Choosing the best quick turn PCBA services in USA is crucial for the success of your project. The global PCB and PCBA market is rapidly expanding, projected to grow from $68.4 billion in 2023 to $105.8 billion by 2032. Industries such as healthcare, automotive, and electronics rely heavily on advanced PCBA services to drive innovation in areas like 5G, IoT, and wearable technology. Opting for reliable quick turn PCBA services in USA ensures your products align with these demands while helping you stay on schedule and within budget.

Key Takeaways

Pick a quick-turn PCBA provider with lots of experience. A good reputation means they are reliable and do quality work.

Fast delivery is important. Ask providers how quickly they can finish to meet your deadlines.

Quality is very important. Choose providers with certifications like ISO 9001 for great products.

Clear pricing helps you trust them. Go for providers who give honest cost estimates to avoid surprises and stay on budget.

Good communication matters. Choose a provider with great customer service to keep your project running smoothly and fix problems fast.

Understanding Quick Turn PCBA Services in USA

What Are Quick Turn PCBA Services?

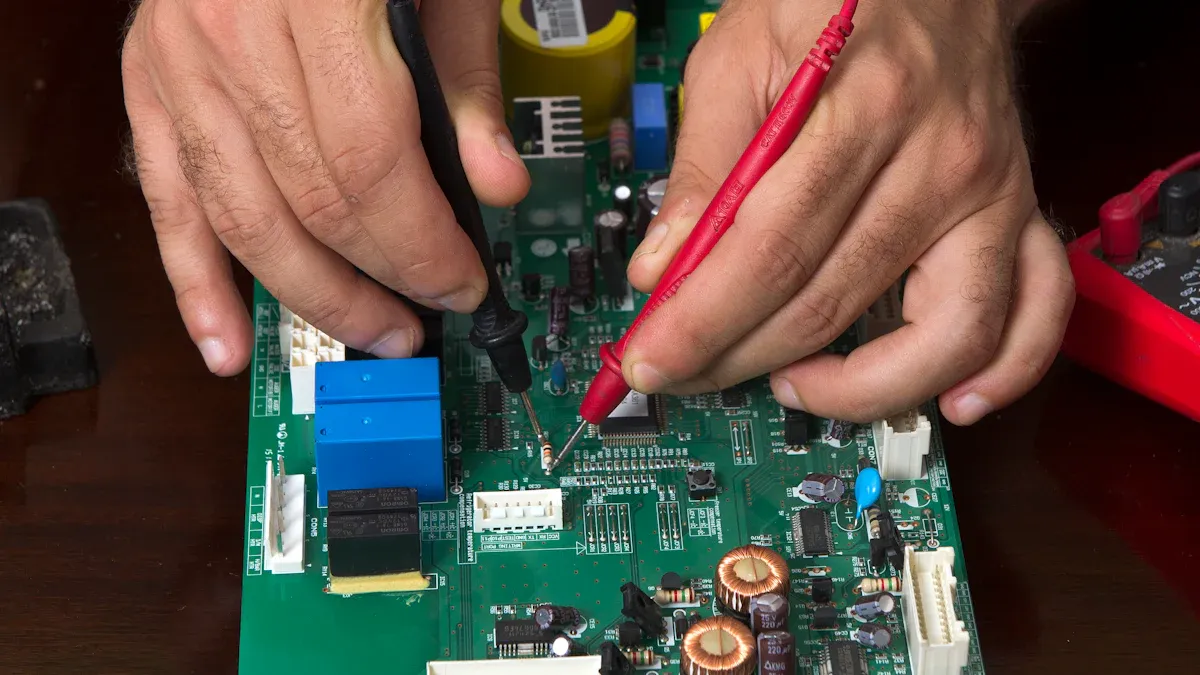

Quick Turn PCBA services focus on making printed circuit board assemblies (PCBA) quickly. These services are great for businesses needing fast prototypes or small production runs. They help test designs and speed up product development. For instance, quick-turn PCB assembly can create DFM-optimized boards in just 24 hours with guaranteed quality.

Service Type | Description |

|---|---|

Quick Turn PCB Assembly | Service for fast PCB production. |

DFM-optimized boards | Boards designed for easy manufacturing, ready in 24 hours. |

Using these services shortens production time and allows design changes. This is especially helpful for industries like electronics and automotive.

