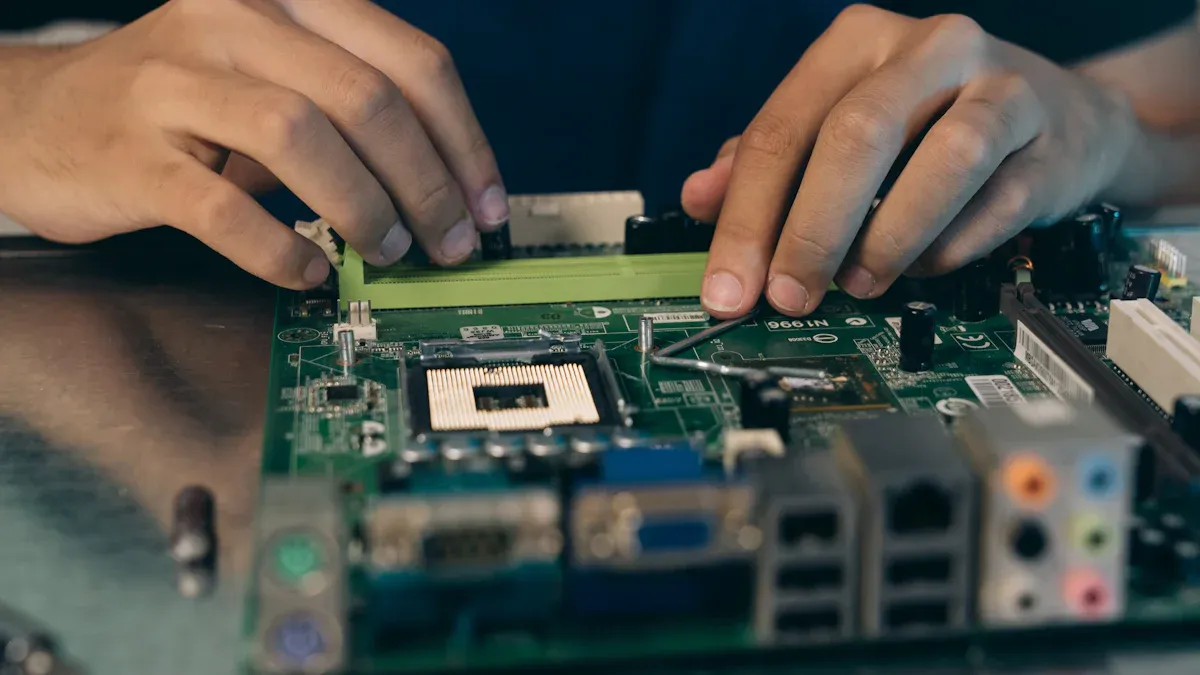

PCBA services involve assembling electronic components onto a circuit board, enabling it to function as a complete circuit. These services play a crucial role in electronics manufacturing by ensuring devices operate efficiently and meet high-quality standards.

The global PCB market reached a value of $65 billion in 2023, highlighting the growing demand for PCBA services.

Leading companies like Jabil, Inc. are advancing their facilities by incorporating robotics and smart technologies to enhance production speed and quality.

By utilizing PCBA services, manufacturers can produce reliable, high-quality electronics that align with modern demands.

Key Takeaways

PCBA services help put electronic parts on circuit boards. This makes sure devices work well and meet good quality rules.

Picking a skilled PCBA company can finish projects faster. It also reduces product problems and speeds up getting products to customers.

Quality checks like Automated Optical Inspection (AOI) are important. Certifications like ISO 9001 also help ensure great PCBA services.

What Are PCBA Services and How Are They Different from PCB?

What is a PCB?

A Printed Circuit Board (PCB) is the base of electronics. It works like a skeleton, linking parts with electrical paths. PCBs are made from materials like fiberglass with copper lines on top. These copper lines let electricity move through the board, making the device work.

For example, a smartphone has a PCB that connects its processor, memory, and other parts. Without it, the phone wouldn’t work. PCBs can be simple or complex, like single-layer, double-layer, or multi-layer boards, depending on the device’s needs.

What is a PCBA?

A Printed Circuit Board Assembly (PCBA) is the next step. It adds electronic parts to the PCB to make it work. These parts include resistors, chips, and capacitors that power the circuit.

Think of a PCBA as a finished PCB. A PCB is just a blank board, but a PCBA is ready to do its job. For example, the PCBA in a TV helps show pictures and respond to the remote control.

Key Differences Between PCB and PCBA

The main difference is how they work. A PCB is an empty board, while a PCBA is a working circuit. The table below shows more differences:

Aspect | PCB Cost | PCBA Cost | Lead Time (PCB) | Lead Time (PCBA) |

|---|---|---|---|---|

Manufacturing Cost | $5 | $30 | 1 week | Several weeks |

Components Cost | N/A | $15 | N/A | N/A |

Assembly Cost | N/A | $10 | N/A | N/A |

This table shows PCBA takes more time and money. But it’s needed to make devices work properly.

