Turnkey PCB assembly is a simple way to make PCBs. It takes care of everything, from getting parts to delivering the final product. With turnkey services, you don’t need to work with many vendors. Instead, one company handles all your manufacturing needs.

Many industries gain a lot from this method.

It saves time and makes work smoother.

Careful testing ensures every product is high quality.

It works for both small projects and big productions, adjusting to market changes.

By making things easier, turnkey PCB assembly lets you focus on new ideas while keeping quality steady.

Key Takeaways

Turnkey PCB assembly makes manufacturing easier by doing everything. It handles part sourcing and delivers the final product, saving time and work.

This process ensures good quality with strict testing. It lets you focus on creating new ideas while keeping products reliable.

Turnkey services save money by combining tasks and buying parts in bulk. This is very helpful for new and small businesses.

Products are made faster with turnkey assembly. It helps you bring products to market quickly, which is important in busy industries.

Having one provider for all assembly needs simplifies communication. It lowers mistakes and makes managing your supply chain easier.

What is Turnkey PCB Assembly?

Definition and Overview

Turnkey PCB assembly means one company handles the whole process. They get the parts, make the board, put it together, and deliver it. This service removes the need to work with many vendors. Instead, one partner takes care of everything quickly and smoothly.

This method makes moving from design to production easier. It helps avoid delays and mistakes. Whether you need a small batch or a big order, turnkey PCB assembly adjusts to your needs. It’s a great choice for businesses wanting to save time and focus on creating new ideas.

Key Features of Turnkey PCB Assembly

Turnkey PCB assembly has many helpful features:

Cost Efficiency: Combining tasks lowers costs. Buying in bulk saves more money.

Time Savings: One company does all the work, speeding up production.

Quality Assurance: Careful tests, like AOI, ensure top-quality boards.

Simplified Communication: You talk to just one company, avoiding mix-ups.

Flexibility: It handles changes and works for both small and big projects.

These features make turnkey PCB assembly a smart and dependable option for businesses.

Comparison with Traditional PCB Assembly

Turnkey PCB assembly is much simpler than older methods. The table below shows how it’s better:

Benefit | Turnkey Assembly | Traditional Assembly |

|---|---|---|

Lower costs for parts and work | Higher costs for in-house work | |

Prototyping | Quick to make and test | Slower, with more design mistakes |

Flexibility | Handles changes and demand easily | Harder to adjust |

Time Management | Faster delivery and market readiness | Slower due to extra steps |

Administrative Burden | Less work, managed by the partner | More work for your team |

Risk Mitigation | Partner takes responsibility | More risk for your business |

Turnkey PCB assembly puts everything in one place. This makes it faster and easier. Traditional methods need many vendors, which costs more and takes longer. Choosing turnkey services saves time, money, and effort.

How Turnkey PCB Assembly Works

Component Sourcing and Procurement

Turnkey PCB assembly starts by finding and buying parts. This step makes sure all parts are good quality and reliable. Companies like JHYPCB follow strict rules to keep standards high. They check suppliers, inspect parts, and track everything carefully. These steps make sure parts are real and meet industry rules.

Turnkey providers also check your bill of materials (BOM) for mistakes. They suggest other options if needed to avoid problems like outdated parts or delivery delays. Engineers review designs to ensure parts fit and work correctly. This helps prevent assembly problems and keeps production smooth.

