In the world of electronics, knowing the differences between blank PCBs and parts and populated PCBs is very important. A blank PCB and parts are made of a base material with wires but have no electronic components. It acts like an empty canvas, allowing for a lot of customization in special uses. On the other hand, a populated PCB is fully assembled with all the necessary electronic parts. It has strong soldered connections for stability. Each type is crucial for the design and function of electronic devices.

Here’s a quick comparison:

Type of PCB | Characteristics |

|---|---|

Blank PCB and parts | – Flexible for different designs and uses. |

Populated PCB | – Made for specific uses, designed for the device’s purpose. |

Knowing these differences can help you pick the right blank PCB and parts for your project.

Key Takeaways

Blank PCBs are basic boards for electronic circuits. They let you change the design and layout easily.

Populated PCBs are already put together with electronic parts. They are ready to use in devices right away.

Knowing the differences between blank and populated PCBs helps you pick the best type for your project.

The cost of PCBs depends on board size, amount, and time needed. These factors affect the total project budget.

Picking the right PCB type can improve how well electronic devices work and how reliable they are.

Blank PCBs

Characteristics of Blank PCB Boards

Blank PCBs are the base for many electronic devices. They are made of a substrate material that gives strength and electrical performance. The most common substrate is FR-4. This material is made from fiberglass and epoxy resin. It balances cost, performance, and durability well. Here are some important traits of blank PCB boards:

Characteristic | Description |

|---|---|

Substrate Material | The material that forms the core, affecting strength and electrical performance. |

FR-4 Properties | Most common substrate with tensile strength 310-440 MPa, flexural strength 480 MPa, dielectric constant 4.0-4.8, dissipation factor 0.015-0.025. |

Copper Foil Thickness | Standard weights include 0.5 oz (17.5 µm), 1 oz (35 µm), and 2 oz (70 µm), affecting current capacity and thermal performance. |

Copper Purity | High-purity copper (≥99.7%) ensures great conductivity and etching behavior. |

Surface Roughness | Affects adhesion and conductor loss; smoother surfaces are better for high-frequency uses. |

Conductivity | Copper is chosen for its great electrical and thermal conductivity, second only to silver. |

These traits make blank PCBs useful for many applications.

Applications of Blank PCBs

You can find blank PCBs in many industries. Their flexibility allows for design changes, making them good for many uses. Here are some common applications:

Automotive: Blank PCBs are used in media devices, control systems, and vehicle navigation systems.

Consumer Electronics: You will see them in smartphones, computers, and home appliances.

Medical Devices: They are important in diagnostics and treatment devices.

LED Technology: Blank PCBs help manage heat in lighting applications.

Industrial Equipment: They are key in machinery for production and distribution.

The ability to customize blank PCBs makes them great for prototyping and testing new designs. This flexibility helps engineers create unique solutions for specific needs.

