Printed Circuit Board Assembly (PCBA) manufacturing, which is essential for understanding what is PCBA manufacturing, transforms plain circuit boards into functioning electronic devices. This process involves adding electronic components to the board to ensure it operates correctly.

PCBA is crucial in today’s electronics landscape. For instance:

The PCB market is projected to grow from $80.33 billion in 2024 to $96.57 billion by 2029.

The global PCB assembly market could reach $21.46 billion by 2032.

The rapid adoption of 5G and IoT technology drives this growth, highlighting how understanding what is PCBA manufacturing can enhance innovation and improve the reliability of devices.

Key Takeaways

PCBA manufacturing turns simple circuit boards into working devices by adding parts.

The PCBA industry is growing fast because of new tech like 5G and IoT. It is very important for today’s electronics.

Good quality in PCBA is key. Strict rules make sure devices work well, especially in healthcare and cars.

Robots and AI are changing how PCBA is made. They make work faster and cut down mistakes.

Green methods in PCBA are becoming popular. Companies now use eco-friendly materials to help the planet.

What is PCBA Manufacturing?

What is Printed Circuit Board Assembly?

Printed Circuit Board Assembly (PCBA) is the process of adding electronic parts to a plain circuit board (PCB) to make it work. This includes attaching parts like resistors, capacitors, and chips to the board using solder. The finished product allows electricity to flow and makes the device work.

Why is this process important? Without PCBA, a PCB is just an empty board that cannot do anything. PCBA turns this empty board into the “brain” of devices, powering things like phones and medical tools.

To make sure PCBA is done well, companies follow strict rules like IPC-A-610. These rules help ensure the products are reliable, which is very important for industries like healthcare and space technology.

How is PCBA Different from PCB?

PCBA and PCB might sound similar, but they are not the same. A PCB is just the board made of materials like fiberglass. It has pathways on it for electricity but cannot work on its own.

PCBA is the next step. It adds and connects parts to the PCB, making it a working device. Think of the PCB as a skeleton and the PCBA as the body with all its parts working together.

This difference is important because PCBA makes the PCB useful. For example, a PCB for a simple gadget may be easy to make, but a PCBA for a space device must meet very high standards. Here’s a table showing the differences:

Specifications | PCB | PCBA |

|---|---|---|

Functionality | Base for circuits | Fully working electronic device |

Components | None | Has attached electronic parts |

Manufacturing Process | Etching and layering | Adding and connecting parts |

Why is PCBA Important in Electronics?

PCBA is key to making modern devices work well. Without it, gadgets like phones, laptops, and smartwatches wouldn’t exist.

PCBA is also important in many industries:

In healthcare, it helps make life-saving tools like pacemakers.

In cars, it powers systems like collision alerts and self-driving features.

In electronics, it helps make smaller, more powerful devices.

The PCBA market shows how important it is. Experts say it will grow from $67.9 billion in 2023 to $92.4 billion by 2029, growing 5.4% each year. New tech like 5G and IoT depends on PCBA to work.

PCBA is more than just making devices; it’s the heart of today’s technology. Learning about PCBA helps you understand how devices are built to be reliable and innovative.

The PCBA Manufacturing Process

The PCBA process turns a plain circuit board into a working one. This happens by adding electronic parts to the board. Each step is important to make sure the final product works well. Let’s look at the main steps:

