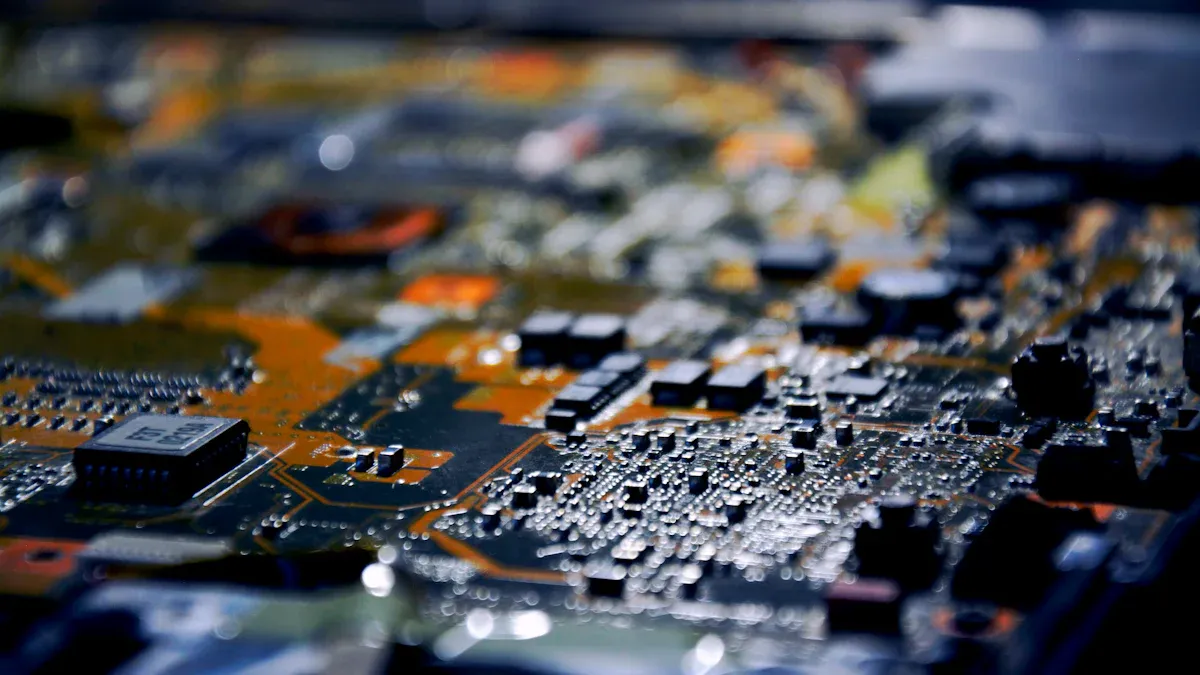

Modern gadgets need to work well, be small, and last long. High-density interconnect (HDI) PCBA are designed to meet these needs. They use advanced technology to make smaller and better devices. HDI PCBA helps connect parts tightly and keeps signals strong. Unlike regular PCBs, HDI PCBA saves space and works better. From phones to medical tools, HDI PCBA make devices dependable and ready for the future.

HDI technology helps create powerful and precise electronics in tiny sizes.

Key Takeaways

HDI PCBs use new technology to make smaller, stronger devices. This makes them great for modern electronics.

These boards improve signal strength and cut down interference. This helps them work better in fast systems.

HDI PCBs save space by using tiny holes and hidden paths. This allows smaller designs for gadgets like phones and smartwatches.

They are made to survive tough conditions, so they are trusted in fields like space, cars, and healthcare.

Even though they cost more to make, HDI PCBs are worth it. They offer better performance and are very reliable for advanced electronics.

What Are HDI PCBs?

Definition of HDI PCBs

HDI PCBs, or high-density interconnect printed circuit boards, are special boards. They are made for small and complex electronic designs. These boards use smart technology to fit more parts in less space. Unlike regular PCBs, HDI PCBs are better for modern gadgets needing small size and high power.

The world market for HDI PCBs shows their rising value. In 2024, it was worth $16.11 billion. By 2032, it may grow to $39.91 billion. This rise is due to more demand for electronics like phones, smartwatches, and gaming devices.

