Choosing the right PCB contract manufacturer can improve your business. It helps make high-quality circuit boards and saves money over time. For instance, using machines cuts labor costs by 40%. Careful quality checks stop rework costs over $18,000 per project. But bad choices in a PCB contract manufacturer can cause delays, higher costs, and faulty products. Focusing on skill and quality helps you find a partner who boosts your growth and success.

Key Takeaways

Pick a PCB maker with good skills and new tools. This helps make great boards and deliver them on time.

Check if they have key certifications like ISO 9001. These prove they meet quality and safety rules.

Ask how they check for quality. Good testing finds issues early, saving money and keeping your name good.

Make sure you get clear price info. Knowing costs avoids surprises and helps you get the best deal.

Clear communication is very important. A helpful maker keeps you updated and fixes problems fast.

Key Factors When Choosing the Right PCB Contract Manufacturer

When picking a PCB contract manufacturer, check important factors. These factors help ensure good products, on-time delivery, and long-term success. Below are the main points to guide your choice.

Technical Capabilities and Expertise

The technical skills of a manufacturer affect your circuit boards’ quality. Check if they can handle your project needs, like complex designs or multilayer boards. Manufacturers with modern tools and skilled workers give better results.

For example, using automation and monitoring tools can boost production by 30%. A good manufacturer should also deliver 98% of orders on time by improving their supply chain. These numbers show they can meet your expectations.

Metric | Industry Benchmark | Recommendation |

|---|---|---|

Production Efficiency | Use automation and monitoring tools | |

Delivery Timelines | On-time delivery target of 98% | Improve supply chain processes |

Quality Control & Defect Reduction | Yield rates reaching up to 95% | Use advanced quality inspection systems |

Look at their past work too. Find case studies or reviews that show they make good products. A manufacturer with proven success is more likely to meet your needs.

Certifications and Industry Standards

Certifications and standards are very important when choosing a manufacturer. These show they care about quality, safety, and the environment. For example, ISO 9001 proves they have strong quality systems, and ISO 14001 shows they care about sustainability.

The Testing, Inspection, and Certification (TIC) market is growing due to stricter rules. This shows why it’s key to pick a manufacturer that follows these standards. Focus on:

Rules for safety and environmental care.

Need for sustainability certifications.

Strong testing and inspection systems.

Also, check their environmental, social, and governance (ESG) efforts. Look at their carbon footprint, worker treatment, and honesty. A company doing well in these areas is trustworthy and reliable.

Quality Assurance and Failure Rates

Quality checks are needed to make sure your PCBs work well. A good manufacturer will test for problems early using methods like functional and reliability testing. These tests improve quality and lower costs from recalls or failures.

Testing Methodology | Description |

|---|---|

Confirms the design works as planned during use. | |

Reliability Testing | Checks if PCBs work well in different conditions. |

Check their defect and yield rates to judge quality. High yield rates, up to 95%, mean good quality control. Finding problems early saves money and keeps customers happy. A manufacturer with strong quality checks helps protect your reputation and meet rules.

Tip: Always ask about their quality checks and failure rates. This helps you make a smart choice.

Cost Transparency and Value

Knowing the real cost of making PCBs is important. A good manufacturer gives clear pricing details. This helps you avoid surprise fees or extra costs. Clear costs let you compare options and pick the best deal.

When checking cost transparency, focus on these points:

Detailed Quotations: Choose manufacturers who list all costs clearly. These include material, assembly, testing, and fabrication fees. Itemized quotes show where your money goes.

Scalability Pricing: See if they offer discounts for larger orders. This helps you grow without spending too much.

Hidden Fees: Ask about extra charges like fast shipping or design changes. Honest manufacturers share these upfront.

Picking the cheapest option isn’t always smart. Balance quality with price for the best value. Spending more on better techniques can save money later by reducing mistakes. The right manufacturer focuses on value, not just low prices. They deliver high-quality PCBs that meet your needs.