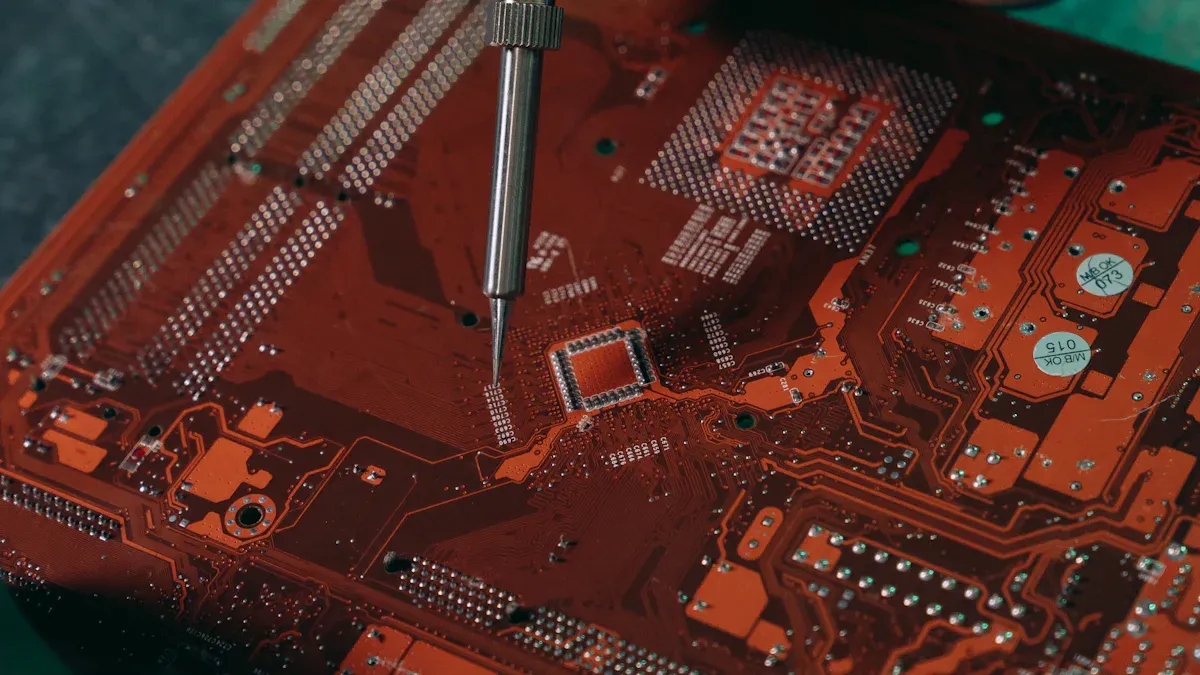

Solder Paste Application

The first step is applying solder paste to the board. Solder paste is a mix of tiny metal bits and flux. It helps stick parts to the board and makes electrical connections.

A stencil matching the board design is used. The stencil is placed on the board, and paste is spread over it with a tool. The paste goes into the stencil holes, landing exactly where parts will go.

Good solder paste application is very important. Studies show 70% of soldering problems come from bad paste printing. To avoid this, machines called SPI check the paste’s amount and position. These checks help catch mistakes early and keep production smooth.

Tip: Keep solder paste in a cool place to keep it fresh.

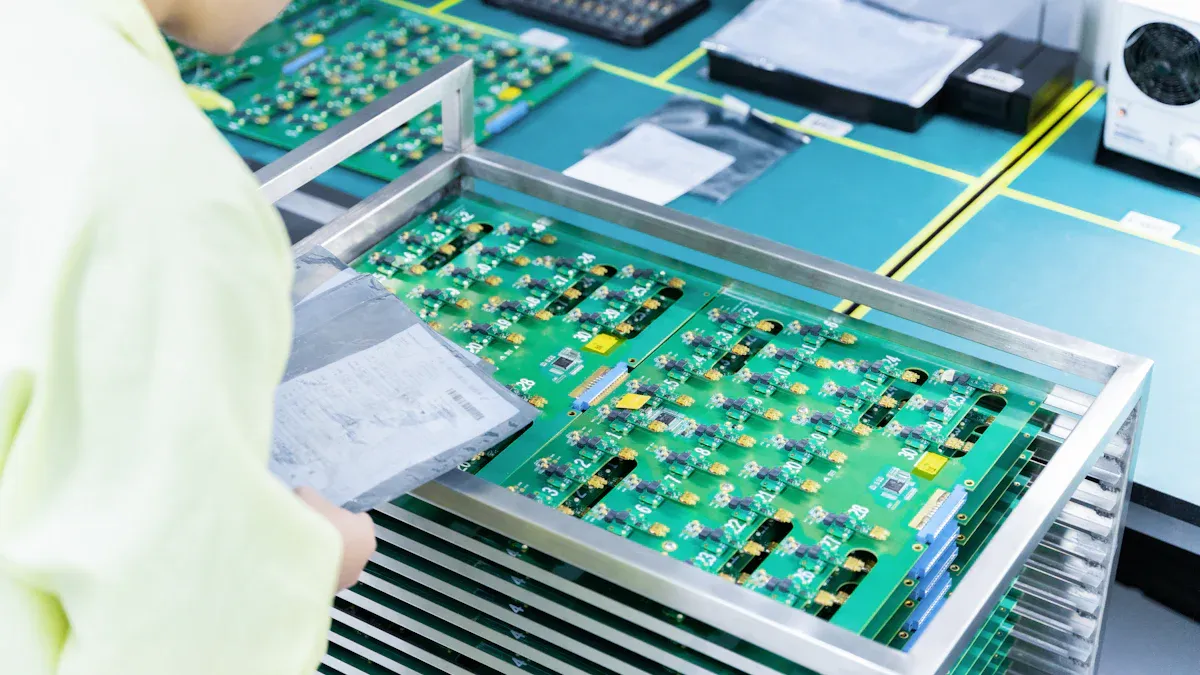

Component Placement

Next, parts like resistors and chips are added to the board. Machines called pick-and-place do this job. They use robotic arms to grab parts and put them on the board.

