When you choose a Made in USA PCBA, you are selecting quality and innovation. U.S. factories adhere to strict regulations to produce reliable PCB assemblies. Being close to local markets allows for faster delivery, sometimes within 24 hours. This quick delivery aids in testing new ideas and maintaining competitiveness. Purchasing from U.S. makers also contributes to economic growth. Over 3.5 million factory jobs were lost due to trade issues, highlighting the importance of supporting local industries. Opting for Made in USA PCBAs also ensures the safety of your ideas and helps avoid counterfeit parts.

Key Takeaways

Picking Made in USA PCBAs means great quality. U.S. factories follow strict rules to make reliable products.

Choosing local factories makes delivery faster. U.S. makers can often deliver in 24 hours, helping with tight schedules.

Buying from American PCB makers helps the economy. Your purchase creates jobs and supports local businesses.

Using U.S. PCB makers keeps your ideas safe. Strong U.S. laws lower the chance of stolen designs or fake parts.

Making products locally helps the environment. It reduces shipping pollution and supports green practices.

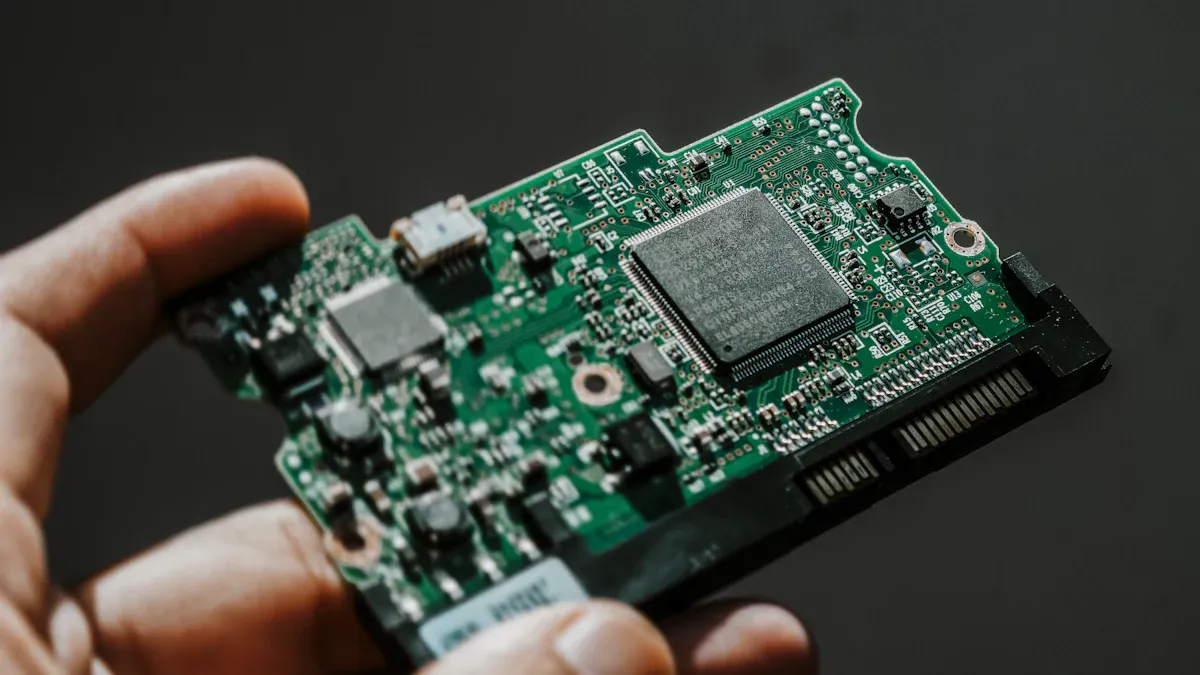

Quality and Standards in PCB Assemblies Made in USA

The quality of PCB assemblies is key to reliable products. Choosing Made in USA PCBAs means strict rules, advanced methods, and tough tests. These ensure your products are safe and work well.

Following Industry Rules

American PCB makers follow some of the toughest rules worldwide. This ensures every assembly meets high standards. For example:

NIST 800-171 has 110 rules to protect sensitive data. This is vital for defense and aerospace work.

ITAR compliance keeps military designs safe from unauthorized access.

ISO certifications like ISO 9001 and ISO 13485 show a focus on quality and meeting rules.

IPC standards ensure PCBs are safe and reliable for many uses.

By picking a USA maker, you know your PCBs follow these rules. This lowers risks and builds trust in your supply chain.

Better Manufacturing Methods

American PCB makers use top technology and smart processes for great results. These methods boost efficiency and keep quality steady. Here are some benefits of USA manufacturing:

Metric/Benefit | Description |

|---|---|

Cuts costs by making large amounts efficiently. | |

Automation | Speeds up assembly and shortens production time. |

Quality Control | Advanced tests ensure standards are met and defects are rare. |

Design for Manufacturability (DFM) | Makes PCB designs better for mass production. |

Automated Testing | Finds defects early with tools like AOI and ICT. |

Supplier Relationships | Ensures steady access to good parts, avoiding delays. |

Monitoring Production Metrics | Keeps all PCB units consistent and uniform. |

These methods help American PCB makers create reliable assemblies. They also meet the needs of industries like aerospace, defense, and medical tech.