Tip: Always ask for a full cost breakdown before signing. This avoids surprises and ensures the deal fits your budget.

Communication and Responsiveness

Good communication is key to working well with a PCB manufacturer. Quick replies and helpful answers show they care about your project. Strong communication keeps things smooth and solves problems fast.

Here’s how to check their responsiveness:

Customer Satisfaction Score: This shows how happy customers are with their service. A score over 80% means they’re reliable and responsive.

Feedback Surveys: Regular surveys help them improve and meet customer needs. This shows they value your opinion.

Notice how fast they reply to questions or give updates. A responsive manufacturer shares timelines, delays, and order changes quickly. They should offer easy ways to contact them, like email, phone, or chat.

Note: Manufacturers with great communication often build lasting partnerships. Their quick responses build trust and keep projects on track.

Picking the best PCB manufacturer isn’t just about skills. Clear and timely communication is also very important. Choose manufacturers who respect your time and share updates often.

Steps to Choose a PCB Assembly Company

Picking the right PCB assembly company is very important. It helps your circuit board projects succeed. By following clear steps, you can find a partner that fits your needs. Below are the main steps to guide you.

Define Your PCB Needs

First, figure out what you need from the PCB company. This helps you explain your goals clearly and avoid problems later. Break your needs into these groups:

Description | |

|---|---|

Regulatory Compliance | Make sure they follow safety rules, legal standards, and EMC guidelines for reliable products. |

Budget and Timeline | Stick to your budget and deadlines to make good PCBs on time. |

Component Requirements | Pick the right parts based on cost, compatibility, and function to meet your design needs. |

Scalability and Future Considerations | Plan for upgrades and market changes to keep your PCB useful in the future. |

Collaboration and Documentation | Focus on teamwork and keeping records to improve communication and share ideas during the process. |

Risk Assessment | Spot possible problems early and plan ways to fix them. This makes your PCB design process smoother and more successful. |

Organizing your needs like this gives you a clear plan to check manufacturers. It also helps you avoid expensive mistakes during production.

Tip: Share your needs clearly with the manufacturer so they fully understand your project.

Research and Shortlist Manufacturers

After listing your needs, look for PCB companies that match them. Start by finding companies with experience and good results. Use these steps to make a shortlist:

Take Your Time: Give yourself enough time to research and choose carefully.

Check Experience: Find companies that have worked on similar projects or in your industry.

Look at Quality: Read reviews, case studies, and defect rates to see their quality.

Ask About Testing: Make sure they do tests like functional and reliability testing.

Check Customer Support: Pick companies with helpful and quick customer service.

Compare Prices: Get detailed quotes to understand costs and avoid hidden fees.

Watch for Problems: Avoid companies with bad communication, no certifications, or very low prices.

This step helps you find the most reliable and skilled manufacturers.

Note: A good PCB company will have certifications like ISO 9001 and a strong record of meeting deadlines.

Request Proposals and Compare Options

Once you have a shortlist, ask for proposals to learn more about each company. A good proposal shows their skills, prices, and value. When comparing proposals, focus on these points:

Price

Quality

Delivery time

Certifications

Flexibility

Ability to handle complex PCBs

Ask yourself these questions to decide:

Can they handle small orders?

Do they have the right certifications?

How fast can they deliver?

Is their quality good enough?

Are their prices fair?

Can they make complex PCBs?

Are they flexible and easy to work with?

By looking at these factors, you can pick the best PCB company that balances cost, quality, and reliability.

Tip: Don’t just pick the cheapest option. Spending a bit more can mean better quality and fewer problems later.

Conduct Facility Audits

Visiting a manufacturer’s site is a great way to check their abilities. A facility audit lets you see how they work and confirm if they meet your needs. This step ensures they can handle your project, from making parts to putting them together.

