Ruggedized edge computing PCBA has transformed industrial IoT in significant ways. It enhances system performance and longevity in challenging conditions. These devices are designed to withstand harsh environments while maintaining optimal functionality. Edge computing processes data locally, minimizing the distance to servers. This local processing reduces latency and supports real-time operations, which is crucial for various industries. The ruggedized PCBA in edge devices is exceptionally durable and ensures stable computing. These attributes make it an essential component of modern IIoT systems, where precision and resilience are imperative.

Key Takeaways

Strong edge computing boards help industrial IoT by handling data nearby. This lowers delays and allows quick operations.

These tough boards survive rough conditions, perfect for factories, oil, and energy work.

Buying strong boards costs more at first but saves money later. They need fewer repairs and have less downtime.

Strong boards keep data safe and follow rules, meeting industry needs.

Using these boards helps spot equipment problems early. This prevents expensive breakdowns.

What is Ruggedized Edge Computing PCBA?

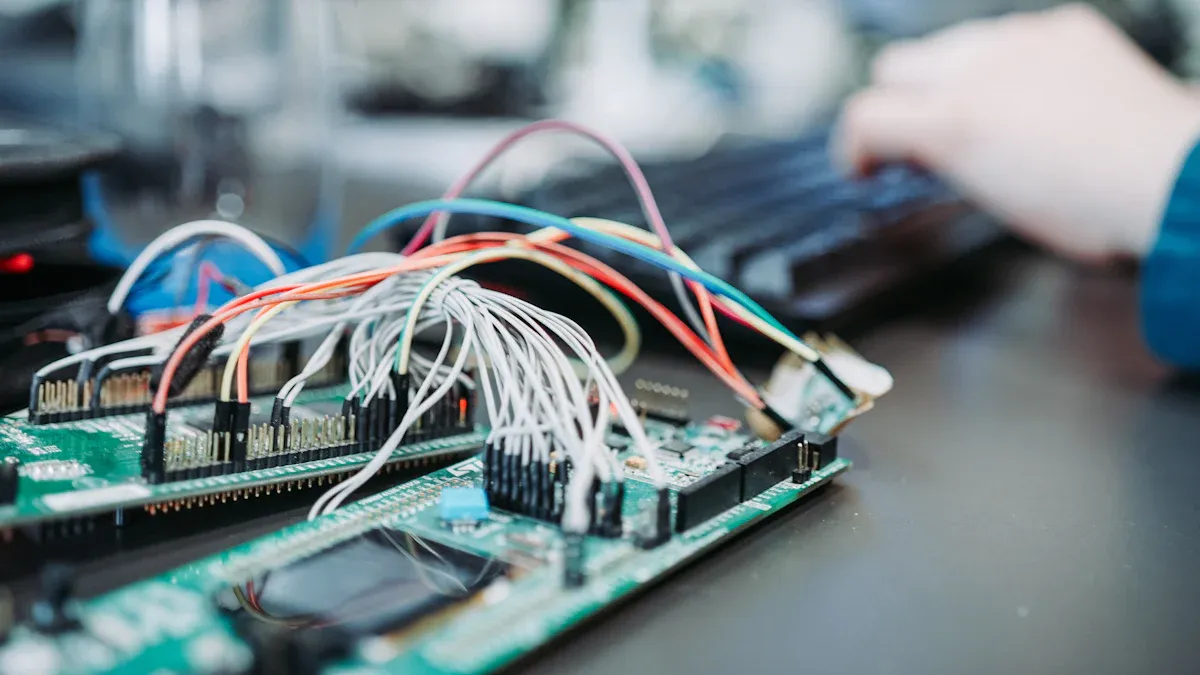

Definition and Features

Ruggedized edge computing PCBA means circuit boards made for tough jobs. These boards are strong and have smart computing abilities. They include features like stronger solder, thicker copper, and tough materials. These help them handle heat, shaking, and wet conditions. They let devices process data quickly and work well in hard places. This makes them very important for industries needing nonstop work.

Differences from Standard PCBA

Regular PCBA works fine in easy conditions, but ruggedized PCBA is for tough spots. They differ in strength, defect handling, and material quality. For example, Class 3 PCBs, used in rugged boards, need perfect solder and no flaws. Class 2 PCBs, however, allow small mistakes.

