When you learn what is PCBA, you discover there are a few main types. Understanding what is PCBA is important because these types help create new technology, such as smaller and smarter devices. The global PCB & PCBA market was valued at about $68.4 billion in 2023 and could reach $105.8 billion by 2032. This rapid growth highlights why knowing what is PCBA and its types is essential. Staying informed helps you keep up with industry changes and choose the best options for your projects in 2025.

Key Takeaways

PCBA is putting electronic parts on a printed circuit board. This helps devices work well and last longer.

There are different PCB types like single-sided, double-sided, multilayer, rigid, flex, and rigid-flex. Each type has special features for different uses.

Single-sided PCBs are simple and cheap. They are good for basic devices. Multilayer PCBs hold many parts in small spaces. They are used for fast and advanced gadgets.

Flex PCBs can bend and save space. They are great for wearables and foldable devices. Rigid PCBs are strong and work well in tough places.

You should pick the right PCB for your device. Think about cost, size, strength, and flexibility. This helps make better and smarter products.

What is PCBA

Definition

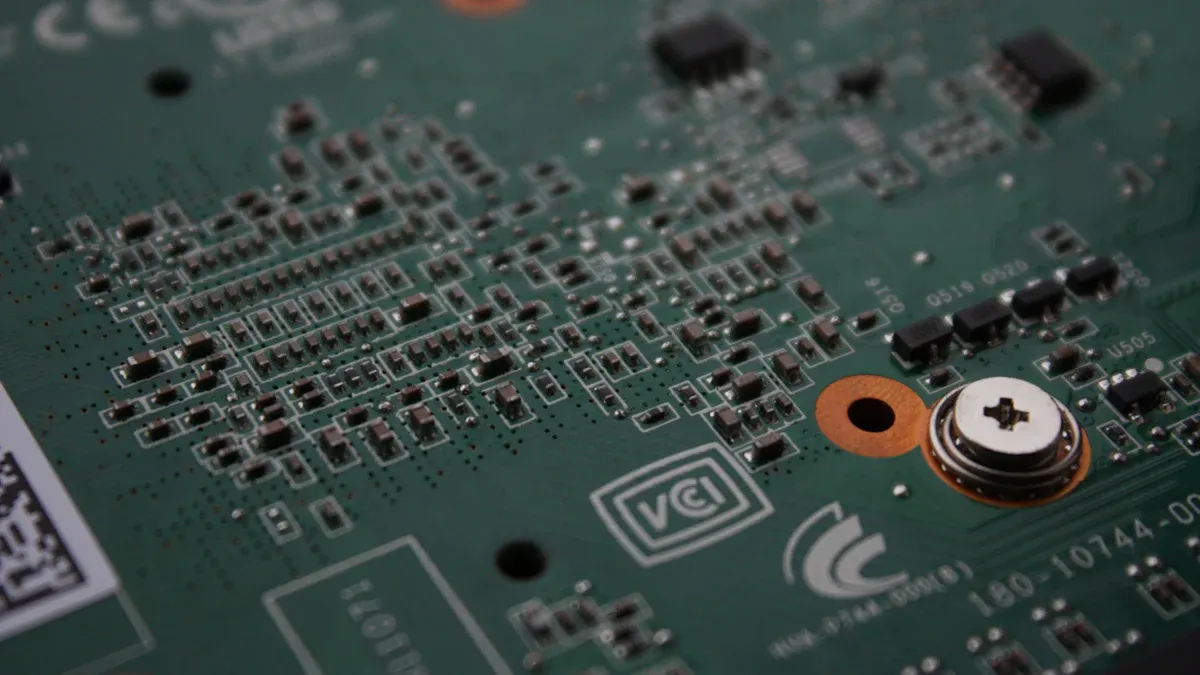

When you ask what is pcba, you find it means Printed Circuit Board Assembly. This is when you take a printed circuit board and put electronic parts on it. Copper traces are thin lines that connect these parts. You might see words like pads, vias, and landings. Pads are places where you put the parts. Vias are tiny holes that link layers of the board. Landings help surface-mount parts stay on the board.

