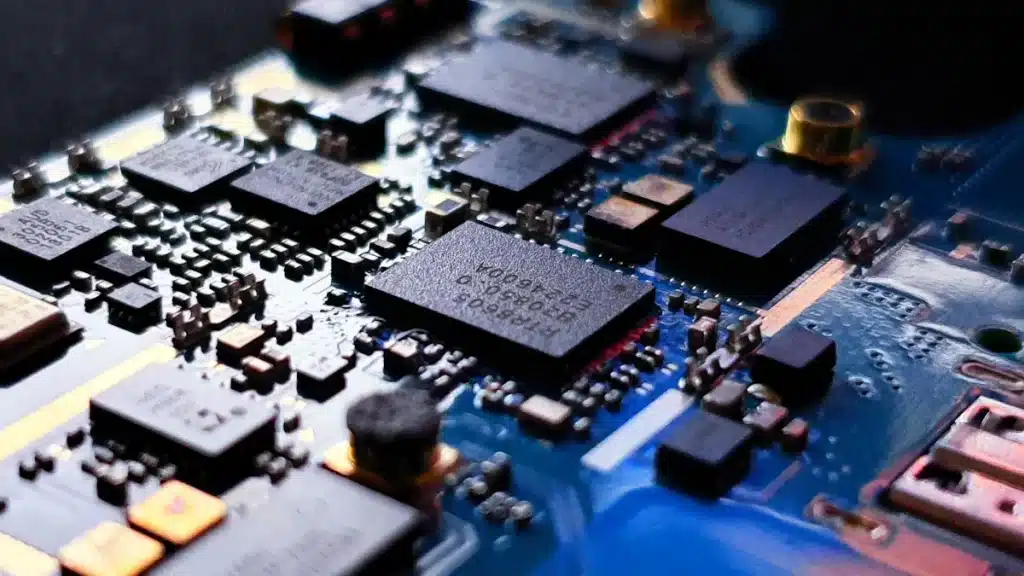

SIL rated circuit board production is crucial for maintaining system safety. These boards adhere to strict safety regulations to minimize risks and prevent failures.

Consider them the backbone of industries where safety is paramount. Even minor issues can lead to hazardous situations. By complying with safety standards, these boards achieve Safety Integrity Levels (SIL) that quantify their effectiveness in risk reduction. For instance:

SIL 2 reduces risks by 100 to 1,000 times.

SIL 3 cuts risks by up to 10,000 times.

SIL 4 reduces risks by 100,000 times or more.

These boards do more than merely mitigate risks; they are designed to be reliable and consistent. This reliability ensures that safety systems function effectively in critical sectors such as transportation, energy, and manufacturing.

Key Takeaways

SIL-rated circuit boards are important for keeping industries safe. They lower risks and stop problems from happening.

Safety Integrity Levels (SIL) go from 1 to 4. Higher numbers mean better safety. Picking the right SIL level helps manage risks well.

Engineers use methods like Fault Tree Analysis to find the right SIL for systems that need to be very safe. This helps make systems safer.

SIL-rated parts are tested carefully to meet safety rules. This makes sure they work well in important situations.

Using SIL-rated circuit boards makes systems safer and more reliable. They protect people and machines from dangers.

Understanding Safety Integrity Levels (SIL)

What is SIL in functional safety?

Safety Integrity Levels (SIL) show how well safety systems work. They measure the chance of a system failing when needed. This is called Probability of Failure on Demand (PFD). The IEC 61508 standard explains functional safety. It ensures safety systems stop dangerous failures in industries like energy and manufacturing.

Think of SIL as a way to rate system reliability. A higher SIL means a system is less likely to fail. This makes it better for important tasks. Engineers choose SIL levels after studying risks and hazards. This helps decide the safest level for each situation.

