You might wonder, what is a PCB and how does it differ from a PCBA? A printed circuit board, or PCB, is essentially the skeleton of an electronic device. It provides shape and support but cannot function on its own. When electronic components are mounted on the PCB, it becomes a PCBA, enabling the board to perform specific tasks like a working system. According to the Global PCB & PCBA Market Research Report 2025, the production of both PCBs and PCBAs is increasing worldwide. Understanding what a PCB is and how it differs from a PCBA can help you make informed decisions in electronics manufacturing. Here’s a simple comparison:

Aspect | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

Definition | Bare, unpopulated board providing electrical connections | Populated PCB with electronic parts, creating a functional circuit |

Function | Mechanical support and electrical pathways for components | Performs specific electronic functions |

Components | None (empty board) | Includes all necessary electronic parts (resistors, capacitors, ICs, etc.) |

Key Takeaways

A PCB is just the board. It holds and connects parts. It cannot work by itself. A PCBA is a PCB with all parts added. The parts are soldered on. This makes it a working circuit.

Making a PCB means building the board. It has copper paths and layers. PCBA assembly adds parts to the board. It uses methods like SMT and THT. The finished board is then tested.

You pick PCB or PCBA based on your project. Use a PCB for the base design. Use a PCBA for a device that works right away.

Design choices can change cost and quality. Material, layer count, and part selection matter. Using standard materials saves money. Simple designs make production faster.

PCB and PCBA are used in many industries. They are important for things like electronics and medical devices. Knowing their roles helps you choose better for your projects.

Definitions

What is a PCB

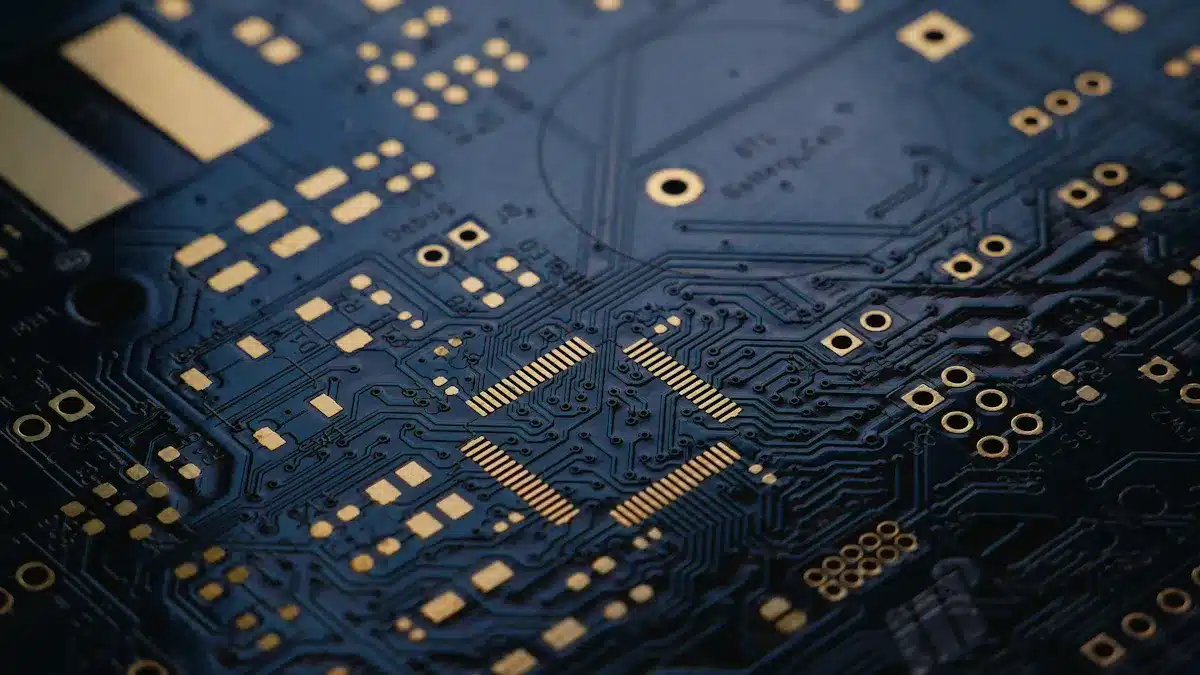

If you ask what a pcb is, think of it as the skeleton inside electronics. A printed circuit board is thin and flat. It is made from fiberglass or resin-bonded paper. The board has copper tracks on top. These tracks are like tiny roads. They guide electricity to different places. The main job of a pcb is to hold parts and connect them with electricity. You cannot make electronics without a printed circuit board.

