Making low volume high mix PCBA manufacturing comes with special challenges. You must handle many product types with small production amounts. The growth of IoT makes this harder, needing new ways to check quality and manage supplies. Being eco-friendly is now very important as people want greener electronics. Also, generative AI is changing how things are done. It helps improve work and save money.

What can you do to solve these problems and succeed in low volume high mix PCBA manufacturing?

Key Takeaways

Work closely with suppliers to get materials on time. This avoids delays in making products.

Use smart manufacturing methods to cut waste and save money. Always look for ways to work better and faster.

Add machines and smart tools to make work quicker and more accurate. These tools find problems early and improve product quality.

Use planning tools to make work smoother and faster. Tracking in real-time stops delays and uses resources wisely.

Train workers to learn new skills and stay motivated. Skilled workers handle changes well and keep quality high.

Key Challenges in High-Mix Low-Volume PCBA Manufacturing

Supply Chain Complexity

Handling the supply chain in this type of manufacturing is tricky. You work with many parts that need careful ordering and delivery. This makes it easier for problems to happen, like delays in production. For example, the Trolley Optimization Problem (TOP) shows how poor loading of parts can slow things down. Switching trolleys often between different PCBs adds more trouble and makes meeting needs harder.

To fix these problems, you need a strong supply chain plan. Build good relationships with suppliers who can meet your needs. Use digital tools to track stock and predict what you’ll need. This helps avoid problems and keeps production running smoothly.

High Production Costs

Making small batches of different products costs a lot. You can’t save money by making large amounts at once. This means each item costs more to make. For example, small batches need more attention and cost more for materials and workers. The table below shows how costs differ between high-mix and low-volume production:

Metric | High Mix PCBA | Low Volume Production |

|---|---|---|

Cost Efficiency | Large batches lower costs per item | Small batches raise costs per item |

Resource Intensity | Smooth operations save time and money | Needs more effort and costs more |

Supplier Challenges | Easy to get big orders | Hard to find cheap materials for small orders |

Upfront Investment | High setup costs | Lower setup costs |

To lower costs, improve how you work. Use lean methods to cut waste and save money. Adding automation can also lower worker costs and make things more consistent.

Frequent Design Changes and Customization

Design changes and custom orders happen a lot in this work. You must quickly adjust to new needs, like changing materials or machine settings. This is important for keeping customers happy but can mess up production. For example, complex PCBs may need extra steps, which can cause mistakes and waste.

To manage this, plan well and keep your team talking. Agile methods help you prepare for changes and adjust quickly. Working closely with design and production teams avoids mistakes. By staying flexible, you can handle custom orders without slowing down.

Quality Assurance in Small Batches

Making sure small batches are high quality is tough. You need to keep standards high while handling design and material changes. Small batches mean fewer chances to fix mistakes, so quality checks are very important in high-mix low-volume PCBA manufacturing.

To keep quality steady, use several steps. First, check incoming materials to ensure parts are good before assembly. Next, organize parts with material kitting to prepare for production. During assembly, use precise soldering methods to avoid errors.

Testing helps find problems early. Here’s a list of common testing methods for small-batch PCBA:

Testing Method | What It Does |

|---|---|

Functional Testing | Checks if boards work as they should. |

Manual Visual Inspection | People look for visible problems. |

Automated Optical Inspection (AOI) | Machines spot errors during assembly. |

X-ray Inspection | Finds hidden issues in solder joints without damage. |

In-circuit Testing (ICT) | Tests parts while they’re still on the board. |

Fly-probe Testing | Tests PCB performance without needing special tools. |

Follow industry best practices to improve quality. For example:

ISO 9001:2015 certification proves your processes meet global standards.

IPC-trained workers bring expert skills to production.

Triple Processes Inspection finds mistakes at different stages.

DFM (Design for Manufacturing) and DFA (Design for Assembly) checks catch problems early.

Using these methods lowers mistakes and keeps quality high, even for small batches. This saves materials, reduces waste, and builds customer trust.

Scheduling and Lead Time Management

Planning schedules and lead times in high-mix low-volume PCBA manufacturing is hard. You must meet customer needs while keeping production on track. Delays can cause problems and upset customers.

To fix this, plan ahead. Match your schedule to customer needs to avoid slowdowns. Use modular production to switch quickly between products. This helps you stay flexible and efficient.