Processes Involved in PCBA Services

Component Procurement and Preparation

The PCBA process starts with getting good parts. Reliable suppliers are needed for quality components. Parts like resistors and chips must be checked for flaws. Organizing these parts helps in smooth assembly later.

Stage | Description |

|---|---|

Design | Ideas turn into plans and detailed design files. |

Fabrication | Designs are made into physical blank PCBs. |

Assembly | Components are added to PCBs to make them work. |

Testing | Assembled boards are tested to ensure they work well. |

Quality Control | PCBAs are checked for problems during the process. |

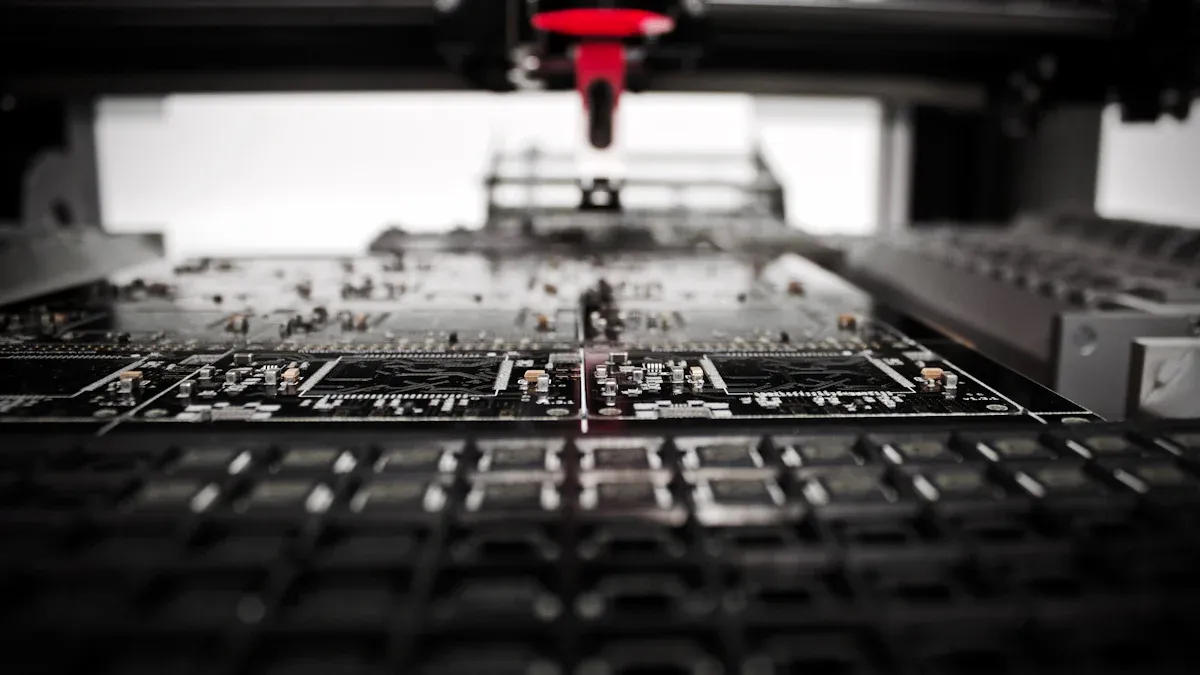

Surface Mount Technology (SMT) Assembly

SMT makes PCBA faster and cheaper. Machines place parts directly on the PCB surface. This method saves time and money. High-speed machines improve accuracy and make designs smaller and lighter.

Benefit/Innovation | Description |

|---|---|

Products are made quicker, helping companies compete better. | |

Increased production capacity | More products can be made with the same tools and workers. |

Lower costs | Better efficiency lowers costs, increasing profits. |

Through-Hole Technology Assembly

Through-hole assembly is still used for some PCBA needs. It places parts into holes drilled in the PCB. This method makes boards stronger and handles more power. But it takes longer and fits fewer parts than SMT.

Advantages | Limitations |

|---|---|

Fewer parts can fit on the board. | |

Accessibility for repairs | Takes more time to produce. |

Higher power handling | N/A |

Inspection and Quality Control

Inspection ensures every PCBA works well. Automated Optical Inspection (AOI) finds soldering mistakes. X-rays check hidden parts, and tests confirm circuits work. Metrics like defect rates track how well the process works.

Automated Optical Inspection

X-ray Inspection

Functional Circuit Testing

In-Circuit Testing

Functional Testing and Final Assembly

Functional testing checks if the PCBA works as it should. Tests measure power and signal performance. After testing, the PCBA is added to the device, finishing the process.

