The printed circuit board is key to every EV battery management system (BMS) PCBA. It helps electric cars run safely and efficiently. It supports power electronics to check and control battery health. High-voltage PCBs manage the tough needs of modern EVs. They allow smooth communication between different parts. The EV battery management system (BMS) PCBA also finds problems early, avoiding big failures and boosting reliability.

Key Takeaways

PCBA helps check battery health, keep it safe, and work better in electric cars.

PCBA gives quick updates to find problems early and avoid big issues.

PCBA designs save space and weight, making cars use less energy and go farther.

Special PCBA materials handle heat well, so batteries charge faster and last longer.

Modular PCBA designs let makers easily upgrade and change batteries for different car types.

Understanding PCBA in Electric Vehicle Battery Management Systems

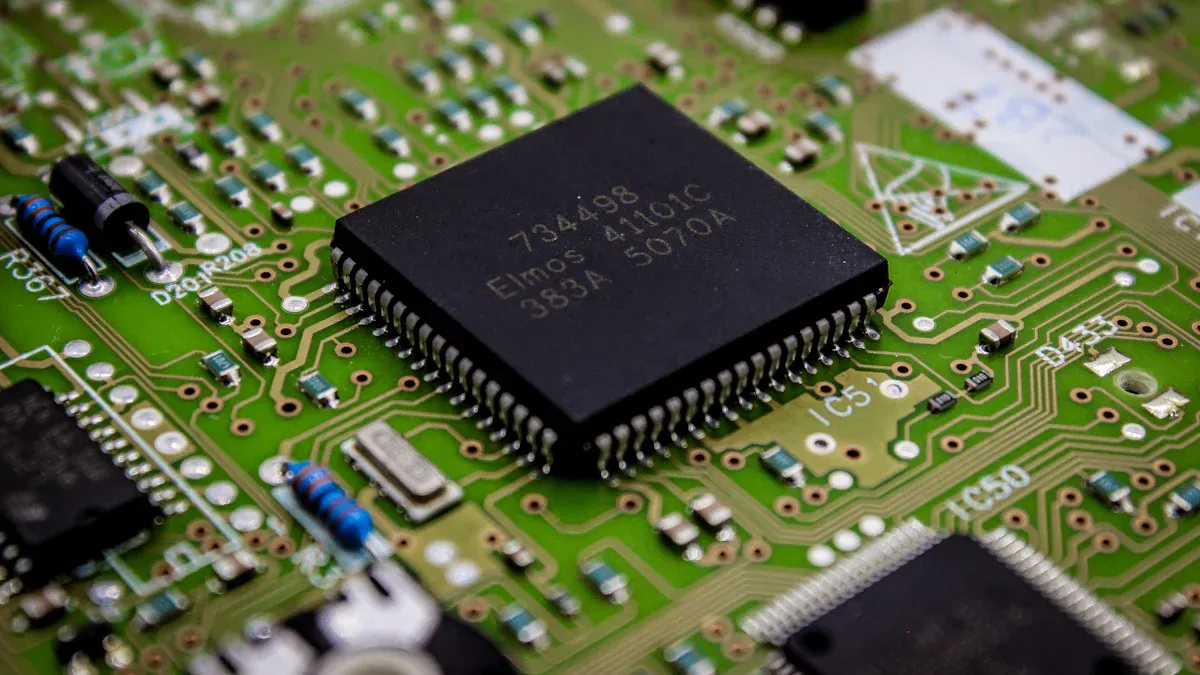

Definition and components of PCBA

A printed circuit board assembly (PCBA) is vital for modern electronics. It is used in electric vehicle battery management systems (BMS). A PCBA includes a printed circuit board (PCB) with parts like resistors, capacitors, sensors, and microcontrollers. These parts work together to check and control how batteries perform.

In electric vehicles, PCBA helps keep the battery system stable and reliable. For example, special PCBs handle fast charging with high currents and voltages. Copper materials in the PCBA help remove heat quickly. Sensors in the PCBA track voltage, current, and temperature. This ensures the system works safely and efficiently.

Role of PCBA in EV battery management systems

The PCBA is like the brain of the EV battery system. It watches over each battery cell and gives real-time updates. It tracks things like voltage, temperature, and how much charge is left. This keeps the battery safe from problems like overheating or overcharging.

The PCBA also balances the voltage of each cell and adjusts charging settings. If something unsafe happens, it can shut the battery down. Sensors and microcontrollers in the PCBA help it talk to other car systems. This improves safety and makes the car work better overall.

Integration of PCBA into lithium-based battery systems

Lithium batteries are popular in electric cars because they last long and store a lot of energy. The PCBA fits perfectly into these systems to manage energy well. It checks the health of lithium cells and slows down aging. It also keeps the battery stable in different conditions.

New designs include tools to find electrical leaks and stop dangers. These features make lithium batteries last longer and safer. They also support the need for more eco-friendly electric vehicles.

