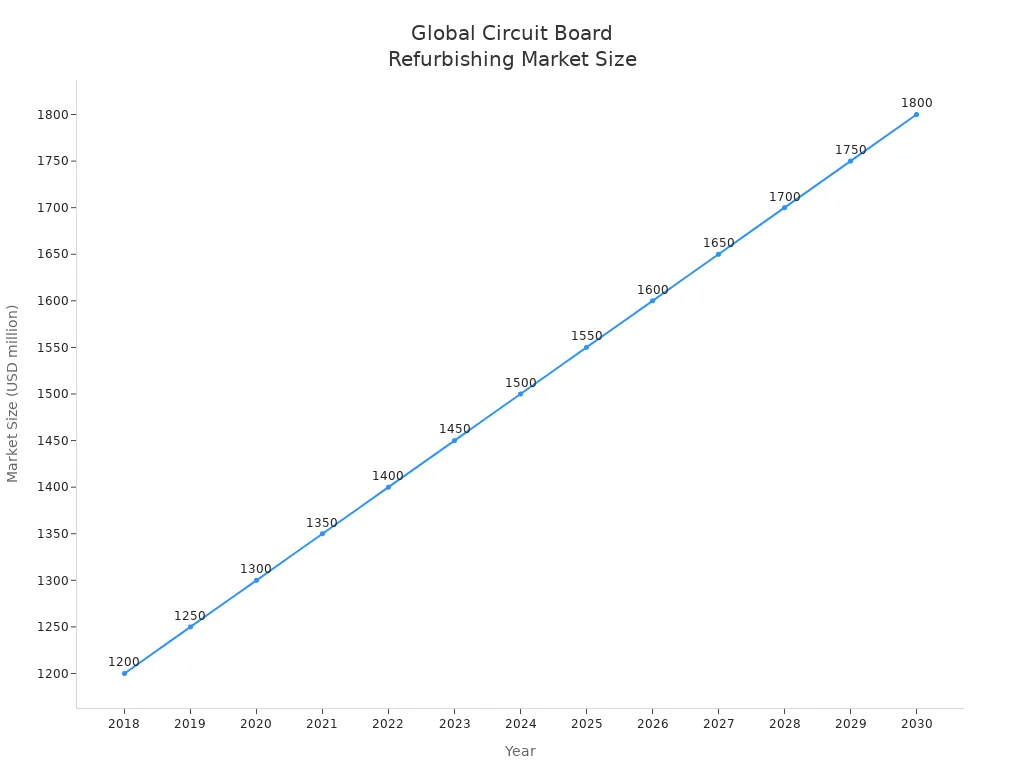

In today’s tech-focused world, circuit board refurbishing is very important. This process helps you fix electronic parts. It makes them last longer and work better. By choosing refurbishing services, you can save money and cut down on waste. This method helps your budget and supports eco-friendly goals in technology. The worldwide market for circuit board refurbishing is expected to grow a lot. This shows how important it is in many industries.

Key Takeaways

Circuit board refurbishing helps you save money. It is a cheaper option than buying new devices.

Refurbishing also cuts down on electronic waste. This helps protect the environment and save resources.

The refurbishing process makes products last longer. This happens through careful checking, fixing, and testing for quality.

Picking a trustworthy refurbishing service means you get good repairs. You will also have reliable service for your electronic devices.

By choosing refurbishing, you help create a better future. You can enjoy reliable and affordable electronics too.

Benefits of Refurbishing

Cost Savings

Refurbishing circuit boards can save a lot of money for businesses and consumers. When you refurbish instead of buying new, you avoid high costs. Refurbishing usually costs much less than new devices. This lets you spend your budget on other important things for your business or personal needs.

Lower Repair Costs: Refurbishing services often have lower prices than new purchases.

Reduced Downtime: Fast refurbishing can help you get back to work quickly.

Environmental Benefits

Circuit board refurbishing helps promote sustainability. By choosing refurbishing services, you help the planet. Here are some important environmental benefits:

Reduces Electronic Waste: Making appliances last longer keeps them out of landfills.

Conserves Resources: Using fewer new materials helps protect natural resources.

