The electronics industry is changing fast, so choose wisely. A reliable PCBA manufacturing company makes high-quality products you can trust. Companies following ISO 9001 or IPC rules show they care about quality. This helps avoid expensive mistakes or harm to your reputation. The chip market is expected to grow 12.5% in 2025. Picking the right reliable PCBA manufacturing company is key to managing more demand. Look for a service with skill and proven dependability.

Key Takeaways

Pick manufacturers with certifications like ISO 9001 and IPC. These prove they make good products and follow rules.

Check if the company knows your industry well. Experienced manufacturers understand your needs and do a better job.

Find companies that use advanced testing tools like AOI or X-ray. These tests help catch mistakes and make products better.

Look at how fast they deliver and if they’re on time. Choose companies with clear schedules and a history of delivering on time.

Think about long-term benefits, not just upfront costs. Good manufacturers save money by making fewer mistakes and delivering on time, which helps your reputation.

Quality and Standards Compliance

When picking a PCBA manufacturing company, focus on quality first. Companies with certifications show they care about making good products. Let’s look at why this is so important.

Importance of Certifications (e.g., ISO, IPC)

Certifications prove a company follows strict rules for quality. For example, ISO 13485:2016 ensures high-quality PCBA for medical devices. It also helps meet European CE mark rules, showing they value quality.

IPC standards like IPC-A-600 and IPC-6012 set clear rules for PCB performance. These rules help manufacturers meet industry needs. Choosing a certified company means you can trust their work meets global standards.

Adherence to Industry Standards

Following industry standards helps manufacturers make reliable products. Here are some key standards and why they matter:

Certification/Standard | Description | Importance |

|---|---|---|

ISO 9001 | Quality management system | Ensures consistent quality in manufacturing |

ISO 14001 | Environmental management | Shows care for the environment |

IPC-A-610 | Assembly quality standard | Ensures good PCB assembly |

RoHS | Lead-free compliance | Protects the environment |

REACH | Materials safety compliance | Meets safety rules in many markets |

UL Listing | Safety certification | Confirms product safety for users |

Look for companies that follow these standards. It shows they make safe, reliable products and care about the environment.

Commitment to Quality Assurance

Good PCBA companies focus on quality at every step. They test, monitor, and control processes to avoid defects. ISO 9001-certified companies have strong systems to ensure great results. Working with them means your products will meet high standards.

Companies using IPC standards also aim for top-quality assemblies. This reduces defects and makes your electronics more reliable.

Tip: Always ask manufacturers about their quality checks and certifications. This helps you find companies that deliver great results and follow the rules.

Experience and Expertise in a PCB Assembly Company

When picking a pcb assembly company, check their experience and skills. These show if they can meet your needs and deliver good results.

Years of Industry Experience

How long a company has worked shows its ability to succeed. Companies with many years of experience have solved various problems. This helps them handle your project well. For example, a company with 20 years of work has improved its methods and built strong supplier ties. You gain from their knowledge and steady service.

Tip: Ask how long they’ve been in the pcb assembly business. Experienced companies often give better service and fewer problems.

Expertise in Specific Applications or Industries

Not all companies are experts in the same fields. Some focus on medical devices, while others work on cars or gadgets. Pick a pcb assembly company that knows your industry. This ensures they understand your special needs. For example, a company skilled in aerospace electronics will meet strict safety rules.

Ask about their past projects. If they’ve done similar work, they’ll likely do well with your product too.

Proven Track Record of Delivering Reliable Products

A good company always makes high-quality products. Look for one with a history of success. Check if they’ve worked with big clients before. Positive reviews show they meet deadlines and keep quality high.

Note: Ask for references or examples of past work. These help you see how reliable they are.

By focusing on experience and skills, you can find a pcb assembly company that fits your needs and ensures success.

Manufacturing Capabilities of the Best PCB Manufacturer

When picking the best PCB maker, check their skills and tools. Advanced machines, handling tricky designs, and scaling up are important traits.

