Smart manufacturing is transforming the way products are created today. Industrial IoT PCB assembly for smart manufacturing plays a crucial role in this transformation. It connects devices, enabling them to share data rapidly. This connectivity allows for real-time monitoring of operations and the automation of tasks. The Internet of Things (IoT) enhances production speed and accuracy, while also enabling factories to expand and manage increased workloads. These advancements make Industrial IoT PCB assembly essential for developing smarter and more efficient manufacturing systems.

Key Takeaways

Collecting live data makes work faster and products better. Use this data to find issues quickly and save cash.

Predictive maintenance lowers machine stops. Check equipment health to fix things on time and keep work smooth.

Machines talking to each other makes work faster and more exact. Link devices to team up and avoid errors.

IoT PCB assembly helps use resources wisely. Watch energy and materials to waste less and work better.

Green practices in IoT PCB assembly protect nature. Use earth-friendly materials to please customers and cut pollution.

The Role of Industrial IoT PCB Assembly for Smart Manufacturing

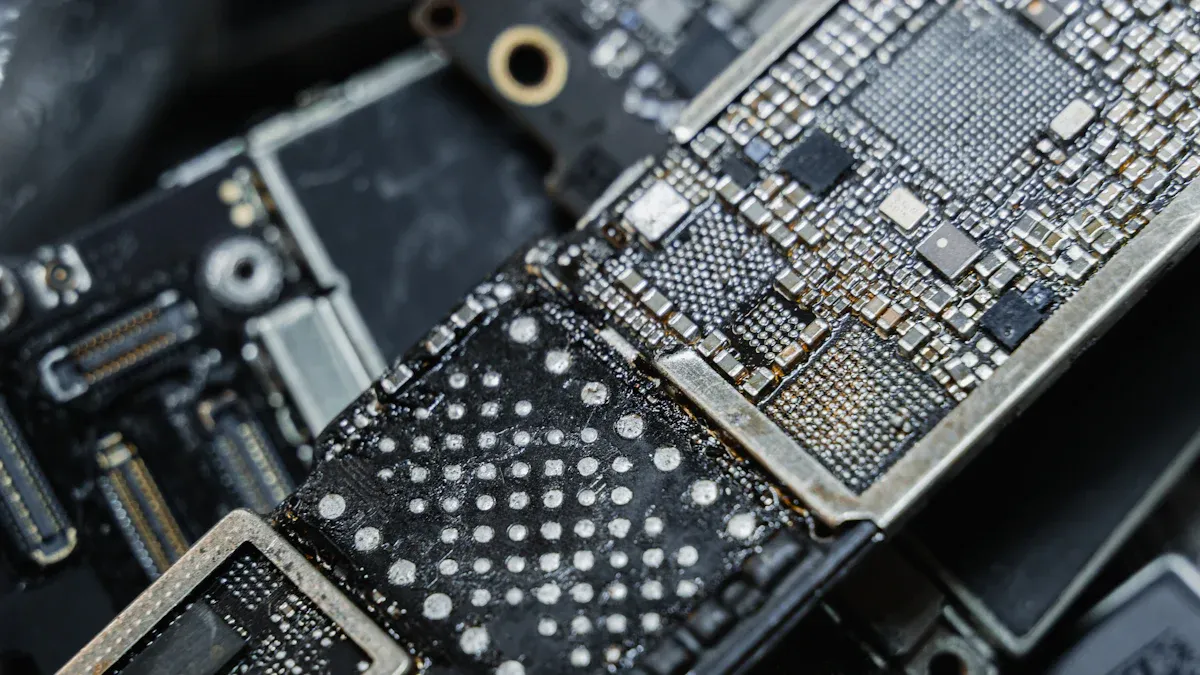

Real-time data collection and monitoring

Collecting data in real-time is key for industrial IoT PCB assembly. Sensors on PCB boards track production as it happens. This helps find problems, check performance, and fix issues quickly. For example, sensors measure temperature, pressure, and vibrations to keep machines working properly.

Tip: Watching data live helps avoid mistakes and saves money.