These machines are very accurate, placing parts within ±0.01mm. This accuracy prevents mistakes like parts being crooked or standing up instead of lying flat. Using these machines saves time and reduces errors. This is especially important for industries like healthcare and space tech.

Note: To avoid fake parts, companies track and check every part they use.

Reflow Soldering

Reflow soldering is the step where parts are attached for good. The board goes through a reflow oven, which heats it carefully. The heat melts the solder paste, making strong connections between the parts and the board.

The oven’s temperature must be just right. If it’s too low, the solder won’t melt. If it’s too high, parts can get damaged. Reflow soldering ensures all connections are solid, improving the board’s quality.

Fun Fact: Reflow ovens are often in super-clean rooms to avoid dirt and ensure perfect results.

Each step is key to making a great PCBA. By using smart tools and following good methods, you can create reliable circuit boards for today’s tech needs.

Inspection and Quality Control

Inspection and quality control are very important in PCBA making. These steps make sure every board works well and lasts long. Finding problems early saves money and keeps customers happy.

Why Inspection Matters

Inspection helps find and stop problems before they grow. Studies show bad solder paste printing causes 70% of PCBA problems. Solder Paste Inspection (SPI) checks the paste to ensure it’s applied right. This step avoids crooked parts or weak connections.

Quality control also makes products reliable and long-lasting. Following strict rules like IPC-A-610 and ISO 9001 ensures boards meet standards. This reduces returns and keeps customers satisfied.

Tools and Techniques

Modern tools make inspection better. Automatic Optical Inspection (AOI) uses lights to check solder joints for mistakes. X-ray tools, like fluoroscopes, show detailed images of solder joints, great for double-sided boards.

Automation improves accuracy even more. Inline tools like SPI and AOI find problems fast, so fixes happen right away. These tools reduce human mistakes and keep quality steady.

Tip: Use barcodes or QR codes to track inspection data. This helps find problems and fix them quickly.

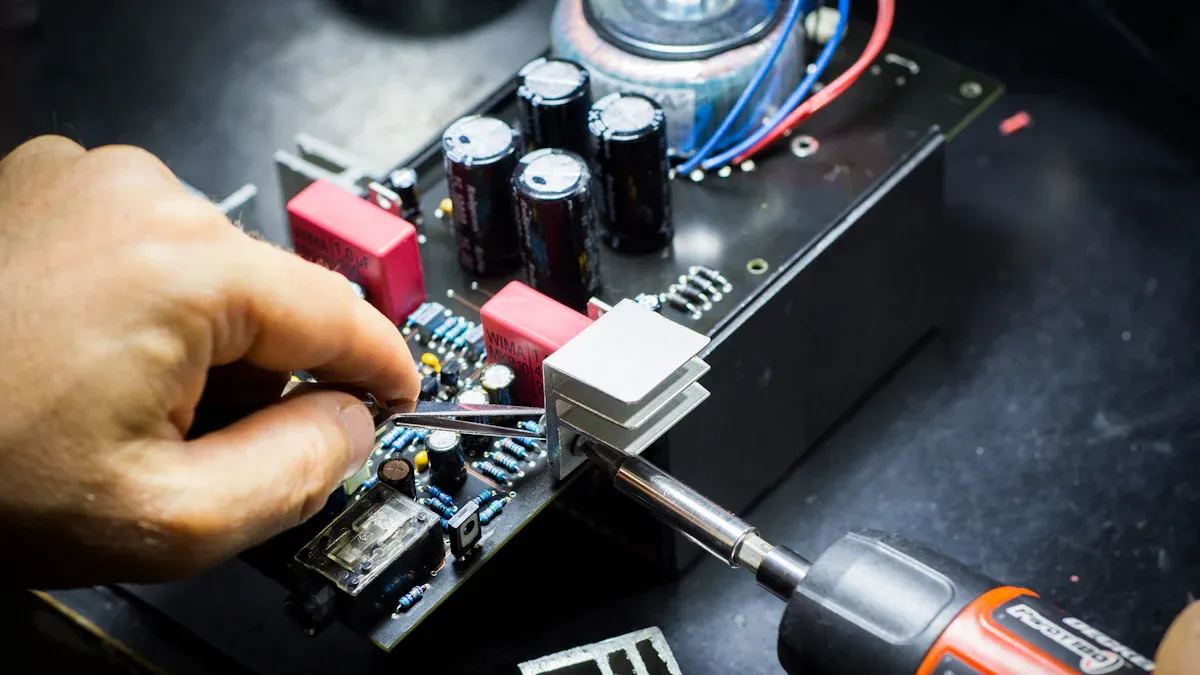

Final Testing and Assembly

Final testing and assembly are the last steps in PCBA making. These steps check if the board works and meets all needs.