Limits Environmental Damage: Making PCBs needs rare metals, which harm the environment. Refurbishing stops these materials from going to landfills and reduces toxins.

Also, refurbishing keeps rare metals in use instead of needing new mining. This practice helps limit the damage caused by mining. By focusing on reducing, reusing, and recycling, you help industries lower their impact on the environment while saving money.

Product Longevity

Refurbishing circuit boards makes electronic products last much longer. The refurbishing process includes steps that improve reliability and performance:

Component Removal and Reconditioning: These steps make sure all parts of the circuit board work well.

Quality Testing: Careful testing checks that the refurbished product works at high standards.

Additionally, design for disassembly (DfD) encourages using repairable and reusable parts. This method not only makes products last longer but also supports a more sustainable way of consuming.

By choosing circuit board refurbishing, you save money and help create a better future while enjoying products that last longer.

Refurbishing Process

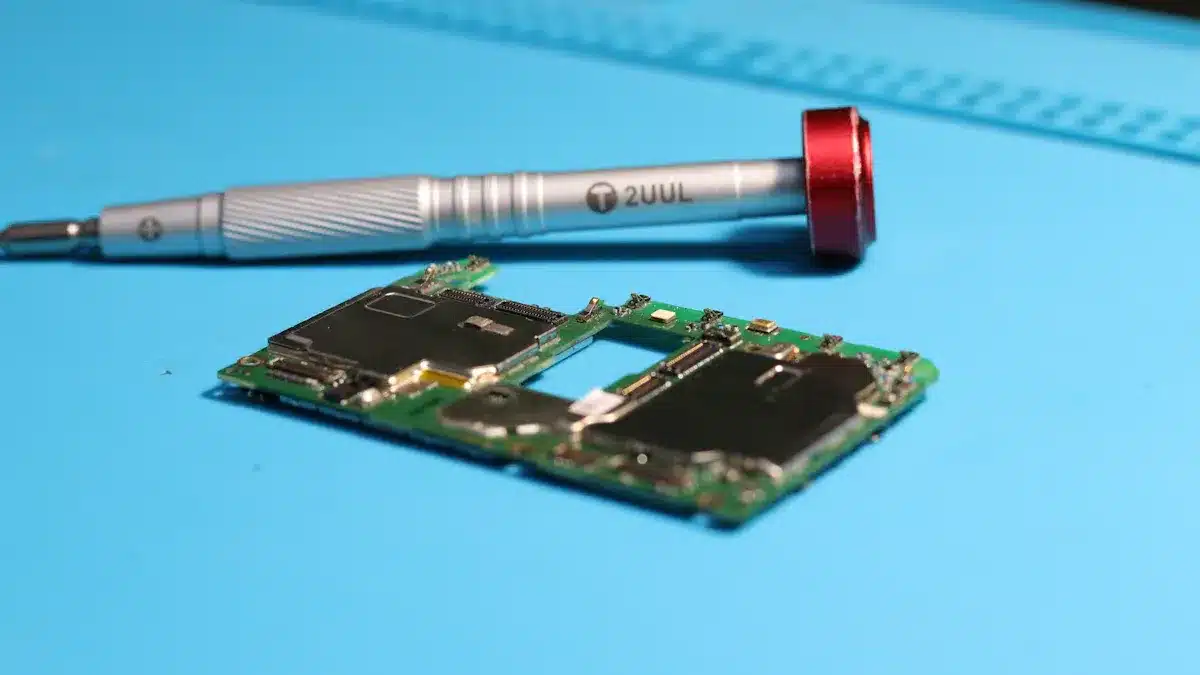

The refurbishing process has important steps to make sure circuit boards work well again. You can split this process into three main parts: assessment, repair techniques, and quality testing.

Assessment

In the assessment part, technicians check the circuit board for problems. This part includes:

Visual Inspection: Technicians look closely at the board using magnifying tools. They search for issues like burned parts and broken solder joints.

Cleaning: The board gets a careful cleaning to remove dirt. This step helps stop problems that could cause short circuits.

Diagnostics: Technicians use special tools like digital multimeters and oscilloscopes. These tools help find shorts, opens, and check component values, making sure to catch problems early.

