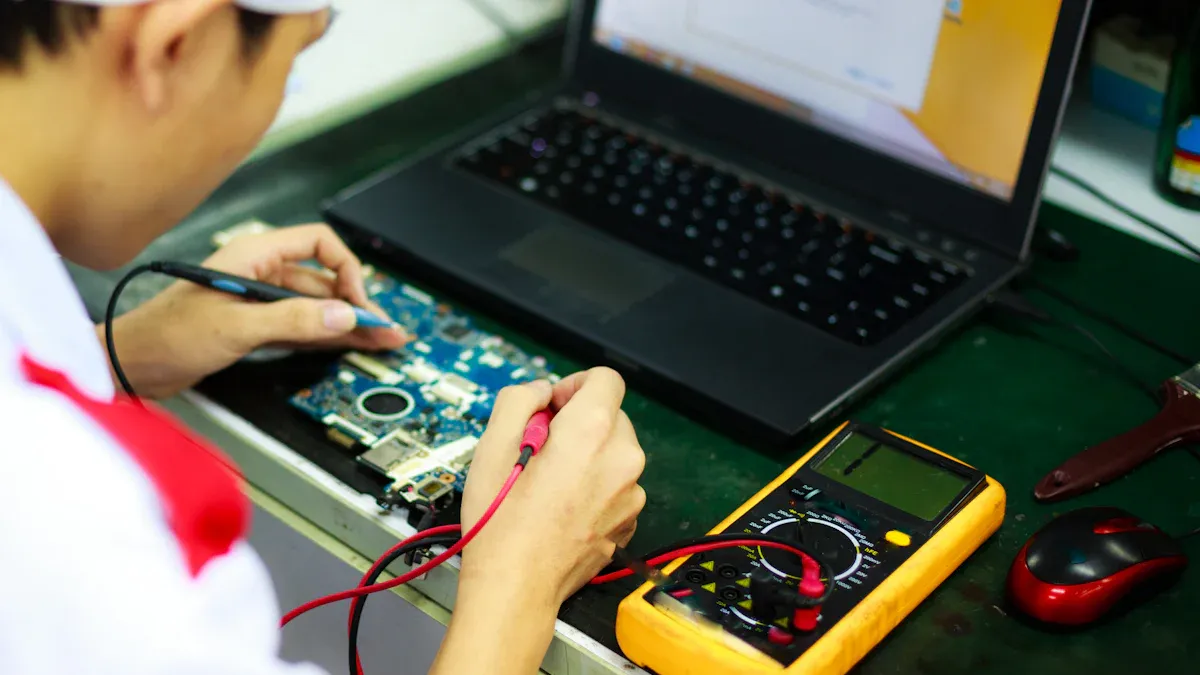

A PCBA tester ensures that a circuit board functions properly by simulating real-life conditions to verify its performance. This process helps identify issues early, such as design flaws or manufacturing errors, before mass production begins. With the growing demand for flawless products, precise tools like PCBA testers play a crucial role in guaranteeing reliability and proper functionality in your product.

Key Takeaways

PCBA testers check if circuit boards work by mimicking real-life use. This helps find design problems early.

Tests like In-Circuit Testing and Functional Testing are important. They find problems, make products more reliable, and lower production costs.

PCBA testing makes customers happy by ensuring products are high-quality. This means fewer returns and complaints.

Environmental Stress Testing checks if circuit boards work in tough conditions. This ensures they are strong and dependable in real life.

Adding PCBA testing to production saves time and materials. It creates better products and builds customer trust.

What Is a PCBA Tester?

Definition and Purpose

A PCBA tester is a tool used to check how well a printed circuit board assembly works. It makes sure the board meets design rules and works correctly. The tester mimics real-world conditions to find problems like bad parts, wrong connections, or design mistakes. This helps companies make better products for customers.

PCBA testers do important jobs during testing. These include:

Functional Tests: Checking if the board works when turned on.

Electrical Performance Tests: Testing current, voltage, and other electrical features.

Temperature Cycling Tests: Seeing if the board handles temperature changes.

Shock and Vibration Tests: Making sure the board survives bumps and shakes.

Testing Method | Description |

|---|---|

Functional Tests | Check if the board works properly when powered on. |

Electrical Performance Tests | Test electrical features like current and voltage levels. |

Temperature Cycling Tests | See if the board can handle changing temperatures. |

Shock and Vibration Tests | Ensure the board survives physical stress like shocks and vibrations. |

Importance in Electronics Manufacturing

Testing PCBAs is very important in electronics production. A single bad circuit board can cause product failures, unhappy customers, and money loss. Using a PCBA tester helps find and fix these problems early.

Different tests are used to check PCBAs. For example:

In-Circuit Testing (ICT): Looks at each part to see if it’s placed and working right.

Functional Testing: Mimics real-world use to check the board’s overall performance.

Burn-In Testing: Puts the board under tough conditions to find early problems.

Environmental Testing: Tests the board in different conditions to check durability.