What is pcba is set by strict rules in the industry. IPC standards, like IPC-A-610 and IPC-J-STD-001, tell you how to build and check each board. These rules make sure every board works well and lasts long. There are other rules too, like ISO 9001 for quality and RoHS for safety. The table below lists some important rules:

Standard/Classification | Description |

|---|---|

IPC Standards | Main rules for design, assembly, and testing of pcb assemblies. |

IPC Classes | Class 1: General use |

ISO Standards | Quality and environmental management for pcb production. |

Other Standards | UL for safety, RoHS for limiting harmful substances. |

Role in Electronics

You use what is pcba in almost every electronic device today. The printed circuit board holds all the parts and lets them work together. Each board connects chips, resistors, and other parts so your device works. Simple gadgets use single-sided boards. Laptops and phones use multilayer boards.

What is pcba helps make devices smaller, faster, and better. The design lets you fit many parts in a small space. You use through-hole and surface-mount technology to put on parts. Through-hole means you put leads through holes in the pcb. Surface-mount means you put parts right on top. Both ways help you build strong and good circuits.

Key points about what is pcba:

You start with a printed circuit board.

You add parts like chips and resistors.

You use copper traces to connect each circuit.

You follow strict rules for quality and safety.

You find pcb assemblies in almost every modern device.

💡 Note: When you know what is pcba, you can pick the right type of circuit and parts for your project. This helps you keep up with new technology and make better products.

Types of Printed Circuit Boards

There are a few main types of printed circuit boards. Each type has special features and is used for different things. The most common types are single-sided, double-sided, and multilayer. You also see rigid, flex, and rigid-flex boards. Knowing about these types helps you pick the best pcb for your project. Picking the right one can make your device work better, save space, and cost less.

Single-Sided PCB

A single-sided pcb has copper traces on just one side. All the parts go on that same side. This type is the easiest and cheapest to make. You often find single-sided boards in simple electronics, toys, and calculators. The design is simple and fast to build.

Many companies use single-sided pcbs for their products. The table below shows why this type is popular:

Aspect | Details |

|---|---|

Projected CAGR | |

Key Growth Drivers | Demand in automotive, consumer electronics, industrial controls |

Largest Market Segment | Automotive (fastest-growing, uses PCBs in engine control, body control, infotainment) |

Other Significant Segments | Consumer electronics (smartphones, tablets, laptops), Industrial controls (PLCs, DCSs) |

Market Concentration | High concentration with few large manufacturers dominating |

Regulatory Impact | Low impact; general electronics regulations like RoHS have minimal effect |

Substitutes | Few substitutes; flexible pcbs exist but are costlier and less suited for high volume |

Trends | Increasing use of surface mount technology (SMT), demand for high-density pcbs |

Regional Dominance | North America, Europe, Asia Pacific (notably China and the US) |

Competitive Landscape | Includes Thomas Instrumentation, Janco Electronics, PGF Technology Group, VR Industries, MacroFab |

You pick single-sided pcbs when you want a simple and cheap circuit. They are not good for complex or fast designs. They work best for things that do not need many parts or special features.

Double-Sided PCB

A double-sided pcb has copper traces on both sides. You can put parts on the top and bottom. This type lets you make more complex circuits than single-sided boards. You use vias, which are small holes, to connect both sides.

Double-sided pcbs are used in many fields. Here are some important facts:

Double-sided pcbs are best for circuits with medium complexity.

You see them in cars, phones, energy, health, and home devices.

They give better signals and less interference than single-sided boards.

You can fit more parts in a smaller space, which is good for tiny devices.

The design allows more features and higher circuit density.

Making double-sided boards needs special skills and tools.

They cost more than single-sided, but you get better results.

AI and machines now help make designs more accurate and improve quality.

Smaller gadgets and IoT make double-sided pcbs more popular.

New materials and green efforts change how these boards are made.

You choose double-sided pcbs when you need more parts and better performance. They are great for products that need strong, small, and flexible circuits.

