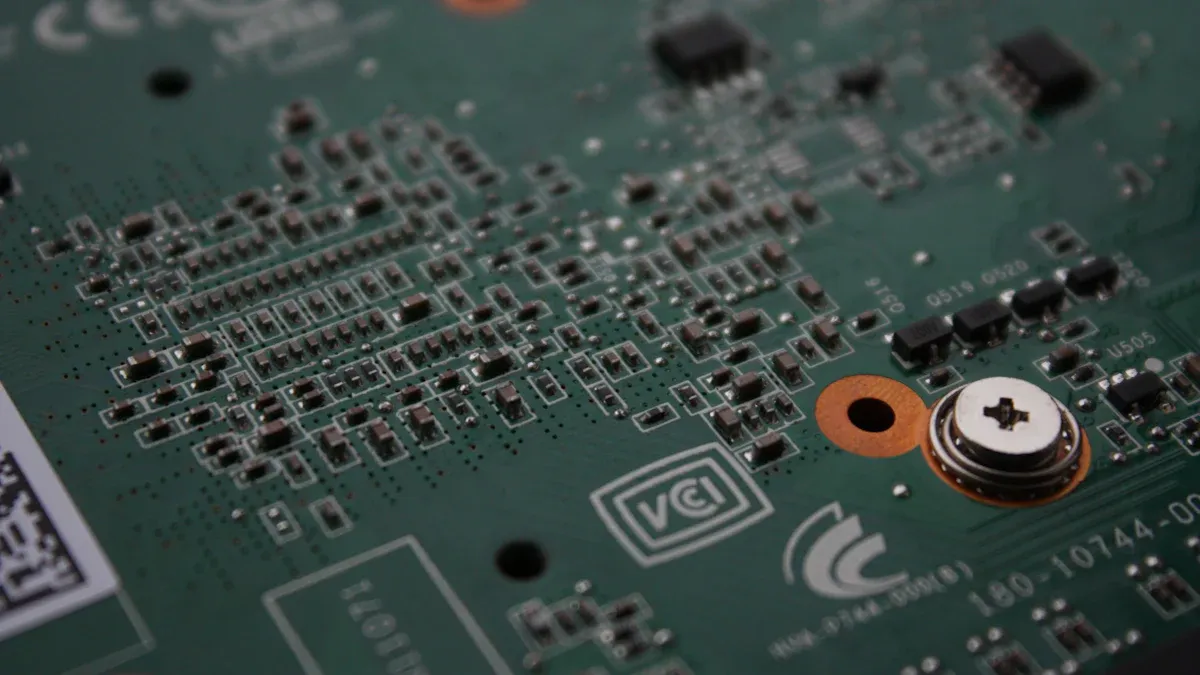

Surface mount technology assembly (SMT) allows for the direct attachment of electronic components onto printed circuit boards (PCBs). This innovative approach has revolutionized the manufacturing and design of modern electronics.

The demand for smaller devices, flexible PCBs, and electric vehicles has significantly increased the adoption of SMT.

The global market, valued at $5,271.9 million in 2023, is projected to grow at a rate of 5.8% annually until 2030.

By 2028, it is expected to reach $8.6 billion, with an annual growth rate of 8.0%.

Major companies continue to innovate, enhancing SMT and making it more competitive.

This transformation facilitates the creation of smaller, more affordable, and higher-quality designs, which are crucial in today’s electronics landscape.

Key Takeaways

Surface Mount Technology (SMT) makes gadgets smaller, lighter, and better by attaching parts directly to circuit boards.

SMT uses machines to work faster, cut labor costs, and improve quality, making it great for phones and home electronics.

SMT helps devices work better by making strong connections and lowering electrical problems, which is important for fast circuits.

Checking and testing during SMT catches issues early, ensuring reliable and good-quality electronics.

SMT is important in healthcare and cars, helping create small and dependable technology.

What is Surface Mount Technology Assembly?

