When building safety-critical systems, using the right tools is important. Below are 10 great products and services for safety integrity level 3 PCB assembly in 2025:

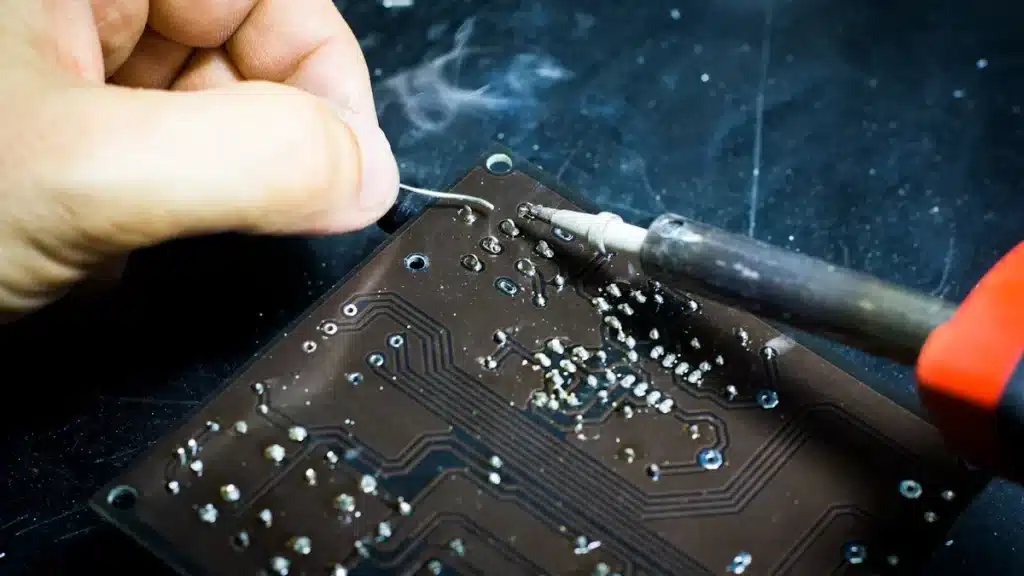

Special PCB design software made for safe and strong systems.

Reliable PCB parts that follow strict safety rules.

Machines that check for tiny mistakes with great accuracy.

Safety-focused microcontrollers designed for SIL 3 projects.

Coatings that protect PCBs from weather and damage.

Testing services to ensure the product can handle tough conditions.

Machines that place parts on PCBs with high accuracy.

SIL 3-certified power supplies for steady and safe energy.

Systems to track every step of PCB production.

Training and certification programs to teach your team about safety.

🛠️ Tip: Make sure these products work well with your project needs for the best results.

Key Takeaways

Pick modern PCB design tools to find errors early and follow safety rules.

Use strong and reliable parts to avoid failures and make PCBs last longer.

Add machines that check PCBs automatically to improve quality and meet safety rules.

Choose SIL 3-approved power supplies to keep systems safe and working well.

Train your team on safety skills to follow SIL 3 rules better.

Advanced PCB Design Software for Safety Integrity Level 3 PCB Assembly

Key Features

Advanced PCB design software is key to making safe PCBs. These tools have special features for creating high-quality designs. They include systems that catch mistakes early in the process. Many programs also check rules automatically to meet standards like IEC 61508.

Modern tools let you test designs in different situations before making them. They also help teams work together easily from design to production. Some software even comes with pre-approved safety modules, making certification easier.

Benefits for SIL 3 Compliance

Using advanced PCB design tools helps meet strict SIL 3 rules. These programs focus on making designs reliable and safe. Automated checks and tests reduce risks and improve PCB safety.

The software works well with modern machines, keeping production smooth and accurate. It also creates clear records, which are important for safety checks.

With smart safety features, you can separate key functions and find problems quickly. These tools are a must for SIL 3 projects. They improve quality, speed up work, and help meet safety rules on time.

💡 Tip: Pick software with reusable safety libraries. They save time and keep designs consistent across projects.