Here’s a simple comparison:

Characteristic | Class 2 PCBs | Class 3 PCBs |

|---|---|---|

Maximum Reliability | Works in normal conditions | Handles tough and extreme conditions |

Tolerance for Defects | Small flaws are okay | No flaws allowed |

Solder Joint Quality | Some mistakes allowed | Must be perfect |

Annular Ring Integrity | Small breaks allowed | No breaks allowed |

Copper Thickness | At least 20 µm | 25 µm or more |

Material Durability | Strong but not extreme | Very strong for tough jobs |

Testing Protocols | Basic checks like visual tests | Deep checks like X-rays |

Environmental Suitability | Good for mild conditions | Made for harsh places |

This accuracy helps ruggedized PCBA handle tough industrial IoT needs.

Role in Industrial IoT

Ruggedized edge computing PCBA is key in industrial IoT. It helps devices process data nearby, cutting delays and working in real time. These boards work well in factories, oil rigs, and power plants. Their strength and speed make them vital for IIoT. They help with automation, fixing problems early, and saving energy.

Benefits of Ruggedized Edge Computing PCBA

Durability in Harsh Environments

Ruggedized edge computing PCBA is built to survive tough conditions. These boards work well where regular PCBA would break down. Strong materials and smart designs help them resist heat, stress, and moisture.

Tests prove their toughness:

Shock Testing: Shows the board can handle hard hits without damage.

Temperature Cycling: Checks if the board stays strong during quick temperature changes.

Humidity Stress Testing (HAST): Confirms the board can resist water and heat without failing.

These features make ruggedized PCBA perfect for factories, oil rigs, and outdoor devices. They keep working even in the hardest environments.

Real-Time Data Processing

Ruggedized PCBA helps edge devices process data instantly. This is very important for industrial IoT systems. By handling data nearby, they avoid delays from sending it far away.

For example, in a factory, these boards can track machines in real time. If a machine starts wearing out, the system warns you quickly. This prevents downtime and saves money. They also help with automation, where fast decisions are needed to keep things running smoothly.

Real-time processing makes operations faster and more accurate. Ruggedized PCBA works well even with vibrations or electromagnetic interference.

Enhanced Security and Compliance

Security is very important in industrial IoT, and ruggedized PCBA does this well. These boards have features to protect data and meet industry rules.

Certifications prove their safety:

Compliance Level | Description | Applications |

|---|---|---|

Stops tampering and reverse-engineering effectively. | Military, Banking, Medical | |

Level 4 | Gives top-level security for data protection. | Airport security, Network communications, Automotive |

Manufacturers also test these boards carefully to ensure they work before and after sealing. Improvements in FIPS features make them even safer against new threats. Ruggedized PCBA is a great choice for industries needing strong data security.

Cost Efficiency

Ruggedized edge computing PCBA helps save money in industrial IoT. It may cost more at first, but it saves money later. These boards lower repair costs, reduce downtime, and last longer.

Frequent repairs or replacements are less needed with ruggedized PCBA. These boards handle heat, water, and stress without breaking. For example, aerospace and defense use special coatings to protect PCBs. These coatings cost more but prevent damage and keep systems running.

Local data processing also saves money with ruggedized PCBA. Edge devices process data nearby, cutting server costs and delays. In factories, real-time data can spot problems early. This avoids big repairs and keeps production smooth.

Strong security features also save money by stopping cyber threats. They protect sensitive data, avoiding breaches and financial losses. Industries like healthcare and finance benefit from these safety measures.

Though ruggedized PCBA costs more upfront, it saves money over time. Premium materials and smart designs make them worth the investment. They keep systems working well and save money in the long run.

Applications in Industrial IoT

Predictive Maintenance

Predictive maintenance helps stop equipment problems before they happen. Ruggedized PCBA collects and studies data to keep machines working longer. This reduces downtime and saves money on repairs.

These boards work well in tough places like factories. They handle extreme temperatures from -40°C to 70°C and voltage ranges of 9 to 48 VDC. Their design lets you add sensors easily for better monitoring. Whether you need simple tracking or advanced AI tools, ruggedized PCBA fits your needs.

For example, in a factory, these boards process sensor data nearby. If a machine starts wearing out, the system warns you quickly. This lets you fix it before it breaks, saving time and money.

Automation and Robotics

Ruggedized PCBA is important for robots and automated systems. These boards are strong enough to work in hard conditions like heat and shaking.

Robots in warehouses use ruggedized PCBA to avoid breaking down. This helps them sort, pick, and move items faster. The boards also process data locally, making decisions quicker. This keeps robots working smoothly, even with interference around.

Using ruggedized PCBA improves robot performance and makes automation more precise. It boosts productivity in industries that rely on robots.

Energy Optimization

Ruggedized PCBA helps save energy in industrial systems. These boards are designed to use less power and prevent waste.

Key features include:

Compact Design: Fits more parts in less space to save energy.

Better Layouts: Stops signal problems for smoother data flow.

