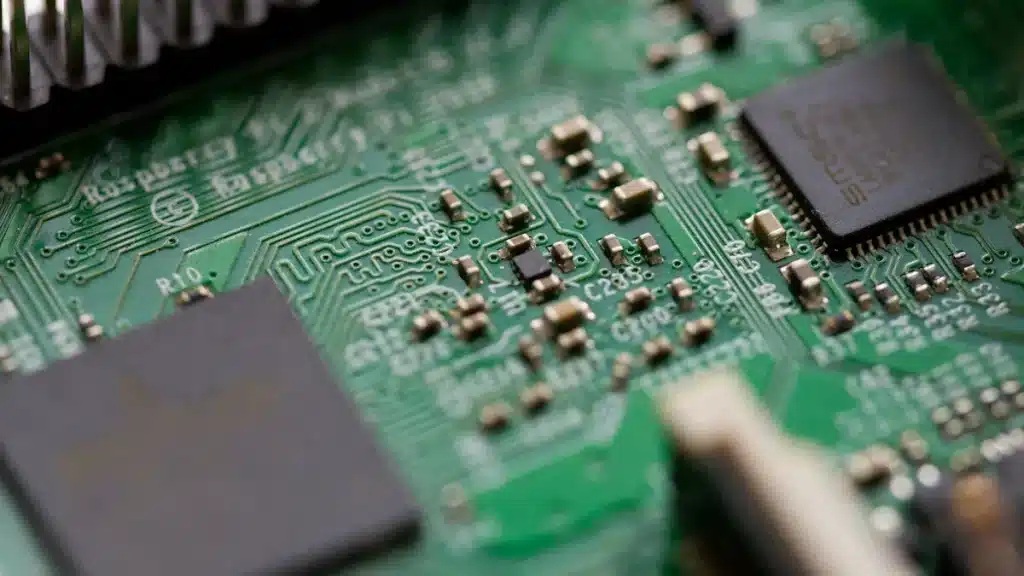

Choosing the best Motor health analysis PCBA systems for 2025 is crucial. These systems ensure smooth operations and help prevent costly disruptions. The growing demand for Motor health analysis PCBA systems is evident in market trends. For instance:

The global PCB and PCBA market, valued at $68.4 billion in 2023, is projected to reach $105.8 billion by 2032.

Automotive industries increasingly depend on robust PCBs for smart technologies like ADAS and electric engines.

The healthcare sector is driving demand for compact, durable PCBs due to the rising use of medical devices.

These developments highlight how advanced Motor health analysis PCBA systems play a vital role in delivering reliable and scalable motor health evaluations.

Key Takeaways

Pick motor health PCBA systems based on how well they work, their features, and price to fit your needs.

Find systems with smart tools like live tracking and wireless links to make checking and fixing easier.

Choose affordable options that cut down on delays and repair costs, keeping them reliable and efficient for a long time.

Focus on systems that can grow and work with other tools so you can upgrade later and get the most value.

Use AI tools and IoT connections to study data better and spot problems early, helping motors run smoothly.

Key Criteria for Evaluating Motor Health Analysis PCBA Systems

When choosing motor health PCBA systems, focus on key factors. These include how well it works, its features, and its cost. Each factor helps decide if the system fits your needs.

Performance Metrics

Performance metrics show how well a system checks motor health. They measure things like motor imbalance, worn bearings, or overheating. Metrics are grouped into four types:

Metric Type | Examples of Metrics | Description |

|---|---|---|

Quantitative | Root-mean square distance, log-likelihood, Kullback-Leibler divergence | Use numbers or math to check performance. |

Qualitative | Fugl-Meyer Assessment, Wolf Motor Function Test | Look at motion quality instead of raw numbers. |

Model-less | Norm of jerk | Check performance without using set models. |

Model-based | Heuristic consistency, prediction intervals | Compare results to a math model for better accuracy. |

For example, systems with vibration and temperature sensors use RMS metrics to find problems. These metrics give clear and useful information for fixing issues early. By focusing on these, you ensure the system is safe and reliable.