Here are some benefits of real-time data:

Improved efficiency: Data shows ways to save time and money.

Enhanced product quality: Monitoring ensures products meet standards and fixes errors fast.

Cost reduction: Using resources wisely lowers waste and energy use.

One car part maker cut downtime by 25% using real-time machine checks. A food company reduced waste by tracking temperature and humidity to keep products fresh.

Benefit | Description |

|---|---|

Data-Driven Decision-Making | Live data helps improve production processes step by step. |

Enhanced Product Quality | Sensors check production details to keep quality high and fix issues fast. |

Cost Reduction | Less waste and better energy use save money. |

Predictive maintenance and reduced downtime

Predictive maintenance is another big benefit of IoT PCB assembly. Sensors on PCB boards watch equipment health all the time. They spot problems like odd vibrations or heat changes that might cause breakdowns. Maintenance can then be planned during quiet times to avoid delays.

For example, Siemens uses IoT sensors to plan repairs for wind turbines and trains. General Electric (GE) uses similar tools for airplane engines to stop failures before they happen.

Company | Application | Impact on Downtime |

|---|---|---|

Siemens | Wind Turbines | Plans repairs better, cutting downtime. |

Rail Systems | Finds worn parts early, improving reliability. | |

General Electric (GE) | Aircraft Engines | Stops failures with live monitoring. |

Power Plants | Saves money and boosts efficiency. | |

Ford Motor Company | Assembly Line Robots | Spots issues early to prevent breakdowns. |

Using predictive maintenance helps equipment last longer, lowers repair costs, and keeps production steady.

Machine-to-machine communication and system integration

Machine-to-machine (M2M) communication is a key feature of IoT PCB assembly. It lets devices talk to each other and work together smoothly. Machines share data, plan tasks, and improve workflows without needing people.

For example, IoT machines in PCB assembly adjust settings based on live data from other devices. This keeps production accurate and consistent. Older machines can also connect with new IoT tech to form one network.

Note: M2M communication reduces mistakes and makes production faster.

A phone maker boosted daily production from 10,000 to 85,000 units using M2M communication. Defects dropped from 2% to 0.02%, and production time was cut by 65%.

Case Study | Key Results |

|---|---|

Smartphone Manufacturer | Production grew from 10,000 to 85,000 units/day; Defects dropped from 2% to 0.02%; Time-to-market cut by 65%; Labor costs fell by 78% per unit; Energy use dropped by 42% per unit. |

Automotive Supplier | Made 230+ product types; First-pass yield rose from 92% to 99.7%; Warranty claims dropped by 83%; Space use improved by 45%; ISO/TS 16949 compliance achieved. |

Medical Implant Manufacturer | Met FDA rules; Cut validation time by 70%; Kept zero-defect production; Scaled output from 100 to 5,000 units/month; Time-to-market dropped from 18 months to 7 months. |

Adding M2M communication boosts efficiency, accuracy, and growth in production.

Key Benefits of IoT PCB Assembly in Industrial Automation

Better production and resource use

IoT PCB assembly changes how factories work and use resources. It connects devices to share live data, improving workflows and cutting waste. For example, sensors track energy and materials, helping factories use them wisely. This keeps every part of production running smoothly.

Reports show IoT devices make factories more efficient. These tools use data to improve monitoring and speed up production. Cloud-based systems also help manage resources and lower costs. New tech like edge computing and AI makes systems more reliable and able to grow as needed.

Tip: Use IoT tools to find ways to save time and money.

Higher accuracy and better quality

Accuracy is very important in making products, and IoT PCB assembly helps. Automated systems place parts perfectly every time. Tools like Surface Mount Technology (SMT) and Automated Optical Inspection (AOI) catch mistakes early, stopping bad products from being made.

Better quality leads to happier customers.

Smart tools fix problems fast and help work with suppliers.

By improving accuracy, IoT PCB assembly cuts waste and ensures top-quality products. This is great for small businesses, helping them compete better in the market.

Note: Accurate manufacturing builds trust and makes your brand stronger.