Multilayer PCB

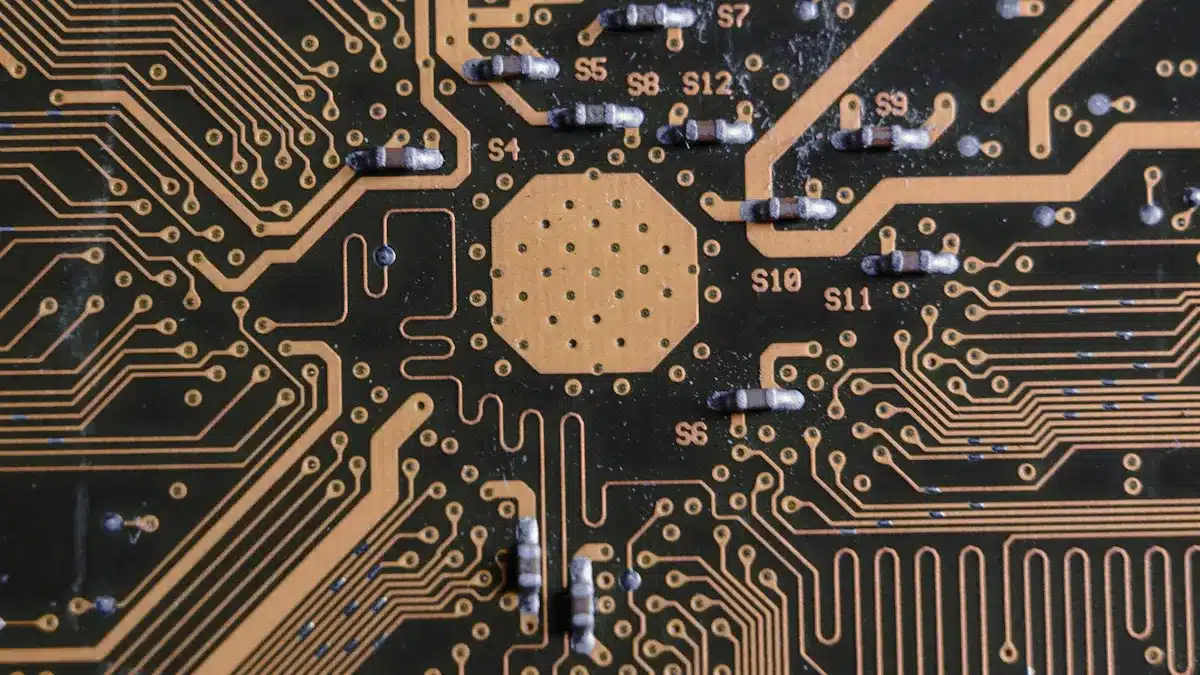

A multilayer pcb has three or more layers of copper traces. These layers are stacked with insulation between them. This type lets you build very complex circuits in a small space. You use multilayer boards in phones, medical tools, and fast computers.

Multilayer pcbs have many good points:

You can put more parts in a small area, which is important for small devices.

The design makes the board stronger and more reliable. It also helps with heat and power.

You get great EMI shielding, so there is less interference.

Multilayer boards are good for fast circuits and advanced features.

You use them in things that need to be light and small, like space and wearable tech.

They work well in tough places, like outside or in factories.

Here is a table that lists the main features of multilayer pcbs:

Aspect | Details |

|---|---|

Multilayer pcbs are smaller than single-layer boards with similar functions. | |

Lightweight Construction | Fewer connectors mean less weight, which is good for mobile devices. |

High Component Density | More layers allow more components, boosting speed and function. |

Enhanced Performance | Shorter paths reduce signal delays and improve EMI shielding. |

Manufacturing Complexity | Needs precise design, advanced machines, and skilled workers. |

Higher Cost | More expensive due to complex design and materials. |

Production Time | Takes longer to make because of many layers and steps. |

Limited Manufacturer Availability | Not all companies can make multilayer pcbs, so you have fewer options. |

You use multilayer pcbs when you need high performance, small size, and lots of parts. The design is harder, and the price is higher. You have to think about these things when you pick this type.

💡 Note: There are more types of printed circuit boards now, like rigid, flex, rigid-flex, hdi pcb, and uhdi. Each type is good for different uses. For example, a flex pcb can bend and twist, which is helpful for wearable and bendy electronics. An hdi pcb uses tiny traces and small vias for high-density circuits. You pick the type based on your design, how many parts you need, and if you need the board to bend.

You need to know about the types of printed circuit boards because each one changes your design, cost, and how your product works. As electronics get smaller and smarter, you must know which pcb type is best for you. This helps you keep up with new trends and make better choices for your projects.