Reliable Testing and Certifications

Testing is key to making sure PCBs work well. USA makers use strict tests to check every assembly. Common testing methods include:

Testing Method | Description |

|---|---|

Uses robotic probes to test prototypes and small batches. | |

Functional Testing | Checks if the PCB works as it should, though it takes time. |

Burn-In Testing | Finds early failures to ensure reliability. |

ISO 9001:2015 Certification | Proves a commitment to quality and improvement. |

Advanced Inspection Equipment | Uses modern tools for detailed checks. |

Experienced Personnel | Skilled engineers and technicians ensure quality testing. |

Detailed Documentation | Keeps records of all tests and inspections. |

Customized Testing Solutions | Creates special testing plans for customer needs. |

Continuous Improvement | Regularly updates testing methods for better results. |

These tests make sure every PCB assembly is top quality. Working with a USA PCB maker gives you access to these advanced tests. This means better performance and fewer problems in your products.

Speed and Efficiency of USA PCB Assembly Services

Faster Turnaround Times

Working with USA PCB makers means faster project completion. They focus on speed, moving designs to production quickly. On-time delivery rates are 97%, with 99.6% defect-free deliveries. This helps meet deadlines and stay competitive. Earthworks Audio improved market speed by 19.8%, boosting sales. Choosing U.S. PCB services means shorter wait times and faster help.

Streamlined Communication

Good communication makes PCB assembly smoother. U.S. makers keep communication clear and steady. Here’s how they do it:

Use tools to solve design or production problems fast.

Hold regular calls and reviews to stay on track.

Join design meetings to share helpful ideas for improvement.

Work closely during prototyping to fix design mistakes early.

This teamwork reduces confusion and answers questions quickly. Fast replies prevent delays and keep projects moving forward.

Proximity to End Markets

Being near factories has big benefits. Close locations improve teamwork and cut mistakes. It also speeds up production changes when needed. For example, nearby factories can handle last-minute design updates faster than overseas ones. This closeness helps products reach buyers sooner, giving you an edge over competitors.

Technological Advancements by American PCB Manufacturers

Access to New Innovations

American PCB makers use the latest technology to stay ahead. They focus on research and development (R&D) to create better designs. Their work allows them to make complex PCBs with great accuracy. Examples include high-speed, HDI, and flexible PCBs. These advanced designs meet today’s product needs.

To improve further, they use artificial intelligence (AI) for smarter processes. AI helps automate tasks and analyze data faster. Digital tools also modernize their factories and workflows. Automation reduces mistakes and speeds up production. These upgrades give you advanced solutions for your projects.

Working with Skilled Engineers

American PCB makers team up with top engineers to improve designs. These experts help make processes better and solve problems quickly. Suppliers are chosen based on delivery speed, quality, and engineering support. This ensures you get reliable help when needed.

Clear goals like low defect rates and fast responses guide teamwork. Regular checks of these goals show areas to fix or improve. This focus on better results means your projects benefit from expert knowledge. The outcome is high-quality PCB assemblies you can trust.

Using Smart Automation

Automation is key in American PCB factories. Machines handle tasks with precision, reducing errors in assembly. For example, robots place parts and check them carefully. This lowers the need for skilled workers and speeds up production.

Automation also saves money by cutting costs and time. Quality checks and inspections ensure products have no defects. These systems make American PCB makers dependable for your needs. Their advanced tools and methods deliver great results every time.

Economic and Environmental Benefits of Made in USA PCBA

Helping Local Jobs and Businesses

Picking PCB assemblies made in USA helps create jobs. It also boosts the economy. Making electronics here adds high-tech jobs and lowers unemployment. States like Michigan and Ohio have seen growth in factories and demand for local goods.

Manufacturing jobs reached 13 million by January 2024. This is higher than before the pandemic. Since 2019, factory numbers grew by 11%, nearing 393,000. Spending on building factories tripled since June 2020, hitting $225 billion in January 2024. These facts show how local production helps communities and businesses grow.

Tip: Buying from local makers strengthens supply chains and helps the economy.

Cutting Carbon Emissions

Making PCBs locally lowers pollution by reducing shipping needs. Shorter transport distances mean fewer greenhouse gases. Companies like Amkor Technology and TTM Technologies lead in eco-friendly practices.

Company | Sustainability Goal | Reduction Achieved (2021-2022) | Source |

|---|---|---|---|

Amkor Technology | Cut GHG emissions, water use, and waste by 20% by 2030 | Water use dropped by 12% | |

TTM Technologies | Better water management systems | N/A |

Choosing made in USA PCBA supports eco-friendly companies. This helps protect the planet for future generations.

