PCBA, or Printed Circuit Board Assembly, refers to the process of attaching electronic components to a printed circuit board (PCB). For those wondering, “what is a PCBA,” it’s the transformation of a plain PCB into a critical component that enables modern devices to function as intended.

PCBA plays a vital role in the electronics industry. Here are some key insights highlighting its growing importance:

The global PCBA market is projected to grow by 4.12% between 2020 and 2025, reflecting its increasing demand.

The PCB coating market is expected to reach $5.59 billion by 2029, driven by the need for durable and reliable electronics.

The rising use of smartphones could contribute an additional $26.8 billion to the global PCB market from 2025 to 2029.

By enhancing device durability and enabling complex designs, PCBA continues to advance technology across various industries.

Key Takeaways

PCBA turns simple PCBs into working parts for electronics.

The PCBA market is growing as people want better electronics.

Good quality checks in PCBA make devices work well and last.

PCBA helps create new tech like smart gadgets and green tools.

Learning about PCBA shows how tech powers phones and medical gear.

What Is a PCBA?

Definition and Meaning of PCBA

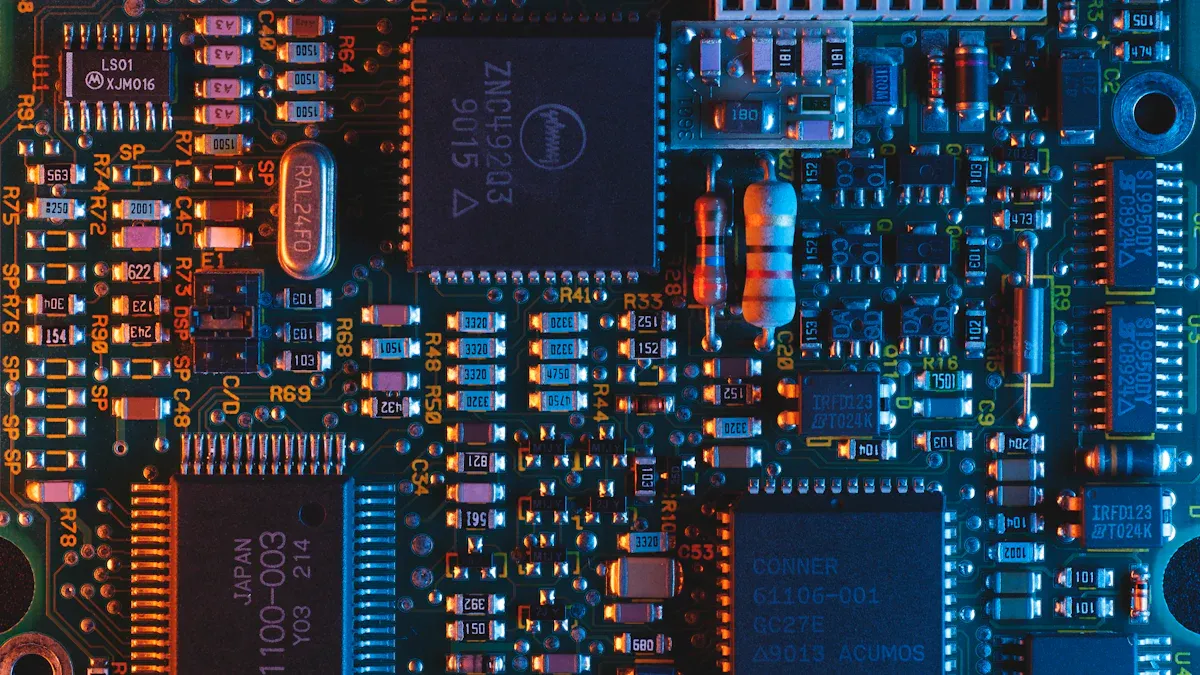

When asking, “what is a PCBA,” it means a Printed Circuit Board Assembly. This is the process of adding electronic parts to a plain PCB to make it work. Experts say a PCBA has all the parts needed for it to function. For instance, EMSG Inc. explains that a PCBA is a finished board with all required parts. PCB Online describes it as a PCB with parts soldered on. This process changes a simple board into the core of modern electronics.

