The rapid growth of AI hardware is transforming the landscape of US-based AI hardware PCB assembly. By 2025, the global AI hardware market is projected to reach $87.4 billion, expanding at an impressive annual rate of 37.94% until 2034. This underscores the critical role that US-based PCB assembly companies play in supporting AI projects. Prominent firms such as TTM Technologies, Sierra Circuits, Jabil Inc., Sanmina Corporation, and Flex Ltd. are recognized for their advanced expertise in this field.

When selecting a company for AI hardware, it is essential to prioritize reliability and expertise. High-quality PCB assembly is crucial for optimal performance, as even minor errors can lead to significant issues in complex systems. For projects involving neural network tools or components for self-driving cars, partnering with the right US-based AI hardware PCB assembly provider is vital to comply with stringent industry regulations.

Key Takeaways

Pick PCB makers based on how good and reliable they are. Good boards stop big problems in AI hardware projects.

Think about the total cost and pricing plans. Find clear prices and extra services that match your budget but still keep quality.

Choose makers with skills in AI hardware. Their knowledge helps them handle tricky designs and give solid results.

Quick delivery and fast work are very important. Makers with speedy services help you finish on time and stay on track.

Great customer help and clear talks matter a lot. Pick makers known for quick replies and clear updates during your project.

Key Evaluation Criteria for PCB Assembly Providers

Picking the right PCB assembly provider for your AI hardware project is important. Checking key factors helps you find a partner who delivers good quality and dependable solutions. Below are the main things to look for.

Quality and Reliability

Good quality and reliability are essential for successful PCB assembly. High-quality boards make sure your AI hardware works well and avoids expensive problems. Quality checks catch mistakes early and stop future issues. Reliable providers use strong testing methods to ensure parts are secure and the board works properly.

Quality checks lower returns and improve engineering work.

Good materials stop failures and save money over time.

Testing tools like optical inspection and functional tests confirm the product meets standards.

Top providers follow strict rules, like FDA-approved paperwork and ISO 13485 certifications. These rules ensure reliability and meet tough regulations. Real-time monitoring and automated reports make their services even more dependable.

Tip: Pick providers with traceable components and advanced checks like X-ray tests. These features help your complex PCB designs meet top quality levels.

Cost and Pricing Models

Cost matters when choosing a PCB assembly provider, but focusing only on price can hurt quality. Instead, check if their pricing fits your budget and needs.

Clear pricing shows you where your money goes.

Turn-key services include materials, assembly, and testing, saving time.

Competitive pricing isn’t always the cheapest. Look at extra services included.

Big projects may get discounts for large orders. Smaller projects might need flexible pricing. Balancing cost with good quality keeps your AI hardware project affordable and reliable.

Note: Ask for detailed quotes and compare providers. This helps you avoid hidden fees and get the best deal.

Technical Expertise in AI Hardware

Expert knowledge is key for AI hardware projects. Providers with skills in PCB assembly for AI know how to handle tricky challenges. They focus on accuracy and scaling to deliver great results.

Metric | Description |

|---|---|

Certifications | |

Specialization | Experts in services for AI hardware projects. |

Quality Management Systems | Strong quality checks during the assembly process. |

Technological Capabilities | Advanced tools like automated inspections and testing. |

Incoming Material Inspection | Checks for quality and authenticity of parts and materials. |

In-Process Quality Checks | Regular checks during assembly to fix problems quickly. |

Automated Optical Inspection | Finds missing parts or solder mistakes using machines. |

X-Ray Inspection | Looks at solder joints and inside PCB layers for hidden issues. |

Functional Testing | Tests the board’s electrical functions to ensure it works. |

Providers with advanced tools, like optical inspection and X-ray checks, make sure your PCB assembly meets high standards. Their skills in handling complex designs and AI needs make them great partners for your project.

Tip: Pick a provider with experience in AI hardware projects. Their knowledge helps them deliver reliable solutions for your needs.

Delivery Speed and Turnaround Time

Fast delivery is very important for your AI hardware project. Quick services help you meet deadlines and stay on track. Top PCB assembly providers use smart methods to avoid delays and work faster.

Fast Turnaround Options: Some companies, like JHYPCB and JLCPCB, finish in 24 hours. Avanti Circuits even offers same-day services for urgent needs. These options help you adjust to changes quickly.

Integrated Services: Providers that handle both PCB making and assembly save time. This setup avoids shipping delays and speeds up the process.