Here are key metrics to improve scheduling and lead times:

Metric | What It Means |

|---|---|

Lead Time | Shortened by planning ahead and matching customer needs. |

Cycle Time | Faster with modular production for quick product changes. |

Machine Utilization | Better with machine learning to improve how machines work. |

Technology can make scheduling easier. Use planning tools and software to organize work and resources. Machine learning can find problems in production and suggest fixes. These tools save time and boost productivity.

Good communication is also important. Keep your team updated about schedules and changes. Regular updates help everyone stay on the same page and avoid delays. By using these strategies, you can manage schedules better and keep production running smoothly.

Strategies to Solve Problems in Low Volume High Mix PCBA Manufacturing

Using Lean Manufacturing Ideas

Lean manufacturing helps cut waste and work faster. It focuses on steps that add value and removes extra ones. For example, mapping out processes shows where delays happen. Fixing these delays saves time and lowers costs.

Companies using lean methods see big improvements. Studies show lean ideas boost productivity by 15% to 25% in small businesses. They also cut changeover time by 10% and downtime by 56%. These results show lean ideas help with design changes and high costs.

Start by improving little by little. Ask your team to find problems and suggest fixes. Use tools like 5S (Sort, Set in Order, Shine, Standardize, Sustain) to keep workspaces neat. By always improving, you can make your manufacturing better.

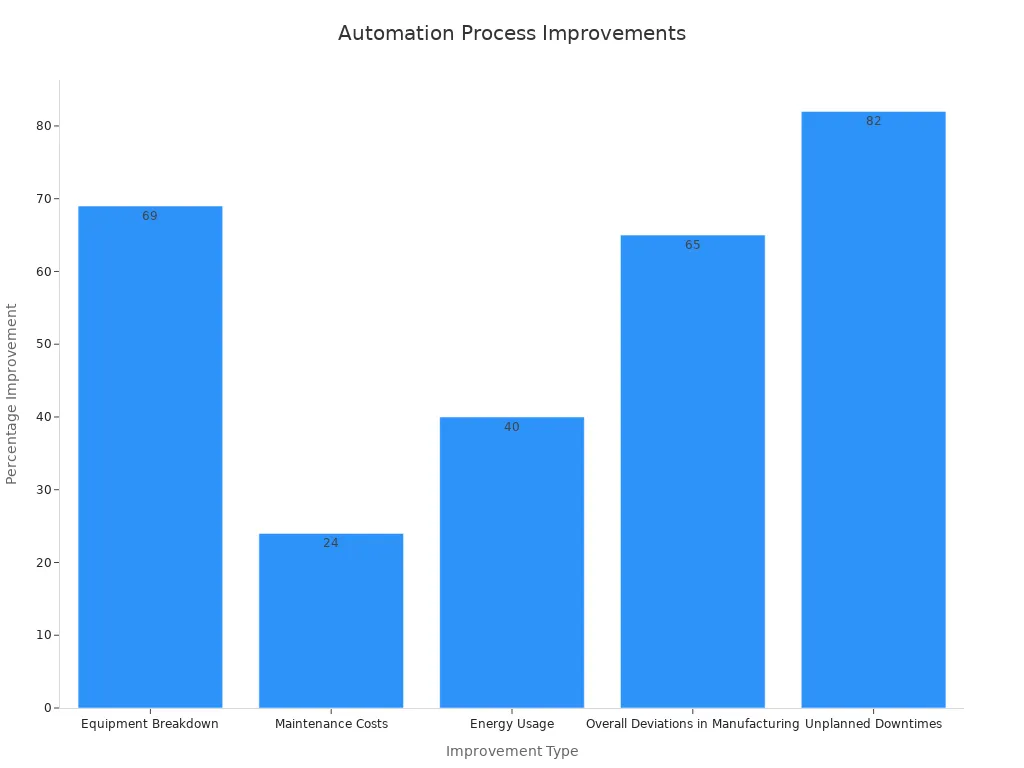

Adding Automation and Smart Tools

Automation and smart tools make work more accurate and faster. They help find mistakes early and improve quality. For example, machines like 3D Solder Paste Inspection (SPI) and Automated Optical Inspection (AOI) spot defects quickly.