Definition and Principles of SMT

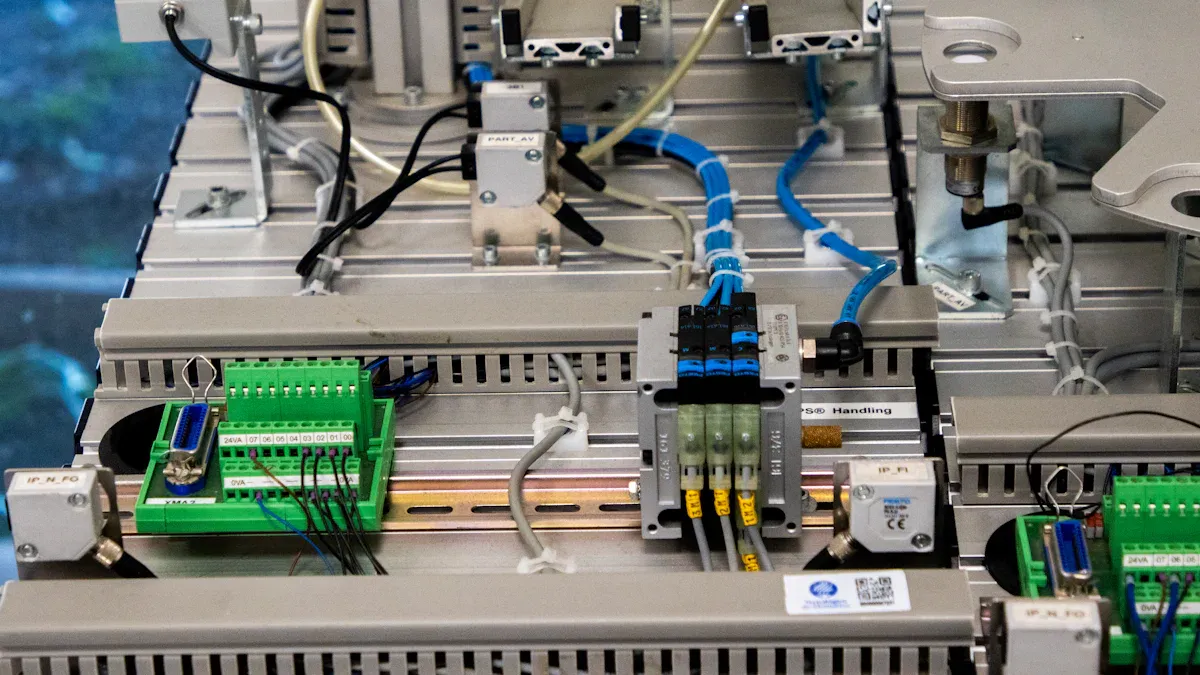

Surface mount technology assembly is a way to attach electronic parts directly onto printed circuit boards (PCBs). Unlike older methods that need holes for part leads, SMT skips this by sticking parts onto surface pads. This method uses machines to save time, cut costs, and improve quality. SMT is now the main method for making modern electronics because it is fast and precise.

Key ideas of SMT include:

Accurate design and layout: Picking the right materials and PCB design helps devices work well and last longer.

