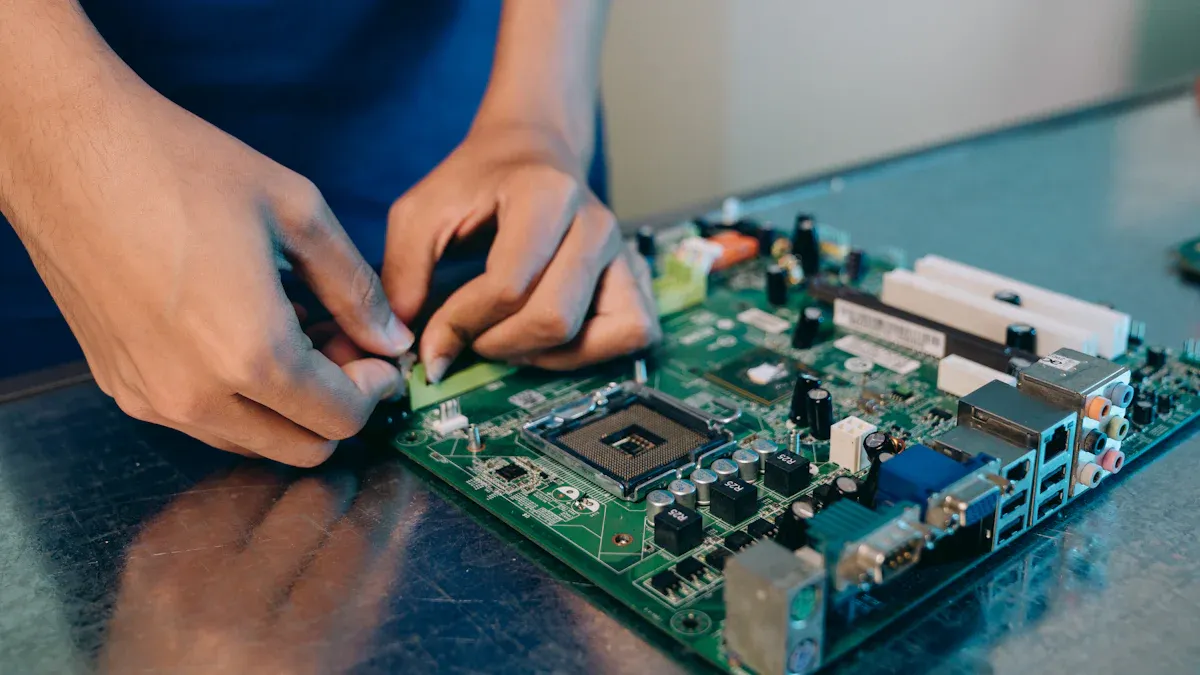

In PCBA assembly, every choice affects the final result. How you handle time, materials, and tools decides your project’s success. Being efficient helps save time and lowers costs. This makes sure your circuit board assembly is good quality and on time.

Using smart tips helps you avoid mistakes and work better. Whether building one PCBA or many, being efficient is key. When you simplify your steps, you save money and get dependable results.

Key Takeaways

-

Set clear goals for your PCBA project. This keeps your team on track and works faster.

-

Make a detailed list of materials (BOM). This helps avoid mistakes and makes teamwork easier.

-

Pick common part sizes to save money and make assembly simple. This speeds up work and reduces errors.

-

Work closely with trusted suppliers. Good teamwork can mean lower costs and better quality.

-

Use modern tools like PCB design programs and machines. These improve accuracy and make assembly quicker.

Plan for Efficient PCBA Assembly

Define Clear Project Goals

Good planning starts with setting clear goals for your project. First, decide what success looks like for your PCBA assembly. Think about things like managing tasks, solving problems, and meeting deadlines. Check industry standards to find areas where you can improve. Use this information to set clear targets for your team to follow.

Work with others in the industry to learn helpful tips. Update how you measure success to match these new goals. Make sure your team knows the goals and checks progress often. This method helps you work better, celebrate wins, and fix problems quickly.

Create a Comprehensive Bill of Materials (BOM)

A detailed BOM is key for smooth PCB assembly. It connects the design and production teams, making sure nothing is missed. Managing the BOM well improves accuracy and makes the supply chain run better.