Advanced Equipment and Technology

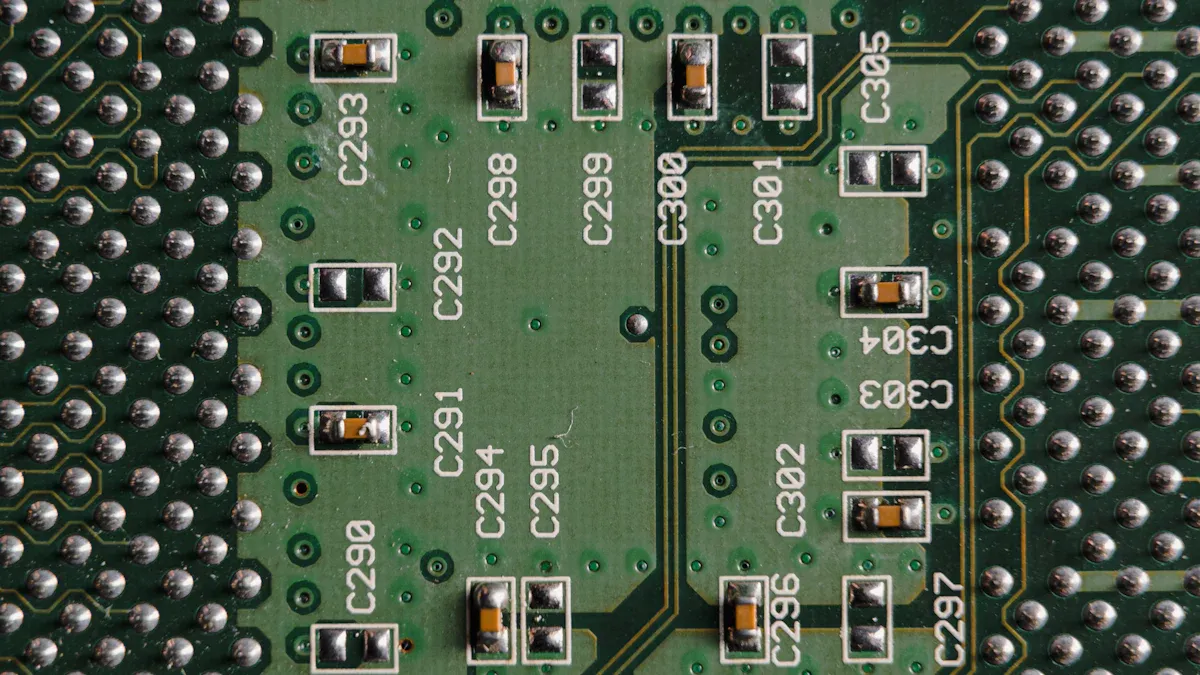

Top PCB makers use modern machines for accuracy and speed. Tools like automated pick-and-place systems and laser drills improve quality. These machines help meet tough design needs while staying consistent.

Great manufacturers track key numbers to improve their processes. Here’s a simple table of what they measure:

Metric | What It Means | Why It Matters |

|---|---|---|

Production Efficiency | Tracks speed, cost, and quality. | Helps them work better. |

Yield Rate | High yield means less waste and better quality. | Saves money and improves results. |

Defect Rate | Watching defects keeps products high-quality. | Makes them more competitive. |

Equipment Utilization | Checks machine downtime to fix slow spots. | Speeds up production. |

Manufacturing Cycle Time | Shorter cycles mean faster work. | Gets products done quicker. |

On-time Delivery Rate | Measures if deadlines are met. | Keeps customers happy. |

By using these numbers, quick-turn PCB makers can deliver fast and high-quality boards.

Ability to Handle Complex and Custom Designs

Good PCB makers can handle tricky designs like flex or rigid boards. Whether you need a sample or a big order, they should meet your needs. They should also handle multi-layer boards and other hard features.

Find a partner who knows your field. For example, if you need medical or aerospace boards, they should follow strict rules for safety.

Scalability for Prototyping and Mass Production

Scaling up is key when moving from samples to big orders. The best PCB makers offer flexible options for every stage. They should be great at quick-turn processes for fast samples and handle large orders too.

A quick-turn PCB maker with scalable systems can adjust to your needs. This ensures steady quality and on-time delivery, no matter the order size.

Testing and Quality Control Processes

Testing and quality checks are vital to ensure top-quality PCBA. A good manufacturer uses advanced tests and strict checks to make reliable products. Let’s break down these important steps.

Types of Testing Offered (e.g., AOI, X-ray, Functional Testing)

A trustworthy PCBA maker uses different tests to find problems. Each test has a specific job to catch and fix issues:

Automated Optical Inspection (AOI): Cameras check for missing parts or soldering mistakes.

X-ray Inspection: Looks at hidden solder joints, like those under BGAs.

In-Circuit Testing (ICT): Tests voltage and current to find faulty parts.

Functional Testing (FCT): Mimics real-world use to ensure the board works properly.

These tests help make sure every board meets the needed standards. This lowers the chance of failures later.

Quality Control at Every Stage of Production

Quality checks happen all through production, not just at the end. Reliable PCB makers watch quality at every step. Here’s how they keep things consistent:

Pre-production Checks: They review designs and materials to avoid early mistakes.