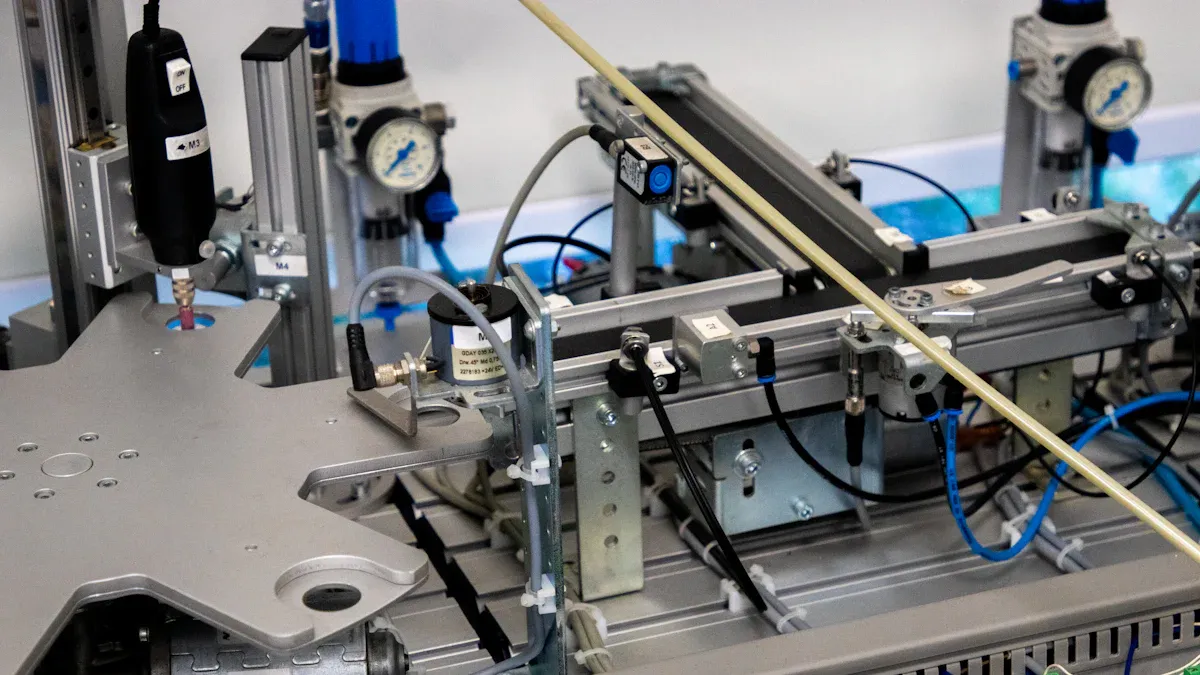

PCB Fabrication and Assembly

After getting parts, the next step is making the PCB and putting parts on it. Turnkey providers use advanced methods to make this faster and better. For example, checking designs early avoids mistakes and saves time. Smart techniques reduce steps, speeding up the process.

This method has clear benefits. Good parts mean fewer breakdowns and longer-lasting products. Quick production helps your products reach customers faster, giving you an advantage. The mix of speed and quality makes turnkey PCB assembly a great choice for businesses.

Evidence | Explanation |

|---|---|

Design Validation | Finds mistakes early, saving time and money. |

Quality Control | Reduces failures and makes products last longer. |

Efficient Manufacturing | Speeds up production by cutting unnecessary steps. |

Testing and Quality Assurance

Testing is very important in turnkey PCB assembly. Providers use different tests to check if boards work well and are reliable. Burn-in testing pushes boards to their limits to find weak spots. Functional testing checks if boards work normally. Automated Optical Inspection (AOI) uses cameras to spot visual problems.

These tests make boards more reliable. Finding problems early lowers failure rates and ensures boards work as expected. Quality checks also keep products consistent, so every item meets your needs. By focusing on testing, turnkey PCB assembly delivers trustworthy products quickly.

|

Packaging and Delivery

After your PCBs pass all tests, they are packaged and sent. This step ensures your boards stay safe and arrive in great shape. Turnkey PCB assembly providers take special care to protect them during shipping.

How Packaging Works

Turnkey providers use special materials to keep your PCBs safe. These include:

Anti-static bags: Stop static electricity from damaging parts.

Bubble wrap or foam inserts: Protect boards from bumps during transport.

Custom-fit boxes: Hold boards securely to prevent movement or breaking.

Every package is checked to meet safety rules. This careful process keeps your boards safe, even on long trips.

Tip: Ask if your provider uses eco-friendly packaging. It helps reduce waste and supports the environment.

Delivery Process

Turnkey services make delivery faster and easier. They work with trusted shippers for quick and safe delivery. You can track your package live, so you know where it is. Whether shipping nearby or far away, turnkey providers handle everything for you.