SIL levels and their risk reduction factors

SIL levels go from 1 to 4. Each level shows how much risk is reduced. Higher SIL levels mean stricter safety rules. Here’s a simple chart about SIL levels:

SIL Level | Risk Reduction Factor (RRF) | Probability of Failure on Demand (PFD) |

|---|---|---|

SIL 1 | 10 to 100 | More likely to fail |

SIL 2 | 100 to 1,000 | Medium safety |

SIL 3 | 1,000 to 10,000 | High safety |

SIL 4 | 10,000 to 100,000 | Rarely used, very critical |

For example, SIL 3 is used in risky places like oil and gas. These systems lower the chance of accidents and keep safety functions working well.

Determining SIL for safety-critical systems

To pick the right SIL, engineers study risks and hazards. They use tools like Fault Tree Analysis (FTA) and FMECA to find problems and their effects.

Method | Description |

|---|---|

Fault Tree Analysis (FTA) | A diagram to find failures and their causes. |

Reliability Block Diagrams (RBDs) | A way to show system reliability using blocks for parts. |

Failure Modes Effects and Criticality Analysis (FMECA) | A method to find failures and how they affect the system. |

These tools help decide what safety functions a system needs. Then, engineers pick the right SIL level. This makes sure the system is safe and reduces risks.

SIL-Rated Components and Their Role in Functional Safety Standards

What are SIL-rated components?

SIL-rated components are special parts made for safety systems. They are tested to work well in tough situations. Their main job is to lower the chance of system failures that could cause danger. Think of them as the key pieces that help safety systems work properly.

To check how well these components perform, engineers use different methods:

Quantitative methods: Use numbers to measure how risks are reduced.

Risk graphs: Show possible dangers and how serious they are.

Hazardous event severity matrices: Look at how bad failures could be.

Layer protection analysis (LOPA): Adds layers of safety to prevent problems.

These tools make sure SIL-rated components meet safety rules and are reliable.

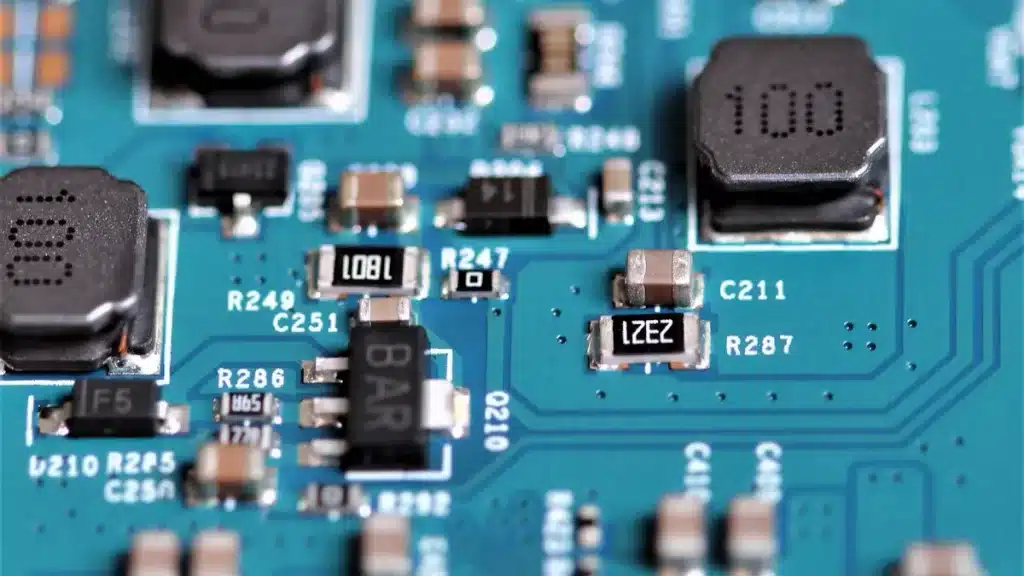

Key features of SIL-rated circuit boards

SIL-rated circuit boards have special traits that make them different. These features are important for keeping safety systems working. Here are some key traits:

Characteristic | Description |

|---|---|

Stops failures caused by one single event. | |

Fail-Safe Principle | Makes sure failures lead to a safe system state. |

Diagnostics Test Interval | Short tests find problems faster and improve safety. |

Safety Margin | Shows how much better the board is than the minimum safety needs. |

Device Failure Rate | Helps figure out how likely the board is to fail. |

These features help SIL-rated boards handle risky jobs. For example, the fail-safe principle keeps the system safe even if something breaks.