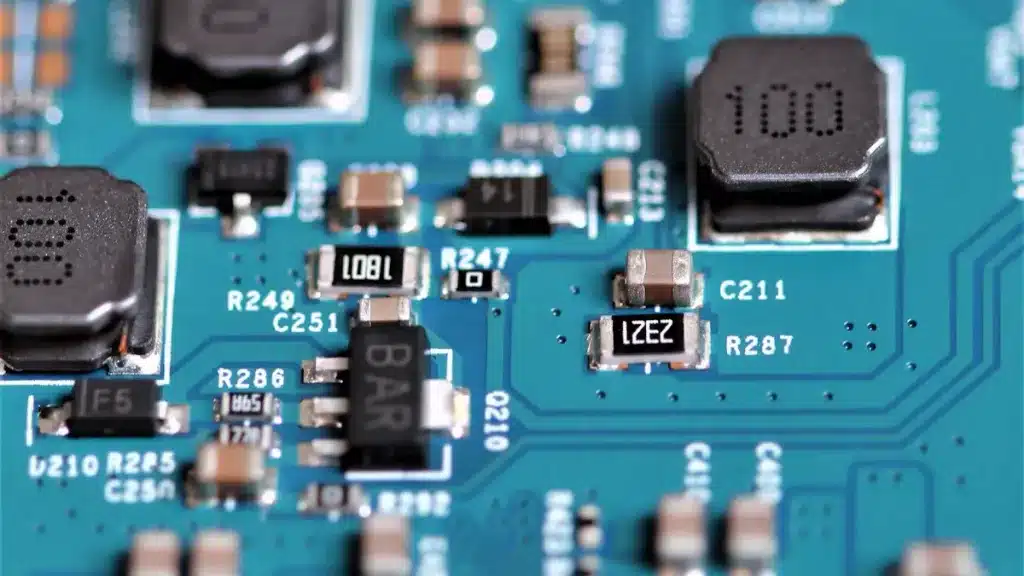

Technological Features

Modern features make motor health PCBA systems work better. They use sensors for vibration, temperature, current, and pressure to monitor conditions. These features help spot problems early and prevent damage.

Some important advancements are:

Systems that work on their own, reducing human effort.

Real-time tracking to warn about risks quickly.

Wireless options like LoRaWAN and BLE 5.2 for hard-to-reach places.

Edge computing for faster local data processing.

For instance, edge computing lets systems analyze data quickly without needing the cloud. Modular designs allow adding new sensors, like sound sensors, for more uses. These features make systems flexible and reliable for many industries.

Cost-Effectiveness

Cost matters when picking a motor health PCBA system. The right system saves money over time by cutting downtime and repairs.

Non-invasive sensors, like clamp-on current sensors, are affordable and easy to install. Self-powered modules use energy from heat or radio waves, saving wiring costs. Strong enclosures protect systems in tough conditions, lowering maintenance needs.

Choosing a cost-effective system keeps your operations running smoothly and safely. It also helps save money while ensuring long-term reliability.

Scalability and Integration

Scalability and integration are key for motor health systems. A scalable system grows as your needs change. Integration helps it work well with current tools and tech. Together, they make a strong solution for tracking motor health.

Modern systems grow easily with modular designs. You can add new parts, like plug-in boards, to expand features. For example, start with vibration sensors, then add sound sensors later. This lets you upgrade without replacing the whole system.

Integration is also very important. Advanced systems use wireless tech like LoRaWAN and BLE 5.2. These make it easier to set up in hard-to-reach places. Edge computing processes data locally, so less cloud use is needed. This makes systems faster and more reliable.

One example is an EEG system with FPGA and wireless tech. It works well for many uses, like tracking signals or linking to phones. This shows how similar ideas help motor health systems stay flexible and useful.

Look for systems with adjustable analytics tools. These can find motor problems or predict part lifespan. Cloud-based AI tools improve maintenance by spotting issues early. Combining scalability and integration keeps systems useful as needs grow.

By focusing on these features, you can pick a system that works now and later. This ensures reliability and gets the most value from your investment.

Technological Advancements in PCBA Systems

Wireless Vibration Monitoring Systems

Wireless systems make checking motor vibrations much easier. They use special sensors to find problems like imbalance or worn bearings. These systems help spot issues early, avoiding expensive repairs. Unlike wired systems, wireless ones are simple to set up and work well in hard-to-reach places.

A big benefit is their connection to cloud platforms. This lets you see live data from anywhere. Dashboards show motor performance clearly, helping you find problems fast. You can track trends and notice unusual changes easily.

Study | Dataset Used | Key Results |

|---|---|---|

Balshaw et al. | IMS dataset from NSF I/UCR Center | Found faults quickly using anomaly detection. |

Civera et al. | Wind farm data from 18 Nordex N100 turbines | Checked motor health using accelerometer data. |

Wang et al. | Bearing and gearbox datasets | Diagnosed faults and tracked wear over time. |

Vos et al. | DST and Airbus datasets | Tested gearbox performance in helicopters. |

Aburakhia et al. | PU, CWRU, and Ottawa Bearing Datasets | Worked well with different motor setups. |

These studies show how wireless systems improve motor health checks and data analysis.

AI-Driven Diagnostics

AI tools make motor health checks smarter and faster. They use machine learning to study sensor data and find patterns. AI predicts problems early, helping you fix them before they get worse.

AI also makes systems work better over time. It learns from new data to give more accurate results. For example, AI can study vibration data to find the cause of a problem. This saves time and keeps your machines running smoothly.

IoT Connectivity

IoT connects motor systems to smart devices for easy monitoring. Sensors collect data and send it to a central hub. This lets you check motors in faraway places without being there. It saves money and makes maintenance simpler.

IoT systems use edge computing to process data nearby. This means faster results and fewer delays. With IoT, you can build a system that grows with your needs. It’s a smart way to keep motors healthy and efficient.