High-Reliability PCB Components for Safety Integrity Level 3 PCB Assembly

Key Features

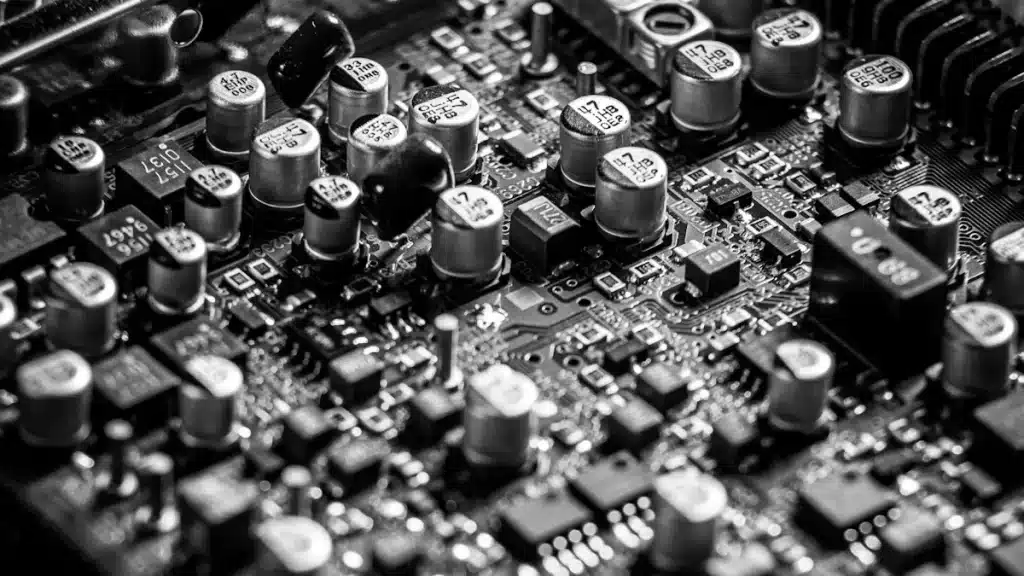

High-reliability PCB components are vital for safety integrity level 3 PCB assembly. They follow strict rules to work well in tough conditions. Certifications like IPC-6012 Level 3 and IPC-610 Class 3 prove they can handle extreme heat, strong vibrations, and sudden pressure changes.

These parts work in temperatures from -260°C to over 300°C. This makes them useful for aerospace and industrial systems. They also resist harmful radiation that can cause system errors. Standards like RoHS ensure these components are safe for the environment.

Manufacturers use advanced tools to make these parts precise and reliable. Special processes stop solder joints from breaking and prevent layers from separating. This keeps the PCB strong and dependable.

Benefits for SIL 3 Compliance

Using reliable PCB components makes meeting SIL 3 rules easier. These parts lower the chance of failure, which is key for safety. They work well in extreme conditions, helping your PCBA meet aerospace and industrial needs.

Certified components speed up the design process. Standards like ISO9001 and AS9100 guide every step, ensuring high quality. Pre-approved parts cut down on extra testing, saving time and effort during certification.

These components make your PCBA stronger by reducing risks like solder wear and layer damage. Their tough design lasts a long time, even in harsh environments. This improves safety and extends the PCB’s life, making it a smart choice for SIL 3 projects.

💡 Tip: Check that your components have the right certifications to avoid delays in production and meeting safety rules.

Automated Optical Inspection Systems for Safety Integrity Level 3 PCB Assembly

Key Features

Automated optical inspection (AOI) systems help check PCB quality. They use cameras and smart programs to find problems during production. These systems spot missing parts, solder mistakes, and misaligned components.

AOI systems carefully inspect each PCB to ensure it meets safety rules. They find issues like broken circuits, solder bridges, or too much solder. This helps make sure every PCB is safe and reliable for SIL 3 projects.

Here’s a table showing what AOI systems can do:

Feature Specification | Description |

|---|---|

Finds missing parts, solder errors, and alignment issues. | |

Quality Assurance | Checks PCB assembly quality with automated tools. |

Types of Defects | Includes broken circuits, solder bridges, and wrong solder amounts. |

These systems work well with modern machines, making them great for automated production and high-quality PCB assembly.

Benefits for SIL 3 Compliance

AOI systems help meet SIL 3 safety rules by improving inspections. They reduce mistakes by automating the process, ensuring every PCB is checked the same way. This is important for industries like aerospace and automation.

These systems also keep records of inspections, which help with audits. Early defect detection saves time and money by avoiding rework and delays.

For SIL 3 PCB assembly, AOI systems make sure every board meets strict safety standards. Their accuracy and speed are essential for creating reliable PCBAs.

💡 Tip: Pick AOI systems with adjustable settings. This lets you customize inspections for your project needs.