Benefits of Quick Turn PCB for Time-Sensitive Projects

Quick Turn PCBA services in the USA are perfect for tight deadlines. Companies using these services have cut project times by over 20%. This means faster design updates and quicker product launches.

Accelerated Product Development: Quickly go from design to physical boards for testing.

Reduced Time to Market: Launch products faster and stay ahead of competitors.

Cost Savings Through Efficiency: Avoid delays to save money and earn revenue sooner.

Improved Risk Management: Fix problems early to avoid big manufacturing mistakes.

Benefit | Description |

|---|---|

Accelerated Product Development | Speeds up testing and design improvements. |

Reduced Time to Market | Helps launch products faster to meet market needs. |

Rapid Iteration on Design Changes | Makes it easier to fix errors and improve designs quickly. |

Cost Savings Through Efficiency | Saves money by avoiding delays and speeding up revenue. |

These advantages make quick-turn PCB services essential for urgent projects.

Why Quick-Turn PCB Design Service Is Critical for Fast-Paced Industries

Fast-moving industries like telecom, electronics, and medical devices depend on quick-turn PCB services. These services shorten development times and give companies an edge. For example, a telecom company used quick-turn PCB manufacturing to create a new RF device. This helped them make changes quickly and launch successfully.

Accelerated Time-to-Market: Stay ahead in competitive industries with faster launches.

Enhanced Prototyping Capabilities: Quickly make prototypes to improve designs without delays.

Cost Savings Through Testing: Small production runs for testing reduce risks before large-scale production.

In North America, demand for quick PCBA services is growing due to tech hubs and custom electronics. Automotive advancements like self-driving cars also need these services. Quick-turn PCBA ensures products meet market needs while keeping quality high.

Key Factors to Consider in Choosing a Quick-Turn PCB Provider

Experience and Reputation in Quick Turn PCBA Services

When picking a quick-turn PCBA provider, check their experience first. A company with a good history is more reliable. Experienced providers know how to handle tight deadlines and tricky designs.

Why Experience is Important:

Skilled providers have smooth processes that avoid mistakes. They also know how to manage complex designs, keeping your project on schedule.Signs of a Good Reputation:

Read reviews, case studies, and testimonials. These show if the provider delivers good results. A strong reputation means they care about quality and customers.

Tip: Pick a provider with experience in industries like cars, healthcare, or telecom. This shows they can meet tough standards.

Turnaround Time and Delivery Speed

Fast delivery is key for quick-turn PCBA services. Your provider must finish on time without lowering quality. Delivery speed depends on design difficulty, materials, and tools.

Factor | Example Turnaround Times |

|---|---|

Simple PCB Design | Ready in 24 hours |

Complex PCB Design | Takes 7-10 days |

Material Availability | Depends on stock |

Advanced PCB Features | Extra time for blind/buried holes |

Manufacturing Tools | Better tools mean faster production |

To get fast delivery:

Pick providers with advanced tools and efficient systems.

Ask about their usual delivery times for different projects.

Check if they can handle urgent orders when needed.

Note: Simple designs are quicker to make. Even complex ones should not delay if the provider is well-equipped.

Quality Standards and Certifications

Quality is a must for quick-turn PCBA services. A good provider follows strict rules and holds important certifications. These prove they deliver top-quality products that meet industry needs.

Certification | What It Ensures |

|---|---|

ISO 9001 | Quality management system. |

ISO 13485 | High standards for medical devices. |

ISO 14001 | Focus on eco-friendly practices. |

ISO 27001 | Protects information security. |

ISO 45001 | Ensures workplace safety. |

IATF 16949 | Automotive quality standards. |

Certified providers follow strict checks for soldering, parts placement, and cleanliness. They also meet IPC-A-610 standards for industries like aerospace and healthcare.

Tip: Always check a provider’s certifications and quality checks. This ensures your project meets all rules and works perfectly.

