Industrial places need strong printed circuit board assemblies (PCBA) that are vibration-resistant for industrial environments. Machines move a lot, and tough conditions cause strong vibrations. These vibrations can damage parts, break connections, and hurt performance. Research says vibration and shocks cause about 20% of PCB problems. This shows why sturdy designs are important for lasting use. A vibration-resistant PCBA for industrial environments keeps systems working well and stops expensive failures.

Key Takeaways

Vibration-resistant PCBA stops damage caused by constant movement in factories.

Tough designs and materials, like strong laminates, make it last longer.

Testing for vibration and shock finds weak spots and improves safety.

Using vibration-resistant PCBA saves money by cutting repairs and delays.

Industries like aerospace and energy use it to stay safe and work better.

Understanding Vibration Resistance in PCBA

What is vibration resistance?

Vibration resistance means a PCBA can handle shaking forces. These forces come from moving machines, transport, or the environment. A vibration-resistant PCBA stays strong and works well. It prevents parts from breaking or connections from loosening. This keeps the board reliable, even in tough conditions.

In factories, vibrations happen all the time. Machines, motors, and tools create constant movement. Without vibration resistance, these forces can damage the PCBA. Over time, this can cause failures and costly repairs. Strong vibration resistance helps systems run smoothly and last longer.

Importance of vibration resistance for PCBA functionality

Vibration resistance is key to keeping PCBA working properly. Without it, parts can break or stop working. Common problems include broken joints, cracked tracks, and damaged capacitors. The table below shows issues caused by weak vibration resistance:

Type of Failure |

|---|

Damaged capacitors |

Broken joints |

Breakage of board tracks |

PCB delamination |

Broken barrels |

Shocks |

Through-hole cracking in pins |

Fatigue of lead wire |

When these problems happen, the PCBA may fail or work poorly. This can cause downtime, safety risks, and high repair costs. Focusing on vibration resistance avoids these issues and makes PCBA last longer.

A study tested how materials and designs affect vibration resistance. Researchers used five types of hybrid fiber metal laminates (FMLs). They tested them for marine use with impact hammer experiments. Results showed materials like aramid-epoxy improved vibration resistance. Picking the right materials and designs makes PCBA stronger for tough jobs.

Applications of vibration-resistant PCBA in industrial environments

Vibration-resistant PCBA is used in many industries. In factories, it keeps robots and machines running without stopping. In transport, it helps vehicles, trains, and ships stay reliable. In energy, it supports wind turbines, power plants, and oil rigs.

It’s also important in aerospace and defense. Planes and military tools face constant motion and shaking. Without strong PCBA, they can’t do their jobs safely. Using vibration-resistant PCBA improves safety and reliability in many fields.

Challenges in Industrial Environments

Effects of constant motion and mechanical vibrations

Industrial places expose PCBA to nonstop movement and shaking. These forces can weaken solder joints and loosen parts. They can also harm the board’s structure. Over time, this causes problems and system failures. For example, factory machines like conveyor belts create constant vibrations. These vibrations put stress on PCBA and can cause cracks or breaks. Without vibration resistance, these stresses damage the board.

Mechanical stress is a big problem for PCBA in factories. The table below shows key stress factors that affect PCBA:

Stress Factor | Description |

|---|---|

Mechanical | Physical forces that can break the PCBA. |

Thermal | Temperature changes that can weaken materials. |

Electrical | High electrical loads that can harm circuits. |

Chemical | Chemicals that can wear down materials. |

Knowing these stress factors helps make stronger PCBA for tough jobs.

Impact of heavy machinery on PCBA

Big machines in factories create strong vibrations and shocks. Tools like drills and turbines shake a lot and can harm PCBA. These forces can move or break parts on the board. For example, car factories use stamping machines that create strong vibrations. These vibrations can damage nearby electronics.

The size and weight of machines also matter. Bigger machines make stronger vibrations, which increase damage risks. To fix this, use vibration-resistant designs and materials. Strong solder joints and shock-absorbing mounts protect PCBA from harm.

Exposure to harsh conditions like temperature changes and dust

Factories often have extreme temperatures and lots of dust. These conditions can wear out PCBA and shorten its life. Rapid temperature changes, called thermal cycling, can weaken solder joints. Materials may expand or shrink unevenly, causing damage. Testing helps find weak spots in solder joints and materials.