Data proves automation works well. IoT tools cut equipment breakdowns by 69%. Real-time tracking lowers energy use by 40%. Unplanned downtimes drop by 82%. The table below shows more benefits of automation:

Improvement Type | Percentage Change | Description |

|---|---|---|

Maintenance Costs | 24% | Automation lowers repair costs. |

Manufacturing Errors | 65% | Smart tools reduce mistakes and improve quality. |

Cost of Unplanned Downtimes | $250,000/hour | Downtime costs manufacturers a lot of money. |

To use these tools, add IoT devices to your production line. These devices give live updates to track performance and spot issues. Also, try Industry 4.0 ideas like digital twins to test and improve processes. Automation helps you stay ahead in the PCBA industry.

Improving Supply Chain Management

Good supply chain management is key to solving problems in high-mix low-volume PCBA work. A strong supply chain delivers materials on time and cuts delays. For example, Seagate Technology improved service and costs by organizing its supply chain better. This shows how important it is to have a solid plan.

Metrics show how better supply chains help. Changeover time dropped by 10%, and line clearance time improved by 85%. Line use went up by 20–30%, and worker productivity rose by 33%. The table below lists these gains:

Improvement Metric | Percentage Change |

|---|---|

Changeover Time | 10% |

Line Clearance Time | 85% |

Quality-Related Downtime | 56% |

Line Utilization Improvement | 20–30% |

Increase in Operator Productivity | ~33% |

Increase in Engineering Productivity | 25–30% |

To improve your supply chain, work closely with trusted suppliers. Use digital tools to track inventory and predict needs. Try just-in-time (JIT) methods to avoid having too much stock. These steps build a strong supply chain for your goals.

Investing in Workforce Training and Skill Development

Training your workers is very important for success. Skilled workers are the heart of your factory. Learning new skills helps them keep up with new tools. Training also makes workers happier and more likely to stay.

📌 Why Workforce Training Matters

Training attracts both new and skilled workers.

Workers feel valued, which boosts job happiness.

Learning keeps workers, lowering the chance they leave.

The need for skilled workers is growing fast. The electronics market may grow from $534 billion in 2023 to $856 billion by 2030. But, the U.S. might lack over 2 million skilled workers by 2031. This shows why training is so important.

Check if training is working by tracking results. Good training can cut mistakes and save time. For example:

Better training lowers assembly mistakes, saving materials.

Skilled workers handle changes faster, avoiding delays.

Find out what skills your team needs. Offer special training like IPC certification to fill gaps. Teach workers multiple skills so they can do different jobs. By training your team, you set up your factory for long-term success.

Utilizing Advanced Planning and Scheduling Tools

Using smart planning tools makes manufacturing easier. These tools help manage resources and schedules. In high-mix low-volume PCBA work, they keep things running smoothly.

💡 Benefits of Advanced Tools

Real-time tracking makes production faster.

Automated schedules reduce human mistakes.

Predictive tools fix problems before they happen.

Here are some key metrics to see how tools help:

Metric | Industry Benchmark | Recommendation |

|---|---|---|

Production Efficiency & Throughput | Use real-time tracking and automation | |

Delivery Timelines | 98% on-time delivery goal | Improve supply chain steps |

Cost Per Unit | 15%-20% lower costs | Follow lean manufacturing ideas |

Quality Control & Defect Reduction | Up to 95% yield rates | Use advanced inspection systems |

For example, real-time tools check machines and find slowdowns. Predictive tools warn about delays so you can fix them early. These tools also help teams work together better.

Start small when adding these tools. Pick software that works with what you already use. Train your team to use the tools well. Show them how it saves time and money. By using technology, you can stay ahead in manufacturing.

The Role of Technology in High-Mix Low-Volume PCBA Manufacturing

Benefits of Digital Twin Technology

Digital twin technology makes virtual copies of real PCBs. These digital copies let you test and study designs before making them. This saves time and money by finding problems early. For example, BMW Group improved factory planning by 30% using digital twins. Wistron cut simulation times from 15 hours to just 3.6 seconds, helping them decide faster.

Digital twins also make work better. Pegatron found 60% more defects and reduced errors by 30%. These tools are great for making manufacturing faster and more accurate.

Importance of Data Analytics and AI

Data analytics and AI are very helpful in modern factories. Real-time data shows problems and predicts machine breakdowns. This reduces downtime and keeps production smooth. For example, General Electric used digital twins to improve quality and speed up testing, getting products to market faster.

AI tools also improve quality checks. They find tiny defects that people might miss. Delta Electronics reached 99.8% accuracy in finding defects with AI. Using these tools keeps quality high and reduces waste.