To make a strong BOM, list every part, its details, and where to get it. This clears up confusion and helps manufacturers know exactly what’s needed. Teamwork makes the BOM process even better. Using version control also reduces mistakes, leading to better products and on-time delivery. Planning with a good BOM saves time and money over time.

Set Realistic Timelines and Budgets

Making realistic timelines and budgets is important for saving money. Start by learning what affects costs and how long things take. For example, some parts are cheap, but special ones cost more and take longer to get. Labor, testing, and quality checks also add to the total cost.

|

Description |

|

|---|---|

|

Component Costs |

Common parts are cheap; special ones cost more. |

|

Assembly Labor and Setup |

Setup costs are high for small runs, raising total costs. |

|

Yield and Rework |

Some boards fail tests; fixing them costs time and money. |

|

Testing and QA |

Testing tools and steps cost extra but ensure good quality. |

|

Lead Time |

Getting parts and assembling takes weeks, longer than bare PCBs. |

By thinking about these factors, you can plan better budgets and timelines. This keeps your project on track and avoids extra costs or delays.

Optimize PCB Design for Cost-Effective PCBA Procurement

Follow Design for Manufacturability (DFM) Guidelines

Designing with cost and manufacturing in mind helps save money. By following DFM rules, you can remove costly design features. This makes sure materials are used wisely and assembly is easier. For instance, simple layouts and fewer extra details save time and resources.

Working with suppliers early can improve your design. Suppliers share tips to match your design with their tools. This teamwork lowers costs and makes production smoother. Using automated systems also reduces mistakes and speeds up the process.

Minimize Component Count and Complexity

Using fewer parts in your design can save a lot of money. Fewer parts mean less time ordering and assembling them. It also reduces mistakes during assembly, leading to better results.

A neat and simple layout makes assembly faster and easier. This saves time and money while making the product more reliable.

Use Standardized Component Sizes

Choosing standard part sizes helps cut costs. Common parts are cheaper because many suppliers sell them. This competition lowers prices and makes ordering easier.

Using fewer types of parts also speeds up assembly and reduces errors. This makes production faster and cheaper. Picking standard parts balances cost savings with smooth assembly.

Tip: Talk to your suppliers to pick parts that are easy to find and affordable.

Choose Reliable Suppliers for PCB Assembly

Check Supplier Certifications and Skills

Pick a good PCBA supplier by checking their certifications. Certified suppliers follow rules to make high-quality PCB assembly. Look for certifications like ISO 9001 for global quality or IPC-A-610 for assembly standards. For special industries, ISO 13485 is key for medical devices, and IATF 16949 works for cars.

|

Compliance Standard |

How It Helps PCB Assembly |

|---|---|

|

UL 94V-0 |

Meets fire safety rules, making products safer. |

|

RoHS |

No harmful materials, safer for people and nature. |

|

ISO 9001 |

Matches global quality rules, opening more markets. |

|

ISO 13485 |

Needed for medical devices, meeting strict rules. |

|

IATF 16949 |

Important for cars, proving quality and safety. |

Certifications show the supplier cares about quality and safety. They also lower risks when buying parts and help meet rules for your project.

Balance Costs and Quality

Saving money on PCB assembly means finding good prices and quality. Don’t pick the cheapest supplier without checking their work. Look at things like defect rates, first pass yield (FPY), and delivery times. Suppliers with fewer mistakes and high FPY save time and money.

Other things to check are speed, wasted materials, and setup time. These show how well a supplier can handle your project. Compare these details to find suppliers with fair prices and good quality.

Tip: Ask for clear quotes and check for extra fees like shipping or setup costs. This helps you plan better and avoid surprises.

Build Strong Supplier Relationships

Working closely with suppliers helps lower PCB assembly costs. Long-term partnerships build trust and teamwork, leading to better deals and faster service. Good suppliers share tips on parts and ways to save money on your design.

Picking trusted suppliers ensures steady quality and on-time delivery. Stay in touch and review their work often to keep the partnership strong. Over time, this teamwork boosts production and cuts costs.

Note: Suppliers who understand your needs can make PCB assembly easier and improve product quality.

Leverage Technology for Efficient PCBA Assembly

Use Advanced PCB Design Software

Advanced PCB design software helps make assembly better. These tools improve accuracy, reducing mistakes in your designs. Fewer errors mean reliable products and less fixing later. The software also makes changes easier, saving time and money.