Testing Protocols

Testing makes sure boards are reliable. Visual checks find big problems, while advanced tools like Structural Process Test Systems (SPTS) use video to improve accuracy. Automatic Laser Test (ALT) measures solder joint height and shape for better control.

Functional Circuit Testing (FCT) checks if the board works in real-life conditions. Stress tests like HASS and HALT push boards to their limits to check durability.

Description | |

|---|---|

Visual Inspection | Finds big problems by looking at the board. |

Structural Process Test System (SPTS) | Uses video to improve visual checks and accuracy. |

Automatic Optical Inspection (AOI) | Uses lights to check solder joints for mistakes. |

Automatic Laser Test (ALT) Measurement | Measures solder joint height and shape for better control. |

X-ray Fluoroscope System | Uses X-rays to check solder joints on single-sided boards. |

X-ray Lamination System | Creates detailed images to check solder joints on double-sided boards. |

Assembly Completion

The final step puts all parts together into one working unit. Careful control of soldering heat ensures strong connections. Keeping the environment clean and dry also helps make better boards.

By testing and assembling carefully, you can make reliable PCBAs. These boards work well in gadgets, medical tools, and cars.

Fun Fact: PCBA turns plain boards into working devices, helping new technology grow.

The Role of PCBA in Modern Electronics

Making Devices Smaller and Better

PCBA helps make gadgets smaller and work better. Using Surface Mount Technology (SMT), tiny parts are placed on boards with great accuracy. This lets us have small devices like phones and watches that do many things.

PCBA also allows more parts to fit on one board. This helps meet the need for smaller electronics. For example, modern gadgets use PCBA to combine features and stay portable. Here’s how PCBA helps with size and efficiency:

Feature | Benefit |

|---|---|

Fits more parts on boards, helping miniaturization. | |

SMT Technology | Places tiny parts precisely, saving time and money. |

Use in Consumer Electronics | Powers compact devices like smartphones with many features. |

These improvements make devices work better and cost less, making them easier to buy.

Making Devices Reliable and Strong

PCBA makes sure gadgets are reliable and last long. Good designs and assembly keep devices stable, even in tough conditions. For example, special materials protect solder joints, making them stronger.

Testing is very important in PCBA. Design for Reliability (DfR) finds problems early and fixes them. Studies show strong PCB designs improve how devices work and make them last longer. Here are some findings:

Key Findings | Details |

|---|---|

Reliability Testing | Checks how strong and reliable systems are using test data. |

DfR Methods | Finds issues early and creates plans to fix them. |

Reliability Growth | Measures how reliability improves over time, focusing on big risks. |

By focusing on quality, PCBA ensures devices work well for a long time.

Used in Many Industries

PCBA is used in many fields, showing its importance. In electronics, it powers laptops, tablets, and gaming systems for smooth use. In cars, it helps with safety systems and self-driving features.

Healthcare also depends on PCBA. Tools like pacemakers and scanners need precise assembly to work well. These examples show how PCBA helps create smart solutions for different needs.

PCBA is key to modern technology, improving size, reliability, and use across industries.

PCB vs. PCBA: Knowing the Difference

What is a PCB?

A PCB, or Printed Circuit Board, is the base of electronics. It is a flat board made from materials like fiberglass. The board has pathways, called traces, that let electricity flow. These traces are made using processes like drilling and layering. But a PCB alone cannot do anything. It is just the starting point for building circuits.

PCBs come in types like single-layer, double-layer, and multi-layer. The type depends on how complex the device is. For example, a single-layer PCB works for simple remotes. A multi-layer PCB is needed for advanced devices like smartphones.

What is a PCBA?

A PCBA, or Printed Circuit Board Assembly, is the next step. It adds electronic parts to the plain PCB. These parts include resistors, capacitors, and chips. After assembly, the PCBA becomes a working circuit for devices.

The process includes steps like applying solder paste and placing parts. Then, reflow soldering connects the parts securely. A PCBA turns a plain PCB into the “brain” of a device. It helps the device perform its tasks.