Technical Expertise and Advanced Capabilities

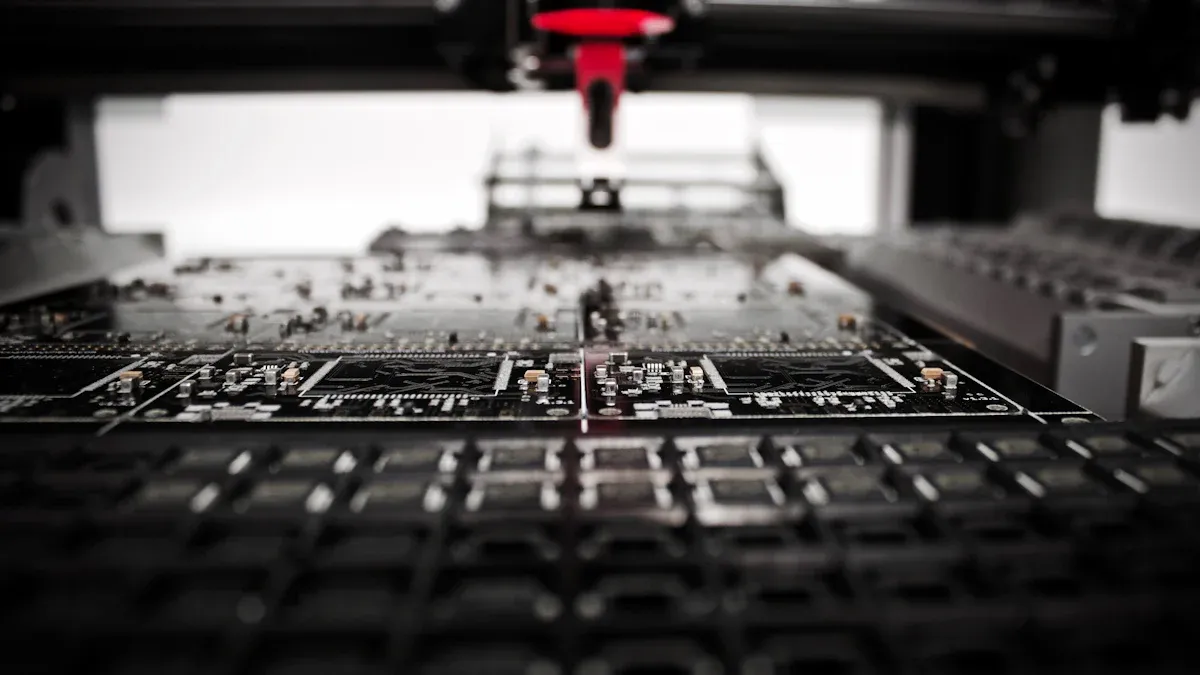

Having strong technical skills is key for successful quick-turn PCB projects. Providers with advanced tools can handle tricky designs faster. New ideas like smaller parts, built-in components, and bendable PCBs have changed the industry. These innovations make production quicker and more efficient.

Innovation Type | How It Speeds Up Production |

|---|---|

Miniaturization and HDI | Makes smaller, better PCBs faster to produce. |

Embedded Components | Boosts performance and saves time by combining parts directly. |

Flexible and Stretchable PCBs | Adjusts easily for different uses, speeding up production. |

Additive Manufacturing and 3D Printing | Helps create prototypes quickly, cutting wait times. |

AI in PCB Design and Manufacturing | Improves processes and reduces mistakes for faster results. |

Pick a provider that uses these new technologies. For example, AI tools can make designing easier and reduce errors. Providers using 3D printing can quickly make prototypes for testing and changes. These skills help keep your project on time and meet industry needs.

Tip: Ask providers about their experience with modern tools like HDI and 3D printing. This shows if they can handle tough and fast projects.

Cost Transparency and Value-Added Services

Clear pricing is important when choosing a quick-turn PCB provider. It builds trust and helps you understand costs upfront. Providers with honest pricing often make customers happier by avoiding hidden fees.

Fair prices keep customers loyal and satisfied.

Honest pricing improves a company’s reputation and success.

Extra services can also make a big difference. Look for providers offering design help, material sourcing, and support after production. These extras save time and money while improving your project’s quality.

Note: Providers who share detailed cost info and offer extra services show they care about your success.

Customer Service and Communication

Good customer service and communication prevent mistakes and keep projects running smoothly. Clear communication lets you solve problems quickly and avoid delays. Providers who respond fast can fix issues and keep your project on track.