When doing a facility audit, focus on these areas:

Equipment and Technology

Look at the machines and tools they use. Modern machines often work faster and more accurately. Check if they use automated systems for tasks like soldering and testing. Advanced tools help reduce mistakes and speed up production.Cleanliness and Organization

A clean and tidy workspace shows they care about details. Check if parts and materials are stored properly. Messy spaces can cause delays or problems with quality.Quality Control Processes

Watch how they check for quality. Ask about their testing methods, like functional and reliability tests. Good quality checks make sure the final product meets your standards.Workforce Expertise

See how skilled their workers are. Experienced staff are important for handling tricky PCB designs. Ask about their training and how they keep workers performing well.Scalability

Find out if they can handle bigger orders in the future. This is important if you plan to grow your business. A manufacturer that can scale up will meet your future needs.

Tip: Write down what you see during the visit. Compare notes with other manufacturers to make the best choice.

Test Communication and Support

Good communication and support are key when working with a PCB company. These help projects run smoothly and fix problems quickly. Testing their communication and support before choosing them can save you trouble later.

Here’s how to check their communication and support:

Response Time

Notice how fast they reply to your questions. A good company gives quick updates and solves issues without delay.Clarity and Transparency

See how clearly they explain their process, costs, and timelines. Being open builds trust and avoids confusion. For example, they should explain each step of making and assembling PCBs.Customer Support Channels

Check if they offer support through email, phone, or chat. Having many ways to contact them makes it easier to get help.Problem-Solving Approach

Ask how they deal with unexpected problems like delays or defects. A company that solves issues quickly is a reliable partner.Feedback Mechanisms

Look for companies that ask for customer feedback. This shows they care about improving their service and value your opinion.

Note: Good communication and support not only help your project succeed but also build a strong, long-term partnership with the PCB company.

Be Aware of Warning Signs When Picking a Manufacturer

When picking a PCB manufacturer, watch for warning signs. Spotting these early helps you avoid problems and costly mistakes.

Missing Certifications or Standards

Certifications show a manufacturer follows rules and industry standards. Without them, you can’t trust their products. Look for certifications like ISO 9001 for quality and ISO 14001 for the environment. These prove they care about quality and sustainability.

A manufacturer without certifications might skip steps, causing bad products. Always ask for proof of certifications to check their quality. If they refuse or delay, it’s a red flag.

Tip: Check certifications through trusted sources to confirm they are real.

Slow Replies or Bad Communication

Good communication is key for a smooth partnership. If a manufacturer replies late or gives unclear answers, it can cause delays. Poor communication leads to mistakes and slows down your project.

Test their communication by asking questions early on. Notice how fast and clear their replies are. If they struggle to communicate now, it won’t get better later.

Note: Trustworthy manufacturers give quick and clear updates to keep you informed.

Too Much Focus on Cheap Prices

Price matters, but choosing the cheapest option can be risky. Low-cost manufacturers may use poor materials or skip quality checks. This leads to more defects and higher costs later.

Instead, balance price with quality and reliability. Spending a bit more upfront can save money by avoiding problems.

Reminder: Don’t let low prices ruin quality. Always check both price and quality before deciding.

Weak Quality Assurance Processes

Quality assurance (QA) is key to making good PCBs. Without strong QA, you might get bad products. This can hurt your reputation and cost more money. Look out for problems like poor testing or no automated tools. These can cause more defects and slow production.

Good QA uses automation and tracking. Automated tools find problems fast, saving time and money. Tracking helps follow each production step. This finds and fixes issues early. For example:

Automated tools catch defects quickly, saving costs.

Following industry rules keeps quality steady.

Tracking stops big recalls by finding faulty items.

When choosing a manufacturer, ask about their QA steps. Do they test for function and reliability? How do they fix defects? A manufacturer with weak QA might skip steps, making bad PCBs. Always pick strong QA to protect your business and customers.

Trouble Scaling for Growth

Scaling up is important when picking a PCB manufacturer. As your business grows, you need someone who can handle bigger orders. A manufacturer with low scalability may fail to meet your needs, causing delays.

