Surface mount capacitors are important parts of modern electronics. They store energy, filter signals, and keep voltage steady. These capacitors help make devices smaller, faster, and more dependable.

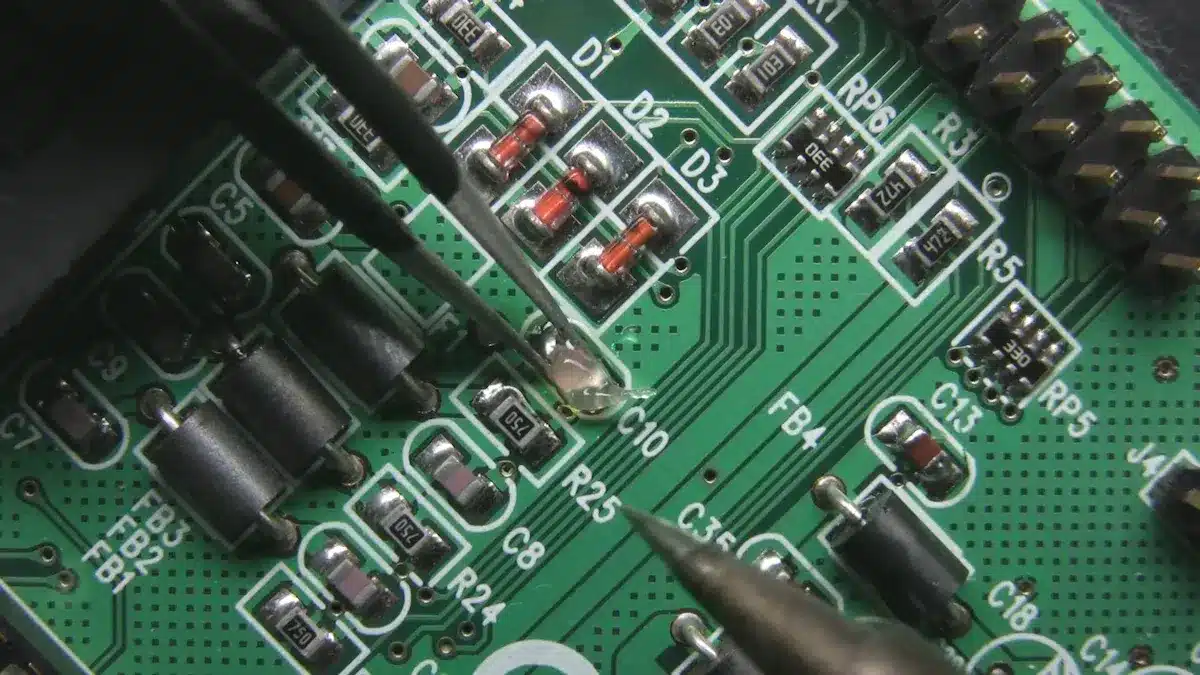

Surface Mount Technology (SMT) changed how electronics are made. It allows smaller parts, like surface mount capacitors, to be used. This makes devices work better by speeding up signals and cutting down interference.

New improvements in surface mount capacitor technology are making them popular in many industries. For example:

The global market was worth $2.87 billion in 2022. It is expected to grow 7.3% each year until 2028.

New trends include tiny MLCCs and bendable surface mount capacitors.

They are used in gadgets, cars, and green energy systems.

These changes show why it’s important to know about surface mount capacitors when designing today’s devices.

Key Takeaways

Surface mount capacitors are important for modern gadgets. They help make devices smaller, faster, and more dependable.

There are different types, like ceramic, tantalum, and aluminum electrolytic. Each type works best for certain uses.

When picking capacitors, think about capacitance, voltage limits, and the environment. This helps your circuit work well.

For high-frequency tasks, ceramic capacitors are the top choice. They are tiny and waste little energy.

To make them last longer, use only 50-70% of their voltage limit. Pick capacitors that fit your device’s needs.

Overview of Surface Mount Capacitors

What Are Surface Mount Capacitors?