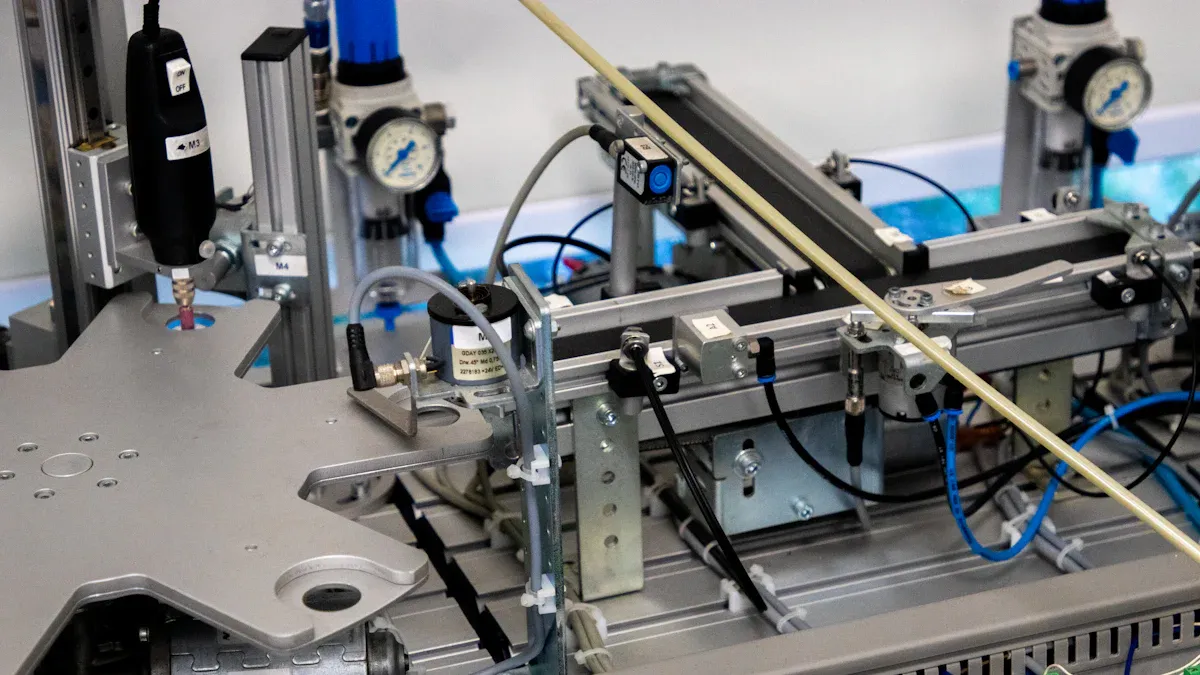

Automated assembly: Machines like pick-and-place tools quickly and accurately place parts.

Process control: Regular testing and checks keep quality high.

By following these steps, SMT helps make small, strong, and high-performing devices.

How SMT Differs from Traditional Methods

Surface mount technology is very different from through-hole technology, which was used for many years. The table below shows the main differences:

Feature | Through-Hole Technology | Surface Mount Technology |

|---|---|---|

Component Placement | Needs drilled holes for leads | Parts placed on surface pads |

Assembly Process | Done by hand or partly automated | Fully done by machines |

PCB Design | Bigger size, fewer parts | Smaller size, more parts |

Soldering | Done by hand or wave soldering | Uses reflow soldering |

Assembly Sides | Often one side only | Commonly uses both sides |

Component Lead Spacing | Usually 0.100” or more | As small as 0.0157” |

Rework | Easier to fix | Harder to fix some parts |

Through-hole technology is still used in some cases, like for high-power or tough environments. But SMT is the top choice for industries needing small and efficient designs.

Importance of SMT in Electronics Manufacturing

SMT is very important in making modern electronics. It helps create smaller, lighter, and more dependable devices. By using machines, SMT lowers labor costs and speeds up production. This is crucial for industries like phones, cars, and communication devices.

For example, studies show SMT solder joints are strong and last long, even in tough conditions. Automated systems make production faster and ensure good quality for large amounts. SMT also supports advanced tech like System-in-Package (SiP), which combines many functions into one part.

SMT assembly technology has changed the electronics world by making smaller, better, and cheaper designs possible.

Advantages of SMT Assembly

Smaller Size and Space Saving

SMT helps make smaller and smarter designs. It places parts directly on circuit boards, skipping the need for drilled holes. This method makes boards stronger and saves space.

SMT allows more parts to fit on a board. This is important for devices like phones and smartwatches.

Tiny and light parts make boards easier to carry and use.

Smaller boards can hold more features, making devices more useful without getting bigger.

Industries like cars and airplanes benefit from lighter boards, which improve speed and save money.

SMT has changed electronics by helping create smaller, better gadgets.

Faster Production with Machines

SMT speeds up making electronics. Machines like pick-and-place tools quickly and accurately put parts on boards. This reduces mistakes and keeps quality high.

With SMT, factories can make many boards quickly. Reflow soldering heats and solders many parts at once, saving time. This fast process is great for industries like phones and communication devices that need quick production.

SMT makes production faster and packs more parts into small designs.

Saving Money in Manufacturing

SMT saves money by cutting labor and material costs. Machines do most of the work, so less manual labor is needed. Small parts also mean using fewer materials.

Key Point | Description |

|---|---|

Regular Maintenance | Keeps machines running smoothly and avoids expensive delays. |

Downtime Costs | Stopping work costs money, so good maintenance is important. |

Cost Challenges | Companies must save money to stay competitive. |

Using SMT helps companies save money while keeping products high-quality. This makes it a smart choice for industries needing affordable and reliable solutions.

Better Performance and Dependability

Surface mount technology (SMT) helps make electronics work better and last longer. It places parts exactly where they need to be and solders them tightly. This creates strong connections that can handle tough conditions.