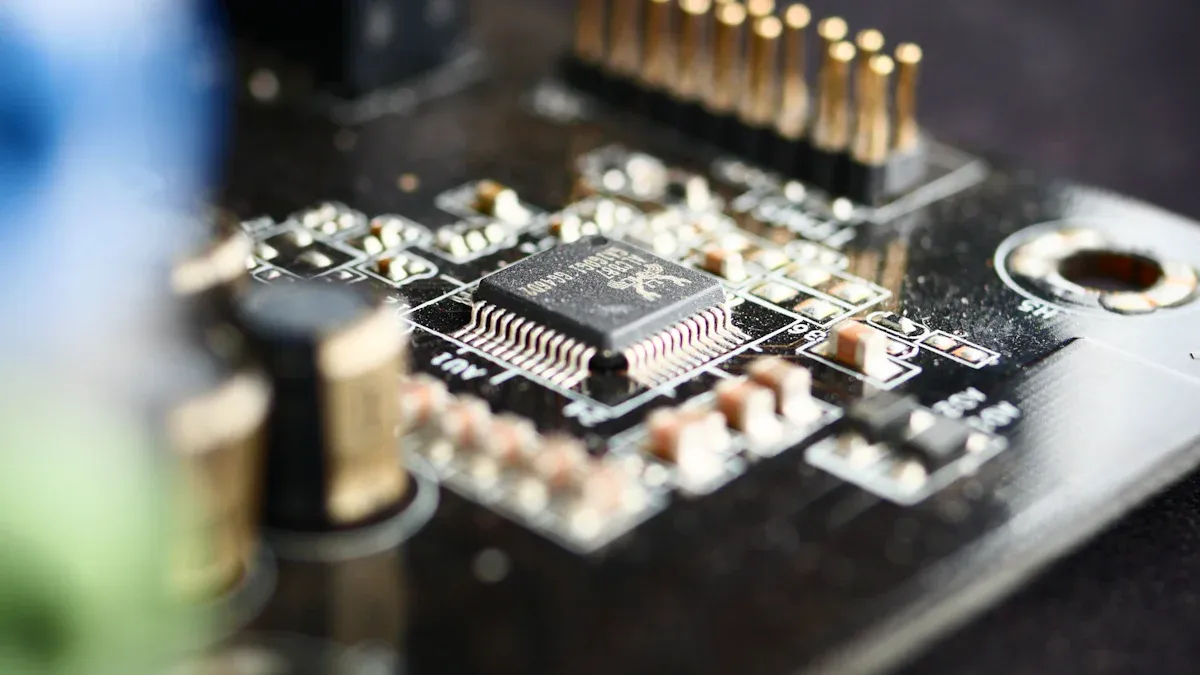

Key Features of HDI PCBs

HDI PCBs have special features that make them work better:

Microvias: Tiny holes link layers of the board, helping save space.

Blind and Buried Vias: These holes connect layers without going through the whole board. This keeps signals strong.

Surface-Mounted Technology (SMT): Parts are placed on the board’s surface, saving space and improving performance.

These features make HDI PCBs perfect for small, advanced gadgets like tablets and smartwatches.

Differences Between HDI PCBs and Traditional PCBs

HDI PCBs are very different from regular PCBs in design and use. Regular PCBs use through-hole vias that go through the whole board. This limits how many parts they can hold. HDI PCBs use microvias, blind vias, and buried vias to save space and work better.

Regular PCBs are fine for simple designs but not for modern needs. HDI PCBs help make smaller, faster, and stronger devices. They are key for industries like electronics, cars, and airplanes.

Key Advantages of HDI PCBs Over Traditional PCBs

Better Electrical Performance

HDI PCBs improve how signals move across the board. Their design reduces unwanted electrical effects, keeping signals clear and strong. This also lowers electromagnetic interference (EMI), making them great for fast digital and RF uses.

Stronger Signal Quality: Shorter paths and better materials keep signals steady.

Faster Speeds: HDI PCBs allow quicker data transfer, perfect for streaming and advanced computing.

For instance, HDI PCBs cut unwanted electrical effects by 15%. This boosts efficiency, making them ideal for fast and reliable devices.

Saving Space and Making Devices Smaller

HDI PCBs are great at saving space. They use tiny holes and smart designs to fit more layers and wires without making the board bigger. This helps create small, lightweight gadgets.

In cars, HDI PCBs are used in electric vehicles and smart systems. They combine many features into small designs, saving space and improving performance.

The global market for these boards is growing fast. It could jump from $12.8 billion in 2023 to $20 billion in 2027. This shows the need for smaller, powerful electronics.

By saving space, HDI PCBs help make tiny gadgets like smartwatches and IoT devices without losing features.

More Reliable and Better at Handling Heat

HDI PCBs are built to last, even in tough conditions. They use advanced materials to manage heat well, keeping devices cool and working properly.

Improved Heat Control: Thin layers and smart materials spread heat evenly, stopping overheating.

Stronger Build: Their compact design makes them less likely to break, lasting longer.

HDI PCBs are also lighter, cutting weight by 13-18% compared to regular boards. This makes them perfect for industries like aerospace, where being light and reliable is important.