Having clear files is also important to avoid errors. Well-organized files protect your design and make future updates easier. Bad documentation can cause expensive mistakes. Providers who focus on good documentation show they care about quality.

Metric | What It Measures |

|---|---|

Client Satisfaction Score | How happy customers are with the service. |

Response Time | How quickly providers reply to questions. |

Resolution Time | How fast problems are fixed. |

First Contact Resolution | Problems solved on the first try. |

Net Promoter Score | How likely customers are to recommend the service. |

Studies show that quick customer support makes clients happier. Providers with fast responses and solutions get better reviews and repeat customers. Working closely with open communication builds trust and keeps projects aligned.

Tip: Pick a provider known for great customer service. This helps avoid delays and ensures your project goes smoothly.

Questions to Ask the Best PCB Manufacturer

What Is Their Experience With Quick-Turn PCB Projects?

Knowing a manufacturer’s experience with quick-turn PCB projects is key. Companies with a strong history in this area are more dependable. Ask about their past work and industries they’ve served. For example, find out if they’ve worked with automotive, healthcare, or telecom sectors. These industries often need high-quality PCBs made quickly.

Here are some simple questions to ask:

Do you have experience with the circuit board I need?

Can you describe your PCB manufacturing process?

Is any part of your process done overseas?

What certifications do you have, like ISO 9001 or IPC?

How do you manage tight deadlines or tricky designs?

These questions help you decide if the manufacturer fits your project needs.

How Do They Ensure Quality Assurance and Testing?

Quality checks are very important when picking a quick-turn PCB provider. A good manufacturer uses strict testing and quality systems. Certifications like ISO 9001 and IPC show they care about making reliable products.

Key Aspect | What It Means |

|---|---|

Proves they follow strong quality management rules. | |

IPC Standards Compliance | Shows they meet industry standards for PCB quality. |

Testing Procedures | Includes tests like functional and environmental checks for reliability. |

Inspection Reports | Gives detailed results of tests for every production batch. |

Ask how they test their PCBs and what methods they use. For example, do they check for function or test under stress? Also, ask how they fix problems if defects are found. These steps show their focus on quality and improvement.

What Is Their Typical Turnaround Time for Quick Turn PCBA Services?

Turnaround time matters a lot when choosing a PCB provider. You need someone who delivers fast without lowering quality. Ask about their usual delivery times for different designs. Simple boards might take 24 hours, while complex ones could need up to 10 days.

Here are more questions to ask:

How long does it take to check the Bill of Materials (BOM)?

Can you handle last-minute changes or urgent orders?

What steps do you take to ensure on-time delivery?

A manufacturer with good tools and systems can meet tight schedules. Their flexibility helps keep your project on track.

Do They Offer Transparent Pricing and Cost Estimates?

Knowing the exact cost is important when choosing a pcb assembly provider. Clear pricing helps you avoid surprise fees later. Good providers give detailed cost breakdowns, including materials, labor, and extra services. This makes it easier to plan your budget and stay on track.

Ask if they provide itemized quotes for every part of the project. These quotes should cover everything from design to delivery. Some companies may charge more for faster services or special parts. Knowing these costs upfront helps you make better choices.

Providers with clear pricing explain how changes affect costs. If you update your design or add features, they should tell you the new price. This open communication builds trust and keeps your budget safe.

Tip: Choose providers with free consultations or cost tools. These can show you the total expenses before starting your project.

How Responsive Is Their Customer Support?

Quick customer support is key for successful pcb assembly projects. You need a provider who answers fast and solves problems quickly. Bad communication can cause delays, mistakes, and extra costs.

Check how they handle questions. Do they reply fast and give clear answers? Good providers assign someone to your project so you always have help.

See if they offer different ways to contact them, like email, phone, or chat. This makes it easier to reach them anytime. Providers with great support often have happy customers, showing they are reliable.

Note: Providers with strong customer service often deliver high-quality results. Clear communication ensures your project meets all needs.

Overcoming Common Challenges in Quick Turn PCBA Services

Managing Delays in Delivery

Delivery delays can mess up schedules and raise costs. These delays often happen because of worker shortages, missing materials, or bad planning. Picking a provider with smart systems and flexible processes can help.

