PCB vs PCBA shows a main difference in electronics. A printed circuit board, or PCB, is the base for connecting parts. Printed circuit board assembly, or PCBA, is the last step. In this step, experts put all parts onto the PCB. Engineers need to know pcb vs pcba to not get confused in design and making. PCBA covers every step after making the pcb. Makers use clear meanings of pcb and pcba to talk clearly.

Key Takeaways

A PCB is just a plain board. It connects parts but cannot work by itself. A PCBA has all the parts put on it. It works as a full device. Making a PCBA needs more steps. It costs more money. This is because you must add parts, solder them, and test the board. Use a PCB for early tests or easy projects. Pick a PCBA if you want something ready to use. It will be a working product. Good design and checking for quality save money. They also help the board work well and last longer. PCBs and PCBAs are used in many fields. You can find them in phones, cars, and medical devices. Each one does a different job.

Printed Circuit Board (PCB)

What is a PCB?

A printed circuit board is found in almost all electronics. This board holds and connects electronic parts. Engineers design each pcb to move electricity using copper lines. These lines join different parts together. The printed circuit board is the base for things like phones, computers, and cars. In 2023, the pcb market was worth $75.85 billion. By 2032, it may reach $117.53 billion. This is because new circuit board types are used more now. High-density interconnect and flexible pcbs are popular. More people use 5G, IoT, and electric cars. This makes more people need good printed circuit boards.

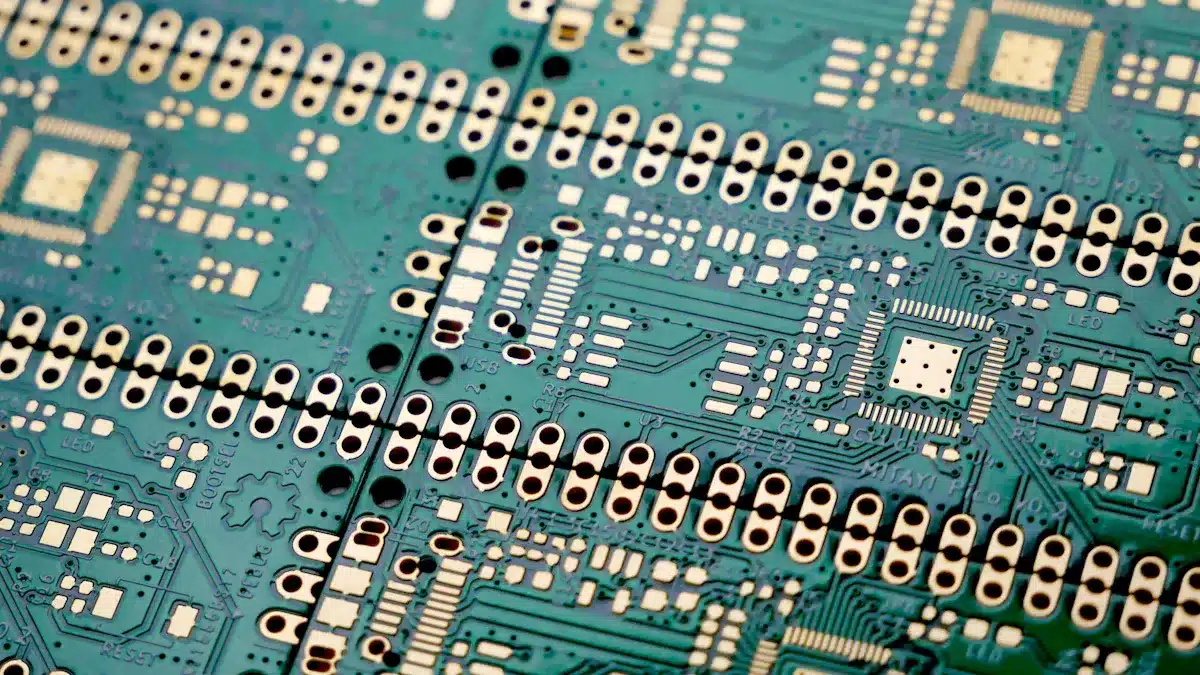

PCB Construction

Making a pcb takes many steps to make it strong and useful. Makers put together layers that conduct and block electricity. Most printed circuit boards use copper and fiberglass layers called FR-4. These layers give strength and stop electricity from leaking. Some pcbs use special stuff like ceramics or metal cores to handle heat better. Makers cut copper to make lines, drill holes, and add coatings to protect the board. Some circuit boards have 14 or even 32 layers. These help make small and fast electronics. The pcb making process follows rules like IPC to keep boards safe and high quality.