These tests help companies keep high standards and satisfy customers. A PCBA tester ensures the board works well and saves money by reducing waste and fixing fewer mistakes.

How Does a PCBA Tester Work?

Overview of the Testing Process

A PCBA tester checks if a circuit board works correctly. It does this by copying real-life conditions the board will face. This makes sure the board works well in its intended environment. Functional testing is an important part of this. It powers the board to see if all parts, inputs, and outputs work properly.

The testing process has several steps to check everything. These include:

Checking how it handles high moisture levels.

Dropping, splashing, and shaking it to test strength.

Special machines like cameras and X-rays also help inspect the board. For example, Automated Optical Inspection (AOI) uses cameras to check parts and soldering. Automated X-Ray Inspection (AXI) looks at hidden solder spots. Functional testing makes sure the board works, including checking voltage and software.

Step | Description |

|---|---|

Automated Optical Inspection | Uses cameras to check parts and soldering quality. |

Automated X-Ray Inspection | Uses X-rays to check hidden solder spots like BGAs. |

Flying Probe Testing | Robotic probes measure electrical properties without powering the board. |

In-Circuit Testing | Multiple probes test parts without turning on the board. |

Functional Testing | Checks if the board works, including voltage and software. |

Key Components of a PCBA Tester

A PCBA tester has important parts that work together to check the board. Each part has a job to make sure testing is accurate and reliable.

Tester Type | Description |

|---|---|

In-Circuit Tester | Tests parts like resistors and capacitors for problems. |

Functional Tester | Powers the board to see if it meets design needs. |

The in-circuit tester checks small parts like resistors to see if they work. It finds problems like wrong placements or short circuits. The functional tester turns on the board and copies real-life use. This makes sure the board works as it should in real situations.

By using these tools, PCBA testing ensures every board is high quality before being sent to customers.

Types of PCBA Testing Methods

In-Circuit Testing (ICT)

In-circuit testing checks each part of a circuit board. It uses probes to measure things like resistance and continuity. The board stays off during testing, so it won’t overheat. ICT finds problems like misplaced parts or broken connections fast. This makes it great for catching mistakes early in production.

Probes touch certain spots on the board to test parts. Each part is checked to see if it works as designed. Since the board isn’t powered, there’s no risk of damage. ICT is popular because it gives detailed results about how parts work.

Flying Probe Testing

Flying probe testing uses robotic probes to check circuit boards. Unlike ICT, it doesn’t need special tools or fixtures. This makes it good for testing prototypes or small batches. It finds issues like broken connections or parts in the wrong place.

This method is very accurate and covers many test points. But it’s slower than other methods, so it’s not ideal for big jobs. Sometimes, it gives false results, but it’s still useful. Flying probe testing works well for different board designs.

PCB Functional Testing

PCB functional testing checks if the whole board works correctly. The board is powered on, and its inputs and outputs are tested. This method copies real-world conditions to make sure the board is reliable.

Data shows this method reduces failures a lot. With functional testing, failure rates drop to 0.0003%. Without it, failure rates are 0.03%. This means it’s 100 times better at preventing problems. Functional testing ensures the board meets design needs and works perfectly.

This testing step is very important for making good products. It checks both electrical parts and software to confirm the board is ready to use. If you want reliable boards, functional testing is a must.

Boundary Scan Testing

Boundary scan testing helps find connection problems on circuit boards. It uses the IEEE 1149.1 standard, also called JTAG, to check connections without touching the board. This is great for finding issues in hard-to-reach spots, like under ball grid arrays (BGAs).

This method improves the accuracy of testing circuit boards. It checks for problems like shorts and open circuits quickly. When combined with other tests, it finds more faults and makes products more reliable.

Studies show how useful boundary scan testing is:

Study Title | Key Findings |

|---|---|

Enhancing Board Test Coverage with Boundary-Scan | Boundary-scan finds hidden issues and works with other tests to improve reliability. |

Exploring the Latest Advancements in IEEE 1149.1 Compliant Boundary Scan Technology | New tools make fault detection more accurate and reliable. |

Finding PCBA Shorts & Other Faults: A Better Method | XJTAG tools use JTAG technology for better testing and debugging. |

Using boundary scan testing saves time and finds hidden problems. It makes sure your circuit boards work well and are dependable.

Environmental Stress Testing

Environmental stress testing checks how a circuit board works in tough conditions. It tests the board with things like heat, cold, shaking, and moisture to find weak spots. This ensures the product can handle real-world use.

One way to do this is Environmental Stress Screening (ESS). ESS copies real-life conditions by using temperature changes and vibrations. Tests are done before, during, and after these stresses to see if the board stays reliable.

Here’s how environmental stress testing is done:

Check if the board design works well.

Use stress methods like ESS, HALT, and HASS.

Watch the board to see how reliable it is.