Worker shortages cause uneven staffing. IBM Bromont fixed this by using better planning tools, cutting staffing problems by 20%.

Missing materials stop production. Providers with good supplier connections and stock systems avoid this issue.

Complicated workflows slow things down. Careful planning keeps all work areas running smoothly.

Experienced providers handle big orders better. They scale operations to keep your project on time.

Fixing Miscommunication in Design Requirements

Miscommunication about designs is a common problem in PCB projects. Studies show 80-100% of new customer designs have mistakes or missing details. This happens because of unclear files or poor communication between teams.

To fix this, talk often and clearly with your provider. Share complete design files early. Providers with review teams can spot mistakes and suggest fixes before production starts. This saves time and avoids expensive errors.

Providers with strong communication systems make sure your designs are correct and followed properly.

Keeping Quality Control and Testing Standards High

Quality checks are key for good PCBA services. Standard tests make sure boards work well and last long. These tests include inspections, soldering checks, and performance testing.

Reliability tests push PCBs to handle tough conditions like heat and moisture. This proves they can survive real-world use.

Testing steps include:

Checking parts for accuracy.

Inspecting solder joints for strength.

Testing electrical connections and performance.

Simulating real-world conditions like heat and humidity.

Analyzing signals for fast-moving applications.

Providers with automated testing tools work faster and more accurately. They also use new tech to lower defect rates. Big production providers often excel at delivering reliable and high-quality boards.

Balancing Costs Without Compromising Quality

Keeping costs low while ensuring quality is a big challenge in Quick Turn PCBA services. You can solve this by using smart methods during design and production. These steps help save money and still meet high-quality needs.

First, make your design easy to produce. Use common part sizes and avoid rare components. This makes production simpler and cheaper. You can also group multiple PCBs into one panel. This reduces waste and saves time. Picking standard materials like FR-4 keeps costs down while staying reliable.

Tip: Work with your manufacturer early to find ways to save money.

Reducing the number of layers in your design is another way to cut costs. Fewer layers mean simpler and cheaper boards. Choosing affordable finishes like HASL (Hot Air Solder Leveling) also helps save money without losing quality. Avoid rush orders by planning ahead. This prevents paying extra for faster services.

Ways to save money:

Ask vendors for discounts on large orders.

Use package deals that combine services for lower prices.

Build long-term relationships with manufacturers for better rates.

By following these tips, you can control costs and keep quality high. Careful planning and early teamwork with vendors ensure your project stays on budget and delivers great results.

Picking the best quick-turn PCBA provider means checking their experience, quality, and speed. Look for a company you can trust and that is clear about their process. Good communication helps keep your project on schedule. Quick delivery is important to meet your deadlines. Always ask how long they usually take to finish projects. Talk to experts to learn how they handle fast deliveries. Get a price estimate to compare choices and decide wisely.

FAQ

What is the difference between quick turn PCB and standard PCB manufacturing?

Quick turn PCB means making circuit boards very fast, often in 24 hours. Standard PCB manufacturing takes more time and is better for big orders. Quick turn services are great for urgent projects needing fast prototypes or small runs.

How can you ensure on-time delivery for quick turn PCBs?

Pick a PCB company that promises fast delivery and has good suppliers. Companies with smart systems and advanced tools can handle rush orders well, keeping your project on track.

Why is design for assembly important in quick turn PCBs?

Design for assembly makes building circuit boards easier and faster. It reduces mistakes and speeds up production. This helps create high-quality boards while saving time and money.

What should you look for in customer reviews when selecting a PCB provider?

Look for reviews that mention reliability, fast delivery, and good quality. Positive feedback about their quick processes shows they are dependable and skilled.

Can quick-turn prototypes help reduce costs in PCB projects?

Yes, quick-turn prototypes let you test designs early to avoid big mistakes. They allow changes, ensuring good designs while keeping costs low.

See Also

Choosing the Right PCBA Manufacturer for Your Business

Essential Advice for Selecting a Trustworthy PCBA Manufacturer

Key Considerations When Picking a PCBA Contract Manufacturer

Finding PCBA Manufacturing Services with Superior Capabilities