Rigid PCB

Features

You pick a rigid PCB when you want a strong base. This board does not bend or move. It keeps its shape even under pressure. Rigid PCBs are made from tough stuff like high-Tg FR-4 or polyimide. These materials help the board stand up to heat and rough places.

Rigid PCBs are very reliable because solder joints stay tight.

The board works well in hot, wet, or shaky places.

Tests like shock, vibration, and heat show rigid PCBs are tough.

Electrical tests check if the board keeps signals safe and working.

Using simple designs and common materials saves money when making them.

A real example showed open circuit testing found cracks in solder joints on medical device PCBs. This helped people fix their process and make stronger boards. Rigid PCBs last a long time and keep devices working.

🛠️ Tip: Pick the right material and test your PCB. This helps you stop problems and save money on repairs.

Applications

Rigid PCBs are used in many important jobs. These boards are good when you need strength and long life.

Automotive: Rigid PCBs are in engine control units. A six-layer board with high-Tg FR-4 can run at 150°C and pass hard vibration tests.

Oil and Gas: Drilling tools use rigid PCBs with polyimide and metal-core layers. These boards work above 175°C and handle strong shaking.

Aerospace: Satellite transmitters use rigid-flex PCBs with ceramic parts. These boards can survive sunlight and big temperature changes in space.

Industrial: Furnace controllers use multi-layer rigid PCBs with special coatings. They work near heat at 160°C.

You also see rigid PCBs in computers, medical tools, and home gadgets. These boards give steady work and cost less over time. If you need a circuit that will not break, a rigid PCB is a smart pick.

Flex PCB

Features

You pick a flex pcb when you need a circuit that can bend. This type of board can twist or fold to fit small spaces. It uses materials like polyimide or polyester film. These materials let the board bend many times without breaking. You can shape a flex pcb to fit around corners or curves. This gives you more options than a rigid board.

A flex pcb has thin copper lines and special glue. Polyimide is good because it can take heat up to 400°C. It also keeps its shape when stressed. Rolled-annealed copper lets the board bend millions of times. You see fewer wires and connectors, so there are fewer things that can break. This makes the board more reliable. The board has layers: a flexible base, copper, glue, and a cover for safety.

You need to think about how much the board will bend. You should not put heavy parts or vias where the board bends a lot. Testing for bending, shaking, and heat helps make sure the board lasts. Flex pcbs use special traces to keep signals strong, even when moving.

📝 Note: Flex pcbs save space and are light. They are also more reliable. They help the environment because they use less material and energy to make.

Applications

You see flex pcbs in many new devices. Their flexible design helps make small, light, and easy-to-use products. Here are some ways people use flex pcbs:

Wearable health monitors like smartwatches and fitness bands use flex pcbs for comfort.

Phones and tablets use flex pcbs for screens, antennas, and hinges.

Medical tools like catheters and implants need flex pcbs for bending and safety.

Car dashboards, seat heaters, and sensors use flex pcbs for saving space and handling shaking.

Planes and military gear use flex pcbs to cut weight and work in hard places.

Industry | Application Examples | Key Advantages |

|---|---|---|

Wearables, phones, tablets, flexible antennas | Space saving, design freedom | |

Medical Devices | Health sensors, implants, catheters | Biocompatibility, reliability |

Automotive | Sensors, seat heaters, dashboards | Durability, vibration proof |

Aerospace | Satellites, avionics, UAVs | Weight reduction, reliability |

Flex pcbs have many good points, but there are some downsides. They cost more to make and need careful design. Making them is hard because the materials are thin. Still, the good things often matter more, especially when you need a board that bends, lasts long, and saves space.

Rigid-Flex PCB

Features

You pick a rigid flex pcb when you want both strength and bending. This pcb mixes rigid and flexible layers together. It lets you make circuits that can bend, fold, or twist. These boards fit into small or odd-shaped spaces. You can build 3D layouts with this design. This helps save space and makes your device lighter.

Rigid-flex pcbs connect parts without extra connectors or cables. This means there are fewer solder joints. Fewer joints mean less chance of breaking.

These boards are more reliable because there are fewer weak spots.

The flexible parts take in shocks and shaking. The rigid parts hold heavy pieces and give support.

You can control signals better by stacking layers. You also pick the right materials, like high-temperature thermoplastics for flex and FR-4 for rigid.

These pcbs handle heat well and last a long time, even in hard places.