Heat Control: Uses heat sinks to stop overheating and energy loss.

Strong Materials: Works well in tough places without wasting energy.

Benefits of Ruggedized PCBA | |

|---|---|

Compact Design | Saves energy with dense components |

Smooth Data Flow | Stops signal issues for efficiency |

Heat Control | Prevents overheating and energy loss |

Tough Materials | Reduces waste in harsh conditions |

For example, in a power plant, these boards track energy use in real time. They find problems and suggest fixes to save power. This lowers costs and supports eco-friendly practices in industries.

Quality Assurance

Quality assurance makes sure ruggedized PCBA works well in industries. These boards go through tough tests to meet high standards. This helps edge devices work smoothly, even in hard conditions.

Ruggedized PCBA is tested in many ways to ensure quality. Environmental tests check for corrosion, humidity, and heat changes. Physical tests look at vibration and drops. Electrical tests confirm the board works correctly in real situations. These tests prove the PCBA can handle industrial needs without failing.

Here’s a simple table of key tests and their benefits:

Test Type | Benefit Description |

|---|---|

Long Lifespan, Less Repairs | Strong design means fewer fixes and saves money. |

Better Device Performance | Keeps systems running well with little wear and tear. |

Faster Build, Lower Costs | Smart designs save time and money during production. |

Environmental Tests | Checks for corrosion, humidity, and heat resistance. |

Physical Tests | Tests for shaking and drops to ensure toughness. |

Electrical Tests | Confirms the board works well in real-world conditions. |

These tests show how ruggedized PCBA meets industrial IoT needs. For example, longer lifespan means fewer breaks in factory work. Faster production saves time and money when adding edge devices.

Quality assurance makes ruggedized PCBA reliable for tough jobs. It ensures the boards process data quickly and keep systems efficient. Whether saving energy or automating tasks, quality checks guarantee top performance.

Challenges and Considerations

Initial Investment Costs

Using ruggedized edge computing PCBA costs more at first. You need to think about these expenses:

Initial Capital Expenditure: Ruggedized PCBA costs more than regular PCBA, especially for new users.

Operational Costs: High upfront costs can be balanced by saving money later with automation.

Total Cost of Ownership: You must also plan for training, repairs, and long-term use costs.

For example, ruggedized PCBA reduces downtime and repair costs in factories. This saves money over time, making the initial expense worth it. Still, you should check your budget and goals to see if this fits your needs.

Specialized Expertise Requirements

Using ruggedized edge computing PCBA needs special skills. Many engineers don’t know enough about automation or AI tools. Only 17% of manufacturing engineers have both skills. This lack of knowledge can cause delays and require outside help.

For example, a Japanese robotics project was delayed by 11 months. Workers needed training to use TensorFlow Lite models. To avoid delays, you may need to train staff or hire experts. This costs more but helps systems work better and faster.

Balancing Scalability and Performance

It’s important to balance growth and efficiency with ruggedized PCBA. Your system must handle more work without slowing down.

Edge devices process data nearby, making decisions faster. But growing these systems needs careful planning. Too much work can slow them down, while unused resources waste money.

To fix this, start with a design that can grow over time. This keeps your edge computing systems working well as your needs change.

Ruggedized edge computing PCBA is key for improving industrial systems. It is strong and works well in tough environments. By processing data nearby, it cuts delays and boosts efficiency. It helps in many areas, like fixing machines early and saving energy. While it costs more at first and needs skilled workers, solving these issues brings big benefits. With ruggedized edge computing, industries can improve operations and stay competitive in the growing IIoT world.

FAQ

How is ruggedized PCBA different from regular PCBA?

Ruggedized PCBA is made with tougher materials and smarter designs. It can handle heat, water, and shaking better than regular PCBA. This makes it dependable for hard industrial jobs.

Can ruggedized PCBA help factories avoid downtime?

Yes, ruggedized PCBA finds problems early by processing data nearby. Fixing issues quickly stops downtime, saving both time and money.

Is ruggedized PCBA good for outdoor use?

Definitely! Ruggedized PCBA works well in bad weather like rain or heat. It’s perfect for places like oil rigs, power plants, and outdoor monitoring systems.

How does ruggedized PCBA save energy?

Ruggedized PCBA uses smart designs to waste less energy. It controls heat and uses power wisely, making systems cheaper to run.

Are ruggedized PCBA systems safe?

Yes, ruggedized PCBA has strong security to keep data safe. It follows strict rules, making it great for industries like healthcare and banking.

See Also

The Role of PCBA in Elevating Today’s Electronics

PCBA’s Unprecedented Impact on Electronic Advancements

Exploring the Benefits and Drawbacks of Flex PCBA