Features like routing tools and part libraries speed up design work. They help place parts smartly, cutting assembly time and mistakes. For example, good trace layouts avoid problems, and neat part placement helps during assembly.

|

Advantage/Principle |

Description |

|---|---|

|

Better Accuracy |

Precise designs lower mistakes and improve product quality. |

|

Time and Cost Savings |

Tools like routing features save time and cut costs. |

|

Easier Design Structures |

Simple designs reduce problems during manufacturing. |

Using advanced design software makes assembly faster and improves quality.

Automate Assembly with Pick-and-Place Machines

Pick-and-place machines make assembly quicker and more accurate. These machines place parts fast and correctly every time. They can handle thousands of parts per hour, speeding up production.

Automation boosts productivity. One operator can assemble millions of parts each year. Contract manufacturers often do better than original equipment makers because of automation.

Tip: Use pick-and-place machines to save time and avoid mistakes in assembly.

Implement Real-Time Monitoring Systems

Real-time monitoring systems track how your assembly is going. They show problems early, helping you fix them fast. This keeps your work on schedule and ensures good quality.

These systems also help teams work together better. Everyone can see updates, reducing confusion and mistakes. For example, tools like Creo AAX share design changes quickly, saving time.

Using monitoring systems improves teamwork and keeps your assembly process efficient and reliable.

Ensure Quality Assurance in PCBA Assembly

Conduct Rigorous Testing at Every Stage

Testing during each step of PCBA assembly ensures good quality. Finding problems early avoids expensive fixes and saves time. Functional testing checks if parts work as they should. This reduces the chance of bad products being sold.

To improve quality, use tools like the chi-square test. These tools find key problem areas in production. Here’s how they help:

-

Spot steps causing defects and fix them.

-

Compare defect rates before and after changes.

-

Focus on big issues to use resources wisely.

|

Improvement Type |

Description |

|---|---|

|

Better Quality |

Early problem detection means fewer bad products. |

|

Higher Efficiency |

Watching key steps lowers mistakes and cuts costs. |

|

Greater Reliability |

Meeting strict rules makes PCBs more dependable. |

Using these methods keeps your PCBA assembly process consistent and high-quality.

Use Automated Optical Inspection (AOI) Systems

AOI systems are important for checking quality in PCBA assembly. They use cameras to find mistakes like bad soldering or missing parts. These systems work faster and better than people, giving steady results.

The benefits of AOI systems are clear. For example:

|

Metric |

Value |

|---|---|

|

Fewer missed defects |

|

|

First-pass success rate |

Up from 92% to 98% |

|

Lower rework costs |

Cut by 60% |

|

Defect tracking |

100% accurate |

|

Investment return |

In 8 months |

Adding AOI systems reduces errors, boosts speed, and ensures great quality in your projects.

Adhere to Industry Standards and Certifications

Following rules is key for keeping quality in PCBA assembly. Certifications like ISO 9001, IPC-A-610, and RoHS prove your products are safe and high-quality. These also help you gain trust and grow your business.

Certifications show you care about making good products. For instance, IPC-A-610 ensures proper assembly, and RoHS removes harmful materials. By following these rules, you make reliable products and meet customer needs.

Tip: Check and update your processes often to follow new industry rules.

Streamline Communication in PCBA Projects

Keep Communication Clear with Suppliers

Talking clearly with suppliers makes PCBA assembly easier. Start by sharing your quality needs and deadlines early. Write these details in contracts to avoid confusion later. This keeps everyone on the same page and reduces mistakes.

Use simple ways to stay in touch, like emails or apps. Plan regular meetings to check progress and solve problems quickly. These talks also help explain design needs better, lowering the chance of errors.

Tip: Ask suppliers for feedback to improve how you communicate. Good communication builds trust and strong teamwork.

Use Tools to Help Teams Work Together

Teamwork tools make projects run smoother and faster. For example, PCB CoDesign lets many people work on one layout at the same time. This helps everyone stay updated and work together better.

These tools also compare and combine design changes easily. This lowers mistakes and saves time when updating designs. Using such tools helps teams finish projects on time and with fewer problems.

Note: Team tools not only improve teamwork but also track changes well.

