Flexible Flat Cable (FFC) connectors are important parts of modern electronics. They use flat, bendable cables to make strong connections between circuit boards. Their small size makes them perfect for devices like phones, smartwatches, and car systems, where space is tight.

FFC connectors are easy to install and remove. This saves time during assembly and helps make production faster. Their efficiency is why they are becoming more popular in many industries.

Why FFC Connectors Are Important:

The global market for FFC connectors was $4.2 billion in 2023. It is expected to grow to $6.3 billion by 2032, showing their rising demand.

Smaller devices and faster data needs in electronics drive this growth.

Because they are flexible and efficient, FFC connectors change how devices are made. They help create thinner and better products.

Key Takeaways

FFC connectors are small and bendable, perfect for tiny gadgets like phones and watches.

They are easy to put in and take out, saving time when building devices.

Picking the right FFC connector with the correct size and power is important for it to work well.

These connectors move data quickly, so they are key for today’s electronics and cars.

Custom FFC connectors can be made to fit special projects, making devices work better and last longer.

What Are FFC Connectors?

Definition and Basic Structure

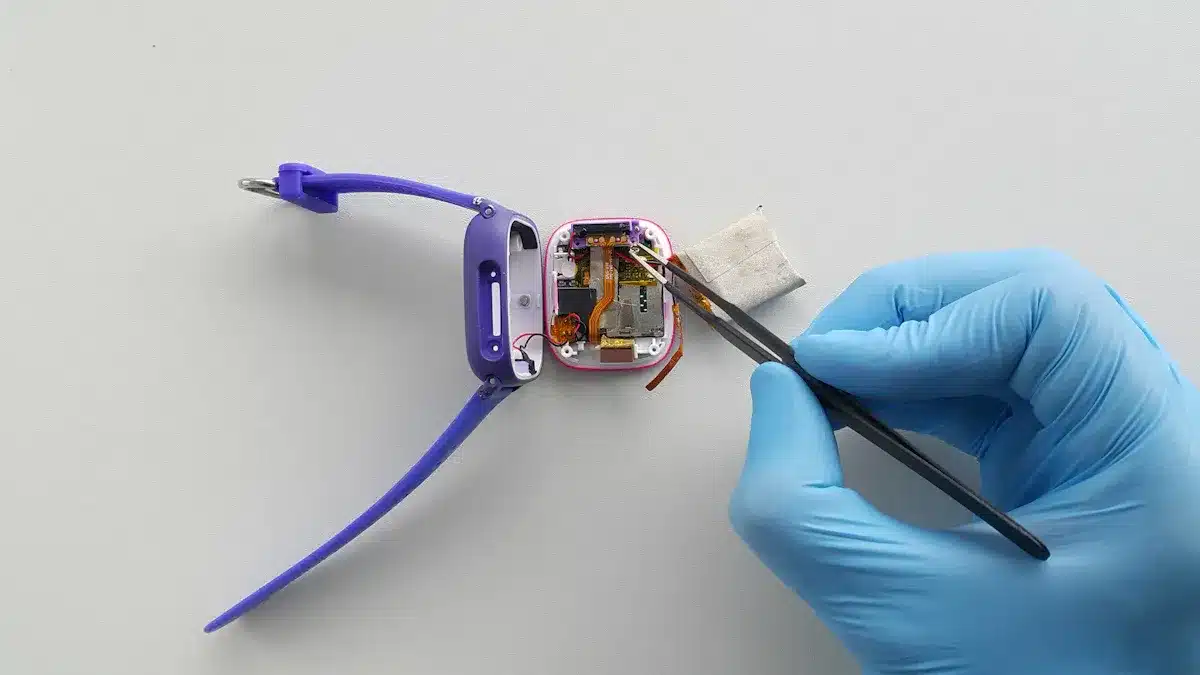

FFC connectors are key parts of modern electronics. They link flat flexible cables (FFC) or flexible printed circuits (FPC) to circuit boards. This helps different parts of a device work together smoothly. These connectors are small, bendable, and dependable, making them great for gadgets like laptops, cameras, and printers.

The main parts of an FFC connector have specific jobs. Here’s a simple overview:

Part | Job Description | Details |

|---|---|---|

Tongue section | Holds, insulates, and connects for strength | Spacing sizes: 0.3, 0.5, 0.8, 1.0, 1.25, 1.27, 2.0, 2.54 mm |

Terminal section | Sends electronic signals | Multi-specification series with 4-50 screen numbers |

Grounding plate | Secures, fixes, and adds strength | Includes strip connectors like pH, XH, 3.96, San, SCN, SM |

FFC features | Thin, flexible, easy to attach and remove, shields against EMI | Made from PET insulation and tinned flat copper wire |

These parts work together to create strong connections. They also resist heat and perform well mechanically.

