efficient.

Checking for Scalability and Customization Options

When picking a turnkey PCB maker, scalability and customization are key. A good provider should adjust to your needs and offer custom solutions. This helps your business grow smoothly without problems.

Companies like Mercer Technologies show why customization matters. They know every project is unique, so they create tailored solutions. For instance, their heat systems use modular designs. These designs can be changed to fit specific needs. This method gives flexibility and supports businesses with different goals. Plus, managing over 100 systems proves they can handle big projects.

Think about these points when choosing a manufacturer:

Production Flexibility: Can they manage both small and big orders?

Custom Features: Do they allow design changes or special options?

Modern Tools: Are they using advanced designs for better flexibility?

Picking a provider with these traits keeps your production smooth and flexible. It also helps you quickly meet market demands or customer needs.

Tip: Ask providers about similar projects they’ve done. This shows how well they can scale and customize.

Importance of Customer Support and Communication

Good customer support and clear communication are very important. A helpful and honest provider avoids delays and keeps your project on track.

Fast replies are crucial in the electronics world. Top makers answer questions within 24 hours. This ensures you get answers quickly. Having many ways to contact them, like email or phone, also makes staying connected easier.

Clear updates build trust and keep you informed. Regular progress reports and quick alerts about issues show transparency. Some makers even ask for feedback to improve their services. This focus on improvement strengthens trust and customer satisfaction.

Look for these in customer support:

Quick Replies: Do they answer your questions fast?

Easy Contact: Can you reach them in different ways?

Honesty: Do they share updates and challenges openly?

Feedback Use: Do they improve based on your suggestions?

Note: Strong customer support not only solves problems but also builds lasting partnerships with your provider.

Turnkey PCB assembly makes electronics manufacturing easier by combining all steps into one service. This saves time, cuts costs, and improves product quality. It’s a smart choice for businesses wanting to stay ahead. Turnkey providers handle design, part sourcing, assembly, and testing, making the process smooth and reliable.

Here’s a simple look at the benefits:

Benefit | Description |

|---|---|

Providers buy parts in bulk, lowering costs for you. | |

Time Efficiency | Faster production means quicker delivery and easier reorders. |

Better Quality | Careful checks and tests reduce mistakes and bad products. |

Easier Management | One contact person makes communication and solving issues simple. |

Expert Help | Providers use advanced tools and offer design advice for better results. |

Picking the right turnkey PCB partner makes manufacturing faster and better. This method speeds up production and ensures high-quality products, perfect for any business size.

FAQ

What industries benefit the most from turnkey PCB assembly?

Turnkey PCB assembly helps industries like IoT, medical devices, cars, and electronics. These fields need reliable and high-quality PCBs for their products. Turnkey services make production faster, improve quality checks, and save money. This makes them perfect for businesses in these areas.

Tip: If your industry needs accuracy and flexibility, turnkey PCB assembly is a smart option.

How does turnkey PCB assembly save time?

Turnkey PCB assembly handles all steps, from design to delivery, with one provider. This avoids delays from working with many vendors. Early testing and quick design fixes also speed things up. This helps your product reach the market faster.

Can turnkey PCB assembly handle small production runs?

Yes, turnkey PCB assembly works for small production runs. Providers offer flexible options to test prototypes or make small batches. This is great for startups or businesses launching new products.

Did You Know? Many small businesses use turnkey services to save money and skip buying costly machines.

What should you look for in a turnkey PCB manufacturer?

Look for experience, certifications like ISO 9001, and good customer support. Check if they can scale production and offer custom options. Compare prices and delivery times to match your project needs.

Key Factor | Why It Matters |

|---|---|

Experience | Shows they can handle tough projects well. |

Certifications | Proves they follow quality and industry rules. |

Customer Support | Ensures fast replies and clear updates. |

Are turnkey PCB assembly services eco-friendly?

Many turnkey providers use eco-friendly methods. They recycle materials, reduce waste, and improve processes to lower harm to the environment. Ask your provider about their green practices to match your values.

Note: Picking an eco-friendly provider helps your business support a cleaner planet.

See Also

Exploring Turnkey PCB Assembly And Its Importance Today

Essential Strategies To Enhance PCB Assembly Productivity

Streamlined PCBA Solutions For Quick Electronics Projects

Ten Professional Insights For Cost-Effective PCBA Assembly

Grasping The Fundamentals Of PCBA Manufacturing And Assembly