A pcb often has many layers. The core, called the substrate, makes the board strong. Copper foil forms the paths for signals. Other layers, like solder mask and silkscreen, protect the board. They also help you know where to put parts. Each printed circuit board is made for a special use. The design and layers can change for each device.

Imagine a pcb as the base of a house. It holds everything together and connects all the rooms. But it cannot be a home until you add things inside.

Here is a table that shows the main layers and materials in a circuit board:

Layer/Material | Description | Function/Role |

|---|---|---|

Core (Substrate) | Solid base, usually FR-4 | Holds the copper traces and gives support |

Copper Foil | Thin copper sheets | Makes paths for signals and power |

Prepreg | Soft insulation | Sticks layers together and keeps out moisture |

Signal Plane | Copper inside the board | Carries signals |

Power Plane | Copper inside the board | Sends power |

Ground Plane | Copper layer | Keeps voltage steady and blocks noise |

Solder Mask | Protective cover | Stops rust and keeps solder in place |

Silkscreen | Printed labels | Shows where parts go and helps you find connections |

What is a PCBA

Now let’s see what happens when you add parts to a pcb. This is called a printed circuit board assembly, or pcba. A pcba is a pcb with all the needed parts, like resistors, capacitors, transistors, and integrated circuits, put on and soldered. When this is done, the board can work in a device.

You can think of a pcba as the body that works, not just the skeleton. The pcb gives shape, but the parts make it do things. Making a printed circuit board assembly means putting each part in the right spot. Then you connect it to the copper tracks. This can be done with Surface Mount Technology (SMT). Machines put small parts right on the board. Or it can be done with Through-Hole Technology (THT). Parts with wires go through holes and get soldered on the other side.

Here are some parts you will see on a pcba:

Resistors

Capacitors

Transistors

Diodes

Integrated Circuits (ICs)

Paths and pads for connections

A pcba is ready to do its job in a device. It can power a phone, run a washing machine, or control a robot. The printed circuit board assembly is the finished product that makers use in all electronics.

Printed Circuit Board Functions

A printed circuit board does more than just hold parts. It has many important jobs in every electronic device. Here are the main things a circuit board does:

Core Function | Explanation |

|---|---|

Mechanical Support | Holds parts in place and keeps them safe. |

Electrical Connections | Makes paths for signals between parts. |

Signal & Power Transmission | Lets current and signals move so parts can work together. |

Circuit Organization | Puts lots of circuits in a small space with layers. |

Heat Dissipation | Moves heat away from parts to keep them safe and working. |

You can see that the pcb is like the backbone and nerves of electronics. It connects all the parts and helps them work together. But the pcb alone cannot do anything. You need to add parts and make it a pcba. The pcba is what makes the printed circuit board work and lets it do its job.

Assembly Process

PCB Manufacturing

First, you make a pcb design. Special software helps you draw the layout. You send this design to the factory. The process starts with your design.

You make the pcb design and save it as Gerber.

The factory prints your design onto photo films.

Photoresist goes on the board. UV light shows the circuit pattern.

Chemicals take away extra copper. Only needed paths stay.

The factory removes leftover photoresist.

Machines check and line up the layers.

Heat and pressure stick the layers together.

Computer drills make holes for parts.

Copper covers the holes and board surface.

The outer layers get their circuit patterns.

The factory removes unwanted copper from outside layers.

A protective layer covers the pcb.

Gold or silver plating helps with soldering.

Labels and markings are printed on the board.

The pcb is tested to find errors.

Quality checks happen at every step. Machines use cameras, X-rays, and tests to find problems early.