Comparison of Leading Motor Health Analysis PCBA Systems

System A Overview

System A is great for tracking motor performance. It checks important areas to give a full picture of motor health. These areas include quality, uptime, customer care, costs, safety, and eco-friendliness. The table below explains these key points:

KPI Category | Description |

|---|---|

Quality | Checks if products meet what customers expect. |

Availability | Measures how often the motor is ready to work. |

Customer Service | Looks at how well customer needs are handled. |

Operating Costs | Tracks money spent on running and fixing the motor. |

Safety | Makes sure work is done safely without accidents. |

Environmental Integrity | Ensures the motor follows environmental rules while running. |

System A uses sensors to monitor vibration, heat, current, and pressure. It processes data locally with edge computing, so it doesn’t need the cloud much. Its modular design lets you add new parts, like sound sensors, for more features. These qualities make System A a strong choice for industries needing reliable motor health systems.

System B Features

System B uses sensors that don’t touch the motor directly. This is helpful when changing equipment isn’t possible. It uses clip-on current sensors and magnetic tools to check motor health without stopping work. This makes it simple and dependable.

The system powers itself by using heat or radio waves, so no extra wires are needed. It also uses wireless tech like LoRaWAN and BLE 5.2, making it easy to set up in hard-to-reach spots. Strong cases protect it from tough conditions, meeting IP67/NEMA 4X standards.

System B is easy to set up with mobile apps and QR codes. These features make it affordable and useful for industries with tricky setups or harsh environments.

System C Innovations

System C brings new ideas to motor health checks. It uses VisionMD, a free software, to study motor movements. This tool uses AI to track body motion and measure movement issues. The table below shows its main features:

Feature | Description |

|---|---|

Tool Name | VisionMD |

Type | Free software for studying motor movements in disorders. |

Technology Used | AI tracks body motion for detailed analysis. |

Key Metrics | Measures movement to check symptom levels. |

Applications | Helps study Parkinson’s and other movement problems. |

Benefits | Gives clear, accurate results; works over time; easy to use. |

System C also has smart tools for analyzing data. It can check for motor issues like worn bearings using AI. Its modular design allows adding new parts, and cloud tools help predict problems early. These features make System C a top pick for industries needing advanced motor health systems.

Real-World Applications of PCBA Systems

Industry Use Case: Manufacturing

PCBA systems are important in factories. They help check motors on assembly lines to keep things running smoothly. These systems find problems like overheating or shaking, stopping expensive delays. For example, capacitive sensors are great for fast production lines. They spot issues by measuring changes in electric signals.

Factories like modular PCBA designs. You can swap parts without stopping the whole system. This makes it easy to adjust to new needs. Wireless connections make checking motors simple, even in big factories. Using PCBA systems saves money and boosts efficiency.

Industry Use Case: Energy Sector

In energy, PCBA systems keep motors in wind turbines and plants working well. They track things like shaking, heat, and pressure in real time. This helps find problems early and plan repairs before breakdowns.

Capacitive sensors work well in tough weather. They give accurate readings even in remote places. For example, wind turbines in harsh areas stay reliable with these sensors. PCBA systems lower the chance of failures and keep energy flowing.

Energy companies also use PCBA systems with IoT. This lets them check equipment from far away and study data for better choices. It makes operations smoother and supports green energy efforts.

Lessons Learned from Implementations

Using PCBA systems teaches useful lessons. First, pick systems that fit your industry. For example, medical tools need small, strong PCBA designs. These systems handle delicate jobs like running ventilators or scanners.

Second, choose systems that can grow. Modular designs let you add features later. Start with basic checks, then add smart tools like AI diagnostics.

Lastly, make sure systems work with your current tools. In medical devices, this ensures accurate data and smooth operations. By focusing on these points, you get the most from PCBA systems and improve motor health care.

Motor health analysis PCBA systems help keep machines running smoothly. They stop problems early and save money by avoiding downtime. The best systems depend on how they perform, their features, cost, and ability to grow or connect with other tools. New tech like wireless sensors, AI tools, and IoT make these systems very useful.

Tip: Pick a system that fits your budget and future plans. For simple needs, go for affordable systems you can upgrade later. For advanced needs, choose AI systems with cloud features.

The right PCBA system protects your motors and improves their performance over time.

FAQ

What is a PCBA system, and why does it matter for motor health?

A PCBA system is a circuit board that checks motor health. It uses sensors to find problems like overheating or shaking. This helps stop motor breakdowns, saves time, and cuts repair costs.

How do wireless PCBA systems help with motor monitoring?

Wireless PCBA systems use sensors to check motors without wires. They are simple to set up, even in hard-to-reach places. These systems send live data to the cloud, so you can watch motor health from anywhere and fix issues fast.

Can PCBA systems handle tough environments?

Yes, many PCBA systems are built for harsh conditions. They have strong cases that block dust, water, and heat. This makes them work well in industries like energy and factories, even in extreme settings.

Are PCBA systems a good deal for small businesses?

Yes! Many PCBA systems are budget-friendly with easy-to-use sensors. They cost less to install and maintain. Modular designs let you start small and add more features later, making them great for growing businesses.

How does AI make motor health checks better in PCBA systems?

AI makes motor checks smarter by spotting patterns in data. It predicts problems early and suggests fixes. Over time, AI gets better at finding issues, keeping motors running smoothly and avoiding sudden failures.