Functional Safety Microcontrollers for Safety Integrity Level 3 PCB Assembly

Key Features

Functional safety microcontrollers are important for keeping systems reliable. They follow strict rules like IEC 61508 throughout their lifecycle. This includes planning, building, and even disposal stages. These microcontrollers fix design problems to remove risks during development.

They can detect stuck-at faults with 99% accuracy for SIL 3 compliance. This is hard for small digital or mixed-signal parts but ensures strong performance. Many microcontrollers come with pre-approved safety modules, making certification easier for your PCBA projects.

These microcontrollers also use smart tools like RAM/ROM tests and watchdog timers. These tools check for problems while the system is running. They help your PCBs stay safe in critical jobs like industrial automation.

Benefits for SIL 3 Compliance

Functional safety microcontrollers make it easier to meet SIL 3 rules. They separate safety tasks, like emergency shutdowns, from other system functions. This design improves reliability and lowers the chance of failures.

Pre-approved safety features, like dual-core lockstep setups, simplify certification. If one core stops working, the other keeps running safely. Using safety libraries like cyclic redundancy checks (CRC) speeds up design while staying compliant.

These microcontrollers work well with modern production machines. They can be adjusted to fit different SIL levels, making them useful for many projects. Whether for aerospace or automation, they offer the safety and reliability you need.

💡 Tip: Pick microcontrollers with proven records of reliability. Past data helps show safety during audits.

Conformal Coating Solutions for Safety Integrity Level 3 PCB Assembly

Key Features

Conformal coatings add a thin layer to protect your PCB. This layer keeps out moisture, dust, and chemicals, making the PCB last longer. It also stops electrical leaks, which is very important for tightly packed circuits in safety systems.

Modern coatings are tough and can handle sudden temperature changes. They resist damage from stress and harsh environments. These coatings bend with the PCB material during heat or movement. This keeps the coating from cracking, even in tough conditions.

Here’s a table showing why conformal coatings are great for SIL 3 PCB assembly:

Feature | Description |

|---|---|

Stops electrical leaks, keeping circuits working properly. | |

Tensile Strength | Handles pulling forces without breaking. |

Thermal Shock Resistance | Survives quick temperature changes without damage. |

Flexibility | Bends with the PCB material during stress or heat. |

Humidity Exposure | Stays strong in wet conditions without breaking down. |

Salt Fog/Spray Testing | Resists damage from salty air or spray. |

Immersion Trials | Protects the PCB even when underwater. |

These features make conformal coatings essential for PCBs in industries like aerospace and automation.

Benefits for SIL 3 Compliance

Conformal coatings help meet SIL 3 safety rules by protecting PCBs from damage. They keep your safety systems working in tough environments.

By stopping electrical leaks, these coatings keep circuits safe. This is especially helpful for tightly packed designs. They also handle heat changes and resist corrosion, so your PCB works well in extreme conditions.

Using conformal coatings makes certification easier. Their proven strength means less testing is needed, saving time and money. This ensures your PCB meets SIL 3 standards faster.

For safety-critical systems, conformal coatings are a smart choice. They protect your PCB, make it last longer, and improve production quality.

💡 Tip: Pick coatings tested for salt spray and water immersion. This ensures your PCBs get the best protection.

Environmental Stress Testing Services for Safety Integrity Level 3 PCB Assembly

Key Features

Environmental stress testing checks if your PCB works in tough conditions. These tests copy real-world situations to find weak spots in your design. They include vibration, temperature changes, and moisture tests to check how strong your PCB is.

Vibration Testing: This test checks if your PCB can handle shaking. It makes sure solder joints, connectors, and layers stay strong during use or transport.

Thermal Cycling: This test heats and cools your PCB quickly. It checks if the PCB can handle temperature changes without breaking or peeling.

Humidity Testing: This test looks at how well your PCB resists water. It helps stop rust and electrical problems caused by moisture.

🌟 Pro Tip: Follow rules like MIL-STD-810 or ISO 16750-3 for vibration tests. This helps meet aerospace or car industry needs.

These tests prove your PCB is tough and meets SIL 3 safety rules.

Benefits for SIL 3 Compliance

Stress testing is important for meeting SIL 3 safety rules. It finds problems early so you can fix them. This makes your PCB more reliable in harsh conditions. These tests are useful for industries like aerospace, cars, and factories.

Stress testing also lowers risks during production. It ensures your PCB works well in factories and in real use. This saves money by avoiding repairs and delays. Test reports give clear proof, making certification easier.