🛡️ Tip: Rigid-flex pcbs help you avoid wiring mistakes. They make assembly easier. You also spend less money and make fewer errors because you use fewer parts.

A table below shows why you might choose a rigid-flex pcb:

Feature | Benefit |

|---|---|

3D design freedom | Fits complex shapes and small spaces |

Fewer connectors | Higher reliability, less weight |

Works in cars, planes, and factories | |

High circuit density | Supports advanced, compact electronics |

Long lifespan | Withstands bending and harsh conditions |

Applications

You see rigid-flex pcbs in many new and advanced products. These boards are used when you need small size and strong circuits.

In aerospace, rigid-flex pcbs build light and tough control systems. These systems survive shaking and very hot or cold weather.

Medical tools like surgical devices, wearable monitors, and implants use rigid-flex pcbs. They fit in tiny spaces and can bend during use.

In cars, you find these pcbs in sensors, cameras, and dashboard controls. These places are small and need strong, reliable circuits.

Foldable phones and smartwatches use rigid-flex pcbs. These boards let the device bend and twist without breaking.

You also find rigid-flex pcbs in military gear and factory machines. These places need circuits that can take shocks, move a lot, and work in tough spots. Using a rigid-flex design means fewer connectors and wires. This lowers the chance of breaking and makes your device work better.

💡 Note: Rigid-flex pcbs let you put many parts in a small space. You can make complex 3D layouts. This helps you build smaller, smarter, and stronger products.

Surface Mount PCBA

Features

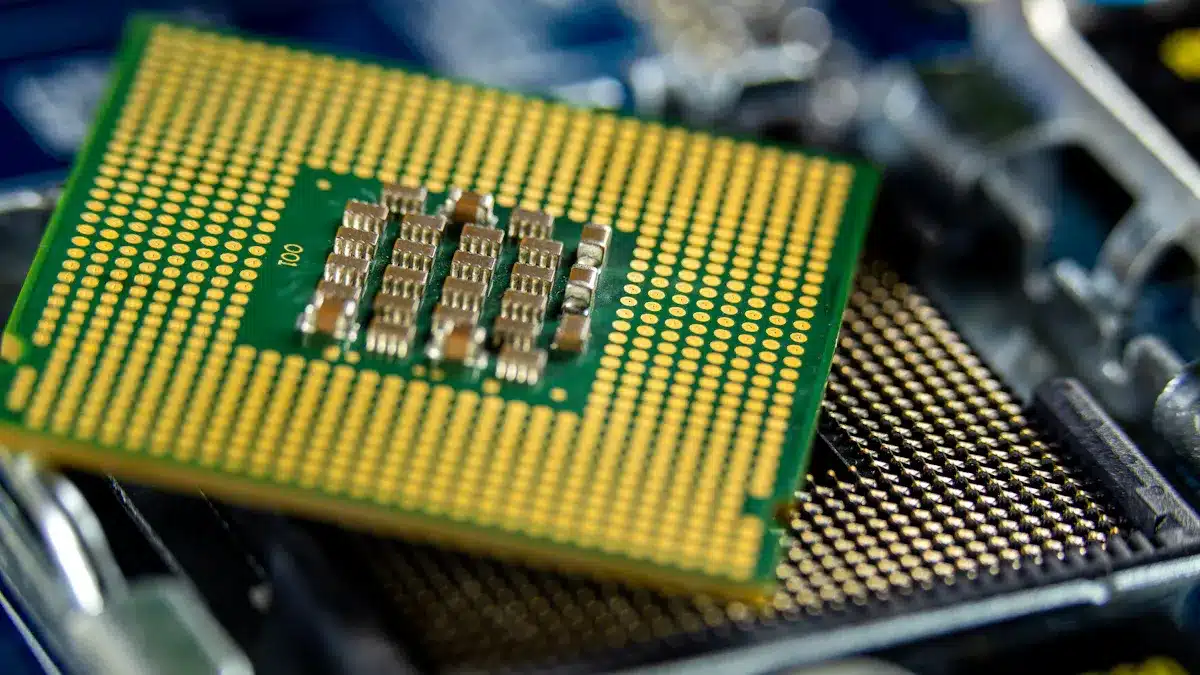

You pick surface mount PCBA when you want to build fast. This way puts parts right on the pcb surface. You do not need to drill lots of holes. This saves both time and money. Machines can place over 136,000 parts each hour. This helps you make many boards quickly.