Manufacturer | Typical Turnaround Time | Pricing | Quality Management |

|---|---|---|---|

PCBWay | 24 hours to a few days | Affordable, often cheaper than US-based | ISO 9001 certified |

JLCPCB | 24 hours to a few days | Very affordable, often less than PCBWay | ISO 9001 certified |

Avanti Circuits | Same-day and 24-hour turn | Higher pricing | Follows strict industry rules |

Companies with good planning and fast systems can meet tight deadlines. They deliver quickly without lowering quality. Picking a provider with proven speed ensures your project runs smoothly.

Tip: Ask providers about their delivery times and rush services. This helps you plan better and avoid delays.

Customer Support and Communication

Good customer support makes your project easier from start to end. Providers with clear communication keep you updated and solve problems fast. This is very helpful for tricky AI hardware projects.

Dedicated Support Teams: Many top companies have teams just for customer help. They give updates and solutions that fit your project.

Transparent Communication: Clear updates build trust. Providers who share real-time progress and reports keep you informed.

Problem Resolution: Quick help fixes issues fast. Responsive teams make sure your project stays on schedule.

Note: Choose providers known for great customer service. Check reviews to learn about their communication and support.

Picking a provider with strong support and clear updates gives you a reliable partner. This teamwork lowers stress and helps you finish your project successfully.

Detailed Comparison of Top Providers

TTM Technologies

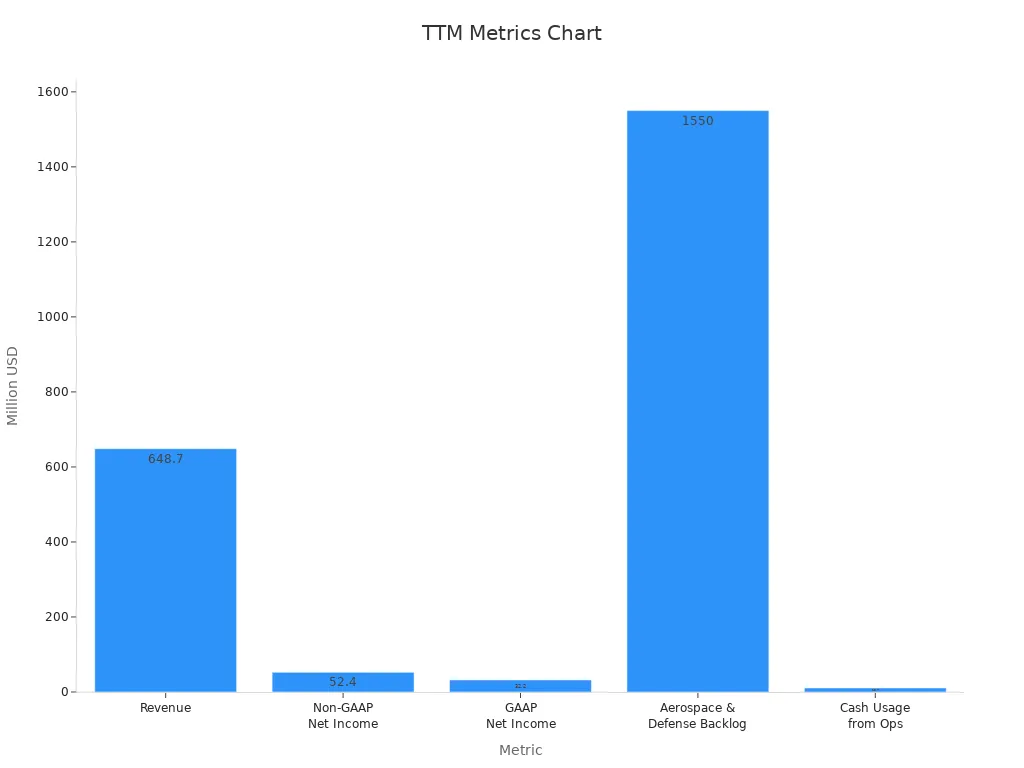

TTM Technologies is a top PCB manufacturer for AI hardware projects. The company earns $648.7 million in revenue, growing 14% yearly. This shows it is stable and can handle big projects. Its book-to-bill ratio is 1.10, meaning steady demand for its services.

TTM specializes in reliable PCB assembly for aerospace and defense. Its backlog in these fields is $1.55 billion. This proves its skill in managing tough, important projects. The company uses advanced tools like optical inspection and X-ray testing. These ensure accuracy and dependability.

Metric | Value |

|---|---|

Revenue | $648.7 million |

Year-over-Year Growth | 14% |

Book-to-Bill Ratio | 1.10 |

Aerospace & Defense Backlog | $1.55 billion |

Adjusted EBITDA | $99.5 million (15.3% of sales) |

Tip: For critical AI hardware projects, TTM Technologies offers reliable and precise solutions.