By doing these assessments, you can find failures quickly. This is important for good repairs and less downtime.

Repair Techniques

After the assessment, technicians start the repair techniques. Here are some helpful strategies used in circuit board refurbishing:

Strategy | Description |

|---|---|

Storage and Handling | Keeping the boards safe prevents dirt and damage, which helps keep PCB quality during storage. |

Know Your Product | Knowing the details of the PCB helps use the right repair methods effectively. |

Divide and Conquer | Splitting tasks among workers makes the process faster and reduces mistakes in repairs. |

These techniques make sure the repairs work well and that the circuit boards run reliably after refurbishing.

Quality Testing

After repairs, quality testing is very important to check the reliability of refurbished circuit boards. Common testing methods include:

Testing Method | Description |

|---|---|

In-Circuit Testing (ICT) | Uses a tool to measure component values and check if the circuit works correctly. |

Flying Probe Testing | Uses robotic probes for flexible testing without special tools, great for prototypes. |

Functional Testing | Simulates real use to check overall operation, thorough but takes time. |

Burn-In Testing | Finds early failures in PCBs to make sure they are reliable. |

These testing methods help ensure that you get a high-quality product that meets your needs.

Cost-Effectiveness

When you think about the cost-effectiveness of circuit board refurbishing, you see big benefits over just replacing your equipment. Refurbishing usually costs much less than buying new circuit boards. This choice lets you use your budget for other important parts of your business or personal projects.

Refurbishing vs. Replacement

Let’s look at the costs of refurbishing compared to replacing:

Aspect | Refurbishing | Replacement |

|---|---|---|

Initial Cost | Usually lower | Higher upfront costs |

Time to Complete | Often faster turnaround | Longer wait for new orders |

Reliability | High, with good quality checks | Depends on the maker |

By picking circuit board refurbishing, you can save money and still get a reliable product.

Long-Term Savings

The long-term savings from refurbishing can be very large. Here are some things that affect these savings:

Factor | Description |

|---|---|

Keeps strong structure with good materials and parts, which helps reliability. | |

Process Quality | Affects how many good products are made; design faults can raise costs due to redesign or repairs. |

Time | The time needed for making PCBs affects overall cost-effectiveness in PCB design. |

By choosing circuit board refurbishing, you not only save money now but also lower future costs for repairs and replacements. This way leads to a more sustainable and cost-effective solution for your electronic needs.

Environmental Impact

Circuit board refurbishing is very important for helping the environment. By using eco-friendly methods, you can lower your impact on nature. Here are some common green practices in the circuit board refurbishing field:

Eco-friendly PCB materials: Using materials like cellulose or paper helps cut down waste.

Lead-Free Solder Materials: Choosing lead-free solder reduces health and environmental dangers.

Recyclable Materials: Using materials like copper and aluminum helps save new resources.

Modular PCB architecture: Designing PCBs with parts that can be easily replaced makes them last longer and cuts waste.

Green manufacturing: Using additive manufacturing methods lowers material waste.

Optimized chemical usage: Cutting down on harmful waste through cleaner production and better waste treatment is very important.

PCB recycling programs: Setting up programs to manage old PCBs responsibly ensures they are disposed of properly.

By picking circuit board refurbishing, you help make electronic devices last longer. This choice lowers the need for new materials and the energy used in making them. The Environmental Protection Agency (EPA) says that fixing and reusing items is key to reducing waste. Keeping materials in use longer helps save resources.

Think about these points regarding resource use:

Making new circuit boards needs raw materials like precious metals and harmful chemicals.

Choosing to repair instead of replace greatly cuts the need for these resources and helps the environment.

PCB repair usually uses less energy than making new boards, which lowers greenhouse gas emissions.

A study by the Fraunhofer Institute shows that repairing electronic products can cut environmental impact by up to 50% compared to making new ones. This refurbishment process fixes damaged devices to like-new condition, which helps them last longer. It greatly reduces electronic waste and fits with waste reduction plans used by big companies.

Compared to other electronic recycling methods, circuit board refurbishing has special benefits. For example, the small-molecule assisted recycling method effectively recycles circuit board parts while keeping their electrical properties. Traditional methods often harm these parts, making them harder to reuse. Also, life cycle assessments show that getting metals from PCBs is better for the environment than mining these metals from natural sources. This shows how circuit board refurbishing helps save resources and lowers negative effects on the environment.