Parts of an FFC

Knowing the parts of an FFC helps you understand how it works. FFCs are made of flat cables with PET insulation and tinned copper wires. These cables are light, thin, and bend easily, making them ideal for small devices.

FPCs, which are similar to FFCs, have conductive paths, insulating layers, and protective coatings. These features let FPCs handle complex signals while staying durable.

In printers, FFC cables connect the printhead to the main board. Over time, they might wear out or get ink buildup, causing problems. Checking them regularly can prevent issues and keep printers running well.

Uses and Applications

FFC connectors are used in many industries. Their small size and flexibility make them perfect for connecting cables to circuit boards in electronics, cars, and medical devices. They are often used to link screens, touch panels, and cameras to boards.

Flexible printed cables are also common in devices needing fast data transfer. They handle complex signals, making them essential for modern technology.

Tip: Choose an FFC connector based on voltage, current, and heat resistance for the best results.

Comparison with Other Connectors

Picking the right connector is important for your device. Knowing how FFC connectors differ from others helps you choose wisely. They are flexible, small, and easy to use.

FFCs vs. FPCs

FFC connectors and Flexible Printed Circuits (FPCs) are alike but have different uses. FFC connectors use flat cables to link parts. FPCs are printed circuits with paths inside a thin, bendable layer. FPCs handle harder signals and last longer. FFC connectors are simpler and cheaper, great for basic links.

FFCs vs. Ribbon Cables

Ribbon cables connect parts with wires in a flat cover. They are useful but not as small as FFC connectors. FFC connectors save space and weigh less. This is helpful for tiny gadgets like phones and smartwatches.

FFCs vs. Traditional Wire Connectors

Traditional wire connectors use single wires to join parts. They are strong but big. FFC connectors are thinner and fit tight spaces better. You can bend and fold them without harm, unlike wire connectors.

Tip: Use FFC connectors for light and bendable connections in your project.

Comparing FFC connectors with others shows why they are special. Their features make them perfect for small and smart designs.

Types of FFCs

Knowing the types of FFC connectors helps you pick the best one. Each type has special features for different uses. Here are three common types:

One-Sided FFC Connectors

One-sided FFC connectors are simple and very popular. They have conductive lines on one side of the cable. This makes them light and easy to use. They work well in small spaces like laptops or cameras.

A good example is the 6893 Series by Kyocera. It makes assembly faster by letting you insert FPC/FFC in one step. This cuts work time by two-thirds, saving money for manufacturers. Its special pin design also removes dirt better, cleaning twice as much as older models.

If your project needs easy and quick connections, one-sided FFC connectors are a great choice.

Double-Sided FFC Connectors

Double-sided FFC connectors have conductive lines on both sides. This makes them more flexible and able to handle harder tasks. They are used in devices needing fast data or strong links, like gaming consoles or medical tools.

These connectors keep signals clear because of their two-sided design. They also bend easily without breaking, making them perfect for foldable cables.

For tough and detailed connections, double-sided FFC connectors are strong and dependable.

Shielded FFC Connectors

Shielded FFC connectors block electromagnetic interference (EMI). They have an extra shield layer to protect signals from outside noise. This makes them great for cars or factory machines with high EMI.

The shield improves signal quality and makes the cable stronger. These connectors are used in high-speed data or sensitive devices like medical tools.

Tip: Use shielded FFC connectors for fast data or EMI-heavy areas.

Market Trends

Different FFC connectors are used in many industries. Common sizes like 0.500 mm, 1.000 mm, and 1.250 mm fit various needs. Electronics, cars, and factories are the main users of these connectors. This shows how useful and important they are today.

By learning about each type, you can choose the right FFC connector. Whether you need simple, flexible, or protected options, there’s one for your project.

Custom FFC Connectors

Custom FFC connectors are made for special needs in unique projects. They let you adjust the design, size, and features to fit perfectly. You can pick pitch size, conductor count, or shielding to match your requirements.

A big benefit of custom FFC connectors is their use in many industries. They work well in different settings and applications, giving dependable results. For example:

How They Are Used | |

|---|---|

Consumer Electronics | Used in phones, tablets, laptops, and wearables for small, strong connections. |

Automotive | Great for car infotainment systems and safety features. They handle high frequencies and resist vibration. |

Industrial Equipment | Help robots and automation systems work smoothly and efficiently. |

Medical Devices | Important for health monitors and diagnostic tools. They are flexible and reliable for critical tasks. |

Custom FFC connectors also let you choose materials and designs for better durability. You can add shielding to block electromagnetic interference (EMI) or pick actuators for easier assembly.