Tip: Choose HDI PCBs for gadgets needing high reliability and good heat control.

Design Flexibility for Complex Circuits

HDI PCBs offer great design freedom for tricky circuits. Their smart features help create detailed designs without losing quality. This makes them perfect for industries needing small, powerful devices.

One reason HDI PCBs work well is their support for many layers. Using microvias, blind vias, and buried vias, they connect parts tightly while keeping signals clear. These features let you fit more functions into smaller spaces, which is key for modern gadgets.

Compact Medical Devices: A company used HDI PCBs to make small, reliable diagnostic tools. The design kept signals strong, ensuring accurate results in healthcare.

Automotive Systems: Car makers used HDI PCBs in driver assistance systems. This saved space and improved performance, fitting many features into tight spaces.

HDI PCBs also let you try creative layouts. You can design circuits with tighter spaces and complex paths. This is important for devices like smartphones, where every bit of space counts. Surface-mounted technology (SMT) in HDI PCBs adds flexibility by placing parts on both sides of the board.

Note: HDI PCBs improve signal clarity and cut down interference. This keeps circuits working well, even at high speeds or frequencies.

HDI PCBs go beyond just layout options. They support advanced materials like high-speed laminates and built-in components. These features let you push your designs further. Whether for electronics, cars, or planes, HDI PCBs meet tough demands.

By using HDI PCBs, you can make designs that are small and efficient. This helps your devices stay competitive in a world that values tiny, high-performing gadgets.

Real-World Uses of HDI PCBs

Gadgets for Everyday Use

HDI PCBs are key in making small and smart gadgets. You can find them in phones, tablets, and wearable devices. These boards help make gadgets smaller and faster, which is important today.

Gadget Type | How HDI PCBs Help |

|---|---|

Smartphones | They make phones smaller and work better. |

Tablets | HDI PCBs shrink parts, helping tablets stay thin and powerful. |

Wearables | Smartwatches and VR headsets use HDI PCBs for small and smart designs. |

In 2023, 40.2% of the PCB market was for everyday gadgets. This shows how much people want phones, laptops, and smart home devices. Big companies like Apple and Samsung use HDI PCBs to make smaller and smarter products.

HDI PCBs help make lightweight gadgets that still work well. For example, smartwatches use HDI boards to be small but powerful.

Car Electronics

HDI PCBs are important for modern car electronics. They help with systems like entertainment, safety, and driver assistance. These boards work well even in tough conditions like heat and shaking.

Feature | Why It Matters |

|---|---|

HDI PCBs keep car electronics working smoothly. | |

Tough Materials | They handle heat, shaking, and wet conditions. |

Long-Lasting Design | Special layers make car electronics last longer. |

HDI PCBs are strong and handle heat well. This makes them great for keeping cars safe and working properly. Electric cars use HDI PCBs to fit many features into small spaces, making them efficient and reliable.

HDI PCBs help cars stay smart and safe. They are key for electric and high-tech vehicles.

Health Devices

Medical tools need to be small, strong, and accurate. HDI PCBs help make these tools work well in tiny spaces. Devices like health monitors and imaging machines use HDI boards to give clear and reliable results.

HDI PCBs make medical gadgets light and easy to carry. For example, diagnostic tools use HDI boards to keep signals clear for accurate readings. Health monitors benefit from HDI PCBs by being small and powerful, making them comfy and useful.

HDI PCBs help healthcare by making small and smart devices. They are important for tools that improve patient care and testing.

Aerospace and Defense Technologies

HDI PCBs are very important in aerospace and defense. These fields need electronics that work well in tough conditions. HDI PCBs handle heat, shaking, and radiation with ease. They are small, strong, and perform at a high level.

Why HDI PCBs Are Needed in Aerospace and Defense

Work Well in Harsh Conditions

Aerospace and defense systems face extreme environments. HDI PCBs are built to last in these settings. They use strong materials and smart designs. They also handle fast signals and many connections. This makes them perfect for radar, satellites, and airplane systems.Small and Lightweight

Weight is very important in aerospace. HDI PCBs are up to 18% lighter than regular PCBs. This helps engineers fit more features into smaller spaces. They are great for satellites, drones, and military tools.Better Signal Quality

HDI PCBs keep signals clear and reduce interference. This is key for navigation, missile systems, and other precise technologies.

Standards and Testing for HDI PCBs in Aerospace and Defense

HDI PCBs must meet strict rules to ensure they work well. These rules check the quality and performance needed for aerospace and defense:

Standard | What It Ensures |

|---|---|

Top-level quality for reliable printed boards. | |

Consistent performance for aerospace products under stress. | |

MIL-PRF-31032 | U.S. military rules for strong and reliable circuit boards. |

These rules make sure HDI PCBs can handle the hard demands of these industries.