For SIL 3 projects, stress testing shows your PCB meets strict safety rules. It checks parts, solder joints, and mounts for strength. This improves your PCB’s quality and reliability, making it safer for critical systems.

💡 Tip: Choose testing services that give detailed reports. These reports help with audits and save time.

High-Precision Pick-and-Place Machines for Safety Integrity Level 3 PCB Assembly

Key Features

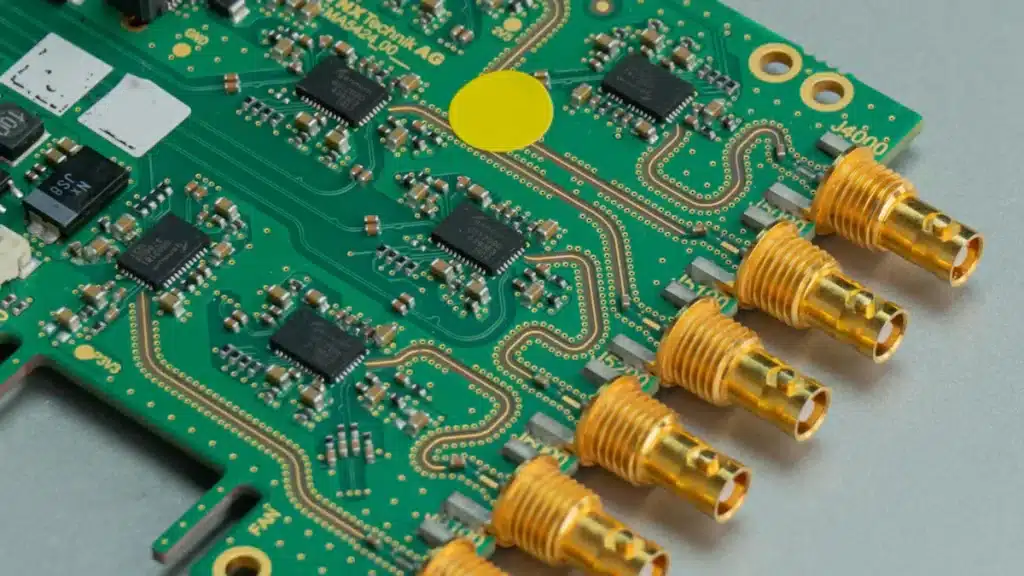

High-precision pick-and-place machines are key for making SIL 3 PCBs. They work fast and accurately, placing parts exactly where they belong. Some advanced models can place over 50,000 parts per hour with ±0.05 mm accuracy.

These machines use cameras to check and fix part alignment before placing them. This ensures every part is positioned correctly, even in crowded designs. They can handle many types of parts, from tiny resistors to big circuits, making them useful for complex projects.

Modern systems connect easily with other production tools, improving workflow. They stay reliable even under tough conditions, making them vital for SMT assembly.

Benefits for SIL 3 Compliance

Precision and reliability are crucial for SIL 3 PCBs. These machines help by reducing mistakes during part placement. Their cameras make sure parts are aligned properly, lowering the chance of safety problems.

They also speed up production by placing thousands of parts quickly. This helps meet deadlines without lowering quality, which is important for industries like aerospace.

The accuracy of these machines meets strict SIL 3 rules. Misplaced parts can cause failures, but these machines ensure every PCB is safe. They also handle different parts, letting you design complex PCBs without worry.

💡 Tip: Pick machines with settings you can adjust for different designs and production needs.

SIL 3-Certified Power Supplies for Safety Integrity Level 3 PCB Assembly

Key Features

SIL 3-certified power supplies are crucial for keeping systems safe. They follow strict IEC 61508-2:2010 rules, which require safety guides, failure checks, and diagnostic tools. These power supplies have smart features like monitors to spot problems quickly.

Their strong designs make them handle faults better. They work with a Probability of Failure on Demand (PFD) between 0.001 and 0.01. This gives a Risk Reduction Factor (RRF) from 1,000 to 10,000. Such reliability makes them great for factories, planes, and medical devices.

SIL | PFD | RRF |

|---|---|---|

SIL 3 | 0.001–0.01 | 1,000–10,000 |

These power supplies use SIL-rated parts, making safety rules easier to follow. Their modular designs fit smoothly into PCB assemblies, simplifying production steps.

Benefits for SIL 3 Compliance

SIL 3-certified power supplies are key for meeting safety rules. Their smart tools find and fix problems, keeping systems safe and reliable. Using pre-approved parts saves time during certification and testing.