Contributions of PCBA to EV Battery Management System Efficiency

Monitoring and control of battery health and performance

The EV battery management system (BMS) PCBA checks your car’s battery health. It watches important things like voltage, current, and temperature. This keeps the battery safe and working well.

The PCBA also tracks the battery’s condition over time. It looks for signs of wear or damage. It calculates how much energy is left in the battery. This helps you know when to charge and avoid running out of power.

The PCBA has a protection circuit board that balances cell voltage. This stops overcharging or undercharging, which can harm the battery. By keeping balance, it makes the battery last longer and work better for your EV.

Data communication and real-time diagnostics

The EV battery management system (BMS) PCBA shares data and finds problems quickly. It sends real-time updates between the battery and car systems. This makes everything work faster and smoother.

Tip: Real-time updates help you understand your battery’s performance.

Here’s how PCBA helps with data sharing:

It allows fast and reliable communication between parts.

It reduces delays, improving energy use and quality checks.

It spots problems quickly to check how the system is doing.

It predicts what might happen in different situations.

The PCBA finds problems early, like unusual heat or voltage drops. It warns you right away. This prevents bigger issues and keeps your EV running well.

Enhancing safety through fault detection and prevention

Safety is very important in EVs, and the PCBA helps a lot. It has tools to find risks like electrical leaks or overheating.

Special devices in the PCBA spot leaks and act fast to stop accidents. For example, if something unsafe happens, it isolates the problem area. This stops further damage.

The PCBA also manages heat well. It uses materials like copper-graphene to cool down quickly. This prevents overheating during fast charging. Liquid cooling spreads heat evenly across the battery pack.

By finding faults, managing heat, and protecting the system, the PCBA keeps your EV safe. It makes sure your battery works well and gives you confidence on the road.

Space and weight optimization in electric vehicle designs

When building electric vehicles (EVs), saving space and cutting weight are key. The small and light design of PCB battery systems helps a lot. These systems combine advanced tech into one platform. This saves space and lowers weight in your EV.

How PCBA Saves Space in EVs

PCB battery systems are small but pack in many features. Unlike old wiring systems with big cables, PCBs are neat. They put circuits on a board, clearing up space for other parts.

Did You Know?

A good PCBA design can shrink a battery system by half. This leaves more room for bigger batteries or extra features.

Here’s how PCBA helps save space:

Integrated Components: Parts like sensors and controllers are built into one board.

Custom Shapes: PCBs can fit odd spaces, perfect for modern EVs.

Layered Design: Multi-layer PCBs stack circuits to save even more room.

Weight Reduction Through PCBA

Weight affects how far and efficiently an EV can go. Heavy cars use more energy, lowering range. PCB battery systems replace heavy parts with lighter ones.

Material Efficiency: PCBs use light but strong materials like fiberglass and copper.

Eliminating Excess Wiring: Fewer wires mean less weight to carry.

Compact Design: Smaller parts make the whole system lighter, boosting efficiency.

Real-World Benefits of Space and Weight Optimization

Saving space and weight does more than improve design. It makes your EV perform better, cost less, and be more eco-friendly.

Feature | Impact on EV Design |

|---|---|

Space Optimization | Adds room for bigger batteries or new features. |

Weight Reduction | Increases range and saves energy. |

Simplified Maintenance | Easier to fix and replace parts. |

Using PCB battery systems makes your EV smarter and greener. These systems improve design and give you a better driving experience.

Innovations in PCB Battery Management Systems

Smaller and More Advanced PCBA Designs

Electric cars need smaller and better systems. This has led to big improvements in PCBA designs. High-density interconnects (HDI) now fit more wires in less space. This makes designs smaller but still powerful. Multi-layer boards (MLB) and special chip connectors, like FC-CSP and FC-BGA, help link chips to PCBs. These updates allow for tiny circuits and better EV performance.

Did You Know?

IC substrate sales are expected to grow from $12.8 billion in 2023 to $20 billion by 2027. This shows the rising need for advanced PCB technology.

Smaller PCBA designs also use robots and precise tools to build them. New soldering methods make sure small parts are placed perfectly. This is great for tight spaces in EVs. These changes save space and make EV systems work better.

Stronger Materials for Better Performance

The materials in PCBA affect how well EV systems work. Special laminates give strong electrical, heat, and mechanical support. For example, copper-graphene materials help remove heat faster. This stops the system from overheating.

Important Material Improvements:

Substrates that don’t absorb water stop moisture damage.

Surface finishes resist sulfides, lasting longer in tough conditions.

Coatings keep insulation stable, even in extreme weather.

Picking the right materials also improves safety. For instance, good designs prevent overheating in certain capacitors. This keeps PCB battery systems safe and reliable for EVs.

Smarter Systems with AI and IoT

Artificial intelligence (AI) and the Internet of Things (IoT) are changing EV batteries. Smart PCBA systems now use AI to watch battery health in real time. They can spot problems like overheating early and fix them before they get worse.