One big benefit of SMT is fitting more parts into smaller spaces. It can shrink product size by 40-60% and cut weight by 60-90%. This makes gadgets smaller and easier to carry. SMT also improves how electricity flows by lowering unwanted resistance and interference. This is especially helpful for fast circuits, where small problems can cause big issues.

Feature | Details |

|---|---|

High-Density Design | Makes products 40-60% smaller and 60-90% lighter. |

Better Electrical Flow | Reduces resistance and interference, great for fast circuits. |

Stronger Connections | Shorter leads mean fewer loose parts, boosting reliability. |

SMT is also very reliable. It uses precise soldering to make strong links between parts. This lowers the chance of loose connections. Devices made with SMT last longer, even in tough conditions like heat or shaking. That’s why industries needing tough and dependable gadgets choose SMT.

SMT has changed electronics by making devices stronger and better. It helps create small, efficient, and long-lasting products that set a high standard.

Using SMT, companies can make gadgets that work well and stay reliable over time. This ensures the devices you use are both high-quality and dependable.

The SMT Assembly Process

Surface mount technology (SMT) assembly uses precise, automated steps to make electronic devices. Each step is important for creating reliable printed circuit boards (PCBs). Let’s look at the main steps in this process.

Solder Paste Application and Stencil Preparation

The first step in SMT is applying solder paste to the PCB. This paste helps parts stick securely to the board. A stencil is used to apply the paste only where parts will go. The stencil acts like a guide for placing the paste correctly.

Steps in this phase include:

Matching the stencil to the PCB design.

Spreading solder paste with a squeegee or machine.

Checking the paste for even coverage and correct thickness.

How well the solder paste is applied affects the success of the process. Things like paste formula, particle size, and flow behavior matter. For example:

Characteristics | Description |

|---|---|

Flow Behavior | Shows how easily the paste spreads during application. |

Particle Size | Helps the paste fill stencil holes and stick to the PCB. |

Better Results | Adjusting these factors improves the process and reduces mistakes. |

Tip: Regularly check solder paste application to avoid problems and improve PCB quality.

Automated Component Placement

After the solder paste is applied, machines place parts onto the PCB. This step shows how fast and accurate SMT can be. Pick-and-place machines can position thousands of parts every hour with great precision.

Here’s how it works:

Machines pick parts from reels or trays.

They place each part on the solder paste-covered spots on the PCB.

Cameras or sensors check if the parts are placed correctly.

Using machines for this step has many benefits:

Speed: Machines work much faster than people.

Accuracy: Robots place parts exactly where they belong.

Efficiency: Less waste and faster production.

Automated placement is key to making small, complex electronic devices quickly and accurately.

Reflow Soldering Process

Once parts are placed, the PCB goes through reflow soldering. This step heats the board to melt the solder paste, connecting parts to the PCB. The process follows a set temperature pattern to ensure good results.

A typical reflow soldering process includes:

Preheat: Slowly warms the board to activate the solder paste.

Soak: Keeps the board at a steady temperature for even heating.

Reflow: Heats the board enough to melt the solder and make connections.

Cooling: Quickly cools the board to harden the solder joints.

Important things to monitor during reflow include:

Metric Type | Description |

|---|---|

Controls how fast the board heats up to avoid damage. | |

Temperature Rise | Limits how quickly the heat increases to protect components. |

Even Heating | Makes sure all parts of the board heat evenly. |

Note: Setting the right reflow temperature is crucial for strong and reliable solder joints.

Reflow soldering is a vital step in SMT. It ensures that the PCB assembly is high-quality and works as expected.

Inspection and Quality Assurance

Inspection and quality checks are very important in the SMT process. They make sure every step, from applying solder paste to reflow soldering, is done correctly. Without proper checks, small mistakes can cause faulty products or failures. This step is key to keeping your devices reliable and working well.

Why Inspection is Important in the SMT Process

Inspection finds and fixes problems before they become expensive. It ensures parts are placed right, solder joints are strong, and the product matches the design. By focusing on quality, you can waste less, work faster, and make dependable products.

Tip: Catching problems early saves time and money. Always include inspection in your SMT process.

Types of Inspection in SMT

There are different ways to inspect during the SMT process. Each method checks specific parts of the PCB assembly to ensure quality.

Automated Optical Inspection (AOI)

AOI uses cameras to take pictures of the PCB. It looks for missing parts, misaligned components, and soldering mistakes. This method is quick and accurate, great for making many boards.X-Ray Inspection

X-rays let you see inside solder joints and under parts. This is helpful for finding hidden problems in complex assemblies like BGAs.Manual Inspection

Sometimes, people need to check boards by hand. Skilled workers use magnifying tools to find defects. It’s slower but gives a close look at specific areas.