Easy to scale for changing needs

Fast-changing markets need flexible production. IoT PCB assembly helps factories adjust quickly. Automation lets factories increase production without losing quality. For example, if demand rises, IoT systems can handle more work easily.

New tech helps factories keep up with market changes.

IoT PCB assembly keeps production competitive in busy markets.

This flexibility is a big advantage. It helps factories handle demand changes while staying efficient. Using IoT PCB assembly keeps you ahead of competitors and meeting customer needs.

Callout: Scaling isn’t just about growing; it’s about staying ready for anything.

IoT Technologies Enabling PCB Assembly

Sensor integration for intelligent data collection

Sensors are crucial for smarter PCB assembly. They gather live data to track production and improve work. Advanced sensors are vital in fields like defense and farming, where accuracy is key. For instance, car sensors collect safety and efficiency data for smooth driving.

Important factors like sensitivity, resolution, and repeatability affect sensor performance. These ensure precise data collection, which helps optimize processes. In PCB assembly, sensors also check temperature and humidity, keeping levels between -40 °C and +80 °C.

Tip: Pick reliable sensors to avoid problems and ensure smooth operation.

Connectivity solutions like Wi-Fi, Bluetooth, and 5G

Connectivity is key for IoT PCB assembly. Wi-Fi, Bluetooth, and 5G help devices share data quickly. Wi-Fi works best for big setups with many devices. Bluetooth is great for short-range use in small spaces.

5G offers super-fast speeds and low delays. It’s perfect for high-speed PCB assembly lines. These technologies create networks where machines work together and adapt fast.

Callout: Switching to 5G can greatly improve speed and reliability.

Data analytics and AI for process optimization

Data analytics and AI turn raw data into useful insights. In PCB assembly, they study sensor data to find patterns and predict results. For example, AI spots inefficiencies and suggests fixes.

Machine learning automates repetitive tasks, reducing mistakes and improving productivity. AI also predicts maintenance needs, keeping machines in good shape. Using data analytics helps optimize processes and make smarter choices.

Note: AI tools can reveal hidden ways to improve your assembly line.

Challenges in Using IoT PCB Assembly

High costs and investment difficulties

Starting IoT PCB assembly needs a lot of money upfront. Factories must buy new tools, add IoT tech, and train workers. These costs can be hard for smaller businesses to handle. Also, if teams forget to plan for production limits, it can cause delays and extra costs.

Problems with supply chains make things worse. For example, during COVID-19, supply chain issues slowed production and raised costs. Good planning is needed to deal with these problems.

Problem | Explanation |

|---|---|

Production Planning | Forgetting production limits can lead to delays and higher costs. |

Supply Chain Issues | COVID-19 showed how supply chain problems can hurt production timelines. |

Resource Management | Working closely with PCB assembly shops helps meet deadlines and save money. |

Problems with older machines

Adding IoT tech to old machines can be tricky. Many older machines can’t connect to IoT devices easily. Fixing them to work with IoT often needs experts and costs a lot.

Old systems also keep data separate, making it hard to study and use. IoT devices don’t always work well together, which makes building a smooth network harder. This limits how flexible and scalable the system can be.

Problem Type | Explanation |

|---|---|

Connection Issues | Old machines may not have the parts to link with IoT devices. |

Expensive Upgrades | Changing old machines to work with IoT can be costly and hard. |

Separate Data | Older systems store data alone, making it hard to combine and analyze. |

IoT Compatibility | IoT devices don’t always work well together, causing network problems. |

Cybersecurity dangers and data safety worries

IoT PCB assembly brings new security risks. Devices connected to the internet can be hacked. Studies show 60% of companies using IoT have had security problems. Weak passwords cause most breaches, so strong passwords are very important.

IoT devices are often targeted by hackers. In 2020, 41% of attacks on big companies focused on IoT devices. These attacks can cause lost data, legal trouble, and damage to your reputation. Strong security steps are needed to keep systems and data safe.