Surface mount capacitors are small parts that store and release energy. Unlike older capacitors, they attach directly to a circuit board. They don’t need wires to connect. Their tiny size makes them perfect for modern gadgets with limited space. You can find them in phones, laptops, and cars. They help control voltage, clean up signals, and make devices work better.

Key Features of Surface-Mounted Capacitors

Surface-mounted capacitors have special features that make them different:

Compact Size: Their small size fits crowded circuit boards.

Good Stability: They work well in different temperatures and frequencies.

High Frequency Response: They handle fast signals easily.

Reliability: They are strong and last a long time.

Here’s a simple comparison of how they perform:

Metric | Surface Mount Capacitors | Other Capacitor Types |

|---|---|---|

Capacitance Value | Lower, but varies | Higher in some cases |

Voltage Withstand | Medium | High (e.g., Mica, Tantalum) |

Temperature Stability | Good | Varies (e.g., Film is high) |

Frequency Response | High | Varies (e.g., Film is low) |

Size | Small | Bigger for some types |

Common Types of SMD Capacitors

There are different kinds of SMD capacitors for various uses:

Ceramic Capacitors: Made from ceramic, they are stable and good for filtering.

Tantalum Capacitors: These are reliable and used in power circuits.

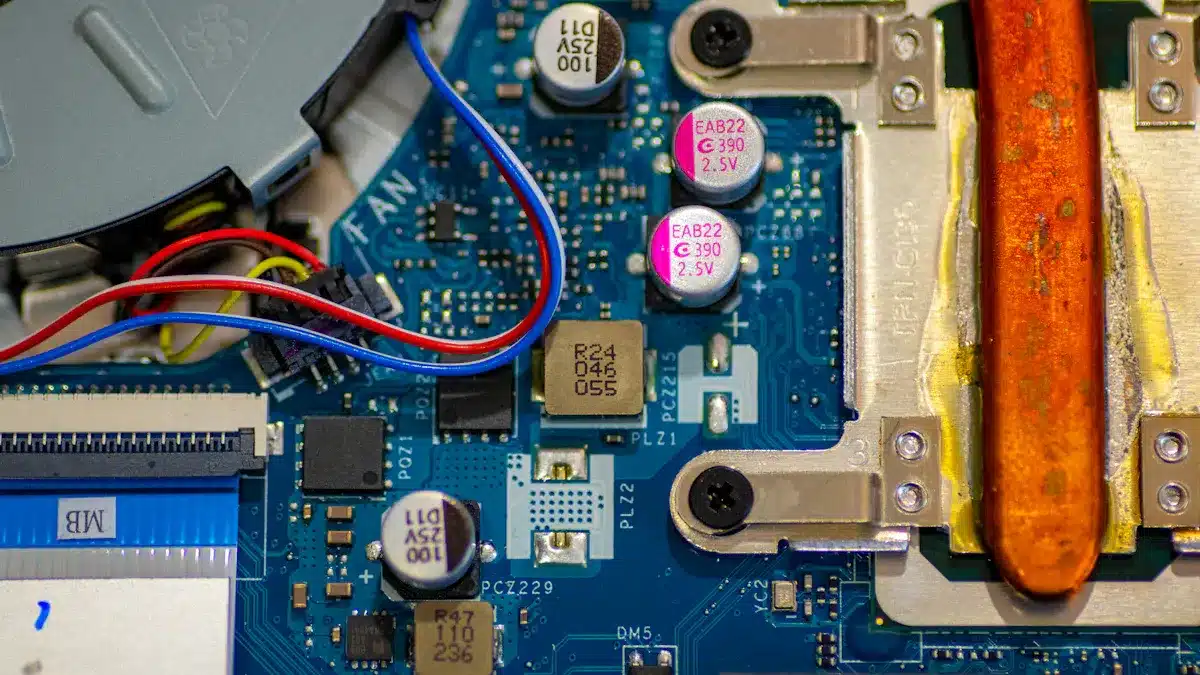

Aluminum Electrolytic Capacitors: They store a lot of energy but are bigger and less stable.

