Think about having all your circuit board needs done by one company. Turnkey PCBA services make this easy with a one-stop solution. They handle everything like design checks, finding parts, assembly, testing, and shipping. This makes the process simple and gives you a great product.

A turnkey provider does it all, so you don’t need to work with many companies. With a full turnkey service, they save you time and make things less stressful. This kind of service is perfect if you want fast and dependable results in one place.

Key Takeaways

Turnkey PCBA services make production easier by managing everything. They handle design, parts, assembly, testing, and shipping in one place.

These services help save money by cutting costs. They avoid using many vendors and buy parts in bulk.

Turnkey services save time so you can focus on other work. They also help deliver products to market faster.

Quality is important, with strong testing to ensure products work well and meet high standards.

Turnkey providers are flexible, making it simple to adjust designs or schedules without big delays.

Benefits of Turnkey PCBA Services

Cost Efficiency

Turnkey PCB assembly helps save money by combining all tasks. You don’t need to work with many vendors for design, parts, or assembly. This simple process lowers extra costs and avoids hidden fees.

Companies like TechInnovate saved 23% on costs after six months of using turnkey services.

Turnkey providers buy parts in bulk, getting better deals, which saves you money.

Also, you avoid problems like miscommunication or delays from using multiple suppliers. This keeps your budget steady and easy to manage.

Time Savings

Time is very important in making products. Turnkey PCBA services save time by handling every step for you. They take care of finding parts, assembling, and testing the product. You don’t have to manage different schedules or vendors.

With turnkey services, you can focus on other business tasks while they deliver on time. Faster production means you can sell your product sooner and stay ahead of competitors.

Quality Assurance

Turnkey PCB assembly focuses on quality at every step. Providers use advanced tests to make sure your product is top-notch.

What It Does | |

|---|---|

Automated Optical Inspection (AOI) | Looks for correct soldering and part placement. |

X-Ray Inspection | Checks hidden solder joints for BGA parts. |

Functional Testing | Makes sure the PCB works as planned. |

Burn-In Testing | Tests the board in real-life conditions to find flaws. |

Providers also do:

First Article Inspection to check the first batch meets your needs.

In-Circuit Testing (ICT) to find shorts, opens, and check part placement.

Functional Testing to test performance in real-world situations.

These strict quality checks reduce errors and ensure your product works well. Choosing turnkey services means your PCBs are reliable and built to last.

Streamlined Processes

Turnkey PCB assembly makes production much easier. You don’t need to work with many vendors or handle separate tasks like finding parts, building boards, and testing. Everything is done in one place, making the process smooth and simple.

Here are some important benefits of turnkey services:

Lead Time: Turnkey services finish assembly faster, so products arrive quickly.

Quality Control: Tests like Automated Optical Inspection (AOI) and Functional Testing ensure high-quality products.

Cost Control: The streamlined process cuts extra costs while keeping quality high.

Choosing turnkey PCB assembly gives you an easier production process. The provider takes care of everything, so you can focus on growing your business instead of managing small details.

Faster Time-to-Market

Speed matters in today’s market. Turnkey PCB assembly speeds up product development, helping you launch electronics faster. With one provider handling everything, you avoid delays from miscommunication or coordination problems.

The table below shows how turnkey services help you launch faster:

Evidence Type | Description |

|---|---|

Turnkey assembly shortens development time for quicker launches. | |

Streamlined Process | A single system reduces delays and errors from multiple vendors. |

Cost Efficiency | One manufacturer ensures steady quality and saves money. |

Flexibility | Turnkey services adjust to changes without big delays. |

Optimization | Processes are improved to bring products to market faster. |

Working with a turnkey provider lets you change designs or schedules easily. This flexibility helps your product reach customers faster, giving you an advantage. Turnkey PCB assembly not only saves time but also makes production more efficient.

The Turnkey PCB Assembly Process

PCB Manufacturing

The first step is making the printed circuit board (PCB). This is the base that holds all the electronic parts. Manufacturers use advanced tools to make sure the board is accurate and reliable. They design the layout based on your needs. Then, they use materials like fiberglass and copper to make a strong and conductive board.

Turnkey providers aim for high-quality boards with fewer defects. The table below shows how turnkey methods compare to traditional ones:

Metric | Quick Turn PCB | Traditional PCB |

|---|---|---|

First Pass Yield | 95-98% | 98-99% |

Defects Per Million Opportunities (DPMO) | 500-1000 | 50-500 |

Customer Return Rate | <1% | <0.5% |

Traditional methods may have slightly better numbers in some areas. However, turnkey services are faster and more convenient. Choosing turnkey ensures your boards are made with care and precision.