By managing packaging and delivery, turnkey PCB assembly saves you time. You get your PCBs ready to use without extra effort. This smooth process keeps your projects on time and within budget.

Advantages of Turnkey Assembly

Cost Savings and Efficiency

Turnkey PCB assembly helps save money by combining tasks. One provider handles everything, so you don’t need many vendors. This reduces extra work and makes things simpler. By using a turnkey service, you can cut costs by up to 15%. Buying parts in bulk also lowers prices, and better processes reduce waste.

Cost Savings Category | Description |

|---|---|

Freight charges | Lowered by using just one vendor. |

Component costs | Reduced through bulk buying. |

Customs fees | Simplified with smoother processes. |

Equipment costs | Cut down by sourcing from one place. |

Testing and certification charges | Often reduced or removed. |

Assembly | Easier with one main contact. |

Nonrecurring engineering (NRE) costs | Lowered by avoiding multiple vendors. |

Extra resources costs | Reduced with better planning. |

Overall cost reduction | Achieved with faster production and smart steps. |

Turnkey services also make products more reliable, giving you better value. By simplifying the process, you can focus on creating new ideas without worrying about hidden costs.

Tip: Working with a turnkey PCB provider saves money and boosts efficiency, helping you stay ahead.

Faster Production Cycles

Turnkey PCB assembly speeds up how fast products are made. It combines part sourcing, making, and assembly into one smooth process. This removes delays caused by miscommunication or dealing with many vendors. The faster process helps your products reach customers sooner, keeping you ahead of others.

Advantage | Description |

|---|---|

One supplier makes things easier, so you can focus better. | |

Faster Time to Market | Experts make assembly quicker, getting products out faster. |

Improved Quality Control | Skilled workers ensure high-quality results. |

Reduced Overall Costs | Better efficiency lowers costs for building products. |

For example, a school robotics team used a turnkey provider to save money and finish their project faster. They ordered parts in batches, which let them focus on improving designs instead of handling logistics.

Note: Faster production not only gets products out quickly but also helps with testing and improving designs, which is key for tech industries.

Enhanced Quality Control

Turnkey PCB assembly providers focus on quality at every step. They use top-quality parts and test boards carefully to meet standards. Tests like AOI, burn-in testing, and functional testing ensure boards work well and last long.

Testing Method | Description |

|---|---|

Burn-in Testing | Finds weak spots by testing boards under tough conditions. |

Functional Circuit Testing | Checks if parts work correctly during normal use. |

Automated Optical Inspection (AOI) | Uses cameras to find visual issues and ensure good assembly. |

Turnkey providers also check designs and parts to avoid problems. This lowers the chance of defects and improves performance. For example, a tech company used a turnkey service to keep costs under $100 per unit while ensuring high quality.

By choosing turnkey services, you can deliver reliable products every time. This builds trust and makes your brand stronger in competitive markets.

Callout: Better quality control means fewer problems, saving time and money on fixes or replacements.

Easier Supply Chain Management

Handling a supply chain can be tough, especially with many vendors. Turnkey PCB assembly makes it easier by letting one provider do it all. You won’t need to manage separate suppliers for parts, board-making, and assembly. Instead, one partner takes care of everything from start to finish.

Main Benefits of Easier Supply Chain Management

Clear Communication

No need to talk to many vendors anymore. A turnkey provider is your only contact, saving time and avoiding confusion. They make sure your needs are understood and met quickly.Less Paperwork

Dealing with invoices and shipping for many suppliers takes time. Turnkey services handle these tasks, so you can focus on your main work.Better Coordination

Turnkey providers make sure all steps fit together smoothly. For example, they match part sourcing with board-making to avoid delays. This keeps your project on track.Fewer Mistakes

Working with many vendors can lead to mix-ups. Turnkey assembly lowers this risk by managing everything in one place. This ensures your instructions are followed correctly.

How Turnkey PCB Assembly Makes Supply Chains Easier

Problem with Traditional Supply Chains | How Turnkey PCB Assembly Helps |

|---|---|

Too many contacts | One provider handles all tasks |

Delays from poor timing | Processes are well-coordinated for faster delivery |

Lots of paperwork | Fewer documents and simpler operations |

Quality problems | Consistent checks at every step |

Tip: Picking a turnkey provider removes the stress of managing many suppliers. It saves time and makes production smoother.