IoT lets your EV connect to other devices, like charging stations or apps. This gives you detailed info about your battery’s health. IoT systems can also plan charging times to save energy and make batteries last longer.

By using AI and IoT, PCBA makes EVs smarter and greener. These tools help your car run its best while protecting the environment.

Modular and Scalable PCBA Designs for Future EVs

Modular and scalable PCBA designs are changing how EVs are built. These designs let battery systems fit different needs, making EVs more flexible. With modular PCBA, manufacturers can make systems that are easier to build, fix, and improve.

Why Modular Designs Are Important

Modular PCBA splits big systems into smaller, easy-to-manage parts. Each part works on its own but connects smoothly with others. This makes production simpler and lowers costs. For example, Tesla uses modular batteries with many identical cells in each pack. This setup speeds up making batteries and works for different EV models.

Tip: Modular designs help you replace or upgrade parts quickly.

Scalability for Future Demands

Scalable PCBA lets you change battery size based on your needs. You can have a small battery for city driving or a big one for long trips. Materials like silicon carbide (SiC) and gallium nitride (GaN) make this possible. They improve energy use and cut charging times, helping create better batteries.

How SiC and GaN Help Modular Designs:

Use less energy for better performance.

Charge faster, saving time.

Support smaller, lighter systems.

Real-Life Benefits

Modular and scalable designs are already making a difference. Tesla shows how using standard parts makes scaling up easier and production faster. As EVs improve, these designs will meet the need for better and more adaptable batteries.

By using modular and scalable PCBA, EVs are becoming smarter and more flexible. These designs ensure your EV stays advanced, affordable, and dependable.

Impact of PCBA on Electric Vehicle Efficiency and Sustainability

Extending Battery Life and Reducing Energy Waste

The PCBA helps your EV battery last longer and waste less energy. It checks each lithium cell in real time to keep it safe. By balancing voltage, it stops overcharging and undercharging, which harm batteries.

A longer-lasting battery means fewer replacements for you. This saves money and reduces waste from making new batteries. The PCBA also makes sure energy isn’t wasted while your car runs.

Modern PCBAs have tools to find energy leaks quickly. These tools protect the battery from losing power or causing safety problems. This makes your EV safer and more efficient.

Improving Charging Efficiency and Thermal Management

Charging and heat control are very important for EVs. The PCBA helps your battery charge fast and safely by managing electricity and heat flow.

Some PCBAs use special materials like copper-graphene to cool batteries. These materials spread heat evenly and stop overheating during fast charging.

Here’s how different materials handle heat:

Material | Heat Conductance (W/K) |

|---|---|

Paraffin Wax | |

n-Eicosane | 0.569 |

These materials keep the battery cool and improve charging speed. They also help the battery last longer.

Liquid cooling and phase change materials (PCM) keep the battery at a steady temperature. Even during fast charging, these systems protect the battery and improve performance.

Supporting Greener and More Sustainable Electric Vehicles

PCBA makes EVs better for the environment. It saves energy and extends battery life, reducing waste and the need for new materials.

Smart PCBA systems can charge during times when clean energy is available. This lowers strain on the grid and supports renewable energy use.

Lightweight and compact PCBA designs make EVs use less energy. This increases driving range and lowers costs.

By driving an EV with advanced PCBA, you help the planet. These systems make your car efficient and eco-friendly.

PCBA is key to making EV batteries work well and stay safe. It checks important things like voltage and temperature to keep the system running smoothly. New PCBA ideas, like smaller designs and better heat control, are improving EVs.

The EV PCB market may reach $4.4 billion by 2035.

Future PCBA designs will handle higher voltages and faster charging.

As EVs improve, PCBA will help make them more efficient and eco-friendly.

FAQ

What is PCBA, and why does it matter for EVs?

PCBA means Printed Circuit Board Assembly. It links and controls parts in EV batteries. It checks battery health, manages energy, and keeps your car safe.

How does PCBA make EV batteries last longer?

PCBA keeps cell voltage balanced and avoids overcharging or undercharging. It watches each cell and stops energy waste. This helps the battery last longer and saves money on new ones.

Can PCBA handle fast charging?

Yes! PCBA uses special materials like copper-graphene to control heat. It keeps charging safe and fast, stopping the battery from overheating.

Why are modular PCBA designs better for EVs?

Modular designs make building and fixing easier. You can swap or upgrade parts quickly. They also let makers adjust batteries for different EV models, making cars more flexible.

How does PCBA help the environment?

PCBA cuts energy waste and makes batteries last longer, needing fewer materials. Lightweight designs save energy, and smart systems use clean energy. Driving an EV with PCBA helps protect the planet.

See Also

Enhancing Workflow Efficiency in PCBA Production Processes

Why PCBA Manufacturing Skills Are Crucial for Electronics Design

The Unmatched Impact of PCBA on Electronics Performance

PCBA’s Role in Elevating Today’s Electronics Industry

Understanding PCBA Services and Their Significance in Manufacturing