Adopting Industry 4.0 Practices

Industry 4.0 uses smart tools like IoT, cloud systems, and 3D printing. These tools improve how factories work, check quality, and stay eco-friendly. Real-time monitoring and predictive tools lower downtime and use machines better. Data insights help factories adjust quickly to new needs.

For example, IoT tracks assembly in real time, making it more efficient. 3D printing speeds up making prototypes and shortens production time. By using Industry 4.0, factories can stay ahead in high-mix low-volume manufacturing.

Best Practices for Success in Low Volume High Mix PCBA Manufacturing

Building Strong Supplier Relationships

Good supplier relationships are key to doing well. Reliable suppliers help with quality, fast deliveries, and new materials. For example, trusted suppliers can cut wait times and improve supply chains. Metrics show how these relationships help:

Metric | Benefit |

|---|---|

Quality Consistency | Keeps products meeting standards, reducing mistakes and making customers happy. |

Supply Chain Efficiency | Speeds up processes, shortens delays, and boosts overall performance. |

Cost Reduction | Brings better deals, bulk savings, and shared cost-cutting ideas. |

Innovation | Gives access to new tools and materials for an advantage. |

Risk Mitigation | Protects against supply problems and quality issues. |

Talk often with suppliers to build trust. Share your goals and challenges to work better together. This teamwork creates a steady supply chain for your needs.

Continuous Process Improvement

Improving processes keeps your factory running well. Using methods like Design for Assembly (DFA) makes assembly easier and cheaper. It also improves product quality.

Certifications help keep high standards. For example:

Certification | Description | Importance |

|---|---|---|

ISO 9001 | Global standard for quality systems. | Ensures steady processes and ongoing improvements. |

ISO 13485 | Focuses on medical device quality systems. | Needed for safe and effective medical PCB assemblies. |

AS9100 | Quality standard for aerospace work. | Ensures reliable PCBs for critical aerospace uses. |

Track progress with metrics like Overall Resource Effectiveness (ORE) and Overall Equipment Effectiveness (OEE). These show where to improve, whether using machines or manual work. Lean manufacturing and quick changeover methods like SMED can also save time and money.

Fostering Collaboration Across Teams

Teamwork is very important in this type of manufacturing. When design, production, and quality teams work together, problems are solved faster. Regular meetings and open talks keep everyone on track.

For example, checking materials early and during production stops mistakes. Automated Optical Inspection (AOI) tools also help by spotting errors quickly. These steps improve quality and cut waste.

Train workers to learn different jobs. This makes them flexible and ready for changes. A skilled and adaptable team is essential for high-mix low-volume production.

High-mix low-volume PCBA manufacturing has special challenges. These include tricky supply chains, high costs, and frequent design changes. To stay efficient and keep quality high, you need smart solutions. Using lean manufacturing, automation, and planning tools can help. These methods cut waste and make work smoother. Training workers and building strong supplier partnerships also help you meet market needs.

📊 Future Trends in PCBA Manufacturing

The industry is changing fast. Staying ready keeps you competitive. Here are important trends shaping the future:

Trend/Forecast | What It Means |

|---|---|

Makes custom designs easier and speeds up production. | |

Sustainability | Focuses on greener methods to meet customer demands. |

Customization | Personalized solutions are key for high-mix low-volume success. |

Stay open to new ideas and always improve your processes. This helps you succeed in this fast-changing industry.

FAQ

1. What is high-mix low-volume (HMLV) PCBA manufacturing?

HMLV PCBA manufacturing means making many types of circuit boards in small amounts. It needs flexibility, quick design changes, and efficient processes to meet different product needs.

2. How can you reduce costs in HMLV PCBA manufacturing?

Cut costs by using lean manufacturing, automating tasks, and improving supply chains. These methods reduce waste, save time, and lower production costs.

3. Why is quality assurance challenging in small-batch production?

Small batches have fewer chances to fix mistakes. Design changes and material differences increase defect risks. Testing like AOI and functional checks keep quality steady.

4. What role does automation play in HMLV manufacturing?

Automation makes work faster and more accurate. Tools like 3D SPI and IoT devices track progress in real time, improving efficiency and reducing errors.

5. How do advanced planning tools help in HMLV manufacturing?

Planning tools organize schedules and resources better. Real-time tracking and predictions stop delays and improve production. These tools ensure smooth and timely work.

See Also

Essential Strategies to Overcome PCBA Manufacturing Challenges

Ways to Enhance Workflow Efficiency in PCB Assembly

Best Practices for Maximizing Quality and Efficiency in PCBA