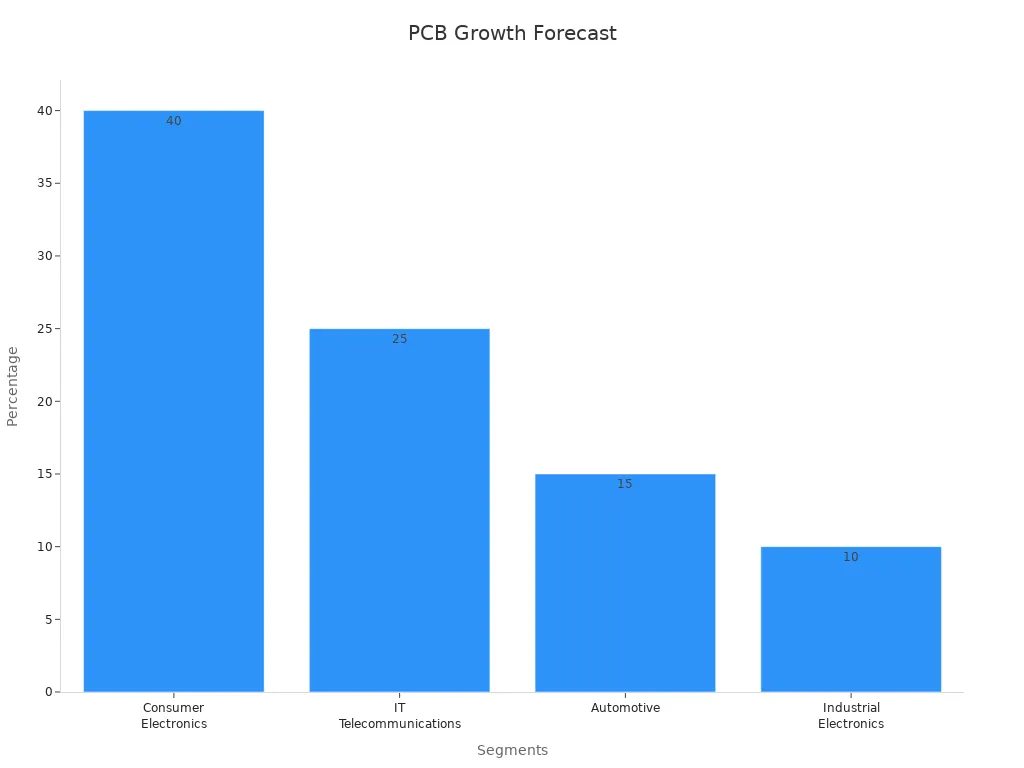

The PCB market is growing fast, thanks to electronics and electric cars. In 2023, it was worth $4.2 billion and is expected to grow 6.2% yearly from 2024 to 2032. This shows why you need a manufacturer who can grow with demand.

Metric | Value |

|---|---|

Market Value (2023) | |

Growth Rate (2024-2032) | 6.2% |

Main Growth Areas | Electronics, EVs |

The global PCB market may reach $75 billion soon. Big parts of this include consumer electronics (40%), IT and telecom (25%), and cars (15%).

Check if the manufacturer can grow with you. Do they have enough workers and modern tools? Can they handle sudden demand increases? A scalable manufacturer helps your business grow smoothly.

Tip: Pick a manufacturer who matches your future plans. This ensures smooth growth as your business expands.

Benefits of Choosing the Best PCB Contract Manufacturer

Reliable and On-Time Production

Picking the right PCB company keeps your projects on track. Good manufacturers follow strict rules like ISO 9001 and IPC standards. These ensure they deliver high-quality boards every time. They use tools like automated optical inspection (AOI) and in-circuit testing (ICT). These tools find problems early, so delays are avoided.

Manufacturers with strong systems can handle big orders easily. They meet deadlines even when demand is high. For example, companies using AS9100D standards show they can stay reliable in tough industries like aerospace.