You can fit more parts on each pcb. Surface mount technology lets you pack parts close together.

You can put parts on both sides of the pcb. This makes your design smaller and neater.

The small parts help you make tiny and light devices.

Surface mount parts usually cost less than through-hole parts. This means you save money.

Solder surface tension helps fix small mistakes. This means you get fewer errors.

The parts sit close to the pcb, so they are strong.

The connections have less resistance and inductance. This helps your circuits work better at high speeds.

You drill fewer holes, so you save more time and money.

Surface mount PCBA uses smart machines to help you work faster. These machines make boards that are strong and reliable. You get better layouts because there are no holes blocking the paths.

💡 Tip: Surface mount PCBA helps your device block unwanted noise. Your device works better with high-frequency signals.

Applications

You see surface mount PCBA in many new products. This way is good for things that need to be small, quick, and strong. You find it in smartphones, tablets, and computers. Medical devices use surface mount pcb for tiny sensors and monitors. Cars use these boards in control units and safety systems.

Consumer electronics use surface mount pcb for small designs.

Industrial machines use these boards for fast and accurate work.

Aerospace and military gear need surface mount pcb for strong and light circuits.

Surface mount PCBA works for many uses. It helps you make lots of boards fast and with good quality. You can trust this way for your next pcb project.

Choosing the Right Type

When you pick the right pcb, you must think about a few things. Each type, like flex or flex pcb, has good and bad points. What you choose depends on what your device does and where it will go.

Cost

Complexity

Application

Durability

Flexibility

Start by looking at your design. Ask if your circuit needs to bend. If your device must fit in a small spot or bend, use a flex pcb or flex-rigid board. These boards are great for wearables, medical tools, and foldable gadgets. They save space, cut weight, and let you make cool shapes. But they cost more and are harder to make.

If you need a strong and steady board, pick a rigid pcb. These boards last long and are easy to put together. They work best in computers, cars, and home electronics. But they do not bend and are not good for tight spaces.

Most people use FR-4 for cheap projects because it is low-cost and works well. For fast or hot uses, you may need Rogers or ceramic. These give better performance and last longer, but they cost more. Cars and planes often use high-Tg FR-4 or polyimide for extra strength.

Smart tools now help you pick the right pcb. They can find problems early in your design. This helps you make better boards and waste less. You should also check if your maker has good tools and support. Good help makes sure your board meets all needs.

📝 Tip: Always weigh the good and bad of each pcb type. Think about how much your board must bend and what it will do. In 2025, flex and flex pcb designs will be used more, especially for new and smart products.

You now know the main PCBA types. These are single-sided, double-sided, multilayer, rigid, flex, and rigid-flex. Each type has special features for different uses. Picking the right PCBA helps your device work better and last longer. It can also help you save money. Big companies like Dell and Fitbit use new materials and test their boards for quality. You should learn about new PCBA trends and materials. When you start a project, look at what you need. Then match your needs to the best PCBA type. This helps you make the right choice.

FAQ

What is the main difference between rigid and flex PCBs?

Rigid PCBs stay flat and do not bend. Flex PCBs can bend and twist to fit into small or oddly shaped spaces. You choose flex PCBs for devices that need to move or fold.

Why should you use a multilayer PCB?

You use a multilayer PCB when your device needs many parts in a small space. These boards help your device work faster and better. They also reduce signal problems and save space.

Can you mix rigid and flex PCBs in one device?

Yes, you can use a rigid-flex PCB. This board combines strong and bendable parts. You get the benefits of both types. Devices like foldable phones and medical tools often use rigid-flex PCBs.

Is surface mount PCBA better than through-hole assembly?

Surface mount PCBA lets you place more parts on both sides of the board. You build devices faster and make them smaller. Through-hole assembly works better for heavy or large parts.

How do you choose the right PCBA type for your project?

Start by thinking about your device’s size, shape, and how it will be used. Check if you need the board to bend or stay flat. Look at cost, strength, and how many parts you need to add.

See Also

Key Uses And Advantages Of PCBA In Electronics Today

Emerging Developments In PCB And PCBA Design Processes

Pros And Cons Of Flexible PCBA In Current Electronics