Inspection Method | Purpose | Advantages |

|---|---|---|

Automated Optical (AOI) | Finds visible problems | Fast and precise |

X-Ray | Spots hidden solder issues | Great for complex boards |

Manual | Checks specific areas closely | Detailed visual review |

Quality Assurance in the SMT Process

Quality assurance is more than just inspection. It means setting up rules and steps to stop problems before they happen. Focus on these areas to improve:

Process Control: Watch each step of the SMT process to keep it consistent. Use inspection data to find patterns and make things better.

Equipment Calibration: Regularly adjust machines to keep them accurate. Misaligned tools can cause placement mistakes and weak solder joints.

Training: Teach your team about the SMT process and how to spot problems. Skilled workers can stop many issues early.

Note: Quality assurance never stops. Keep checking and improving to avoid future problems.

Benefits of Inspection and Quality Assurance

Spending time on inspection and quality checks has many benefits:

Better Reliability: Fewer mistakes mean products work better and last longer.

Saving Money: Fixing problems early reduces waste and extra work.

Happy Customers: Good products build trust and keep customers coming back.

Inspection and quality checks are key to a good SMT process. They help you make reliable, high-quality devices while cutting costs and waste. By focusing on these steps, you can succeed in your PCB assembly projects.

Applications of Surface Mount Technology

Surface Mount Technology (SMT) is crucial in many industries. It helps make small, efficient, and powerful devices. Let’s see how SMT is used in gadgets, communication tools, and healthcare.

Consumer Electronics and Wearable Devices

You use SMT daily in your favorite gadgets. It helps create slim designs and cool features in devices like:

Fitness Trackers: Gadgets like Fitbit Flex use flexible PCBs made with SMT. This improves battery life and adds features like Bluetooth.

Smart Clothing: Levi’s Jacquard jacket shows how SMT makes flexible, washable PCBs for wearable tech.

Advanced Prosthetics: Ottobock’s bionic limbs use small PCBs for better control, helping users.

The need for smaller gadgets and wearables boosts SMT use. By 2032, the SMT market is expected to grow from $6.25 billion in 2024 to $9.59 billion. This shows how SMT shapes the future of electronics.

Telecommunications and Networking Equipment

Modern communication depends on SMT. It helps make dense PCBs for 5G, routers, and network devices. The SMT market in telecom is set to reach $85 billion by 2028.

Reports highlight SMT’s role in telecom growth:

Report Title | Key Insights |

|---|---|

Global Surface Mount Technology (SMT) Equipment Market – Industry Trends and Forecast to 2031 | Shows how SMT improves telecom technology. |

Surface Mount Technology Equipment Market Size, Report Forecast 2035 | Explains fast progress in electronic manufacturing. |

Thanks to SMT, you get faster internet, clearer calls, and better connections.

Medical Devices and Healthcare Technology

In healthcare, SMT helps make small and reliable medical tools. Devices like the Zio Patch use biocompatible PCBs for comfort and long-term use. SMT also powers advanced prosthetics and trackers like AngelSense, which have durable, power-saving PCBs.

SMT ensures medical devices work well, even in tough situations. This makes it key to improving healthcare technology.

SMT keeps changing industries by enabling smart designs and dependable performance. From your gadgets to life-saving tools, SMT drives modern technology forward.

Automotive and Aerospace Electronics

Surface Mount Technology (SMT) is crucial for cars and planes. It helps make small, strong, and high-performing systems. These systems meet the tough needs of these industries. You can find SMT in electric cars and advanced airplane systems.

Why SMT is Important for Cars

Car electronics need SMT for accuracy and dependability. Parts like sensors and control systems are smaller and lighter with SMT. This is very helpful for electric cars, where saving space boosts energy use. SMT also makes parts strong enough to handle shaking and stress while driving.

🚗 Tip: Lighter cars made with SMT use less fuel and pollute less.

How SMT Helps in Planes

In planes, SMT is used for systems like navigation and communication. Its small designs let engineers add more features in less space. This is important for planes and spaceships. Strong soldering in SMT keeps parts working in extreme conditions like high altitudes and temperature changes.