Source | Definition |

|---|---|

EMSG Inc. | A PCBA is a finished board with all parts included. |

PCB Online | A PCBA is a PCB with parts soldered on it. |

Arena Solutions | A PCBA is the final board after adding all components. |

Difference Between PCB and PCBA

A PCB and a PCBA are not the same. A PCB is just a plain board with pathways for electricity. A PCBA is a complete board with all its parts. The table below shows their main differences:

Aspect | PCB | PCBA |

|---|---|---|

Definition | Plain board with electrical paths | |

Function | Supports and connects circuits | Performs specific tasks in devices |

Components | None | Includes resistors, capacitors, and chips |

Manufacturing | Copper layers are etched | Parts are placed and soldered |

Applications | Used for testing and designing circuits | Found in devices like phones and computers |

Importance of PCBA in Electronics

PCBA is very important in today’s electronics. It turns a plain PCB into a working part of devices. You can find PCBAs in phones, medical tools, and more. For example, the rise of IoT gadgets and electric cars has increased the need for PCBAs. In healthcare, PCBAs help devices like patient monitors work reliably. Aerospace industries also use PCBAs that meet strict standards, like IPC-A-610 Class 3, to ensure safety. Without PCBA, modern devices wouldn’t work as well or last as long.

The Role of PCBA in Electronics Manufacturing

Making Electronic Boards Work

The PCBA process changes a plain PCB into a working board. This is done by adding parts like resistors, capacitors, and chips. Each step ensures the board works as it should. Metrics like DPMO and FPY check how well this process is done.

Metric | Description |

|---|---|

Defects per Million Opportunities (DPMO) | Counts defects per million chances, helping compare quality. |

Shows the percentage of boards passing tests the first time. | |

Rework Rate | Tracks how many boards need fixing after assembly. |

Scrap Rate | Measures the number of boards that can’t be used due to flaws. |

By improving these metrics, manufacturers make better and more reliable boards.

Keeping Quality High

Quality is very important in PCBA production. Advanced tools like AI help improve it. AI can do tasks accurately, find problems early, and watch processes in real-time. This lowers mistakes, saves time, and reduces waste. Metrics like defect rate and failure rate show how well these methods work.

Metric | Description |

|---|---|

First Pass Yield (FPY) | Shows how many products pass tests on the first try. |

Defect Rate | Tracks the percentage of faulty products; lower is better. |

Return Rate | Measures how many products are sent back by customers. |

Failure Rate | Counts how often products fail during use; lower is ideal. |

Reliability Metrics | Includes MTBF and MTTR to check product dependability. |

Cost of Quality (COQ) | Tracks costs related to quality, like fixing or preventing issues. |

Process Capability Index | Checks if the production process is stable and consistent. |

These steps ensure PCBA products are dependable for many uses.