Sierra Circuits

Sierra Circuits is known for fast PCB production. It can deliver boards in just one day. This makes it great for projects with tight deadlines. Its 70,000 sq/ft facility ensures high-quality work.

The company provides many assembly options, like SMT, BGA, PTH, and rigid-flex. These services fit different AI hardware needs, from prototypes to full production. Sierra Circuits also offers turnkey assembly, handling everything from materials to testing.

Fast production: Boards ready in one day.

Many assembly options: SMT, BGA, PTH, and rigid-flex.

Large facility: 70,000 sq/ft for quality production.

Sierra Circuits is certified by the National Minority Supplier Development Council. This shows its focus on quality and diversity.

Note: For quick delivery and flexible assembly options, Sierra Circuits is a trusted choice.

Jabil Inc.

Jabil Inc. is a global leader in PCB assembly for AI hardware projects. It handles both small prototypes and large productions. Jabil works in industries like healthcare, automotive, and electronics.

The company uses advanced tools for precise and efficient assembly. Testing methods like functional testing and optical inspection ensure quality. Jabil also focuses on eco-friendly practices in its processes.

Company | Product Details | Pros | Cons |

|---|---|---|---|

Jabil Inc. | PCB assembly services for AI hardware projects. | Scalable production; advanced testing methods; eco-friendly practices. | Higher costs for small-scale projects. |

Jabil’s focus on innovation and sustainability makes it a top choice for modern projects.

Tip: Pick Jabil Inc. for scalable solutions and eco-friendly practices in your AI hardware project.

Sanmina Corporation

Sanmina Corporation is a top company in the PCB industry, especially for AI hardware projects. It is known for its advanced manufacturing and focus on quality. Sanmina offers complete services, from design to assembly, ensuring high standards for your project.

Sanmina’s strength is its testing abilities. They provide many tests like electrical, x-ray, and optical inspections. These tests make sure your PCB works well and is reliable. Sanmina also uses modern tools like the RoBAT RCI system. This equipment helps with fast and accurate assembly, even for complex AI hardware designs.

Capability/Expertise | Description |

|---|---|

Offers full manufacturing services with top quality and support. | |

Extensive Testing Capabilities | Includes electrical, x-ray, and optical inspections for reliability. |

Strategic Partnerships | Works with key AI hardware companies to improve services. |

Latest Technology Implementation | Uses tools like RoBAT RCI for fast and precise assembly. |

Global Facilities | Worldwide locations to meet different manufacturing needs. |

Sanmina has facilities all over the world. This global reach ensures consistent service no matter where your project is located. The company also partners with major AI hardware firms to provide innovative solutions that fit your needs.

Tip: For complex AI hardware projects, Sanmina Corporation is a reliable choice with advanced tools and expertise.

Flex Ltd.

Flex Ltd. is another leading company in PCB assembly for AI hardware projects. It combines advanced technology with a focus on customers to deliver great results. Whether you need a prototype or large production, Flex has the skills and tools to help.

Flex is great at handling the special needs of AI hardware. They use modern tools like automated optical inspection and functional testing. These methods check for problems early, saving time and money. Flex also cares about the environment. They use eco-friendly practices to reduce waste and protect nature. This makes them a good choice for green projects.

Key Features of Flex Ltd.:

Advanced testing like optical inspection and functional testing.

Flexible solutions for small and big projects.

Eco-friendly practices for sustainable manufacturing.

Flex also provides excellent customer support. Their teams guide you from start to finish. They give updates and solve problems quickly. This helps you stay on schedule and meet your goals.

Note: For flexible and eco-friendly PCB assembly, Flex Ltd. is a smart and reliable option.

Comparison Table of Providers

Overview of Key Attributes

When picking PCB assembly providers for AI hardware projects, focus on key traits. These traits help you find the best fit for your needs. Below is a table showing the main factors to consider:

Attribute | Description |

|---|---|

Project Requirements | Details about your PCB design and how complex it is. |

Production Volume | The number of PCBs your project will need. |

Technical Capabilities | Skills to handle tricky designs like HDI and SMT. |

Turnaround Time | How fast they can make and deliver your PCBs. |

Material Availability | Access to special materials needed for your project. |

Pricing Structure | Clear breakdown of costs for making and assembling. |

Quality Control | Tools like AOI and X-ray checks for top-quality boards. |

Communication | How well they support and respond during your project. |

Assembly Services | Extra options like surface mount or through-hole assembly. |

This table gives a simple way to compare providers. By focusing on these traits, you can make sure your project runs smoothly and meets its goals.

Tip: Choose providers with strong quality checks and clear pricing. These features are key to a successful AI hardware project.