Film Capacitors: Great for high voltage and precise tasks like audio equipment.

Each type has its own strengths. Picking the right one depends on your needs.

Detailed Comparison of Capacitor Types

Ceramic Capacitors

Ceramic capacitors are very common because they work well in many situations. They are made from ceramic materials, which give them special electrical abilities. These capacitors are often used in devices that need signal filtering, steady signals, or high-frequency performance.

Key Features of Ceramic Capacitors:

Great for High Frequencies: They work well in fast circuits due to low unwanted inductance.

Low ESR: They waste less energy and stay cooler.

No Polarity: They can be used in AC circuits without worrying about direction.

Small Size: Their tiny size fits into tight spaces on circuit boards.

Here’s how ceramic capacitors compare to others:

Feature | Ceramic Capacitors | Other Capacitor Types |

|---|---|---|

High-Frequency Performance | Excellent, low unwanted inductance | Often lower |

Equivalent Series Resistance (ESR) | Low, saves energy | Higher, may waste energy |

Polarity | Non-polarized, works in AC circuits | Usually polarized (e.g., electrolytic) |

Capacitance | Lower than electrolytic capacitors | Higher in some types |

Sensitivity to Temperature/Voltage | Can change with conditions | Some types are more stable |

Durability | Reliable, doesn’t leak | May leak or dry out |

Ceramic capacitors are great for small devices like phones, laptops, and car electronics.

Tantalum Capacitors

Tantalum capacitors are known for being reliable and storing a lot of energy in a small space. They are made from tantalum, which makes them stable and good for power circuits. You’ll find them in things like power supplies and converters.

Why Pick Tantalum Capacitors?

High Energy in Small Size: They store more energy than ceramic capacitors of the same size.

Steady Performance: They work well even in extreme temperatures.

Long-Lasting: They are dependable, especially when used below their maximum voltage.

Recent studies show their reliability:

Tantalum polymer capacitors are better than older MnO2 ones.

New ways to test their reliability help prevent failures.

They are often used in DC-DC converters for steady power and efficiency.

Tip: Use tantalum capacitors at 50-70% of their voltage limit. This helps them last longer and work better.

Tantalum capacitors are ideal for devices needing steady power, like medical tools and industrial machines.

Aluminum Electrolytic Capacitors

Aluminum electrolytic capacitors are popular for storing lots of energy at a low cost. They use aluminum and an electrolyte to achieve high capacitance, making them great for power-heavy tasks.

Features of Aluminum Electrolytic Capacitors:

Stores Lots of Energy: Perfect for circuits needing high power.

Handles High Voltages: They can work with voltages up to 400V.

Works in Extreme Temperatures: They can handle -55°C to +125°C.

Here’s a quick look at their performance:

Voltage Rating | Lifespan (Hours) | Temperature Range |

|---|---|---|

40 V | 6000 | -55 to +125 °C |

63 V | 6000 | -55 to +125 °C |

400 V | 4000 | -55 to +125 °C |

New improvements in electrolytes make them even better:

Special liquids improve conductivity and voltage strength.

Tests show that lower-capacitance versions last longer under stress.

These capacitors are used in power supplies, audio systems, and green energy devices.

Film Capacitors

Film capacitors are known for being precise and dependable. They use a thin plastic layer, called a dielectric, to work. This gives them special electrical abilities. These capacitors are great for circuits needing high voltage or steady performance.

Key Features of Film Capacitors:

High Stability: They keep their capacitance steady even with temperature or voltage changes.

Low Losses: They waste very little energy, making them efficient.

Wide Voltage Range: They can handle from a few volts to thousands of volts.

Durability: They are tough and can handle harsh conditions.

Film capacitors are often used in audio equipment, power supplies, and industrial machines. For example, they help make audio sound clear because they don’t distort signals.

Tip: Pick film capacitors for circuits needing accuracy and low signal noise.

Film capacitors are perfect for tasks where stability and reliability matter, like in medical tools and green energy systems.