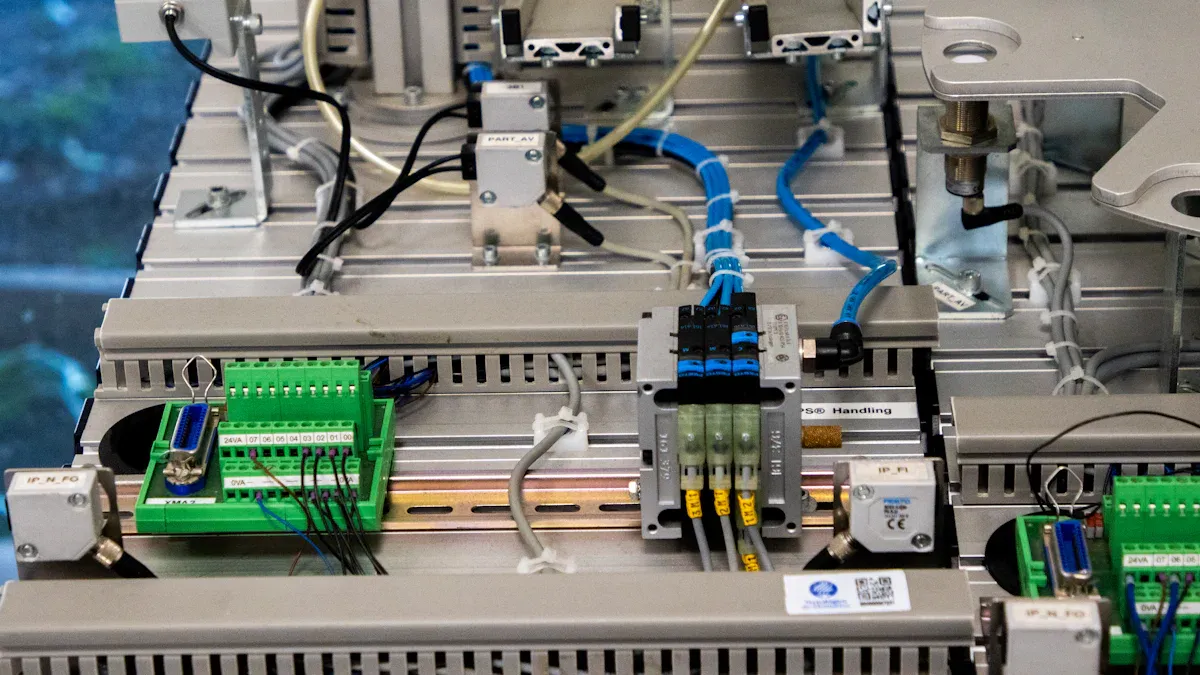

Used in Many Industries

PCBA is important in many fields. In aerospace, special PCBs handle complex circuits. Healthcare uses flexible PCBs for medical tools. Cars rely on strong materials for better electronics. Telecom needs high-frequency PCBs for 5G. Small PCBs are key in phones and wearables.

Aerospace: Special PCBs handle tough and complex circuits.

Healthcare: Flexible PCBs make medical devices more adaptable.

Automotive: Strong materials improve car electronics’ performance.

Telecommunications: High-frequency PCBs support fast 5G networks.

Consumer Electronics: Small PCBs fit into phones and smart gadgets.

These examples show how PCBA meets the needs of different industries.

The PCBA Assembly Process

Solder Paste Application

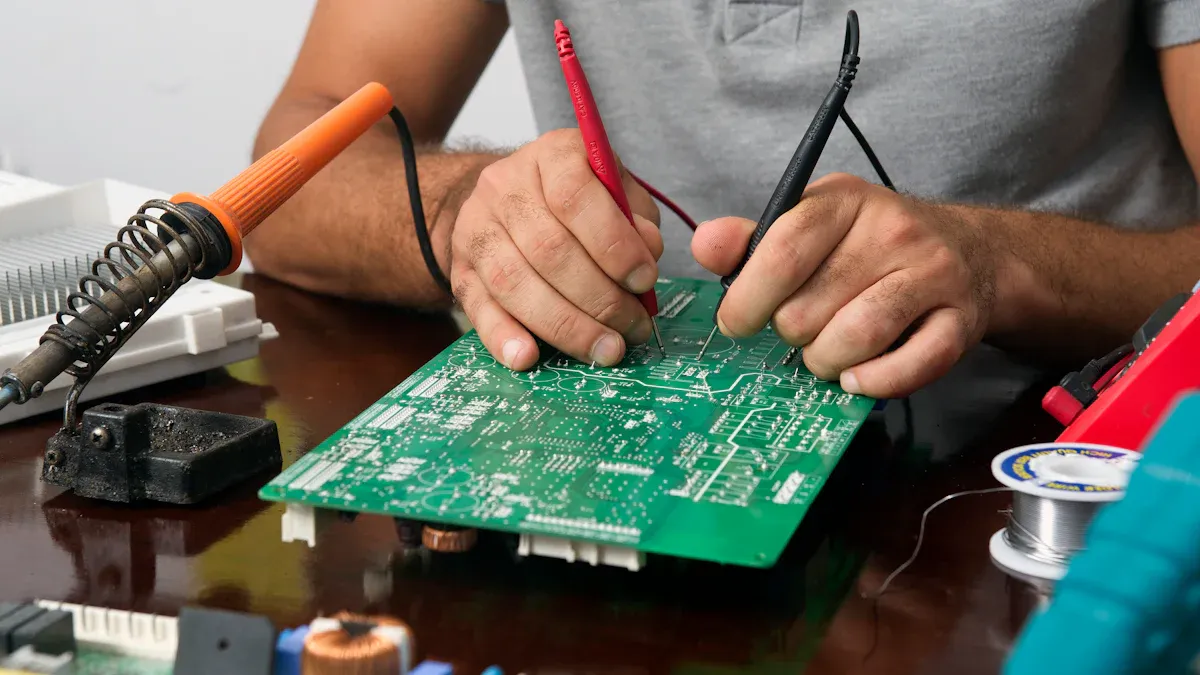

The first step in making a PCBA is adding solder paste. This paste is a mix of powdered solder and flux. It helps parts stick and makes strong electrical links. Think of it as glue for the components before soldering.