By following these green practices, you help create a healthier planet while enjoying reliable electronic devices.

Choosing a Service Provider

Picking the right service provider for circuit board refurbishing is very important. You want to make sure you get good repairs and dependable service. Here are some key things to think about when you choose.

Key Considerations

When looking at possible refurbishing service providers, think about these factors:

Reputation: Check the service provider’s reputation using search engines and forums. Look for reviews and feedback from past clients to see if they were happy.

Services Offered: Make sure the provider offers careful fault checking, troubleshooting at the component level, and diagnostics. A complete service can save you time and money later.

Certifications: Look for specific industry certifications like IPC-7711 / 7721. These show that the provider has the right skills and follows high-quality standards.

Supply Chain Relations: Confirm that the provider uses trustworthy parts and has strong supply chain connections. This ensures the parts used in refurbishing are of good quality.

Questions to Ask

Asking the right questions can help you understand what a potential service provider can do. Here are some important questions to think about:

Question/Consideration | Description |

|---|---|

Make sure technicians have certifications like IPC 7721, showing they meet industry standards. | |

Quality Assurance | Look for a strong quality control process, including checks by a QC department. |

Innovative Techniques | Ask about using advanced repair methods for tricky PCB problems. |

Specialized Equipment | Check if they use advanced tools and equipment for effective repairs. |

By asking these questions, you can learn more about the provider’s skills and commitment to quality.

Also, you can check the history and skills of a service provider by looking at their certifications and experience. Here’s a quick look at some providers:

Provider Name | Certifications | Experience | Compliance |

|---|---|---|---|

Certified Technicians | Many years with multi-generational hardware | ISO 9001:2008 standards | |

Circuit Technology Center | IPC-certified technicians | Over 40 years of expertise | Unconditional guarantee |

Suntronic | N/A | N/A | N/A |

Global Tech Sourcing has certified, skilled technicians with many years of experience.

Circuit Technology Center has over 40 years of expertise and IPC-certified technicians.

Suntronic has invested in PCB testing and repair tools to help clients.

Choosing the right circuit board refurbishing service provider can greatly affect the quality and lifespan of your electronic devices. By thinking about these factors and asking the right questions, you can make a smart choice that fits your needs.

Refurbishing circuit boards has many benefits for businesses and consumers. You can save money by making your devices last longer. This means you won’t need to buy new ones as often. This method also helps reduce e-waste and saves important resources. Here are some main points:

Refurbishing makes products last longer and work better.

It is a cheaper option than buying new ones.

You help the environment by choosing to repair instead of throw away.

By thinking about circuit board refurbishing, you make a smart choice for your wallet and help the planet.

FAQ

What is circuit board refurbishing?

Circuit board refurbishing means fixing and restoring electronic circuit boards to make them last longer. This service helps improve how well they work and how reliable they are. It also cuts down on waste and costs compared to buying new boards.

How long does the refurbishing process take?

The refurbishing process usually takes a few days to a couple of weeks. This depends on how complicated the repairs are and if parts are available. You can often get your boards back faster than if you ordered new ones.

Is refurbishing cost-effective?

Yes, refurbishing is usually cheaper than replacing circuit boards. You save money by not buying new ones. You also get high-quality repairs that make your electronics work well again and last longer.

Can all circuit boards be refurbished?

Most circuit boards can be refurbished, but it depends on how badly they are damaged and if replacement parts are available. A qualified technician will check your board to see if refurbishing can be done.

How can I choose a reliable refurbishing service?

To find a good refurbishing service, look at their reputation, certifications, and experience. Ask about how they ensure quality and what methods they use. Reading customer reviews can also help you make a smart choice.

See Also

Navigating the Hard Reset Techniques for PCBA Devices

Unveiling the Advantages of PCBA Surface Mount Technology

Proven Strategies for Performing PCBA Failure Assessments

Understanding In-Circuit Testing for PCBA and Its Importance

Investigating PCBA Testing Methods in Modern Electronics Production