Quality Control Measure | What It Ensures |

|---|---|

ISO 9001 | Consistent quality in production. |

IPC Standards | High-quality circuit boards. |

AS9100D | Reliability for complex industries. |

Tip: Work with a manufacturer that values on-time delivery and strong quality checks. This keeps your projects running smoothly.

High-Quality PCB Products

Good PCBs are key to your business success. Top manufacturers use advanced tools like X-ray machines and 3D scanners. These tools make sure the boards are made with precision. They also follow strict rules like ISO 13485 and RoHS to ensure safety and quality.

Regular checks of AOI data help catch mistakes early. They also store inspection results in databases to find patterns and fix issues. This reduces defects and ensures the boards meet your needs.

Tool Type | What It Does |

|---|---|

CMM | Measures shapes and sizes accurately. |

Profile Projector | Checks length, angles, and shapes with precision. |

XRF Material Verification Gun | Measures materials without causing damage. |

For example, PCBWay follows ISO 9001:2015 and UL certifications. This shows they are serious about making high-quality boards.

Note: Always pick a manufacturer with strong quality systems. This protects your reputation and keeps customers happy.

Scalability for Business Growth

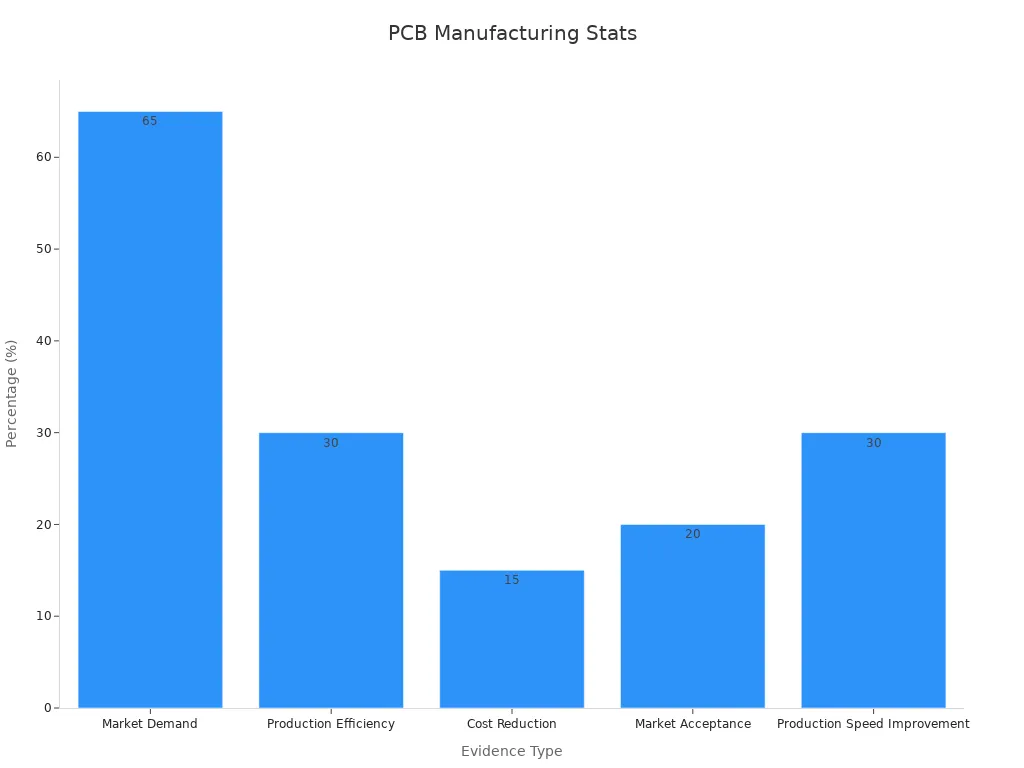

Scalability helps your business grow. A flexible manufacturer can adjust to your needs as you expand. Using automation in PCB production boosts efficiency by over 30%. This means faster production and lower costs.