To apply the paste, a stencil is used. The stencil fits over the PCB, and the paste is spread on it. This makes sure the paste only goes where parts will sit. Accuracy is very important here. Things like stencil thickness and paste texture affect how well this works.

Parameter | Description |

|---|---|

Print Performance | |

Bridging Potential | Tests how well paste avoids bridging at different speeds. |

Stencil Life | Measures paste changes after pauses during printing. |

Reflow Performance | Looks at solder quality through tests like wetting and voiding. |

Washability | Tests how well water-based pastes clean after heating. |

This step is key for a good PCBA. Mistakes here can cause problems later.

Component Placement

After the solder paste is added, parts are placed on the PCB. Machines called pick-and-place do this job quickly and accurately. These machines use arms or suction to put parts like resistors and chips onto the paste.

Surface Mount Technology (SMT) is the main way to place parts. It allows for small and complex designs, perfect for modern gadgets. Advanced machines can place thousands of parts every hour. This saves time and reduces mistakes.

SMT places parts like chips, resistors, and BGAs.

Pick-and-place machines handle even the smallest parts precisely.

Automation makes production faster and more consistent.

This step turns the PCB into a nearly finished board, ready for soldering.

Reflow Soldering

Reflow soldering attaches the parts to the PCB permanently. The board goes through a reflow oven, which heats it up. The heat melts the solder paste, creating solid connections between the parts and the PCB.

The oven uses a set temperature plan to ensure good results. For example, a peak heat of 225°C is common, but it depends on the parts used. Short heating times, like 31 to 40 seconds, help protect sensitive parts.

Reflow profiles reduce damage to insulation resistance.

New flux types improve heat performance.

Good temperature control makes strong solder joints.

This step completes the electrical links, making the PCBA ready for testing.

Inspection and Testing

Inspection and testing make sure every PCBA is high quality. These steps check if the PCBA works well and lasts long. Different methods are used to find problems and test performance. Each method focuses on a specific part of the PCBA to ensure it works properly.

Here are some common ways to inspect and test PCBAs:

Description | |

|---|---|

FAI (First Article Inspection) | Done before production to check accuracy and create a report. |

ICT (In-Circuit Test) | Checks if the circuit works after soldering. |

FCT (Functional Test) | Tests if the whole PCB works as expected. |

Aging Test | Measures how reliable the PCBA is over time. |

Temperature and Humidity Test | Tests how it performs in different environments. |

Drop Test | Checks if the PCBA can handle impacts. |

SPI (Solder Paste Inspection) | Looks at the quality of solder paste application. |

X-Ray Inspection | Finds hidden problems in solder joints and connections. |

AOI (Automated Optical Inspection) | Uses cameras to find surface defects automatically. |

These methods make sure the PCBA is free of problems and works well. For example, AOI uses cameras to spot surface issues, while X-Ray checks inside connections. Together, these tests ensure the PCBA is reliable.

Final Assembly and Quality Control

The final assembly step puts all parts together to finish the PCBA. This includes adding any last pieces, like connectors, and doing final checks. Think of this as the last step to make the PCBA ready to use.

Quality control here checks if the finished PCBA is strong and works well. Below are some methods used:

Description | |

|---|---|

Visual Inspection | Uses eyes or magnifiers to find visible problems. |

Automated Optical Inspection | Uses cameras to find defects by comparing images. |

X-Ray Inspection | Looks inside the PCB to find hidden issues like bad solder. |

Testing Methods | Checks if parts and the whole PCBA work correctly. |

These methods confirm the PCBA meets all requirements and works as it should. For instance, visual inspection finds surface problems, while X-Ray looks for hidden flaws. Testing ensures the PCBA works in real-life situations.

After this, the PCBA is ready to power the devices you use daily. Careful checks at every step make sure the final product is reliable and long-lasting.

Advantages of PCBA in Modern Electronics

Better Reliability and Strength

PCBA makes devices more reliable and long-lasting. It ensures strong connections and good performance. Manufacturers test PCBAs to handle real-world challenges. For example, stress tests check how they perform under heat and vibrations. Electrical tests see if they can manage power loads. Life tests find weak spots over time.