Testing Method | Purpose |

|---|---|

Environmental Stress Screening (ESS) | Finds hidden problems by exposing boards to stress, making them more reliable. |

Adding environmental stress testing to your process makes products stronger and more reliable. It works with functional testing to ensure boards perform well in harsh conditions.

Benefits of PCBA Testing

Ensures Quality Assurance

PCBA testing makes sure every circuit board is high quality. It finds problems early, stopping bad boards from reaching customers. This process makes products more reliable and lowers the chance of recalls. For example, functional testing checks if boards work in real-life situations. It ensures they meet design rules.

Testing also improves quality by spotting issues like short circuits or bad soldering. Advanced tests, like in-circuit and functional testing, give detailed results. Industry data shows these methods find more defects, making boards more dependable.

Metric | Change Description |

|---|---|

Defect Detection Rates | Better with advanced tests like ICT, finding faults early. |

Reliability Verification | Improved with thorough testing to meet quality standards. |

Reduces Manufacturing Costs

PCBA testing saves money by catching problems early. Fixing issues before assembly ends avoids wasting materials. This approach cuts costs and uses resources wisely.

Automated tests, like flying probe and functional testing, speed up the process. They are fast and accurate, perfect for large-scale production. Early test feedback helps fix design or production problems quickly, saving time and money.

Cuts rework costs by solving problems early.

Saves money by improving production steps.

Improves Customer Satisfaction

Reliable products build trust with customers. PCBA testing ensures every board works properly. This gives confidence in product quality. Customers like products that work right away, boosting satisfaction and loyalty.

Functional testing is key to this. It checks if boards perform well in real-world use. High-quality testing reduces failures and warranty claims. This improves your reputation and makes customers happy.

Finds faulty boards before they reach customers.

Gives customers confidence that products will work.

Builds a strong reputation for reliable, quality products.

Enhances Product Reliability

PCBA testing helps make sure your products stay reliable. It finds weak spots early, so you can fix them before they cause problems. This testing improves how strong and long-lasting your circuit boards are. It also makes your products work better overall.

Functional testing is a key part of improving reliability. It copies real-life conditions to check if circuit boards work right. For example, it tests if the board handles different inputs and outputs without mistakes. This ensures your products meet design needs and work well in various situations.

PCBA testing also helps improve design, materials, and manufacturing. The table below shows how these areas help products last longer:

Contribution Area | Description |

|---|---|

Design Improvements | Finds weak spots and suggests fixes to prevent failures. |

Material Choices | Helps pick materials that handle stress and last longer. |

Manufacturing Processes | Improves soldering and quality checks to avoid defects. |

By focusing on these areas, you can make products that are strong and reliable. For instance, using better materials and improving soldering can lower the chance of problems. These changes lead to fewer failures and longer-lasting products.

When you use PCBA testing, customers trust your products more. Reliable items mean fewer returns and complaints, which boosts your reputation. Functional testing ensures your products work well, giving customers confidence in their quality.

Adding PCBA testing to your process is important for making dependable products. It helps find and fix problems early, so your circuit boards work well in real-world conditions.

PCBA testers are important tools in making electronics. They help find and fix problems early, so products meet quality rules. Using tests like in-circuit, functional, and boundary scan testing makes products more reliable and lowers costs.

Testing Method | What It Does | Why It Helps |

|---|---|---|

Quickly checks certain parts of the board. | Finds problems fast, making products better. | |

Functional circuit testing | Tests if the whole board works at the end. | Makes sure the final product works right. |

Boundary scan testing | Looks at wires in tricky designs without touching them. | Allows deep testing of complex boards. |

In-process testing | Happens during production to spot problems early. | Saves time and avoids expensive mistakes later. |

Using these tests together helps make strong, high-quality electronics while improving how they are made.

FAQ

What is the main purpose of PCBA testing?

PCBA testing checks if circuit boards work and meet standards. It finds problems like bad parts or design mistakes before production. This helps make sure your electronic products are reliable and high-quality.

How does PCBA testing improve product reliability?

Testing finds weak spots in circuit boards early. Fixing these makes boards stronger and work better. Functional tests copy real-life use to ensure products work in different conditions.

Can PCBA testing reduce manufacturing costs?

Yes, it can. Finding problems during production avoids wasting materials or fixing mistakes later. Automated tests, like in-circuit or flying probe testing, make the process faster and cheaper.

What types of defects can PCBA testing detect?

PCBA testing finds problems like short circuits, bad connections, or misplaced parts. Advanced tests, like boundary scan testing, also find hidden issues in complex designs.

Is PCBA testing necessary for all electronic products?

Yes, it is. Whether for home gadgets or industrial tools, testing ensures safety and good performance. It lowers failure risks and builds customer trust in your brand.

See Also

Understanding PCBA: Definition And Its Importance In Electronics

Innovative Testing Methods For PCBA In Electronics Production

The Significance Of PCBA Services In Electronics Production

Defining PCBA And Its Importance In Electronic Devices

Enhancing Testing Accuracy Through PCBA Automation Techniques