PCBA Assembly

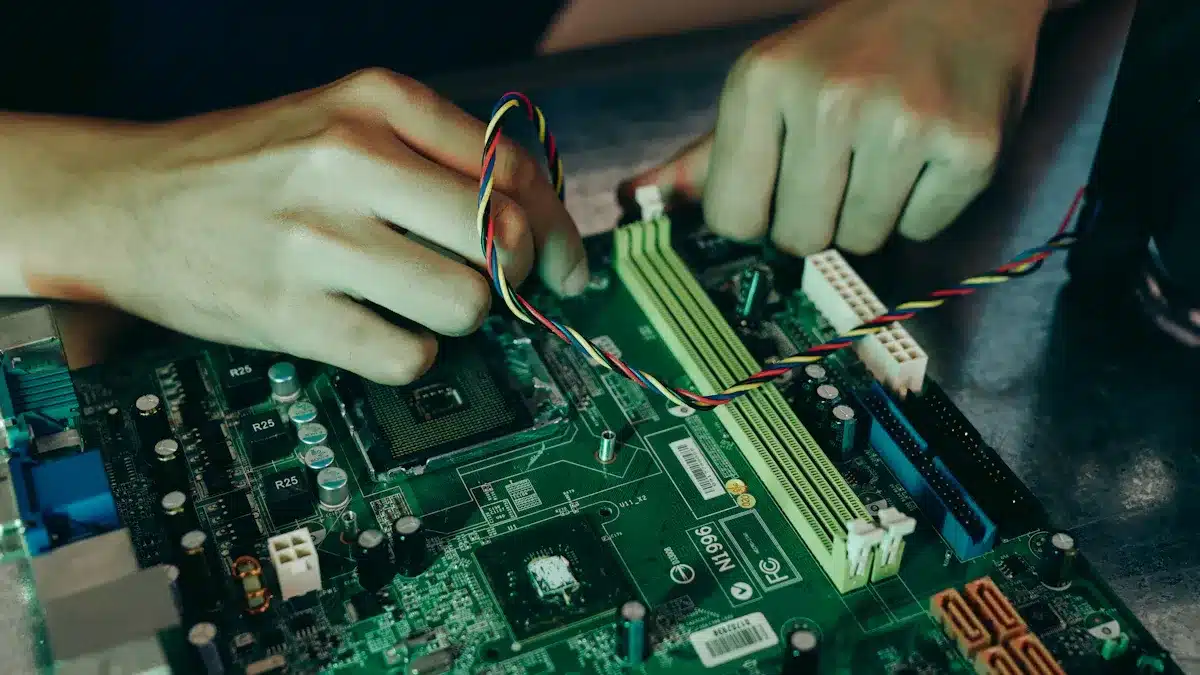

The assembly process turns your pcb into a working device. First, you put solder paste on the pads. Machines place parts onto the board. The pcb goes through a hot oven. The solder melts and connects the parts.

Next, you check the board. You use manual checks, cameras, and X-rays. If there are through-hole parts, you put them in. You use wave soldering or hand soldering. Last, you test the board. You make sure the pcb assembly works right.

Here are the main ways to assemble:

Description | Key Characteristics | |

|---|---|---|

Surface Mount Technology (SMT) | Puts parts on top and uses hot solder. | Fast, uses machines, fits many parts. |

Through-Hole Technology (THT) | Puts wires through holes and solders them. | Strong, good for big parts. |

Uses both SMT and THT. | Flexible, balances speed and strength. | |

Ball Grid Array (BGA) | Uses solder balls for tight connections. | Advanced, needs careful checking. |

Key Differences

PCB manufacturing makes the empty board. It is strong and has copper paths. There are no parts yet. PCBA assembly adds all the parts. Now the board can work.

PCB manufacturing uses chemicals, layers, drills, and copper to build the board.

PCBA assembly gets parts, puts them on, solders, and tests.

PCB is just the base. PCBA is the finished, working board.

Moving from pcb to pcba makes production faster. You can buy parts and build boards at the same time. Machines like SMT help you build boards quickly. This lets you go from test boards to full production fast.

Comparison

PCB vs. PCBA Table

You can find the main differences between a pcb and a pcba in this table. The table lets you compare how they are built, what they do, and how they are made.