Populated PCBs

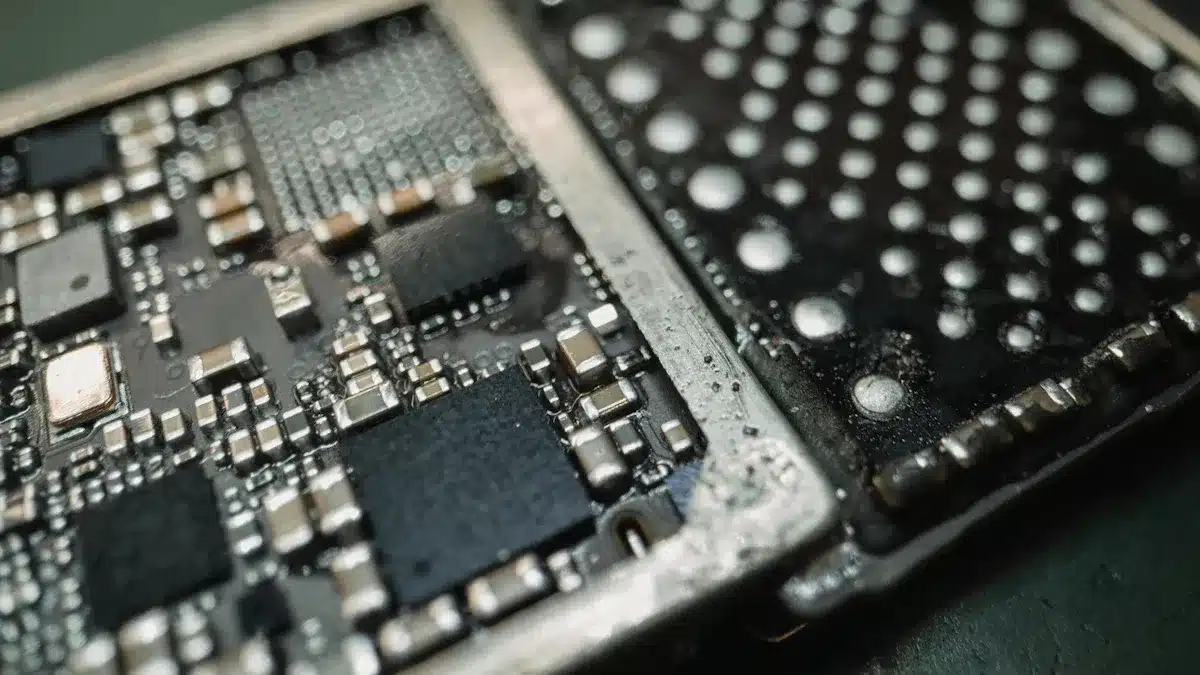

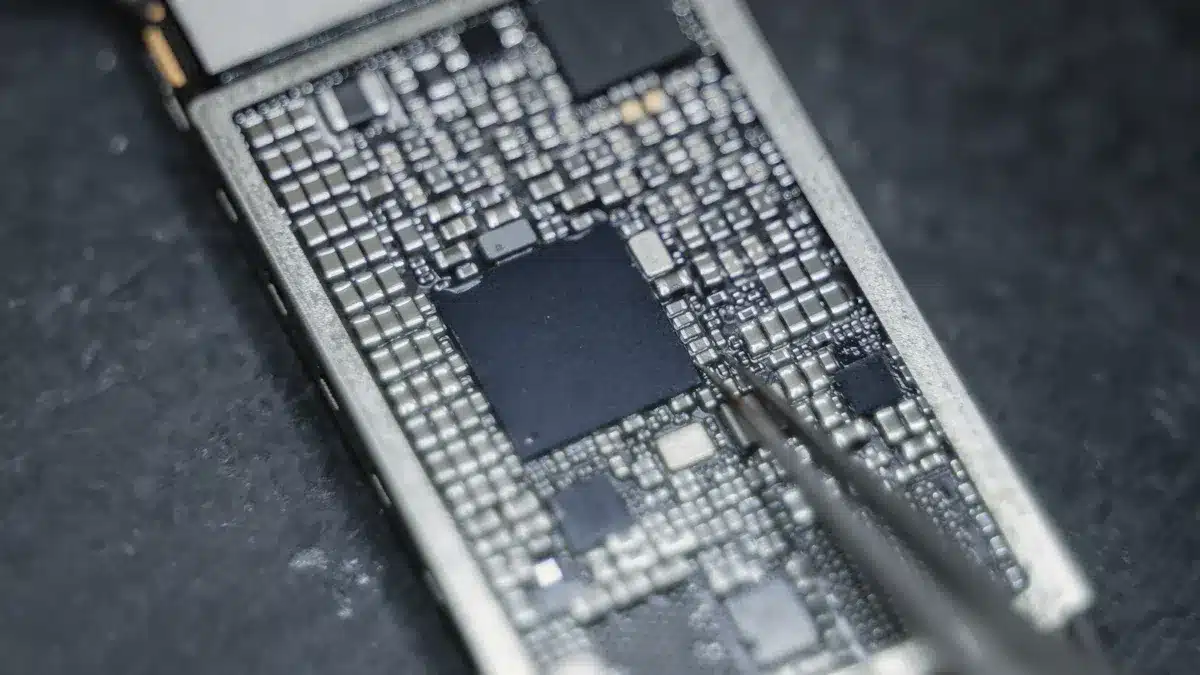

Characteristics of Populated PCBs

Populated PCBs are very important for many electronic devices. They come fully built with electronic parts. This means they are ready to use right away. Here are some key features of populated PCBs:

Feature | Description |

|---|---|

Assembly Methods | Different ways are used to put parts on the PCB. |

Layout Efficiency | A good layout helps reduce mistakes and improves how well it works. |

Placement Speed Optimization | Machines speed up work by grouping similar parts and cutting down on turns. |

Quality Control Measures | Includes checking by eye, using cameras, and testing for reliability. |

Visual Inspection | Manual checks look for misaligned parts and problems, especially for small batches. |

Automated Optical Inspection (AOI) | Cameras scan boards to find issues like missing parts. |

Checks electrical connections and looks for shorts or breaks using special tools. | |

Functional Testing | Simulates real use to make sure the board works as it should. |

Burn-In Testing | Tests under tough conditions to find weak spots before shipping. |

These features make sure that populated PCBs are dependable and work well. The soldered connections create strong electrical paths. This reduces problems like loose connections. This reliability is very important in areas where equipment failure can cause big issues.

Applications of Populated PCBs

You can find populated PCBs in many industries, each with different uses. Here are some common applications:

Automotive: In electric cars, driver-assistance systems, and entertainment systems, populated PCBs are very important.

Consumer Electronics: Devices like smartphones and tablets depend on populated PCBs for small and powerful designs.

Industrial Automation: These PCBs help improve efficiency and allow real-time monitoring in factories.

Healthcare: In diagnostics and patient tracking, populated PCBs help improve medical results by ensuring reliable performance.

The North America High Density Interconnect (HDI) PCB market is growing fast because of the need for smaller devices. Populated PCBs help create sleek and powerful consumer products, making them essential in today’s tech world.