Component Sourcing

After the PCB is made, the next step is getting the parts. Turnkey providers take care of finding all the components needed. This saves you from dealing with many suppliers. They work with trusted vendors to get high-quality parts at good prices.

Turnkey providers buy in bulk, which lowers costs. They also check each part to make sure it’s real and not fake. This guarantees your product meets standards and works well. By letting the provider handle this step, you can focus on other parts of your project without worrying about delays or bad parts.

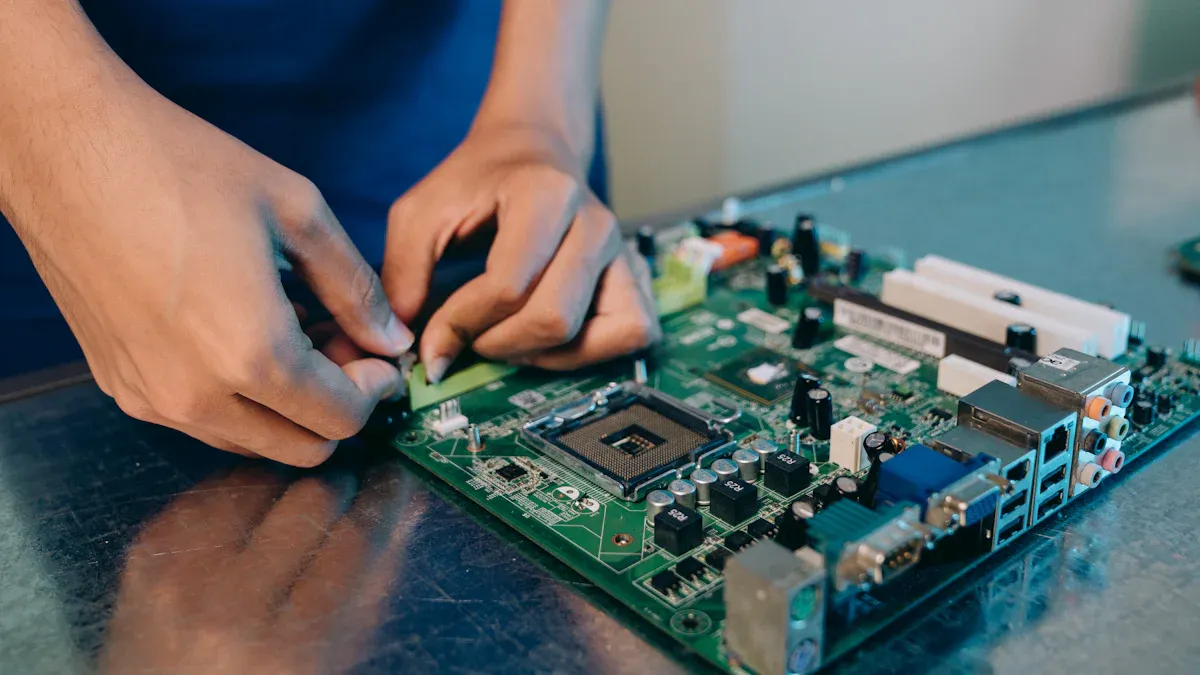

Assembly

The final step is putting everything together. Turnkey providers use machines to place parts on the board accurately. Robots like pick-and-place machines ensure every part is in the right spot. After that, soldering secures the parts to the board.

During assembly, providers run checks to catch mistakes. Automated Optical Inspection (AOI) looks for problems like misplaced parts or bad soldering. Functional testing makes sure the board works as it should. These checks ensure your product is reliable and ready to use.

By using a turnkey provider, the whole process becomes easier. They handle everything from start to finish and deliver a fully assembled product to you.

Testing and Quality Control

Testing and quality checks are very important in turnkey PCB assembly. These steps make sure your product works well and meets high standards. Turnkey providers use smart tests to find problems early and keep quality steady.

Some key testing methods include:

Automated Optical Inspection (AOI): Finds mistakes like wrong soldering or misplaced parts.

X-Ray Inspection: Looks at hidden solder joints, especially in tricky parts like BGAs.

Functional Testing: Checks if the PCB works properly in real-life situations.

Burn-In Testing: Puts the board under tough conditions to spot weak points.

Turnkey providers also do First Article Inspections (FAI) to confirm the first batch matches your needs. This step helps catch mistakes before making more products. They also use In-Circuit Testing (ICT) to find electrical problems like shorts or open circuits.