Aspect | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

Definition | Bare board made from non-conductive stuff. It has copper lines, solder mask, and silkscreen. There are no parts on it. | PCB with all electronic parts put on and soldered. It is now a working assembly. |

Functionality | Gives support and paths for electricity. It cannot do electronic jobs by itself. | Does electronic jobs like signal work, power control, and talking to other devices. |

Complexity | Simple design with copper lines and layers that protect. | More complex because it has resistors, capacitors, ICs, and other parts. |

Manufacturing Process | Needs layout design, copper etching, drilling, and adding solder mask and silkscreen. | Needs putting on parts, soldering (SMT, THT, BGA), checking, and testing. |

Components | No electronic parts, just the board. | Has all the electronic parts needed for the device to work. |

Cost | Costs less because it is only the board. | Costs more because of parts, assembly work, and testing. |

Applications | Used as the base for building circuits. It cannot work alone. | Used in finished things like phones, computers, and medical tools. |

Testing | Checked for physical and electrical problems. | Tested to see if it works, using AOI, X-ray, and live tests. |

Tip: If you look at a pcb, you only see the base. If you look at a pcba, you see the finished, working part of your device.

Main Differences

Here is a simple list to show how a pcb and a pcba are not the same. Look at their structure, what they do, and how they are made.

A pcb is made of copper layers and material that does not conduct electricity. It gives paths for signals but has no parts.

A pcba is a pcb with all the electronic parts put on and soldered. It is now a full, working circuit.

Making a pcb means building the board with copper lines, holes, and layers that protect. You work on the design and layout here.

Making a pcba starts after the pcb is done. You add parts using SMT, THT, or BGA. Then you solder and test it.

The biggest change between pcb and pcba happens when you add the parts. The plain board turns into a working pcba when you connect everything.

A pcb is easier and costs less. You use it as the starting point for your design. A pcba is harder and costs more because it has all the parts and needs careful work and testing.

Checking a pcb means looking for physical and electrical problems. Checking a pcba needs more tests, like optical checks, in-circuit tests, and live tests.

You use a pcb as the base to build circuits. You use a pcba in finished products, from simple calculators to advanced smartphones.

Note: If you want just the base for your design, pick a pcb. If you need a ready-to-use, working part for your device, pick a pcba.

The pcb is like the skeleton for your electronics project. The pcba is the working body, ready to power your devices. Knowing these differences helps you make better choices when you design, build, or buy electronics.

Applications

PCB Uses

You can find a pcb in almost every electronic device. The circuit board is the base that holds all the parts. Many things use pcb technology:

Communications devices like smartphones, tablets, smartwatches, and radios

Computers such as desktops, laptops, and screens

Entertainment systems like televisions, video game consoles, and stereos

Home appliances such as refrigerators, microwaves, and coffee makers

Recording devices like camcorders, digital cameras, and microphones

A pcb gives your project a strong base. You can make different designs for each device. The circuit board helps you put parts in order and connect them with copper lines. Picking the right pcb is important for your project to work well.

PCBA Uses

A pcba is a pcb with all the parts added. This makes the board work inside your device. You see pcba technology in many areas because it can do hard jobs. Here are some places where you find it:

Cell phones, laptops, and smartwatches

TVs, remotes, and smart home devices

Medical devices like heart monitors and diagnostic tools

Automotive systems such as navigation, safety, and engine control

Industrial machines and automation equipment

You need a pcba to make your design work. The assembly puts each part in the right place. The finished board can handle power, signals, and control. You should match your design to the right assembly for the best results.

Industry Examples

Both pcb and pcba are used in many industries. The circuit board starts as a blank base. The assembly adds all the parts to make it work. Here is a table that shows real-world uses for both:

Industry Sector | Examples of Products Using PCBs/PCBAs |

|---|---|

Automotive | Engine control systems, audio systems, digital displays, radar, ABS, LED lighting, navigation units |

Aerospace | Lighting, power supply equipment for satellites, communication and monitoring equipment |

Consumer Electronics | Smartphones, computers, televisions, kitchen appliances like blenders and coffee makers |

Medical | Heart monitors, CT scan systems, ultrasonic devices, blood pressure monitors, MRI scanners |

Military | Temperature sensors, targeting systems, automation networks, control tower systems, power supplies |

LED Lighting | LED bulbs using metal core pcbs for heat dissipation in automotive indicators, medical examination lights, telecom |

You can see that pcb and pcba are used in many real products. Each industry needs special designs and ways to put the boards together. Picking the right parts and layout helps your board last longer and work better.

Tip: When you plan a project, think about your design, the type of circuit board, and how you put on the parts. The right mix helps your product work better in real life.