Features That Make HDI PCBs Perfect for Tough Jobs

Tiny Holes: Microvias and blind vias save space and keep signals strong.

Special Materials: They resist heat and radiation, lasting a long time.

Thorough Testing: HDI PCBs go through tests for heat and shaking to ensure they work.

Note: HDI PCBs are tested for durability. This ensures they can handle the stress of aerospace and defense tasks.

Real-World Uses in Aerospace and Defense

HDI PCBs are used in many aerospace and defense tools, such as:

Satellites: Their small size and light weight fit tight spaces.

Military Drones: They process data fast and support clear communication.

Airplane Systems: HDI PCBs improve navigation, communication, and control in planes.

The need for advanced aerospace and defense tools is growing. HDI PCBs are key because they are strong, reliable, and compact. They are a big part of modern technology in these fields.

Challenges and Considerations

Higher Manufacturing Costs

Making HDI PCBs costs more because of complex steps. These boards need special materials and skilled workers, which raises expenses. For example:

A 2023 survey showed projects with RF shielding cost 20-30% more than regular PCBs.

Apple said their Vision Pro PCBs cost 18% more to meet strict rules.

Changing material prices also make things harder. When raw material costs go up, it affects profits and pricing stability.

Challenge | Description |

|---|---|

Complex steps make HDI PCBs more expensive to produce. | |

Material Cost Volatility | Changing raw material prices hurt profits. |

Technological Complexity | Keeping quality high in dense designs is tough. |

Competition from Alternative Technologies | New technologies may compete with HDI PCBs. |

Specialized Design and Production Requirements

Designing HDI PCBs needs strict rules and advanced methods. These include:

Many layers with different via types like blind and buried vias.

Circuit spacing of 0.005 inches or less.

Rules like IPC/JPCA-2315 and IPC-2226 guide HDI PCB designs to ensure they last. But making detailed patterns and managing quality in many-layered boards is still hard.

Standard | Description |

|---|---|

IPC/JPCA-2315 | Guide for designing HDI and microvias. |

IPC-2226 | Rules for HDI PCB design. |

IPC/JPCA-4104 | Standards for HDI and microvia materials. |

IPC-6012 | Quality rules for rigid printed boards. |

Limited Availability of Skilled Manufacturers

Not many manufacturers can make high-quality HDI PCBs. These boards need advanced tools and expert skills, which many companies lack. This shortage slows production and increases wait times.

Companies without HDI skills lose out in competitive markets. For example, some electronics firms saw profits drop 35% because they couldn’t meet miniaturization needs. Training workers and upgrading tools can help fix this problem.

HDI PCBs, using high-density interconnect (HDI) PCBA technology, change modern electronics. They offer better performance, save space, and are very reliable. These PCBs help improve gadgets, cars, medical tools, and aerospace systems.

HDI PCBs are needed more as AI and fast networks grow.

Multi-layer PCBs with over 18 layers may grow 41.7% by 2025.

The HDI PCB market might grow 10.4%, showing its use in data-heavy tech.

Even though they cost more, HDI PCBs are the future of circuit boards. They help devices stay advanced and competitive.

Tip: Pick HDI PCBs for designs needing accuracy and high performance.

FAQ

What makes HDI PCBs better than traditional PCBs?

HDI PCBs have smart features like microvias and blind vias. These save space and make devices work better. They handle faster signals and cut down interference. This makes them great for modern gadgets like phones and medical tools.

Are HDI PCBs more expensive to produce?

Yes, making HDI PCBs costs more because of complex steps. They also need special materials. But their benefits, like saving space and being reliable, make them worth it for advanced designs.

Can HDI PCBs handle extreme conditions?

Yes, HDI PCBs are made with strong materials. They can resist heat, shaking, and radiation. This makes them perfect for cars, planes, and defense systems where they must be dependable.

Why are HDI PCBs important for small devices?

HDI PCBs help fit more parts into tiny spaces. Their small size allows gadgets like smartwatches and IoT devices to stay light and powerful.

Are HDI PCBs suitable for high-speed applications?

Yes, HDI PCBs are great for high-speed uses. Their design keeps signals clear and reduces interference. This helps with fast data transfer in 5G and advanced computers.

Tip: Use HDI PCBs for gadgets needing speed, accuracy, and small designs.

See Also

Exploring Benefits And Obstacles Of Flex PCBA In Electronics

The Importance Of Custom PCBA Manufacturing In Electronics

PCBA’s Role In Advancing Modern Electronics To New Levels