Importance of SIL-rated circuit board production

Making SIL-rated boards needs strict quality checks. This ensures they work well in safety-critical jobs. Good production lowers the chance of failures, which is very important in fields like healthcare, energy, and aerospace.

Manufacturers follow rules like IPC to ensure quality. For example:

IPC rules help make sure boards work reliably.

Following these rules lowers the chance of system failures.

Real-life examples show why quality matters. One company fixed electrical shorts by cleaning better. Another solved flux problems by changing how it was applied. These fixes made the boards more reliable and met safety rules.

By focusing on quality, SIL-rated boards can be trusted to work well, even in tough conditions.

How SIL-Rated Circuit Boards Improve Safety Systems

Lowering risks and handling failures

SIL-rated circuit boards help reduce risks and handle failures. They are built to stay safe even when something goes wrong. For example, they use the fail-safe principle. This means if a failure happens, the system moves to a safe mode. This is very important in places where even small problems can cause big dangers.

These boards work well in tough conditions. Many can handle temperatures from -40 to 85°C. This makes them reliable in places like factories or outdoor setups. Some safety circuits have a failure chance of less than one in 10 million. This meets the strict rules of SIL3. These features make SIL-rated boards essential for keeping systems safe and reducing risks.

Keeping systems reliable and running

Reliability is key for safety systems, and SIL-rated boards are great at this. They are made to keep systems running without stopping. Here are some reasons why they are so reliable:

Feature | What It Does |

|---|---|

Measures how safe and reliable the system is. | |

Redundancy and Fault Tolerance | Keeps systems working even if something fails. |

Predictive Maintenance | Finds problems early to fix them before they cause downtime. |

These boards meet high reliability standards. For example, SIL4 systems are 99.99% reliable. This means they fail less than once in 10,000 uses. They achieve this with smart designs, backups, and good diagnostics. These features help keep safety systems running smoothly and safely.

Stopping dangerous events with SIL-rated boards

The main goal of safety systems is to stop dangerous events. SIL-rated boards are made to do just that. They follow strict rules like IEC 61508. They are tested to meet safety measures like Safe Failure Fraction (SFF) and Dangerous Undetected Failure Rate (λDU). These tests show how well the boards prevent problems and stay safe.

A process called FMEDA checks these boards for possible failures. It ensures they meet safety standards. Using SIL-rated parts lowers the chance of dangerous events. This keeps people and equipment safe.

In real life, these boards work very well. For example, Moore Industries’ safety solutions are certified for SIL2 and SIL3. They don’t need extra testing and work in extreme conditions. This makes them perfect for industries like energy, transport, and manufacturing. Adding SIL-rated boards to your systems gives you better safety and peace of mind.

Standards and Certifications for SIL-Rated Circuit Boards

What is IEC 61508 and why it matters?

IEC 61508 is a key safety standard for critical systems. It gives clear rules for designing, using, and maintaining safety functions. This ensures systems stay safe and reliable throughout their use.

Important points about IEC 61508:

It covers the entire safety lifecycle, from design to removal.

It helps avoid failures caused by design mistakes.

It ensures parts like SIL-rated circuit boards work well in tough conditions.

Following IEC 61508 helps meet global safety rules and lowers risks.

How are SIL-rated components certified?

Certifying SIL-rated parts means testing them to meet safety rules. Companies must prove their parts are safe and reliable. The process includes:

Safety Analysis Reports (SAR): These reports show safety checks and calculations.