Write Down Changes and Updates Clearly

Writing down changes keeps projects accurate and organized. Record all updates to designs, schedules, and costs. This helps everyone know the latest details and avoids confusion.

Share updates using team platforms so everyone can see them fast. These tools make it easy to review changes and stay accountable. Updating records often also helps track progress and find ways to improve.

Tip: Keeping good records helps with future projects. It shows what worked and what didn’t, making things better next time.

Reduce Waste and Rework in PCBA Assembly

Spot and Fix Common Mistakes

Cutting waste starts by finding and fixing common mistakes. Errors during assembly often waste materials and cause delays. For example:

-

Faulty parts lead to scraps and extra repairs.

-

Making too many items creates unneeded stock and waste.

-

Poor tracking lets these problems continue unnoticed.

You can avoid these issues by watching production data closely. Fix mistakes quickly to keep things running smoothly and reduce waste.

Choose Strong Materials to Avoid Problems

Using strong materials helps stop failures in your products. Good materials last longer and handle wear better. This makes your products work well for a long time and reduces repairs.

Better materials also make customers happier. Reliable products mean fewer complaints and returns. Plus, using quality materials saves money by avoiding repair costs.

Tip: Check your materials often to ensure they are durable and high-quality.

Keep Improving Your Processes

Improving your processes regularly helps cut waste and rework. Look for ways to make your steps faster and simpler. For example, lean manufacturing removes extra steps and boosts efficiency.

Here’s how improving processes helps:

-

It inspires your team to find smarter ways to work.

-

It lowers risks by solving problems early.

-

It keeps quality steady, which earns customer trust.

|

Metric |

Before Changes |

After Changes |

Improvement |

|---|---|---|---|

|

First-Pass Yield (FPY) |

96.35% |

97.25% |

Up by 0.90% |

|

Defective Parts per Month |

6,000 |

0 |

Down by 6,000 |

By following these steps, you can save money and work more efficiently.

Optimize Inventory Management for PCBA Procurement

Avoid Overordering or Underordering Components

Managing parts well means ordering just the right amount. Buying too many parts wastes money and needs extra storage. Buying too few parts slows production and causes delays. Both problems can cost you more in the end.

To fix this, check what your project needs carefully. Use past data to guess how many parts you’ll need. Plan ahead for parts that take longer to arrive. Check your stock often to spot patterns and avoid running out or having too much.

Tip: Work with suppliers to know delivery times and stock availability. This helps you plan smarter and save money.

Use Just-in-Time (JIT) Inventory Systems

A Just-in-Time (JIT) system delivers parts only when needed. This lowers storage costs and reduces waste. Match your orders with your production schedule to make things run smoothly.

JIT also helps save money. Instead of spending on unused parts, you can use the money for other needs. But JIT needs good supplier relationships and accurate planning. Stay in touch with suppliers to get parts on time and avoid problems.

|

Description |

|

|---|---|

|

Initial Purchase Costs |

Includes buying price, shipping, and handling fees. |

|

Acquisition Costs |

Covers testing, setup, and integration expenses. |

|

Operating Costs |

Includes energy use, repairs, and supplies. |

|

Downtime Costs |

Caused by delays from missing or bad parts. |

|

Cost of Quality |

Includes fixing mistakes, scrap, and returns. |

|

Resilience Costs |

Covers risks and backup plans for supply issues. |

Using JIT can cut these costs and make your PCBA process better.

Track Inventory Levels with Software Tools

Software tools help you track parts and avoid mistakes. These tools show real-time updates, making it easy to see what’s in stock. They also help you plan orders and predict future needs.

For example, inventory software can warn you when stock is low. This helps you order parts before they run out. The software can also create reports to find trends and improve your ordering process.

Note: Pick software that works with your current systems. This makes your work easier and more efficient.

Think About Outsourcing for Affordable PCBA Assembly

Outsourcing is a smart way to lower production costs in PCBA assembly. Contract manufacturers have the tools and skills to simplify your work. This lets you focus on your main business goals. Below are tips for successful outsourcing.