In-process Inspections: Regular checks during assembly catch problems quickly.

Post-production Testing: Final tests, like continuity checks, confirm the board works well.

Quality Control Metrics | What It Means |

|---|---|

Counts defects per unit, showing overall quality. | |

First-Pass Yield | Measures products passing tests without fixes. |

Rework Rates | Tracks how often fixes are needed. |

Customer Returns | Counts returned items, showing quality issues. |

By tracking these numbers, manufacturers can deliver better products every time.

Ensuring Zero-Defect Products

Zero-defect products need strong testing and a focus on quality. Good manufacturers use advanced tools to remove errors. Common tests include:

Continuity Test: Finds open circuits or shorts in the board.

Hi-pot Test: Checks isolation to prevent electrical problems.

Resistivity of Solvent Extract (ROSE) Test: Finds leftover flux that may cause issues.

Time Domain Reflectometry (TDR): Tests signal paths for proper performance.

Tip: Pick a manufacturer that aims for zero defects. This ensures better product performance and reliability.

Working with a manufacturer skilled in testing and quality control ensures your PCBA is top-notch. This saves money and boosts your reputation for great products.

Turnaround Time and Delivery

Getting your PCBA on time is very important. A dependable company helps keep your projects on track. Whether it’s a prototype or a big order, timing matters. Let’s look at what affects turnaround time and delivery.

Lead Times for Prototyping and Production

Knowing lead times helps you plan better. Prototypes are faster because they’re simpler and smaller. Big production takes longer due to more parts and steps. Here’s a simple comparison:

Feature | Prototype PCB Manufacturing | Mass Production PCB Manufacturing |

|---|---|---|

Lead Time | Longer due to higher volume |

Here’s a breakdown of typical timelines:

Prototypes: 1-3 days

Small orders (up to 1,000): 5-10 days

Medium orders (1,000-10,000): 10-15 days

Large orders (10,000+): 15-30 days

These timelines help you pick a company that fits your schedule.

On-Time Delivery Performance

Delivering on time shows how reliable a company is. If they’re late, it can mess up your plans and cost more. Always ask about their on-time delivery record. Companies with good records are more dependable.

Tip: Pick companies that give real-time updates on your order. This keeps you informed and ready.

Flexibility to Meet Tight Deadlines

Sometimes, you need your PCBA quickly. A good company offers fast services for urgent needs. Quick-turn PCB manufacturing is great for tight schedules. They focus on your order without lowering quality.

Choose a company that can adjust to last-minute changes. This helps with rush orders and unexpected needs. Flexible delivery can help you meet your goals.

Note: Talk about your deadlines early to avoid problems later.

Cost and Value for Money When You Choose a PCB Assembly Company

Picking the right pcb assembly company isn’t just about price. You need to balance cost and quality, check for clear pricing, and think about long-term savings. Let’s see how to get the most for your money.

Balancing Cost with Quality

Cheap prices might look good but can cause problems. Low-quality PCBs may fail, need repairs, or hurt your reputation. A good pcb assembly company uses quality materials, modern tools, and skilled workers. This makes strong, reliable products that save money over time.

Here’s a simple breakdown of PCB assembly costs:

Cost Component | Percentage of Total Cost |

|---|---|

Bill of Material Cost | |

Cost of PCB Material and Fabrication | 23% |

Cost of Component Assembly | 13% |

Tooling Costs | 3% |

Most costs come from materials and assembly. Picking a company that improves these areas without lowering quality gives you better value.

Transparency in Pricing and Avoiding Hidden Costs

Clear pricing builds trust. A good company gives quotes with all costs upfront. Hidden fees, like rush delivery or extra tests, can raise your budget. Always ask for a detailed cost list to avoid surprises.

Things like certifications, order size, and delivery time affect prices. For example:

Certifications need long-term investment.

Bigger orders often lower per-unit costs.

Faster delivery may cost more.

Knowing these factors helps you plan better and avoid extra charges.

Long-Term Cost Savings Through Reliability

A reliable pcb assembly company saves you money over time. High-quality PCBs mean fewer defects, cutting repair costs. Reliable companies also avoid delays, helping you meet deadlines and avoid penalties.

Here’s a chart showing PCB assembly costs for 2025:

Choosing a dependable partner gives you better quality, fewer returns, and happy customers. These benefits save money and improve your reputation.

Tip: Focus on quality and reliability instead of just saving money. This ensures better results and long-term success.