Third-Party Verification: Groups like TUV or EXIDA check the parts for safety.

Proven Operating History: Parts with a safe history may skip extra tests.

Certification ensures SIL-rated circuit boards are safe for important jobs.

How to follow safety standards?

Meeting safety rules like IEC 61508 and ISO 26262 is very important. To do this:

Use certified designs and parts, like special microcontrollers, for better results.

Keep detailed records of design, testing, and checks.

Use safety design libraries to save time and meet rules faster.

A table of key standards and what they mean:

Standard | What It Covers |

|---|---|

IEC 61508 | Rules for safety in electrical and electronic systems. |

ISO 26262 | Uses SIL ideas for car electronics during their lifecycle. |

Certification Schemes | Tests to see if a device meets a certain SIL level. |

Safety Analysis Report | Shows safety checks needed for meeting rules. |

Third-Party Verification | Outside groups like TUV or EXIDA check for safety. |

By following these steps, you can make systems safer and more reliable.

Applications of SIL-Rated Circuit Boards in Safety Systems

Industrial automation and process control

SIL-rated circuit boards are important for keeping automated systems safe. They work well even in risky places. These boards help systems run smoothly and avoid dangerous failures.

Key benefits include:

Better fault detection: They find problems early to reduce downtime.

Meeting safety rules: These boards follow strict standards like IEC 61508.

SIL-rated monitors make it easier to follow safety rules. They help with certifications and improve safety checks. Diagnostics are key for meeting IEC 61508, which has different rules for each SIL level.

Adding SIL-rated boards to automation systems boosts safety and efficiency.

Transportation and energy systems

Transportation and energy systems need SIL-rated boards for safety. These boards handle big jobs like managing power grids or train signals.

In transportation, they stop accidents by keeping systems working. For example, they make sure train brakes work in all conditions. In energy, they protect power networks by finding and fixing problems.

Key uses include:

Train signals: Boards help trains talk to control centers safely.

Power systems: They stop outages and protect equipment from damage.

Using SIL-rated boards makes these systems safer and more reliable.

Real-world examples of SIL-rated circuit boards

SIL-rated boards work well in many industries. Moore Industries made SIL2 and SIL3 boards that work in tough conditions. These boards are used in energy, transportation, and factories.

Another example is oil and gas facilities. SIL-rated boards check pressure and temperature to stop equipment failures.

Industry | Use | SIL Level |

|---|---|---|

Energy | Power grid checks | SIL3 |

Transportation | Train signal systems | SIL2 |

Manufacturing | Assembly line controls | SIL2 |

These examples show how useful SIL-rated boards are. Adding them to systems improves safety and protects people and machines.

SIL-rated circuit boards are key to keeping systems safe. They follow safety rules and have designs that lower risks. These boards stop dangerous problems, making them important for energy, transport, and factories.

Using SIL-rated boards makes systems safer and protects people and machines. They meet tough safety standards and give confidence that systems work safely.

FAQ

What do SIL-rated circuit boards do in safety systems?

SIL-rated boards help safety systems follow safety rules. They lower risks by stopping failures and staying reliable. These boards are very important in energy, transport, and factories where safety matters most.

How do SIL-rated boards meet safety rules?

SIL-rated boards follow strict rules like IEC 61508. They go through tough tests to prove they are safe. Features like fail-safe designs and fault handling help them meet safety needs.

Can all industries use SIL-rated boards?

Yes, SIL-rated boards work in many industries. They are used in healthcare, airplanes, and factory machines. Their ability to handle big jobs makes them useful everywhere.

Why are SIL-rated boards so reliable?

SIL-rated boards have special features like backups and fault fixes. These help them stay safe and reliable, even in tough places. They are built to meet safety rules and keep working well.

Why is following safety rules important for SIL-rated boards?

Following safety rules makes sure SIL-rated boards work safely. It lowers risks, stops dangers, and keeps people and machines safe. It also helps industries meet world safety standards.