The PCB market is growing fast, thanks to industries like electronics and electric cars. About 65% of tech startups prefer quick prototyping. This shows why scalable manufacturing is so important.

Evidence Type | What It Shows | Value/Impact |

|---|---|---|

Market Demand | Tech startups needing fast prototyping | Up to 65% |

Production Efficiency | Cost savings from automation | Over 30% |

Cost Reduction | Savings from reducing waste in production | Up to 15% |

Manufacturers with scalable systems can handle sudden demand increases. They do this without lowering quality. This helps your business grow while keeping production standards high.

Tip: Choose a manufacturer that matches your growth plans. This avoids problems as your business expands.

Strong and Supportive Partnerships

Working closely with your PCB company helps your business succeed. A good manufacturer is more than a supplier. They become a partner who helps you reach your goals. This teamwork ensures smooth projects and shared growth.

A helpful manufacturer listens to your needs. They give updates, fix problems fast, and adjust to changes. For example, if your design changes, they should offer quick fixes without lowering quality. This builds trust and keeps your production on schedule.

Good partnerships also spark new ideas. Manufacturers with advanced tools can suggest better designs. They may help lower costs or improve performance. This forward-thinking approach adds value and keeps you ahead of others.

Tip: Pick a manufacturer who values teamwork and supports your success. Strong partnerships lead to better results and lasting reliability.

Long-Term Cost Efficiency

Choosing the right PCB company saves money over time. High-quality manufacturers focus on making durable products. This reduces repairs and replacements, saving you money. For example, smaller devices with better parts are great for portable electronics.

Cost savings also come from smart processes. Companies using cloud tools cut costs by needing less hardware. Pay-as-you-go models make it cheaper to grow your business. These methods give you more value for your money.

Top manufacturers also use materials wisely. They waste less during production, which lowers costs. They can fit complex circuits on small boards, making them more efficient. These benefits save money and improve product quality.

Reminder: Spending more on a reliable manufacturer now saves money later. Fewer failures and repairs mean long-term savings.

Picking the right PCB manufacturer is very important for success. Checking them carefully helps you find one that fits your needs. Look at things like how they pick suppliers, check processes, and inspect products. These steps help you avoid problems and keep quality steady. Clear plans and strong checks also help finish on time. Spending time to research and choose wisely helps your business grow and stay reliable.

FAQ

What matters most when picking a PCB manufacturer?

The most important thing is quality assurance. A good manufacturer uses advanced tests like functional and reliability testing. These tests make sure your PCBs meet standards and work well. Always check their defect rates and quality control steps before deciding.

Tip: Yield rates of 95% or higher show strong quality assurance.

How do I check a manufacturer’s certifications?

Ask for copies of their certifications, like ISO 9001 or IPC standards. You can also confirm them through official certification organizations. Verified certifications prove the manufacturer follows strict safety and quality rules.

Note: Be cautious of manufacturers who won’t share proof of certifications.

Why is scalability important for a PCB manufacturer?

Scalability means the manufacturer can handle more orders as you grow. A scalable partner meets higher demand without lowering quality or missing deadlines. This is key for businesses planning to expand or enter new markets.

Reminder: Pick a manufacturer with modern tools and enough workers.

How can I test a manufacturer’s communication?

Check their responsiveness by asking questions early on. See how fast and clearly they reply. Good manufacturers give updates, share timelines, and solve problems quickly.

Tip: Clear communication builds trust and keeps projects running smoothly.

Should I choose cost over quality when selecting a manufacturer?

No, choosing cost over quality can cause more problems later. Defects and delays can increase expenses. Focus on value instead. Spending a bit more upfront often means better quality and fewer issues.

Reminder: Balance cost and quality to keep your product reliable.

See Also

Key Strategies for Selecting Your Ideal PCBA Partner

Finding the Perfect PCBA Manufacturer for Business Growth

Choosing the Most Suitable PCBA Manufacturer for You