Why Knowing the Difference is Important

Knowing the difference between PCB and PCBA is important. A PCB is just the base, while a PCBA is the finished product. This difference changes how they are made.

Making a PCB focuses on creating the board’s structure. PCBA making involves adding parts and testing for quality. The table below shows the main differences:

Term | Definition |

|---|---|

PCB | A plain board with pathways, made by drilling and layering. |

PCBA | A board with added parts, making it a working circuit. |

By learning about PCBA, you see how electronics are made. It shows how a simple board becomes a powerful tool for innovation.

Future of PCBA Manufacturing

Automation and AI in PCBA

Automation and AI are changing PCBA manufacturing. Machines like pick-and-place and reflow ovens work faster and more accurately. AI helps by studying data to find and fix problems early. For example, AI tools like SPI and AOI spot soldering mistakes quickly. This reduces waste and improves product quality.

AI also makes supply chains better. It helps track parts, stop fake components, and follow industry rules. These improvements make production faster and more dependable.

Sustainable Manufacturing Practices

PCBA makers are focusing on being eco-friendly. Electronics cause 4% of global greenhouse gas emissions, so changes are needed. Companies now use lead-free solder and recycle materials to cut waste. Some even try bio-based materials like paper and bio-plastic to save energy and reduce trash.

New methods like reusing chemicals and skipping heat-based processes are becoming popular. These ideas lower waste and energy use. By using these practices, PCBA makers can help protect the planet.

Aspect | Description |

|---|---|

Sustainable substrate options | Bio-based materials like paper and bio-plastic films reduce waste. |

Etchant regeneration | Techniques to recycle chemicals used in PCB manufacturing. |

Lead-free solder | Eco-friendly alternatives to traditional solder materials. |

Impact of IoT, 5G, and Emerging Technologies

IoT and 5G are changing how PCBA is made. IoT devices need advanced PCBs to handle tough tasks. 5G gadgets need special boards for faster data speeds. Big investments in telecom systems are increasing the need for high-quality PCBs.

New tech like self-driving cars and smart medical tools also depend on better PCBA designs. These push makers to create smaller and smarter boards. Even with high costs and competition, there are big chances to grow in telecom, cars, and healthcare.

Category | Insights |

|---|---|

IoT Solutions | Advanced PCBs are key for IoT devices to work well. |

Consumer Electronics Demand | 5G devices create new markets for high-speed PCBs. |

Strategic Growth Opportunities | Growth areas include telecom, cars, and medical devices. |

The future of PCBA depends on new ideas. Using automation, eco-friendly methods, and advanced tech will help you succeed in this growing field.

PCBA manufacturing is crucial for the electronics world. It changes plain boards into smart tools that power new ideas and ensure devices work well. By making gadgets smaller and fitting more parts on boards, PCBA helps create compact and useful devices. Flexible and rigid-flex boards make designs adaptable, while better materials increase strength and performance.

Trends like automation and smart factories lower mistakes and improve efficiency. Using green materials helps protect the environment. The global PCB market is growing fast, expected to hit $90.413 billion by 2028, with a yearly growth of 5.40%. These changes show how PCBA can transform industries and meet future tech needs.

PCBA manufacturing is not just a process—it’s the backbone of today’s technology, helping fields like healthcare, cars, and electronics move forward.

FAQ

What is the difference between PCB and PCBA?

A PCB is just a plain board with no parts. A PCBA has all the parts added, making it work. Knowing PCB vs. PCBA shows how a simple board becomes useful.

Why is PCBA important in electronics?

PCBA makes devices work properly. It connects parts to the board so they can function. Without PCBA, things like phones, medical tools, and cars wouldn’t work.

How does automation improve PCBA manufacturing?

Automation makes production faster and reduces mistakes. Machines like pick-and-place robots put parts in the right spots. This improves quality and lowers costs, making PCBA better.

What industries rely on PCBA?

PCBA is important for healthcare, cars, and electronics. It powers things like pacemakers, self-driving cars, and phones, helping them work well.

How does PCBA support miniaturization in electronics?

PCBA uses special methods like SMT to add tiny parts to boards. This helps make smaller and stronger devices like smartwatches and small medical tools.

See Also

Understanding PCBA Services And Their Importance In Electronics

Defining PCBA In Electronics And Its Significance

Exploring The Concept Of PCBA And Its Definition

The Functionality Of PCBA Motherboards And Their Importance

The Significance Of PCBA And Its Contribution To Electronics