The success of these checks is shown in these numbers:

Metric | Rate |

|---|---|

PCB Manufacturing Pass Rate | |

PCBA Manufacturing Pass Rate | >99% |

On-Time Delivery | >98% |

Customer Satisfaction | >95% |

First Article Inspection Approval Rate | >98% |

These high rates show how reliable turnkey PCB assembly is. Picking a turnkey provider means your product will meet strict quality rules.

Packaging and Shipping

After testing, the last step in turnkey PCB assembly is packaging and shipping. Turnkey providers pack your products safely to avoid damage during delivery. Good packaging keeps your PCBs in perfect condition.

They use materials like anti-static bags, bubble wrap, and custom boxes to protect your items. Clear labels on packages make shipping easier and reduce mistakes or delays.

Turnkey providers also work with trusted carriers for fast delivery. Here’s how long major shipping methods usually take:

Shipping Method | Delivery Time (Business Days) |

|---|---|

DHL | |

UPS | 3-7 |

TNT | 4-9 |

FedEx | 4-7 |

With these options, you get your products quickly and meet deadlines. Providers also offer tracking, so you can see where your shipment is. This helps you plan better and feel confident.

By managing packaging and shipping, turnkey providers make things easier for you. You can focus on your work while they ensure your products arrive safely and on time.

Turnkey PCBA Services vs. Consigned Assembly

Key Differences

Turnkey and consigned assembly handle production differently. Turnkey providers do everything, like buying parts, testing, and shipping. You only need to give them the design files. In consigned assembly, you supply the parts, and they only assemble and test.

Here are some main differences:

Turnkey services save money by buying parts in bulk at lower prices.

Turnkey providers speed up production, so products are ready faster.

They also check quality at every step, reducing product defects.

Consigned assembly works better if you already have parts or want control over sourcing. But it takes more time and effort to manage.

Advantages of Turnkey PCBA

Turnkey PCB assembly has many benefits for businesses. First, it makes production easier. You don’t need to deal with many vendors or find parts yourself. The provider does it all, saving you time and stress.

Second, turnkey services help you save money. Providers get discounts on parts because they buy in bulk. This lowers your costs. Plus, fewer mistakes mean you spend less on fixing problems.

Third, turnkey providers focus on quality. They use tests like Automated Optical Inspection (AOI) to ensure your product works well. This makes your product more reliable and less likely to fail.

When to Choose Consigned Assembly

Consigned assembly is a good choice in certain cases. If you already have parts or want to use your own inventory, this option gives you control. It’s helpful if you need special or rare parts that turnkey providers might not have.

You might also pick consigned assembly if you’re on a tight budget and don’t want a full-service option. But remember, this method needs more work from you. You’ll have to buy parts and make sure they arrive on time for assembly.

Turnkey PCBA services make PCB production simple and efficient. They combine design, manufacturing, and testing into one easy process. This saves time, cuts costs, and ensures great quality. For instance, buying parts in bulk lowers costs, and automation reduces labor expenses.

Cost Factor/Strategy | How It Saves Money | How It Saves Time | How It Improves Quality |

|---|---|---|---|

Buying Parts in Bulk | Saves money by getting discounts | N/A | N/A |

Testing for Quality | Ensures reliability, avoids costly mistakes later | N/A | Prevents product failures |

Using Automation | Lowers labor costs, speeds up work | N/A | N/A |

This all-in-one method lets you focus on creating new ideas. You also get faster delivery and dependable results. Turnkey PCBA services make production easier, helping businesses improve efficiency and product quality.

FAQ

What files are needed to begin a turnkey PCBA project?

You must give design files like Gerber files, a Bill of Materials (BOM), and assembly drawings. These files show the provider what you need for accurate production.

💡 Tip: Check your files for mistakes before sending them to avoid delays.

How long does it take to complete a turnkey PCBA project?

The time depends on how complex your project is and the order size. Most providers finish in 2-4 weeks. Some offer faster options for quicker delivery.

🚀 Note: Ask about lead times when you first talk to your provider.

Can small production runs be done with turnkey PCBA services?

Yes, many providers handle small-batch production. This is great for startups or testing prototypes. You can increase production later if needed.

Are turnkey PCBA services good for custom designs?

Yes! Turnkey providers are experts in custom designs. They adjust the process to match your needs, making sure your product fits your vision.

How do turnkey providers make sure components are real?

Turnkey providers buy parts from trusted suppliers. They also check the parts to ensure they are real and not fake.

✅ Pro Tip: Pick providers with ISO certifications for extra trustworthiness.

See Also

Understanding Turnkey PCB Assembly And Its Importance

The Significance Of PCBA Services In Electronics Production

Exploring The Uses And Advantages Of PCBA Today