They also separate safety tasks from other system functions. This lowers risks and improves system safety. These power supplies work well with modern machines, making production faster and more accurate.

For safety-critical projects, these power supplies are flexible. You can adjust them for different SIL levels, making them useful in many industries. Their proven safety and compliance with IEC 61508 make them essential for SIL 3 projects.

💡 Tip: Pick power supplies with clear safety guides and smart tools. These features make audits easier and ensure SIL 3 compliance.

PCB Traceability Systems for Safety Integrity Level 3 PCB Assembly

Key Features

PCB traceability systems are important for keeping your PCBs safe. They let you track every part from start to finish. This helps ensure all parts meet quality rules and work properly.

These systems also make the supply chain clear. You can see where parts come from, which helps stop fake components. Tracking each part’s lifecycle ensures it is real and works as expected.

Modern systems follow rules like IPC-1782. This rule focuses on keeping data accurate and using automation. It also sets levels for collecting data based on defect risks. These features make traceability systems a must for high-quality PCB production.

Benefits for SIL 3 Compliance

Traceability systems help meet SIL 3 rules by improving quality checks. They let you fix problems fast, ensuring your PCBs meet strict safety standards. Tracking parts ensures they are real and not low-quality.

These systems also help with following global safety rules. They make audits and certifications easier to handle. Knowing your supply chain improves safety and makes production smoother.

Using IPC-1782 guidelines helps you collect the right data and check risks. This makes sure your system supports SIL 3 needs. With good tracking, you can build safer and more reliable PCBs for critical jobs.

💡 Tip: Pick traceability systems that work well with your tools. This will make your production faster and more efficient.

Functional Safety Training and Certification Services for Safety Integrity Level 3 PCB Assembly

Key Features

Functional safety training helps your team learn about SIL 3 rules. These programs teach practical skills to follow safety standards. Topics include finding risks, spotting faults, and checking systems for safety.

Workshops give hands-on practice for designing and testing systems. Certification programs explain global rules like IEC 61508 and ISO 26262. They ensure your team knows how to meet these standards.

Some courses are made for specific industries, like aerospace or cars. These special lessons focus on the unique safety needs of those fields.

Many services also offer reusable safety tools. These tools include pre-checked designs for tasks like timers and error checks. They make creating safe systems faster and easier.

Benefits for SIL 3 Compliance

Training helps your team build safer PCBs by reducing mistakes. It teaches them how to follow safety steps during production. This improves quality and saves time.

Certification programs make meeting safety rules quicker. They give clear records and proof for audits. This makes getting approvals easier and faster.

Reusable tools save time by using tested designs. Your team can focus on improving systems instead of starting from scratch. These tools also help pass certifications more easily.

Safety training prepares your team to handle tough safety tasks. It boosts their confidence in designing and testing SIL 3 systems. With these programs, you can make better PCBs and speed up production.

💡 Tip: Pick training programs with lessons for your industry. This ensures your team learns skills that match your projects.

Picking the best tools for SIL 3 PCB assembly is important. It helps your safety systems follow strict rules. Tools like design software and safety training make systems safer and more reliable.

Key Points:

Precision and reliability: Accurate machines and certified parts lower failure chances.

Protection and testing: Coatings and stress tests keep PCBs safe in tough conditions.

Knowledge and traceability: Training and tracking tools make audits and approvals easier.

🛠️ Advice: Choose tools that fit your project. For example, use stress tests for harsh conditions or tracking systems for detailed supply chains.

Smart choices lead to safer and stronger systems.

FAQ

What does Safety Integrity Level 3 (SIL 3) mean for PCB assembly?

SIL 3 is a safety rule for critical systems. It makes sure PCB assemblies are reliable and have low failure rates. This level is used in industries like aerospace, cars, and factories.

How do switching parts help with SIL 3 rules?

Switching parts improve reliability by cutting electrical noise. They keep systems steady and safe, helping meet SIL 3 standards.

Can coatings protect PCBs in tough conditions?

Yes, coatings guard PCBs from water, dirt, and chemicals. They also handle heat changes and stress, making them great for SIL 3 projects.

Why is tracking parts important for SIL 3 PCB assembly?

Tracking parts ensures they meet quality rules. It helps stop fake parts and makes audits easier for SIL 3 compliance.

Is special training needed for SIL 3 PCB assembly?

Yes, safety training teaches teams how to design and test SIL 3 systems. It helps follow global rules and improves production quality.