Example in Real Life

Think about making a new smart gadget. Normally, you’d get parts from one vendor, boards from another, and assembly elsewhere. Each step needs planning, and delays can mess up your schedule. With turnkey PCB assembly, one provider does it all. This keeps your project moving without interruptions.

Using turnkey PCB assembly simplifies your supply chain. You’ll spend less time on logistics and more time creating great products.

Callout: A simple supply chain saves time and money, helping you stay ahead in fast-moving industries.

Main Benefits of PCB Assembly for Industries

Consumer Electronics and IoT

PCB assembly is key for electronics and IoT devices. It helps products like phones, smartwatches, and smart home systems work well. Compact designs allow more features in smaller gadgets. High-quality assembly makes these devices stronger and last longer.

Turnkey PCB assembly makes IoT device production easier. It handles sourcing, building, and testing in one process. This reduces mistakes and speeds up production. Tools like cameras and X-ray machines check quality carefully. These steps help create reliable products that customers trust.

Automotive and Transportation

In cars, PCB assembly supports advanced tech like electric vehicles and self-driving systems. PCBs manage sensors, engines, and safety features. Good assembly ensures these systems work smoothly in tough conditions.

Turnkey providers use strong materials to protect boards from heat and vibration. This is important for vehicles in extreme environments. Automated tests find hidden problems before products are sold. These benefits help make safer and better transportation solutions.

Medical Devices and Healthcare

Medical devices need to be precise and dependable. PCBs power tools like health monitors and diagnostic machines. These devices must give accurate results and work consistently.

Turnkey PCB assembly improves medical device production with strict quality checks. Tests ensure devices work properly in real-life situations. Compact designs make tools lighter and easier to carry. By using turnkey services, you can focus on creating new ideas while meeting healthcare standards.

Aerospace and Defense Applications

Turnkey PCB assembly is very important for aerospace and defense. These fields need strong and reliable PCBs for advanced systems. The boards must handle tough conditions like heat, shaking, and radiation. Turnkey services make sure your PCBs meet these strict needs.

Why Turnkey PCB Assembly Matters

Precision and Reliability

Aerospace and defense systems need accurate and dependable PCBs. Turnkey providers use special tests, like X-rays and heat checks, to ensure every board works perfectly.Strength in Tough Conditions

Your PCBs must survive harsh environments. Turnkey services use strong materials, like heat-resistant laminates and protective coatings, to keep boards safe.Following Industry Rules

Aerospace and defense follow strict rules, like AS9100 and MIL-STD. Turnkey providers help you meet these rules by checking quality at every step.

Advantages for Aerospace and Defense Projects

Feature | Benefit |

|---|---|

Advanced Testing | Makes sure boards work in critical missions. |

High-Quality Materials | Protects boards from extreme conditions. |

Streamlined Production | Speeds up delivery for urgent projects. |

Regulatory Compliance | Meets safety and performance standards. |

Tip: Pick a turnkey provider with aerospace and defense experience. They know how to handle the challenges of these fields.

Turnkey PCB assembly makes production easier. It ensures your boards are ready for tough jobs. By working with a skilled provider, you can focus on creating new ideas while delivering dependable solutions for aerospace and defense systems.

Why Turnkey PCB Assembly Matters

Importance for Startups and Small Businesses

Turnkey PCB assembly is very helpful for startups and small businesses. It makes manufacturing easier by handling everything in one place. You don’t need to work with many vendors, which saves time and effort. For startups, this means more time to focus on new ideas and growing your business.

Small businesses often have tight budgets and fewer resources. Turnkey services solve this by offering affordable options. Buying parts in bulk lowers costs, and smooth processes reduce expenses. Turnkey providers also handle small orders well, so you don’t need to worry about storing too much inventory.