Dust is another big issue. It can build up on PCBA and cause short circuits or overheating. IoT devices used in factories face extra challenges like heat, humidity, and dust. Testing ensures these devices stay reliable. Solving these problems makes PCBA last longer and work better in tough places.

Risks of Weak Vibration Resistance

System failures and downtime

Weak vibration resistance can cause systems to fail often. This stops work and costs a lot to fix. Machines and the environment create vibrations that harm solder joints and parts. Over time, this stress damages the PCBA. For example:

Too much bending can crack copper lines and solder spots.

Vibrations can weaken solder joints, causing cracks and breaks.

Shaking or shocks can knock parts loose, lowering their performance.

When these problems happen, systems stop working right. This pauses production and raises repair costs. Using vibration-resistant designs can prevent these issues.

Shorter life of PCBA parts

Vibrations wear out PCBA parts faster, making them fail sooner. Strong vibrations cause damage that ages the board quickly. Tests show vibrations speed up how fast parts break down. Without good vibration resistance, PCBA may fail early. Using strong materials and designs helps systems last longer and work better.

Safety risks in important industries

In fields like aerospace, defense, and energy, weak vibration resistance is dangerous. Vibrations and shocks can break solder joints or leads, causing system failures. Parts like relays and oscillators are at high risk. Vibrations near a board’s natural frequency can make damage worse. This raises the chance of big failures. Strong vibration resistance keeps equipment safe and protects lives.

Benefits of Vibration-Resistant PCBA for Industrial Environments

Stronger and More Reliable

Vibration-resistant PCBA is built to last in tough places. Techniques like conformal coating and staking make it stronger. Conformal coating protects the board from dust, water, and heat changes. Staking keeps parts tightly in place, stopping them from moving. These steps make equipment more reliable and less likely to break.

A strong PCBA lasts longer. Parts stay in place, and connections don’t fail. This keeps systems working well for a long time. In fields like aerospace and energy, this is very important. Equipment failure in these areas can cause big problems. A vibration-resistant design helps systems work smoothly, even in hard conditions.

Steady Performance in Tough Conditions

Factories and other places have strong vibrations and shocks. Vibration-resistant systems stay steady and work well in these situations. Tests like vibration and shock testing check how strong the board is. For example:

Test Type | Purpose |

|---|---|

Checks if solder joints and parts stay strong. | |

Mechanical Shock Testing | Tests if the board can handle sudden hard hits. |

These tests show the board can handle constant shaking and sudden impacts. Standards like MIL-STD-810 prove the board works in real-world tough conditions. With these features, your systems stay reliable even under stress.

Saving Money with Less Fixing and Replacing

Vibration-resistant PCBA saves money by needing fewer repairs. Strong boards break less often, so there’s less downtime. For example, vibration-resistant systems in factories run longer without needing fixes. This saves money over time.

Using better materials and designs also helps the board last. Problems like broken solder joints or damaged parts happen less. This means you don’t have to replace parts or systems often. In the end, vibration-resistant PCBA is a smart way to save money and keep things running well.