Mica Capacitors

Mica capacitors are valued for their great stability and accuracy. They use mica as the dielectric, which gives them excellent electrical properties. These capacitors are common in high-frequency circuits and precise applications.

Why Mica Capacitors Are Special:

Mica capacitors perform very well in precise electronic systems. Their features include:

Feature | Description |

|---|---|

High Stability | Capacitance barely changes with temperature, voltage, or frequency shifts. |

Low Losses | They waste little energy, working well in high-frequency circuits. |

High Precision | Tight tolerances ensure accurate and reliable performance. |

High-Temperature Operation | They can handle heat without losing effectiveness. |

Reliability and Longevity | Strong build ensures long-lasting and dependable use. |

High Voltage Capabilities | Suitable for high voltage tasks due to mica material. |

These features make mica capacitors ideal for radios, oscillators, and military electronics.

Note: Mica capacitors are chosen for circuits needing stability and reliability in tough conditions.

Their ability to handle high frequencies and voltages makes them essential in specialized fields.

Polymer Capacitors

Polymer capacitors are a newer option compared to older electrolytic capacitors. They use a conductive polymer instead of liquid, which improves their performance. These capacitors are widely used in gadgets and power systems.

Benefits of Polymer Capacitors:

Low ESR: They lose less energy, making them more efficient.

Handles High Ripple Current: They manage large current changes without overheating.

Long Lifespan: Their solid design doesn’t dry out like liquid capacitors.

Compact Size: Their small size fits well in tight spaces.

Polymer capacitors are great for laptops, phones, and car electronics. For example, they are used in voltage regulators to keep power steady.

Tip: Use polymer capacitors in circuits needing efficiency and small designs.

Their mix of reliability and performance makes them a favorite for modern devices.

Selection Criteria for Surface Mount Capacitors

Capacitance and Voltage Needs

When picking surface mount capacitors, check capacitance and voltage needs. Capacitance, in microfarads (µF), shows how much charge it holds. Voltage ratings tell the highest voltage it can handle safely. Both are key for proper function.

Capacitors have labels showing capacitance and voltage. For example, “33 6V” means 33 µF and 6 volts.

Pick a capacitor with a voltage rating higher than your circuit’s maximum voltage. Using one with too low a rating can cause failure or damage.

If AC voltage is added to DC voltage, make sure the total voltage stays below the capacitor’s DC rating. This avoids breakdowns.

For critical uses, like medical tools or industrial machines, use capacitors with extra safety margins. Running them at 50-70% of their max voltage helps them last longer and work better.

Environmental and Temperature Factors

Where capacitors are used affects how they perform. They must handle temperature changes, humidity, and other conditions.

Aluminum electrolytic capacitors work in extreme temperatures, from -55°C to +125°C. They’re great for outdoor or industrial uses.

Ceramic capacitors stay stable across wide temperature ranges, making them good for sensitive, high-frequency circuits.

Polymer capacitors resist moisture, so they’re better for humid places and last longer.

Thermal stability is also important. Some capacitors, like film types, keep their capacitance steady even with temperature changes. This is crucial for precise circuits, like those in audio gear or medical devices.

Size and Space Limits

Modern gadgets need small parts, so capacitor size matters. Size depends on capacitance density, dielectric thickness, and efficiency.

Thinner dielectrics allow higher capacitance in the same size. This is helpful for SMD capacitors in tight spaces.

Volumetric efficiency (capacitance × voltage ÷ volume) compares capacitor performance. New designs improve this, making smaller, better parts.

Aluminum electrolytic capacitors are bigger but store lots of energy, so they’re used in power-heavy tasks.

For small devices like phones or wearables, choose capacitors with high capacitance density and small sizes. Polymer and ceramic capacitors are great options.

Tip: Balance size with performance. A tiny capacitor saves space but might not meet your circuit’s needs.

Cost and Budget Factors

When picking surface mount capacitors, cost is very important. Prices differ based on type, size, and features. For example, tantalum capacitors cost more than ceramic capacitors. This is because they store more energy and last longer. However, their higher price is worth it for tasks needing reliability.