Tip: Think about the environment where the connector will be used. Temperature, vibration, and signal needs can affect the design.

By using custom FFC connectors, you can improve your device’s performance and meet your industry’s demands.

ZIF and NON-ZIF FFC Connectors

ZIF (Zero Insertion Force) and NON-ZIF FFC connectors are two common types. Each has its own advantages for different uses.

ZIF FFC Connectors

ZIF connectors make installation simple and reduce cable wear. They use a lock that needs little force to insert or remove the FFC. This makes them great for devices that need frequent connections, like testing tools or modular gadgets.

These connectors also keep signals strong, even in vibrating environments. Their design protects the FFC during setup, making the connector last longer.

NON-ZIF FFC Connectors

NON-ZIF connectors use friction to hold the FFC in place. They are simpler and often cheaper than ZIF connectors. These are best for devices where the FFC stays connected for a long time without being removed often.

While they are harder to install, NON-ZIF connectors are strong and reliable for fixed connections. They are commonly found in printers, where the FFC stays attached throughout the product’s life.

Note: Choose between ZIF and NON-ZIF connectors based on how often connections change and the precision needed.

Both ZIF and NON-ZIF connectors are important in modern electronics. Knowing their differences helps you pick the right one for your project to ensure great performance and reliability.

Key Specifications of FFC Connectors

Pitch Size

Pitch size is the space between one conductor’s center and the next. It shows how small or large the connector is. Smaller sizes, like 0.5 mm or 1.0 mm, fit tiny gadgets like phones and smartwatches. Bigger sizes, such as 2.54 mm, work well for machines with more room.

When picking an FFC, think about your device’s design. Small pitch sizes fit more conductors in tight spaces. This helps send data faster but needs careful assembly to avoid mistakes.

Tip: Use smaller pitch sizes for compact devices needing fast signals.

Number of Conductors

The number of conductors shows how many signals or power lines the FFC can carry. Complex devices, like laptops, need more conductors. Simple gadgets, like cameras, use fewer conductors.

Most FFC connectors have 4 to 50 conductors or more. Choose based on your device’s needs. More conductors can lower heat dissipation per conductor, which affects performance.

Note: Match the conductor count to your device to avoid overheating or extra complexity.

Current Rating

Current rating is the most current each pin can handle safely. If too much current flows, it can cause overheating or damage.

Manufacturers test current ratings to ensure safety. Heat and conductor resistance affect how much current the connector can handle. More conductors mean less heat per pin, but higher temperatures increase resistance.

Current Rating | Description |

|---|---|

The highest current the connector can handle safely. |

Pick an FFC with a current rating that fits your device’s power needs. Shielded connectors help manage heat in high-power devices.

Tip: For devices needing lots of power, choose connectors with strong heat control for safety.

Temperature Range

The temperature range of FFC connectors is very important. It shows how well the connector works in different conditions. Devices often face extreme heat or cold, so picking the right connector keeps them safe and reliable.

FFC connectors are made to handle various temperatures. For example, the 6274 series works between -40℃ and 85℃, making it great for outdoor or factory use. The 6208 series operates from -30℃ to 85℃, which fits most home electronics.

Series | Operating Temperature Range |

|---|---|

6274 | -40℃ to 85℃ |

6208 | -30℃ to 85℃ |

Think about where your device will be used when choosing a connector. Cold weather can make materials crack, while heat might bend them or mess up signals. Always match the connector’s temperature range to your device’s needs for the best performance.

Tip: Use connectors with wide temperature ranges for tough environments.

Flexibility and Durability

FFC connectors are flexible and strong. These features make them great for devices that move or bend often, like foldable phones or robots.

Tests show how durable FFC connectors are. FlexibleTest’s fixtures can bend 20,000 times without breaking. This is much better than older ZIF connectors, which wear out faster. Flexible Test Connectors also last through 20,000 mate/demate cycles, proving they are built to last.

Durability Highlights:

Survives 20,000 bends without losing function.

Stronger than traditional ZIF connectors.

Handles 20,000 connections/disconnections for long-term use.

FFC connectors keep signals clear even under constant stress. This makes them a top choice for devices where reliability is key.

Note: Check connectors in moving devices often to keep them working well.

Actuator Types and Configurations

Actuators in FFC connectors help secure the cable to the connector. They come in different types and designs for various uses.

The two main actuator types are flip-lock and slide-lock. Flip-lock actuators are simple and quick to use. Slide-lock actuators need sliding to lock, which makes them better for shaky environments.