Performance Indicator | Description |

|---|---|

Input Power Measurement | Measures power signals after assembly. |

Receiver Sensitivity Tests | Checks if receivers work without issues. |

Why PCBA Services Are Important in Electronics Manufacturing

Making Products Work and Last Longer

PCBA services help devices work the way they should. They carefully put parts together to make circuits that meet standards. Tests like heat and stress checks ensure the product is strong. For example, stress tests mimic real-life use to find weak spots. This makes sure PCBAs can handle tough conditions like heat or shocks.

Testing Type | What It Does |

|---|---|

Mechanical Loading | Tests for strength under weight, shaking, and impacts. |

Thermal Loading | Checks how well it handles heat and cold changes. |

Electrical Loading | Tests power and signal safety under high use. |

Environmental Stress Tests | Simulates aging to see how long it will last. |

These steps make sure electronics are reliable for cars, hospitals, and planes.

Saving Money and Time in Production

PCBA services make production faster and cheaper. They improve designs to use fewer parts and simpler layouts. For example:

Using the same parts saves money when buying in bulk.

Easy designs make assembly quicker.

Finding ways to cut costs without losing quality.

A clear plan helps save money and speeds up production. This gives companies an advantage in making electronics quickly and affordably.

Helping New Ideas and Big Projects

PCBA services help create new and better products. Advanced methods like surface mounting make smaller and smarter designs. This helps make things like smartphones and smart devices. PCBA processes can also handle large orders, meeting high demand. Whether for a small test or big production, PCBA services keep quality steady.

Industry | Needs |

|---|---|

Consumer Electronics | Small, cheap, and mass-produced items like phones and tablets. |

Automotive | Strong and reliable parts for engines and car systems. |

Medical Devices | Accurate and safe tools for health checks and monitoring. |

Telecommunications | Reliable parts for networks like routers and cell towers. |

Following Rules and Staying Safe

Following rules is key in electronics manufacturing. PCBA providers follow safety and quality rules like UL and ISO. For example, ISO 13485:2016 sets rules for medical device quality. Tests include heat checks, strength tests, and signal checks.

Testing Type | What It Checks |

|---|---|

Safety Testing and Certification | Makes sure products meet safety rules like UL standards. |

Performance and Reliability Testing | Tests strength, heat handling, and signal quality. |

Overall Testing Capability | Covers many tests like chemical, electrical, and mechanical checks. |

By following these rules, PCBA services help avoid problems and make products that meet customer needs.

Tips for Picking the Best PCBA Service Provider

Looking at Experience and Skills

Choose a provider with lots of experience. Skilled providers make fewer mistakes and finish projects faster. They also help avoid product failures and deliver items quickly. For example, experienced providers can reduce delays and improve reliability.

Benefit | What It Means |

|---|---|

Faster lead times | Quicker delivery of needed parts |

Fewer product failures | Less chance of items breaking after being sold |

Speedier time to market | Products reach customers sooner |

Picking a knowledgeable provider ensures your PCBA projects are done well and on time.

Checking Quality Control Methods

Quality checks are very important in PCBA work. Find providers who use tools like AOI and X-ray tests. Certifications like ISO 9001 show they care about quality. Over a million companies worldwide follow this standard to ensure good processes.

Certification/Standard | What It Does | Fun Fact |

|---|---|---|

ISO 9001 | Sets rules for managing quality. | Used by over 1 million companies globally. |

These certifications help you find providers who focus on making reliable products.

Verifying Certifications and Rules

Certifications prove a provider meets industry standards. Providers often use tech systems to track training and follow rules. These systems keep records for audits and show gaps in compliance. Clear records build trust and ensure transparency.

Working with certified providers helps you meet rules and avoid problems in your PCBA projects.

Thinking About Growth and Custom Options

Scalability and custom designs are key for your needs. Providers offering flexible PCBs or HDI PCBs can improve performance.

Design Type | Advantages |

|---|---|

Flexible PCBs | Smaller designs that keep signals strong without extra connectors. |

HDI PCBs | Sharper signals, stronger boards, and lighter materials for better use. |

These options let you grow production while keeping quality high. A provider with scalable solutions supports your business as it expands.

PCBA services are key to making modern electronics work well. They help devices stay reliable, useful, and advanced. Picking a good provider ensures top-quality products that follow rules. > Tip: Work with skilled PCBA providers to speed up production and turn your electronic ideas into reality easily.

FAQ

What industries gain the most from PCBA services?

PCBA services help industries like electronics, cars, healthcare, and communication. These fields need strong, reliable, and flexible electronic parts for their products.

How do PCBA services make products better?

PCBA services use smart tests like AOI and X-ray checks. These tests make sure every board works well and meets high standards.

Can PCBA services create special designs?

Yes, many providers make custom designs like flexible or HDI PCBs. These designs make products smaller, faster, and fit special needs.

Tip: Share your project needs with your PCBA provider for the best outcome.

See Also

The Essential Role of PCBA Prototyping in Electronics

Significance of PCBA Test Jigs in Today’s Electronics Manufacturing

The Impact of PCBA on Advancing Modern Electronics

Choosing the Best PCBA Manufacturer for Your Business Growth