Fair Manufacturing Practices

American PCB factories follow strict rules for fair work and clean production. Unlike overseas factories, they protect workers and the environment. They manage waste responsibly and use energy-efficient methods.

Fair practices build trust with buyers. Choosing USA-made products means supporting human rights and sustainability. Ethical production improves your brand and attracts eco-conscious customers.

Intellectual Property Protection and Risk Mitigation in USA PCB Assembly Services

Keeping Your Designs Safe

Choosing an American PCB maker helps protect your intellectual property (IP). The U.S. has strong laws to keep your designs safe. Overseas factories may not enforce IP rules as strictly. U.S. companies follow tough regulations, giving you peace of mind.

Aspect | China | United States |

|---|---|---|

Legal Framework | Improving, but enforcement remains a challenge. | Strong legal protections for IP, providing peace of mind. |

Trade Secret Protection | Risk of theft is a concern, though regulations are tightening. | Generally considered more secure for protecting trade secrets. |

Working with a U.S. PCB maker lowers the chance of design theft. Your ideas stay protected, letting you focus on making great products without fear of misuse.

Tip: Check that your PCB maker follows IP protection laws to keep your designs secure.

Stopping Fake Parts

Fake parts can ruin your product’s reliability. U.S. PCB makers use trusted suppliers to avoid counterfeit components. They also test parts carefully with tools like AOI and ICT. These checks ensure every part meets high quality standards.

Section 851 of U.S. rules limits buying PCBs from certain countries. This reduces the risk of fake parts. Choosing a U.S. maker means safer components and better performance for your products.

Building Secure Supply Chains

A strong supply chain keeps products reliable and on time. U.S. PCB makers use smart methods to lower risks and improve transparency.

Metric/Practice | Description |

|---|---|

Tracks all suppliers to spot problems early. | |

Regular Supply Chain Risk Assessments | Finds and fixes risks quickly through regular checks. |

Historical Data Analysis | Uses past data to predict future supply needs. |

These steps make supply chains steady and efficient. U.S. makers also use AI and data tools to prevent problems. For example:

Check supplier performance using delivery and defect data.

Use AI to spot patterns that show possible risks.

Analyze data to improve supply chain clarity and fix issues early.

Note: Section 841 of U.S. rules helps modernize supply chains and reduce risks. This keeps your supply chain safe and ready for changes.

Partnering with a U.S. PCB maker gives you access to these advanced methods. This helps you create reliable products and stay ahead of competitors.

Picking Made in USA PCBA means top quality and fast service. American PCB makers follow strict rules, work quickly, and keep communication clear. The table below shows these advantages:

Benefit | Description |

|---|---|

High Quality Standards | U.S. factories follow strict rules like ISO for quality. |

Quick Turnaround Times | Local factories make and deliver faster than overseas ones. |

Better Communication | Local teams give quick updates and solve problems fast. |

Faster PCB Shipping | Nearby suppliers ship parts quickly and adjust schedules easily. |

Safer Designs and IP Protection | U.S. makers protect your designs from theft and misuse. |

Making PCBs in the U.S. also helps the planet. They use eco-friendly materials and cut pollution from shipping. These steps match global green goals like the CSRD. Supporting local factories boosts jobs, protects designs, and ensures fair work. In 2025, choosing U.S.-made PCBAs is a smart and responsible choice.

FAQ

1. Why is Made in USA PCBA better for quality assurance?

American factories follow strict rules like ISO and IPC standards. These rules ensure products are reliable and consistent. Advanced tests like AOI and ICT find problems early. This means you get high-quality products that meet industry needs.

Tip: Check certifications before picking a PCB manufacturer.

2. How does choosing Made in USA PCBA help the environment?

Making PCBs locally cuts pollution from long-distance shipping. Many U.S. factories use eco-friendly methods like saving energy and reducing waste. Supporting these factories helps your business meet green goals.

Note: Choose companies with clear environmental plans.

3. Can Made in USA PCBA protect my intellectual property?

Yes, U.S. factories follow strong IP laws to keep designs safe. They protect your ideas and trade secrets better than overseas factories. This lowers the risk of theft or misuse.

Aspect | USA | Overseas |

|---|---|---|

IP Protection Strength | Strong | Weak |

Risk of Design Theft | Low | High |

4. Are USA PCB makers faster than overseas ones?

Yes, being close to customers allows quicker production and delivery. Clear communication and local support prevent delays. You’ll get prototypes and finished products faster.

5. Does Made in USA PCBA cost more?

It may cost more upfront, but it saves money later. Reliable quality means fewer repairs or replacements. Fast delivery helps you stay competitive. Ethical and green practices improve your brand’s value.

Reminder: Think about total costs, not just the price tag.

See Also

The Importance of Custom PCBA Manufacturing in Today’s Tech

Essential Aspects to Evaluate in Selecting a PCBA Provider

Understanding PCBA Manufacturing and Its Significance Today

Important Factors to Weigh When Selecting PCB or PCBA

Best Practices for Finding Trustworthy PCBA Manufacturers in China