Trends and Key Facts

The need for electric cars and advanced planes is growing. This increases the use of SMT. Reports show its benefits, like better accuracy and smaller parts. The table below shows key points:

Evidence Type | Description |

|---|---|

Market Insights | SMT is growing in cars and planes due to its precision and space-saving features. |

Industry Forecast | More electric car sales mean higher demand for SMT in car electronics. |

Application | SMT is strong enough for tough conditions in cars and planes. |

✈️ Note: SMT keeps important systems in cars and planes working well, even in hard conditions.

With SMT, designs can be efficient and tough. This makes it perfect for the challenges of cars and planes. SMT is shaping the future of travel and aviation.

Comparing SMT and Through-Hole Technology

Main Differences Between SMT and Through-Hole

Surface mount technology (SMT) and through-hole technology attach parts differently to circuit boards. Through-hole needs holes drilled into the board for part leads. SMT skips drilling and places parts directly on the board’s surface. This makes SMT designs smaller and more compact.

Through-hole parts are bigger and often need hand assembly. SMT parts are tiny and light, perfect for machine assembly. Through-hole works well in tough conditions, but SMT is better for modern electronics because it saves space and is more efficient.

Why SMT is Better Than Through-Hole

SMT has many benefits that make it better than through-hole in most cases. These include faster assembly, smaller parts, and better reliability. The table below shows some key advantages:

Advantage | Description |

|---|---|

Automation | Machines place parts quickly and accurately, saving time and money. |

Smaller Parts | Tiny parts save space, making products smaller and lighter. |

Reliability | SMT parts handle vibration better and have stronger soldering. |

High Component Density | More parts fit on small boards, great for tight spaces. |

These benefits make SMT popular in industries like electronics, cars, and communication. SMT helps make products faster, better, and smaller.

When Through-Hole is Still Useful

Even though SMT is common, through-hole is still useful in some cases. It’s great for things needing strong parts, like machines and airplanes. Through-hole parts are also easier to fix, so they’re good for testing and prototypes.

For example, power supplies and connectors often use through-hole because they handle stress well. In these cases, through-hole’s strength is more important than SMT’s space-saving. But for most other uses, SMT is faster, smaller, and more reliable.

Surface mount technology (SMT) has changed how electronics are made. It helps create smaller designs, speeds up production, and improves how devices work. The table below shows its main benefits and future possibilities:

Feature | Explanation |

|---|---|

Smaller Designs | SMT makes tiny, efficient circuits for modern gadgets. |

Faster Production | It speeds up making products, saving time and boosting efficiency. |

Better Performance | SMT helps build high-quality devices for many industries. |

Industry Importance | It’s key in areas like phones, cars, and home electronics. |

Future Growth | SMT keeps improving, solving problems, and driving new ideas in tech. |

In the future, SMT will lead in these areas:

Making electronics even smaller and lighter to meet demand.

Using more machines to make production faster and more accurate.

Adding high-density PCBs for compact designs with many features.

Supporting eco-friendly practices by reducing waste and saving materials.

Helping 5G and IoT grow by improving data handling in smart networks.

As technology grows, SMT will stay important. It will keep making electronics better, faster, and more reliable.

FAQ

What is the main advantage of SMT over traditional methods?

SMT helps make smaller and lighter electronic devices. It skips drilling holes, allowing compact designs. Machines speed up production and lower costs, making it great for modern electronics.

Can SMT components handle harsh environments?

Yes, SMT parts are strong in tough conditions. Their tight soldering and small size resist heat, vibration, and stress. This makes them perfect for cars, planes, and medical tools.

Is SMT suitable for all types of electronic devices?

SMT is best for small, dense designs like phones and wearables. But through-hole technology works better for high-power devices or those needing strong parts, like industrial machines.

How does SMT improve production efficiency?

SMT uses machines like pick-and-place tools and reflow ovens. These machines are faster and more accurate than people. They reduce mistakes, speed up work, and keep quality high.

What industries benefit the most from SMT?

Industries like electronics, telecom, cars, planes, and healthcare use SMT a lot. It helps make things like smartphones, 5G tools, electric cars, and medical devices.

Tip: When designing for an industry, think about SMT’s ability to save space, cut weight, and boost performance.

See Also

Exploring The SMT Process In PCBA Production And Assembly

A Comprehensive Guide To PCBA Manufacturing And Assembly

The Benefits And Challenges Of Flex PCBA In Electronics