Evidence | Description |

|---|---|

One-stop solutions save time and speed up production. | |

Cost-Effectiveness | Lets startups focus on growth while outsourcing tough tasks. |

Demand Growth | Complex devices increase the need for all-in-one solutions. |

Tip: Turnkey PCB assembly is perfect for small orders that need fast delivery without losing quality.

Role in Accelerating Product Development

Turnkey PCB assembly helps speed up product development. It manages every step of production, so you avoid delays from working with multiple vendors. This smooth process ensures faster delivery, helping you launch products quickly.

With one supplier, communication improves, reducing mistakes. Better quality checks also save time by catching errors early. For example, turnkey providers handle everything from getting parts to testing, keeping your project on schedule.

Faster delivery happens when one supplier manages all steps.

Smooth workflows prevent delays and keep projects on track.

Clear communication reduces mistakes and misunderstandings.

Note: Quick production cycles help you meet deadlines and give extra time to improve your designs.

Contribution to Innovation and Scalability

Turnkey PCB assembly encourages innovation by saving your resources. Instead of managing tricky supply chains, you can focus on designing better products. This setup boosts creativity and lets you try new ideas without distractions.

Scalability is another big advantage. As your business grows, turnkey services adjust to your needs. Whether you need a few prototypes or large orders, turnkey providers handle it well. They ensure quality stays high, even with bigger production.

Advantage | Description |

|---|---|

Handles all PCB needs in one place. | |

Faster Time-to-Market | Quick processes mean faster product launches. |

Consistent Quality | Quality checks at every stage ensure great results. |

Reduced Risk | Fewer mistakes with one company managing everything. |

By using turnkey PCB assembly, you get a partner who helps you grow while keeping quality high. This support allows you to innovate and expand without losing efficiency or standards.

Callout: Turnkey services let you focus on what matters—creating amazing products and growing your business.

Turnkey PCB assembly makes production easier by handling all steps. It covers everything from getting parts to checking quality. This method speeds up work, manages inventory well, and keeps quality steady. For instance, making PCBs in-house avoids delays, while regular checks improve reliability. Companies like Ninja Circuits and Venture PCBA offer affordable services with high success rates and tracking. These perks make turnkey PCB assembly great for growing projects smoothly. By using this method, you can focus on new ideas, meet deadlines, and keep quality high.

Advantage | Description |

|---|---|

Component Sourcing | One supplier handles all parts, even rare ones, for a complete BOM. |

Inventory Management | Good inventory control prevents delays and shortages during production. |

In-house PCB Fabrication | Careful manufacturing ensures boards meet quality and design needs. |

Reduced Lead Times | Making PCBs in-house saves time on shipping and coordination. |

PCB Assembly Quality Assurance | Regular checks during production keep quality consistent and reliable. |

PCB Project Management | Managing all steps ensures smooth progress and meets project goals. |

Tip: Try turnkey PCB assembly to simplify production and grow your projects easily.

FAQ

What makes turnkey PCB assembly different from traditional PCB assembly?

Turnkey PCB assembly does all the work for you. It finds parts, builds boards, and delivers them. Traditional assembly needs you to work with many vendors. Turnkey services save time and avoid mistakes by keeping it simple.

Can small orders use turnkey PCB assembly?

Yes, small orders are perfect for turnkey PCB assembly. Providers adjust their process to fit your needs. They deliver on time and keep quality high. This makes it great for startups and small businesses.

How do turnkey PCB services ensure good quality?

Turnkey providers use smart tests like AOI and burn-in checks. They check every step, from getting parts to building boards. These tests find problems early and keep quality steady.

Is turnkey PCB assembly a money-saving option?

Yes, turnkey PCB assembly helps save money. It combines tasks and buys parts in bulk. You don’t need many vendors, which cuts costs for shipping and paperwork. This method lowers overall expenses.

Can turnkey PCB assembly handle tough projects?

Yes, turnkey PCB assembly works for hard projects like medical tools or space tech. Providers use strong materials and special tests to meet strict rules. They make sure your boards work well in tough conditions.

See Also

Understanding PCBA Services and Their Importance in Electronics

The Significance of PCBA: What It Represents

Exploring PCBA Manufacturing and Its Importance in Industry