Purpose | What It Shows | |

|---|---|---|

Environmental Stress Testing | Tests PCBs/PCBAs in tough conditions | Checks heat expansion, solder strength, and durability |

Electrical Stress Testing | Measures electrical performance and strength | Finds heat issues, solder problems, and ESD risks |

Accelerated Life Testing | Speeds up lifecycle testing | Reveals weak designs and failure risks |

These tests make sure PCBAs work well for industries like healthcare, cars, and airplanes.

Saves Money in Production

PCBA helps lower production costs. Making more units reduces the cost per item. Fixed costs, like setup fees, are spread out over many units. Buying materials in bulk and managing inventory smartly also saves money. Simple designs and automation cut labor costs too.

Description | |

|---|---|

BOM Cost Optimization | Focus on lowering costs by analyzing and managing expenses. |

Impact of Manufacturing Volume | Making more units lowers the cost per item by spreading fixed costs. |

Material Management | Buying in bulk and managing inventory reduces expenses. |

Process Optimization | Using simple designs and machines saves time and money. |

These methods help make production cheaper without losing quality.

Fits Many Uses

PCBA works for many types of devices, from gadgets to machines. It can even support new ideas like eco-friendly electronics. For example, researchers made a biodegradable mouse using special materials. These materials work as well as traditional ones but are better for the planet.

Eco-friendly materials like LCNF are great for PCBA.

Biodegradable electronics meet rules and still perform well.

PCBA supports new tech like 5G for faster connections.

This flexibility helps PCBA meet the needs of different industries. It also drives new ideas and supports greener technology.

Driving Innovation in Electronics

PCBA technology is key to creating new ideas in electronics. It changes how devices are made, designed, and improved for better use. With new advancements, PCBA is shaping the future of electronics.

One big change is the rise of smart factories. These factories use tools like big data, IoT, and AI to work better. For example, AI-powered Automated Optical Inspection (AOI) systems check production lines live. They find and fix problems fast, making sure products are high quality. This not only makes devices more reliable but also cuts waste, helping the environment.

Automation and robots have also changed PCBA processes. Robots now do tasks like placing parts and soldering with great accuracy. They make fewer mistakes and need less human help. This means manufacturers can make more products faster and cheaper. You get quicker production and lower-cost electronics.

Modern automation has made PCBA production very flexible. Factories can easily switch to making different designs. This helps create advanced tech like 5G devices and smart wearables. As a user, you enjoy faster internet and smarter gadgets thanks to these changes.

Tip: When you use a smartphone or fitness tracker, remember PCBA makes it all work. It powers the smooth performance and cool features you love.

By always improving, PCBA technology drives innovation in every part of life. From smarter factories to better devices, it’s building a future with faster, smarter, and more reliable electronics.

PCBA, or Printed Circuit Board Assembly, changes a plain PCB into a working part for electronics. It helps devices last longer and work better. In 2023, the global PCBA market was worth $68.4 billion. By 2032, it is expected to grow to $105.8 billion, with a yearly growth rate of 4.9%.

More people buying gadgets boosts this growth.

PCBs are key for new tech like IoT, 5G, and self-driving cars.

By helping create new ideas and improving technology, PCBA shapes the future of electronics.

Statistic | Value | Year |

|---|---|---|

Market Size | $68.4 billion | 2023 |

Projected Market Size | $105.8 billion | 2032 |

CAGR | 4.9% | 2023-2032 |

Note: When you use smartphones or IoT gadgets, remember PCBA makes their cool features possible.

FAQ

What is the difference between a PCB and a PCBA?

A PCB is just a plain board with circuits. A PCBA has all the parts added, making it work in devices.

Why is PCBA important in electronics?

PCBA turns a plain PCB into a working part. It helps devices like phones, medical tools, and cars work properly by linking their electronic parts.

How does solder paste help in PCBA?

Solder paste works like glue for parts on the PCB. It makes strong connections during heating, which is key for the board to work.

What industries use PCBA?

Industries like healthcare, cars, space, and telecom need PCBA. It powers things like medical tools, car systems, satellites, and 5G networks.

Can PCBs be reused after assembly?

Some PCBs can be reused if in good shape. Parts can be replaced, but it must be done carefully to avoid damage.

See Also

Understanding PCBA: Its Importance in Electronic Systems

Exploring PCBA: Definition and Its Significance

Defining PCBA: Its Function in Electronic Equipment