Quick Reference for Decision-Making

To make choosing easier, here’s a quick table of benchmarks for PCB assembly providers. These benchmarks help you pick a manufacturer that fits your AI hardware project needs:

Benchmark Type | Description |

|---|---|

High-Density Interconnect (HDI) | Best for small designs, using tiny vias and fine-pitch parts. |

Lead-Free Soldering Techniques | Meets RoHS rules for safe and reliable boards. |

Automated Optical Inspection | Finds mistakes with great accuracy, improving quality. |

X-Ray Inspection | Checks hidden solder joints and inside PCB layers without damage. |

Surface Mount Technology (SMT) | Fast assembly for dense designs using automated systems. |

Through-Hole Technology (THT) | Strong connections for parts that face high stress. |

Speeds up prototypes and production for tight deadlines. |

This table shows the skills and services to look for in a provider. For example, if you need fast prototypes, pick providers with quick-turn services. For complex designs, choose experts in HDI and SMT technologies.

Note: Match your project’s needs to these benchmarks to find the right provider. This ensures your project is both high-quality and efficient.

Case Studies of Successful AI Hardware Projects

Example 1: AI Neural Network Accelerator by Sierra Circuits

Sierra Circuits helped build an AI neural network accelerator for a top tech company. The project needed HDI PCBs to handle the accelerator’s complex design. Sierra Circuits provided fast and precise solutions. They used advanced tests like optical inspection and X-ray checks to ensure perfect boards.

Their quick prototype production let the client test designs faster. This sped up development and reduced the time to launch. Sierra Circuits’ skill with detailed designs made them a great partner for this project.

Tip: For advanced AI hardware, choose Sierra Circuits for their speed and expertise.

Example 2: Autonomous Vehicle PCB Assembly by TTM Technologies

TTM Technologies worked on PCBs for an autonomous vehicle project. The project needed strong boards to handle tough conditions. TTM used advanced tools to make durable PCBs that met strict car industry rules.

They focused on quality with tests like functional checks and stress screening. TTM’s ability to scale production helped the client move from testing to full production smoothly. This made them a reliable partner for the project.

Note: For durable and scalable projects, TTM Technologies is a trusted choice.

Example 3: AI-Powered IoT Device by Jabil Inc.

Jabil Inc. teamed up with a startup to make an AI-powered IoT device. The project needed small PCBs with advanced features for AI tasks. Jabil used miniaturization and SMT to create a high-performing solution.

Their eco-friendly methods and fast production added value. Jabil’s quick prototypes let the client test the device in real-world settings. This ensured the final product met market needs.

Tip: For creative projects needing fast prototypes and green practices, Jabil Inc. is a great option.

Each company is great at different things. TTM Technologies is very reliable for important projects. Sierra Circuits is known for quick delivery and many assembly choices. Jabil Inc. focuses on scalable solutions and cares about the environment. Sanmina Corporation is skilled in testing for tricky designs. Flex Ltd. mixes flexibility with eco-friendly production.

FAQ

What matters most when picking a PCB assembly provider for AI hardware?

The key factor is technical expertise. Providers with AI hardware experience know how to handle complex designs and testing needs. Their skills help your project meet high standards for performance and reliability.

Tip: Check a provider’s certifications and past work to confirm their expertise.

How can I make sure my PCB assemblies are high quality?

Pick providers with advanced testing tools like automated optical inspection (AOI) and X-ray testing. These tools find problems early, ensuring your boards work well.

Quality Assurance Checklist:

ISO certifications

Verified components

Functional testing

Are US-based PCB assembly providers pricier than overseas ones?

Yes, US providers often cost more due to labor and rules. But they offer faster delivery, better communication, and stricter quality checks. These benefits can make the extra cost worth it for important AI projects.

Note: Compare quotes carefully to see the value of services offered.

How do I meet tight deadlines for PCB assembly?

Choose providers with fast-turn services. Some companies focus on quick prototypes and speedy production. Providers with in-house manufacturing and assembly also save time.

Example Providers:

Sierra Circuits (1-day delivery)

TTM Technologies (scalable production)

Can I grow production with the same provider after prototyping?

Yes, many providers offer scalable services. Companies like Jabil Inc. and Sanmina Corporation can handle both small prototypes and large orders. Their flexible systems make it easy to expand as your project grows.

Tip: Ask about scalability early to avoid switching providers later.

See Also

Top 10 Strategies for Cost-Effective PCBA Assembly Success

Choosing PCBA Manufacturing Services with Cutting-Edge Features

A Comprehensive Guide to PCBA Manufacturing and Assembly