Achieving Vibration Resistance in PCBA

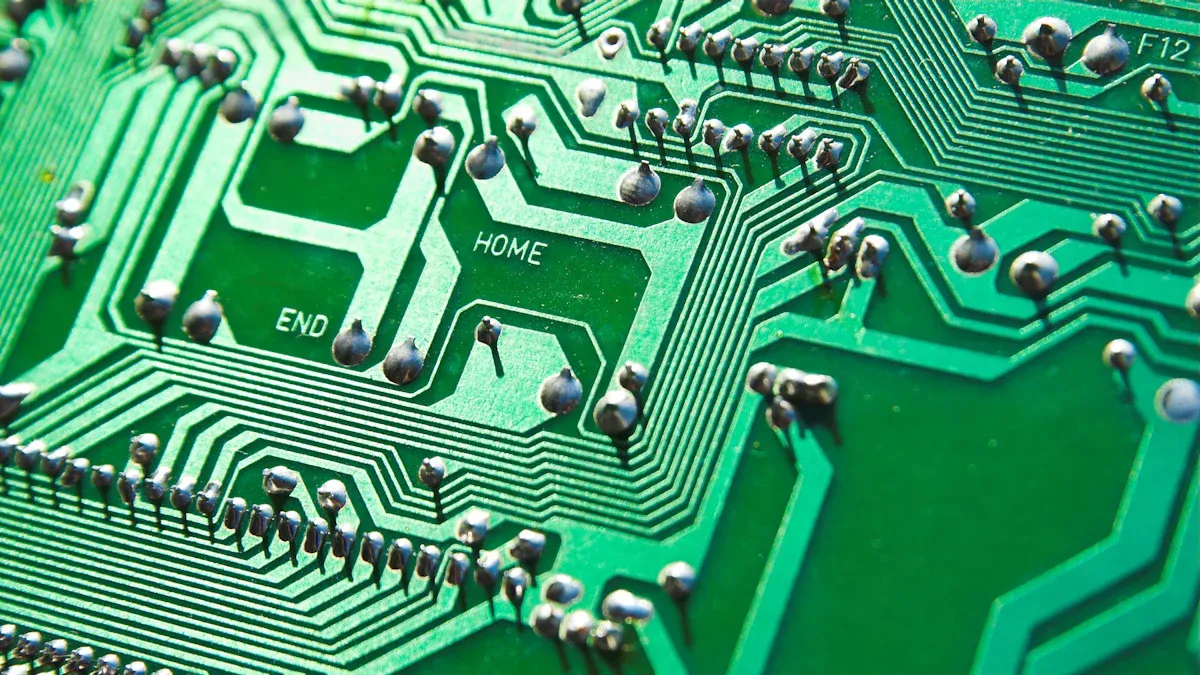

Effective design strategies for vibration resistance

To make PCBAs handle vibrations, smart design is key. Flexible circuits are a good choice. They bend and absorb vibrations without breaking. Adding strain relief stops sharp bends that can weaken parts. Following vibration and shock standards ensures the design works in real-world situations.

Engineers use rounded corners and curved lines to spread out stress. This lowers the chance of cracks or bending. Placing similar-sized parts together reduces stress during assembly. Coatings protect boards from water and shaking. Stiffeners add strength to thin or bendable designs.

Finite element analysis (FEA) is a helpful tool. It shows where stress might harm the board. Fixing these weak spots early makes the design stronger for tough conditions.

Tip: Using vibration-proof computers adds extra stability for important tasks.