Cost and Design

PCB Cost Factors

When you make a pcb, you must think about what changes the price. The material you pick is very important. Some boards use FR4, but others need special stuff for heat or high-frequency jobs. The number of layers in your pcb also matters a lot. More layers mean more work and higher prices. The size and shape of your pcb can change the cost, too. Big or strange-shaped boards use more material and take longer to make.

Here is a table to show what changes pcb cost:

Factor | Impact on Cost | Description |

|---|---|---|

Material Selection | High | Different substrates and thicknesses change price |

Layer Count | High | More layers add complexity and material |

Board Size & Shape | Moderate to High | Larger or complex shapes use more resources |

Trace Width & Spacing | High | Finer features need advanced process |

Surface Finish | Moderate | Special finishes like ENIG cost more |

Assembly Complexity | Moderate to High | More components and placement raise cost |

Delivery Time | Moderate | Rush orders cost extra |

Lot Size | Significant | Bigger runs lower per-unit cost |

Inspection & Testing | Moderate | More quality checks add to cost |

You can see that every part of making a pcb, from start to finish, changes the price.

PCBA Cost Factors

The price of a pcba depends on many things. The number and kind of parts you use matter most. Expensive chips or rare parts make the cost go up. The way you put the board together also changes the price. SMT is faster and cheaper for big jobs, but THT needs more work by hand. If you add special steps like coating or memory flashing, the price gets higher.

You also pay for machine time, setup, and tools. Labor costs go up if your design needs careful hand work. Testing and checking the board adds to the total, but helps you get better quality. The materials you pick, like the type of solder or coating, change the price too.

Component count and type: More parts and tricky packages cost more.

Assembly method: SMT is cheaper for big runs, THT costs more for hand work.

Special processes: Coating, flashing, or extra tests raise the price.

Tooling and setup: Stencils, jigs, and fixtures add to the cost.

Labor and machine time: More steps mean higher prices.

Material selection: Good but cheap materials help save money.

Testing and inspection: More checks mean better quality but higher cost.

You can save money on pcba by picking common parts and easy steps.

Design Choices

Your design choices change both pcb and pcba prices. You can save money and get better boards by following smart tips. Try to use normal materials and do not add extra layers unless you need them. Keep your trace paths simple and neat. Only ask for special finishes or tight rules if your project really needs them.

Here are some tips to help you:

Use standard materials like FR4 for most pcb jobs.

Keep the number of layers low for easy circuits.

Pick common parts for easy building and lower cost.

Put parts in a good order to help assembly.

Make trace spacing good so the pcb is smaller and easier to make.

Test your design with a prototype before making many.

Talk to your manufacturer early to find ways to save money.

Order in big amounts when you know your design works well.

Tip: Good design helps you get better boards, faster builds, and lower prices. Always think about how to make and build your board when you start your design.

When you look at pcb and pcba, pcb is like the skeleton. Pcba is the body with all its parts. You should pick the right assembly for your project. If you only need the base, pcb is enough. If you want a working product, choose pcba with all the parts. Always check your design and pick good suppliers. Make sure your assembly is high quality. As technology gets better, pcb and pcba will use smarter parts and designs. Your project will do well if you focus on the right assembly, design, and parts for what you need.

FAQ

What is the main purpose of assembly in electronics?

Assembly puts all the parts onto the board. This changes the board from simple to useful. Each part must go in the right place. The parts need to work together as a team.

How do you choose the right components for your assembly?

First, think about what your design needs. Choose parts that fit your device’s job and size. Good suppliers help you get strong parts. Make sure the parts fit your board and work well together.

Why does assembly quality matter for pcba?

Good assembly makes your pcba last longer and work better. Using the right parts and steps means fewer problems. Careful work also keeps your device safe and strong.

Can you reuse components from an old assembly?

You can sometimes use old parts if they are not broken. Take them off the old board with care. Test each part before using it again. Reusing parts saves money, but always check if they still work.

What steps help you avoid mistakes in assembly?

Begin with a clear plan and a list of parts. Use checklists while you build. Check your work at each step to find mistakes early. Teach your team to handle parts gently. Good planning and careful work help your assembly go well.

See Also

Understanding How PCBA Differs Functionally And Structurally From PCB

Key Distinctions Between PCB And PCBA In Electronic Production

Unveiling The Lesser Known Differences Between PCBA And PCB