Customer Support and Communication

Good customer support and clear communication are very important. They help solve problems fast and make teamwork easier. Let’s see what makes a good PCBA partner.

Quick Replies to Questions and Problems

A good manufacturer answers your questions quickly. Fast replies show they care about your time and needs. Here are some ways to check their response quality:

Metric | What It Means |

|---|---|

Average Handling Time (AHT) | Time spent helping a customer, showing service speed and quality. |

Average Speed of Answer (ASA) | How fast they answer calls, affecting customer satisfaction. |

First Contact Resolution (FCR) | Solving problems in one call, which keeps customers happy. |

Customer Satisfaction Score (CSAT) | Measures how happy customers are with the service they get. |

Studies say solving problems in one call is most important. If customers need to call again, satisfaction drops by 15%. Companies with high FCR rates, around 86%, give better service.

Honest and Clear Communication

Clear communication builds trust and avoids confusion. A good company gives regular updates about your project. They explain things simply and tell you about any delays or issues. Being honest helps you plan better and avoid surprises.

Tip: Be careful if they give unclear answers or miss updates. This might mean they have poor communication.

Help After Delivery and Teamwork

Support doesn’t stop after you get your product. Good companies help with fixes, warranties, and upgrades. They also listen to your feedback to improve their service.

Teamwork is also key. A great partner helps improve designs, cut costs, and boost quality. If they don’t offer help after delivery, it’s a warning sign for future projects.

Note: Always ask about their support policies before signing a deal. This can save you from problems later.

Reputation and Reviews of a Reliable PCBA Manufacturing Company

When picking a reliable PCBA company, check its reputation. Reviews and feedback show what the company does well or poorly. Let’s see how to evaluate this.

Checking Online Reviews and Testimonials

Online reviews give useful details about a company’s work. Websites like Google Reviews, Trustpilot, and forums share customer opinions. These reviews talk about things like product quality, prices, and service.

Here’s a quick look at common review findings:

Aspect | Findings |

|---|---|

Customer Service | Mixed reviews; some praise but also complaints about service. |

Product Quality | Good overall, but some issues with defects and problems. |

Pricing | Competitive, though hidden fees and extra charges noted. |

Reliability | Mostly okay, but delays and quality problems reported. |

Security Measures | Decent, but could improve for stronger data protection. |

Reading these reviews helps you spot trends and decide if the company fits your needs.

Requesting References from Past Clients

Asking for references is another smart way to check reputation. A good PCBA company will share past client contacts. Talking to these clients lets you ask about their experiences. For example, you can ask if the company met deadlines or handled tough projects well. This direct feedback helps you choose wisely.

Evaluating Industry Reputation and Awards

Awards and recognition show a company’s reliability. Certifications and prizes mean they focus on quality and innovation. Look for companies that win awards or join industry events. This shows they stay updated with new trends and standards.

By using reviews, client references, and industry awards, you can pick a trustworthy PCBA company that meets your needs.

Picking a good PCBA company improves product quality and success. Choose manufacturers with certifications like ISO 9001 for better standards. Advanced tools like AOI and X-ray find problems early. These tools make products more reliable and safer. Companies using FMEA analysis fix issues before they happen. This keeps customers happy and builds trust. Working with a dependable manufacturer saves money and avoids delays. It also helps your reputation grow stronger. Focus on quality, skill, and fast delivery to succeed in your projects.

FAQ

1. How can I check a PCBA manufacturer’s certifications?

Ask for copies of their certifications, like ISO 9001 or IPC-A-610. Many companies show these on their websites. Verify them by contacting the organization that issued the certification.

2. What is the usual time for PCBA production?

The time depends on the order size and design complexity. Prototypes are faster, taking 1-3 days. Larger orders may take 10-30 days. Talk to your manufacturer about timelines to match your project needs.

3. How do I make sure the manufacturer meets my quality needs?

Ask about their testing methods, like AOI or functional tests. Request a sample to check their work. Good manufacturers share quality details, like defect rates or first-pass success rates.

4. What makes good customer support?

Good support means fast replies, clear updates, and help after delivery. Check how quickly they respond and ask about their policies for solving problems or making changes.

5. Are there extra costs I should know about?

Yes, extra costs might include fast shipping, extra tests, or tooling fees. Always ask for a full price list to avoid surprises later.

Tip: Share your needs and expectations early to work smoothly with your PCBA manufacturer.

See Also

Key Strategies for Finding a Trustworthy PCBA Supplier

Crucial Advice for Selecting a Skilled PCBA Producer

Guidelines for Choosing the Right PCBA Manufacturer for You