Check the Benefits of Outsourcing

Outsourcing has many perks that make it a money-saving choice. You don’t need to buy expensive machines or rent big spaces. Instead, you can use those savings for other important needs.

|

Advantage |

How It Helps |

|---|---|

|

Less Spending |

No need to buy costly equipment or hire extra workers. |

|

Facility Savings |

Cuts costs for storage space, freeing up money for other uses. |

|

Efficient Setup |

Uses manufacturers’ ready-made systems, saving time and effort. |

|

Expert Knowledge |

Skilled workers spot problems early, making projects smoother. |

|

Focused Work |

Lets your team concentrate on key areas like design and marketing. |

|

Faster Delivery |

Manufacturers’ supply chains speed up order completion. |

|

Bigger Capacity |

Larger teams handle big orders quickly and efficiently. |

Outsourcing gives you access to experts and faster delivery times. It also helps you focus on smart PCBA procurement while keeping quality high.

Pick Trusted Contract Manufacturers

Choosing the right manufacturer is key for affordable PCB assembly. Look for companies with good reviews and certifications like ISO 9001 or IPC-A-610. These show they follow strict quality rules.

Experienced manufacturers often have supplier connections that save time and money. They also help improve designs and avoid mistakes. Compare several manufacturers to find the best one for your needs.

Tip: Ask for detailed quotes and check their experience with similar projects. This helps you make better choices.

Keep an Eye on Outsourced Work

Even with a good partner, you should watch outsourced work closely. Use tracking tools to spot problems early and stay updated. Regular talks with the manufacturer ensure your needs are met.

Set clear quality goals and ask for progress updates often. This helps catch mistakes early and keeps your PCBA procurement plan on track.

Note: Watching outsourced work improves quality and builds trust with the manufacturer. This leads to better results over time.

Stay Updated on PCBA Assembly Trends

Attend Industry Events and Conferences

Going to industry events helps you learn new PCBA ideas. These events show the latest tools and methods to improve your work. For example, the IPC Apex Expo focuses on automation and quality checks. PCB East 2025 highlights AI-based PCB design and UHDI technologies.

|

Event Name |

Focus Areas |

|---|---|

|

IPC Apex Expo |

New trends in automation and quality control for PCBA. |

|

PCB East 2025 |

AI tools and ultra-high-density PCB design updates. |

By attending these events, you learn about new trends. You also meet experts who can help improve your processes.

Follow Innovations in PCBA Technology

Keeping up with new technology helps you stay competitive. Many companies now use machines instead of hand assembly, even for small jobs. Robots are smarter and cheaper, making automation easier.

-

Smaller parts and dense PCBs make hand assembly harder.

-

Rules like RoHS and WEEE push for less waste and safer materials.

Using these new technologies makes your work faster and eco-friendly.

Adapt to Changing Market Demands

The PCBA market changes quickly, so you need to adjust. Customers want faster delivery, better quality, and greener products. UHDI designs and AI tools are now important to meet these needs.

Watch what customers want and invest in better tools. Staying flexible helps your business stay strong and competitive.

Good PCBA assembly needs smart planning and steady quality checks. Use these 10 tips to make your process easier and cheaper. By improving designs and using better tools, you save time and money while ensuring success.

Start now! Try advanced tools, find trusted suppliers, or ask experts for help. These ideas improve your work and keep you ahead in the PCBA field.

FAQ

What is the most important step in PCBA assembly?

Setting clear project goals is very important. It helps guide all other steps. Knowing your goals lets you plan well, avoid errors, and keep assembly smooth.

How can you reduce costs in PCBA assembly?

Lower costs by using common parts, following DFM rules, and outsourcing to reliable manufacturers. These methods make production faster and cut down on waste.

Why is testing important in PCBA assembly?

Testing checks quality and reliability. Finding problems early saves money and ensures your product meets required standards.

What tools improve PCBA efficiency?

Tools like advanced PCB design software and pick-and-place machines help a lot. They reduce mistakes, speed up work, and improve product quality.

How do you choose the right supplier for PCBA?

Pick suppliers with certifications like ISO 9001 and IPC-A-610. Check their defect rates, delivery speed, and reviews to match your needs.

Tip: Strong supplier relationships can bring better prices and steady quality.

See Also

Enhancing Workflow Productivity in PCBA Production Processes

Essential Advice for Selecting a PCBA Manufacturing Partner

An In-Depth Overview of PCBA Production Procedures

Locating the Ideal PCBA Manufacturer Within Your Budget

Crucial Actions to Identify a Reliable PCBA Supplier