Fact | Explanation |

|---|---|

60% of companies using IoT had security problems | Over half of companies using IoT faced at least one security issue. |

41% of attacks in 2020 targeted IoT devices | Many cyberattacks focus on IoT devices, showing their weakness. |

91% of breaches caused by weak passwords | Most IoT breaches happen because of poor password practices. |

Future Trends in IoT PCB Assembly for Smart Manufacturing

Miniaturization and flexible PCB advancements

The future of IoT PCB assembly is about smaller, adaptable parts. Tiny components fit more features into small spaces. This is important for wearables and smart gadgets. Flexible PCBs use new materials like graphene and conductive polymers. These materials are strong and work well, making them great for medical tools and smart fabrics.

Topic | Summary |

|---|---|

Advancements in Miniaturization | Smaller parts and circuits are changing how electronics are made. |

Flexible PCB Materials | New materials improve flexibility and performance for modern devices. |

Tip: Flexible PCBs help meet the need for lightweight, high-tech products.

Special PCBs for IoT need compact designs. As IoT grows in areas like healthcare and smart homes, manufacturers must make PCBs that fit sensors, Bluetooth, and Wi-Fi modules perfectly.

Adoption of edge computing in IoT devices

Edge computing changes how IoT PCB assembly works by processing data nearby. This makes decisions faster and improves safety. For example, edge devices in factories analyze sensor data quickly. This boosts efficiency and keeps workers safe. Local data handling also saves money and improves security.

Benefit/Challenge | Description |

|---|---|

Real-time Data Processing | Fast data analysis improves safety and operations. |

Cost Efficiency | Less cloud use saves money and bandwidth. |

Security Concerns | Local data needs strong security to stay safe. |

Note: Switching to edge computing needs skilled workers and careful planning.

Even with challenges like system compatibility, edge computing has big benefits. It helps factories work better and adapt to changes fast.

Focus on sustainable and eco-friendly manufacturing

Sustainability is now important in IoT PCB assembly. Factories are using recyclable materials and energy-saving methods to help the environment. Recycling circuits can cut a product’s carbon footprint by half. Eco-friendly materials also work well for simple devices like TV remotes.

Key Findings | Description |

|---|---|

Environmental Impact | Green practices lower the environmental harm of devices. |

IC Recycling Benefits | Recycling parts reduces the overall carbon footprint. |

Callout: Green manufacturing helps the planet and meets customer expectations.

Using eco-friendly methods helps factories stay competitive and protect the environment. Sustainable production is now a must for smart manufacturing.

IoT PCB assembly changes smart manufacturing with better efficiency and accuracy. It helps improve production, cut waste, and grow operations easily. Though there are challenges like high costs and setup issues, the benefits are much greater in the long run.

Tip: Use IoT PCB assembly to stay ahead and prepared for the future.

The future holds exciting changes, like smaller PCBs and eco-friendly methods. By using these new ideas, you can lead in automation and meet market needs.

FAQ

What is IoT PCB assembly?

IoT PCB assembly makes circuit boards for the Internet of Things. These boards help devices talk, share data, and automate tasks. They are important for smart factories and modern automation.

How does IoT PCB assembly improve production efficiency?

Sensors and live data make workflows better. IoT PCB assembly cuts waste, speeds up work, and uses resources wisely. This makes production faster and saves money.

What industries benefit most from IoT PCB assembly?

Industries like cars, healthcare, electronics, and farming gain a lot. IoT PCB assembly improves accuracy, growth, and automation, helping sectors that need high-quality work.

Are there challenges in adopting IoT PCB assembly?

Yes, it can cost a lot at first and be hard to connect with old machines. Cybersecurity risks are also a problem. Good planning and strong security can solve these issues.

What is the future of IoT PCB assembly?

Smaller parts, bendable boards, and edge computing are coming. These changes will make devices smarter, smaller, and better for the planet. They will lead the next big steps in automation.

Tip: Begin with small IoT PCB projects and grow as you learn.

See Also

Effective Strategies for Enhancing PCB Assembly Productivity

Significance of PCBA Production Skills in Electronic Design

Grasping the Essentials of PCBA Production and Assembly

The Value of Tailored PCBA Production in Today’s Electronics