The global market shows rising demand for capacitors. Here’s a quick summary:

Metric | Value |

|---|---|

Market Size Value in 2024 | |

Market Size Value by 2035 | $15.24 Billion |

CAGR (Till 2035) | 8.20% |

Market Share by Passive Components | 75.34% by 2035 |

These numbers show how capacitors are used more in industries. To save money, pick capacitors that fit your needs. For example, aluminum capacitors are cheaper for high-capacitance tasks. Ceramic capacitors are better for small designs needing high frequencies. By balancing price and performance, you can stay within budget.

Tip: Buying in bulk and choosing trusted suppliers can lower costs without losing quality.

Reliability and Lifespan

Reliability matters a lot when choosing capacitors. This is especially true for tasks where failure isn’t an option. Manufacturers test capacitors to meet strict standards. One test, called HALT, uses heat and electricity to predict how long a capacitor will last.

Several things affect how long capacitors work:

Temperature: High heat makes them age faster.

Voltage Stress: Using too much voltage can break them early.

Dielectric Material: Materials like tantalum and ceramic are strong and stable.

Mechanical Stress: Physical damage during use can hurt performance.

Data and models help predict reliability, like Mean Time to Failure (MTTF). For example, tantalum capacitors last long if used below their voltage limit. Aluminum capacitors work well for power tasks but may not last as long due to liquid drying out.

Note: To make capacitors last longer, use them at 50-70% of their voltage rating and keep them cool.

Application-Specific Recommendations

Different tasks need specific capacitor types. Here’s a simple guide:

Application | Market Segmentation |

|---|---|

Yes | |

Automotive | Yes |

Industrial Machinery | Yes |

Defense | Yes |

Others | Yes |

For gadgets, ceramic capacitors are great because they’re small and handle high frequencies. In cars, tantalum capacitors are reliable in tough conditions. Factories use aluminum capacitors for high power and voltage. Defense systems prefer mica capacitors for their accuracy and toughness.

When choosing capacitors, think about capacitance, voltage, and environment. For example, polymer capacitors are good for small designs needing low ESR and long life. Film capacitors are best for circuits needing stability and clear signals.

Tip: Choose the right capacitor for your task to get the best results and longer use.

Surface-mounted capacitors are key parts of modern electronics. Different types have special benefits for specific uses. Picking the right one means checking capacitance, voltage, size, and environment. For instance, better placement methods, like symmetrical layouts or via-in-pad designs, can cut radiated emissions by up to 20 dB. See the table below:

Measurement Type | Before Changes | After Changes | Improvement |

|---|---|---|---|

Radiated emissions at 1 GHz | -35 dBm | -55 dBm | 20 dB lower |

Conducted emissions on power lines | -70 dBμV | -85 dBμV | 15 dB lower |

Knowing how surface mount capacitors differ helps improve your designs. This ensures your devices work well and meet today’s needs.

FAQ

What are the main types of capacitors in SMT?

The main types are ceramic, tantalum, aluminum electrolytic, film, mica, and polymer. Each type works best for specific tasks like energy storage or signal filtering.

How do capacitor features impact circuit performance?

Features like capacitance, voltage rating, and ESR affect how capacitors store energy, filter signals, and manage current. Picking the right one helps your circuit work properly.

Which capacitors are best for high-frequency circuits?

Ceramic capacitors are great for high-frequency circuits. They are small, have low ESR, and stabilize signals effectively.

Can surface mount capacitors handle very hot or cold conditions?

Yes, some types like aluminum electrolytic and tantalum capacitors can handle extreme temperatures. Always check the manufacturer’s temperature range.

How do I choose the right capacitor for my needs?

Look at your circuit’s capacitance, voltage, and environment needs. Think about space limits and reliability. Match these with the strengths of different capacitor types.

See Also

Exploring The Benefits And Challenges Of Flex PCBA

The Importance Of SMD Components In Today’s Electronics

The Significance Of Custom PCBA Production In Electronics