Actuator Type | Key Features | Best Use Case |

|---|---|---|

Flip-Lock | Easy to use, quick setup | Home electronics |

Slide-Lock | Strong hold, good for vibrations | Cars or factory machines |

Actuators can also be top-entry or side-entry. Top-entry lets cables insert from above, while side-entry allows insertion from the side. These designs make FFC connectors fit different layouts easily.

When picking an actuator, think about how easy it is to install and where the device will be used. Flip-lock actuators are great for fast setups, while slide-lock actuators work better in tough conditions.

Tip: Choose the actuator type based on your device’s assembly and environment.

Advantages of FFCs for Devices

Compact Design

FFC connectors are small and fit tight spaces easily. They are perfect for gadgets like smartphones and tablets. Their flat shape helps save space without losing performance.

Traditional wire connectors are bulky and take up more room. FFCs are thin and neat, making devices look better. If your project needs a slim and light design, FFC connectors are a great choice.

Enhanced Flexibility

FFC connectors can bend and twist without breaking. This makes them ideal for devices that move, like foldable phones or robots. They keep connections strong even with constant motion.

Their flexibility also makes them last longer. They handle repeated bending and folding well, staying reliable over time. This is why they work well in devices needing frequent adjustments.

Tip: Check connectors often in moving devices to keep them working properly.

Cost-Effectiveness

FFC connectors are affordable and easy to install. Their simple design lowers production costs and saves time during assembly. This is helpful for making many devices quickly.

Compared to other connectors like FPCs, FFCs cost less but still work well. They offer good quality at a lower price, making them popular in different industries.

By using FFCs, you get great performance without spending too much money.

Improved Signal Integrity

Signal quality is very important for devices needing steady data transfer. FFC connectors keep signals clear and stable, even in tough conditions. Their design helps avoid problems like skew and crosstalk that can mess up data. Using impedance-matched pairs, they keep signals strong over longer distances. This is useful for gadgets like phones, wearables, and car systems.

Fast systems need good signal quality to work well. FFC connectors, like Hercules® connectors, reduce interference and improve performance. They use precise designs to control skew and crosstalk better. This makes them great for tasks needing quick decisions, like driver assistance in electric cars.

Besides signal clarity, FFC connectors are small and flexible. This makes them fit many devices, from home electronics to factory machines. Whether you’re building a phone or medical tool, these connectors offer the reliability needed for top performance.

Tip: Pick FFC connectors with impedance-matched designs for clear data transfer.

High-Speed Transmission Compatibility

Modern devices need fast data transfer to handle hard tasks quickly. FFC connectors are made for this purpose. They support high-speed data, making them ideal for gaming consoles, laptops, and car infotainment systems.

A big benefit of FFC connectors is their ability to work well at high speeds. Their design lowers electromagnetic interference (EMI) and keeps connections steady. This is key for devices needing quick and accurate data, like medical tools and robots.

Cars also use high-speed FFC connectors. As vehicles switch to electric power and advanced systems, reliable connections become more important. FFC connectors provide the strength and speed needed for these uses.

Note: For fast data devices, choose shielded FFC connectors to reduce EMI and keep signals clear.

FFC connectors have changed how devices are made today. They help create small, powerful, and multi-use gadgets. Their bendable design makes them fit tricky spaces easily. Strong materials make them last longer and keep signals clear. These connectors work well for Industry 4.0, IoT, and 5G systems. They ensure smooth communication in networks. Cars use them because they handle tough conditions and help with self-driving features.

Use FFC connectors to build smarter and faster devices. They are great for electronics, robots, and car systems. Their flexibility makes them very useful. Try FFC connectors to improve your project and discover new ideas in technology.

FAQ

What does an FFC connector do?

An FFC connector joins flat flexible cables to circuit boards. It helps parts in small devices like phones, laptops, and cameras work together.

How are FFC connectors different from FPCs?

FFC connectors and FPCs have different designs and uses. FFCs use flat cables for simple links, while FPCs are printed circuits for harder tasks. FPCs last longer but cost more.

Can FFC connectors transfer data quickly?

Yes, FFC connectors can send data at high speeds. Their design reduces interference, making them great for gaming systems, medical tools, and car devices.

Are FFC connectors good for tough conditions?

FFC connectors can handle harsh environments. Many types resist heat and vibrations, making them dependable for outdoor gear and factory machines.

How do you pick the best FFC connector?

Think about your device’s size, power needs, and where it will be used. Look at details like pitch size, conductor count, and temperature range to find the right one.

See Also

Exploring The Benefits And Drawbacks Of Flex PCBA

Understanding FCT In PCBA And Its Importance

Creating Tailored Android PCBAs For Specific Device Requirements

Enhancing Electronics Performance Through Innovative PCBA Solutions