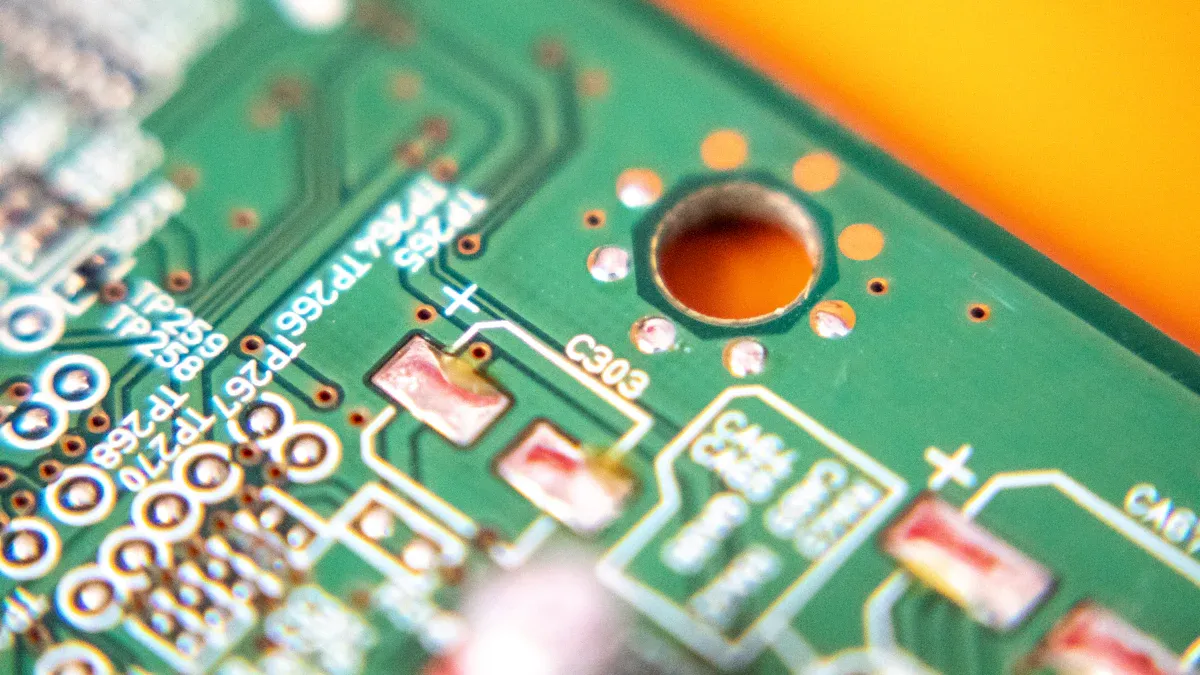

Role of material selection and component placement

Choosing the right materials is very important. High-Tg laminates, which handle heat above 150°C, stop layers from peeling and last longer. Moisture-resistant coatings, like acrylic or silicone, protect against rust and damage. These materials help PCBAs survive heat changes and shaking.

Where parts go on the board also matters. Grouping similar-sized parts reduces stress during use. Putting heavier parts in the middle lowers vibration effects. Shock-absorbing mounts protect delicate parts even more.

Testing checks if these choices work. Sinusoidal tests copy repeated shaking, while random tests cover many vibration types. Shock tests see if the board can handle sudden hits. These tests make sure the board is ready for tough jobs.

Evidence Type | Description |

|---|---|

Material Selection | High-Tg laminates (> 150°C) stop peeling and improve strength. |

Coating Recommendations | Moisture-resistant coatings prevent rust and damage. |

Vibration Testing | Checks if the board handles shaking during use. |

Sinusoidal Vibration Test | Copies repeated shaking, like in cars. |

Random Vibration Test | Tests many vibration types to match real-life situations. |

Shock Testing | Sees if the board survives sudden hard hits. |

Importance of vibration testing and industry standards

Testing for vibrations is crucial to ensure PCBAs work well. It checks if the board can handle shaking and shocks during transport and use. Environmental tests also check how the board performs with heat, cold, and moisture. These tests find weak spots to fix before use.

Following standards like MIL-STD-810G is important. This standard includes tough vibration and shock tests. It proves the board can work in harsh places. Aerospace companies using advanced tests have fewer problems. Car makers investing in vibration tests report better reliability.

Meeting these standards helps create strong, anti-vibration systems. These systems last longer and need fewer repairs, saving money.

Note: Following MIL-STD-810G builds trust in your product’s ability to handle tough conditions.

Vibration-resistant PCBA is important for keeping systems safe and reliable. It prevents breakdowns, reduces delays, and keeps things running smoothly. Using tests like vibration and shock testing finds problems early. Fixing these issues improves how well systems work over time.

Aspect | Description |

|---|---|

Makes sure PCBAs work well in different conditions. | |

Saving Money | Finding problems early lowers repair and recall costs. |

Safety | Stops failures that could cause dangerous situations. |

Happy Customers | Reliable products make customers trust and like your brand. |

Following Rules | Meets strict rules for safety and product reliability. |

Choosing vibration-resistant PCBA helps avoid risks and ensures success in tough jobs.

FAQ

What helps a PCB resist vibrations?

A vibration-resistant PCB uses strong materials and smart designs. Engineers add coatings and mounts to protect it in tough places.

Why is vibration resistance important in factories?

Machines in factories vibrate a lot and can harm PCBs. Vibration resistance keeps systems working well and lasting longer.

How do engineers check a PCB for vibration strength?

They test it with vibration and shock experiments. These tests show if the PCB can handle shaking in real-life situations.

Can vibration-resistant PCBs lower repair costs?

Yes, they prevent damage from vibrations, so repairs are needed less. This saves money and reduces downtime in factories.

Which industries need vibration-resistant PCBs the most?

Industries like aerospace, cars, energy, and factories use them. These fields need reliable systems in tough conditions.

See Also

Understanding PCBA Manufacturing Skills Essential for Electronics Design

The Significance of PCBA Cleanliness for Dependable Performance

Defining PCBA Manufacturing and Its Critical Importance

Exploring PCBA Services and Their Role in Electronics Production