Key Differences Between Blank and Populated PCBs

Design and Functionality

When you look at the design and function of PCBs, you see big differences between blank and populated types. A blank PCB is the base for your electronic circuit. It lets you change the layout to fit your needs. You can pick where to put parts based on what the circuit needs. This flexibility is very important when you are testing ideas and might need to change things often.

On the other hand, a populated PCB is a complete product. It has all the needed parts soldered onto it. The design of a populated PCB makes sure that all parts work well together. Whether a PCB stays blank or gets populated depends on its purpose. A bare PCB is like a blank page, made to hold different parts based on the circuit’s needs. Meanwhile, a populated PCB does its job by including all the important parts.

Manufacturing Process

The ways to make blank and populated PCBs are quite different. Here are the main steps for each process:

For Blank PCBs:

Design the layout with EDA tools.

Set dimensions and where parts go.

Choose layer stack and routing.

Create fabrication data for making it.

For Populated PCBs:

Capture the schematic using EDA tools.

Decide on card size and part locations.

Choose the layer stack and how signals connect.

Place parts and mark vias.

Route signal traces and create fabrication data.

Making blank PCBs usually takes 1 to 3 weeks, depending on how complex the design is. In contrast, populated PCBs take longer because they need extra steps like placing parts and soldering. This added work can make the time longer.

Quality control is also different for both types. For populated PCBs, makers must ensure parts are placed correctly. This accuracy affects how fast they can make them. Each step in making populated PCBs must be done carefully to keep quality high. You might face problems when moving from blank to populated PCBs, like connection issues and mechanical faults. These problems can happen due to dirt, misalignment, or overheating in tightly packed designs.

Cost Implications of Blank PCB and Parts vs Populated PCBs

When you think about the costs of blank PCBs and populated PCBs, many things matter. Knowing these things can help you make smart choices for your projects.

Factors Affecting Cost

Many things affect the cost of blank PCBs and their parts. Here are the most important factors:

Board Size: The size of the PCB changes how many boards fit on a panel. Bigger boards can raise costs because of wasted space.

Quantity: Buying in large amounts can lower the cost for each board. More boards often mean lower prices.

Lead Time: If you need your boards fast, expect to pay more. Quick production can really change your budget.

Other things that matter include:

Board complexity

Production volume

Special features

Turnaround time

Also, specific traits like layer count, substrate material, and trace width can change prices. For example, more layers mean more materials and harder manufacturing, which raises costs. Different substrate materials have different prices, affecting the total PCB cost. Smaller trace sizes need advanced manufacturing, which can also increase costs.

Cost Comparison

Comparing the costs of blank PCBs and populated PCBs shows clear differences. Blank PCBs usually have lower starting costs since they don’t have parts. But, you need to think about the extra costs for parts and assembly when you choose populated PCBs.

Here’s a table that sums up the cost differences:

Type of PCB | Initial Cost | Additional Costs | Total Cost Consideration |

|---|---|---|---|

Blank PCB | Lower | Parts + Assembly | Can add up quickly |

Populated PCB | Higher | None (ready to use) | More predictable |

In populated PCBs, assembly labor and automation are key to costs. Here’s how different things affect labor costs:

Factor | Impact on Labor Costs | Considerations |

|---|---|---|

Manual Assembly | Higher labor cost per unit | Good for low volume production and complex prototypes |

Lower labor cost per unit for high volume | Needs skilled workers for setup and maintenance | |

Geographical Location | Big cost differences based on area | Trade-off between cost, delivery times, and quality |

By knowing these cost factors, you can better check your options. If you want to know how much PCB assembly service costs, think about these factors carefully. Also, when picking a PCB assembly manufacturer, remember to balance cost and quality.

Knowing the differences between blank and populated PCBs is very important for your projects. You need to set clear goals for your project. Then, choose a blank PCB that fits your size and complexity needs. The materials you pick can greatly affect how well it works, how reliable it is, and how much it costs. Understanding these differences helps you make smart choices about production costs and how well it functions. This knowledge improves quality control and boosts performance in your electronic devices.

By understanding these ideas, you can improve your design process and make sure your projects achieve their goals.

FAQ

What is a blank PCB?

A blank PCB is a board that has no parts on it. It is used as a base to create custom circuits. You can change its layout to meet your project needs.

How do populated PCBs differ from blank PCBs?

Populated PCBs are fully built with electronic parts. They are ready to use right away. Blank PCBs need extra parts and assembly to work.

What are the main uses of blank PCBs?

You can find blank PCBs in many areas, like car systems, consumer electronics, medical devices, and industrial machines. Their flexibility allows for custom designs and testing.

How long does it take to manufacture a populated PCB?

Making a populated PCB usually takes more time than a blank PCB. The process includes putting parts together, which can take several days to weeks, depending on how complex it is.

Why are populated PCBs more expensive?

Populated PCBs usually cost more because of the parts, assembly labor, and quality checks. These things make them a bigger investment than blank PCBs.

See Also

Uncovering The Subtle Variations Between PCBA And PCB

Examining The Functional And Structural Variances Of PCBA And PCB

Understanding The Fundamental Distinctions Of PCB And PCBA