Characteristic/Type | Description |

|---|---|

Alternating conductive and insulating layers for strength and function | |

Component Types | Surface-mount and through-hole components |

PCB Types | Single-sided, double-sided, multi-layer, rigid-flex, flex, metal-core, ceramic, HDI |

Materials | FR-4, ceramics, metal cores, PTFE for special needs |

Design Rules | ECAD software ensures manufacturability and reliability |

PCB Role

The printed circuit board is very important in electronics. It connects parts, controls power, and helps with heat. In cars, the board must handle shaking and heat changes. In home gadgets, the pcb helps make things smaller and faster. Makers check pcbs for problems to make sure they work well. Studies show printed circuit boards help with heat, stop signal loss, and lower interference. Some pcb materials can be used again in other things. The printed circuit board helps new ideas in electronics. It is used in smart homes and medical tools.

Printed Circuit Board Assembly (PCBA)

What is PCBA?

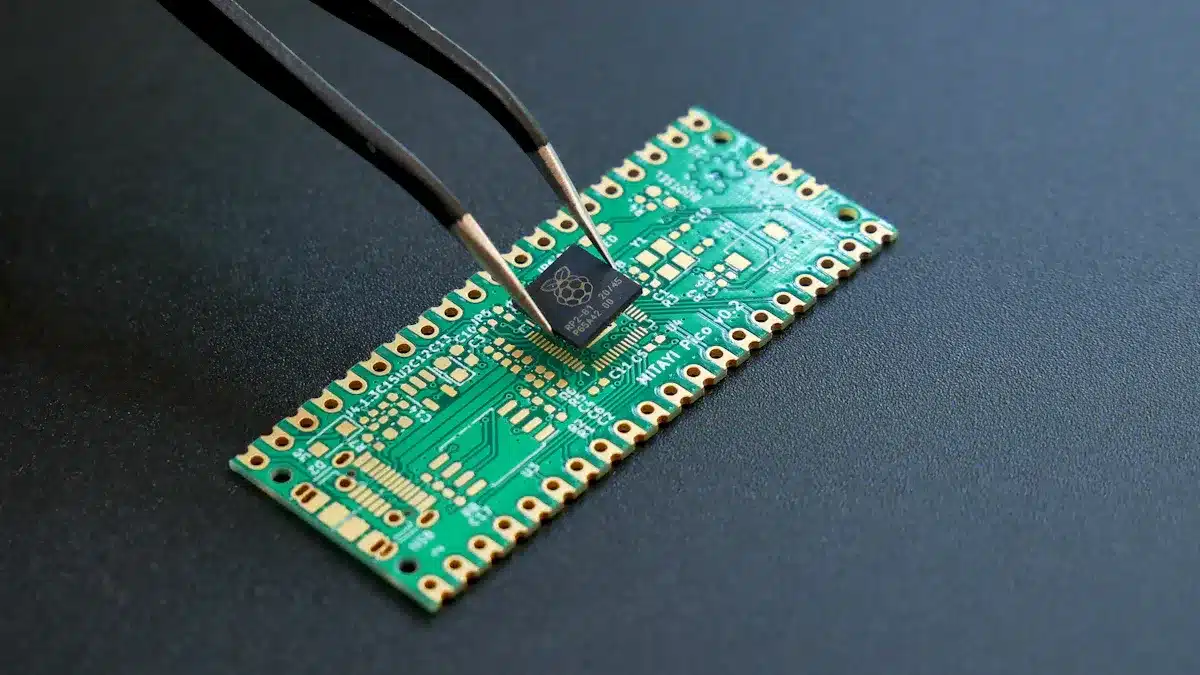

PCBA changes a plain PCB into a working device. In this step, workers put and attach parts onto the board. Rules like IPC-A-610 and J-STD-001 help make sure the work is good. The assembly house uses special machines to finish the job. These machines include printers, mounters, and reflow ovens. Drawings and lists show workers where each part should go. PCBA makes the final product for phones, cars, and medical tools.

Assembly means putting all needed parts on the PCB.

Drawings help workers know where parts belong.

The assembly house has the right tools for good work.

PCBA Process

The pcb assembly process has many careful steps. First, engineers use EDA tools to make a plan. Next, they pick the board’s size and shape. Then, they place parts, draw lines, and make files for building. Machines put surface mount and through-hole parts on the board. Soldering, cleaning, and coating keep the board safe. At the end, tests check for problems and make sure it works.

Make a plan and choose the layout

Place parts and attach them

Clean and coat the board

Use machines to check and test

Note: Good design helps make assembly faster and with fewer mistakes.

PCBA Role

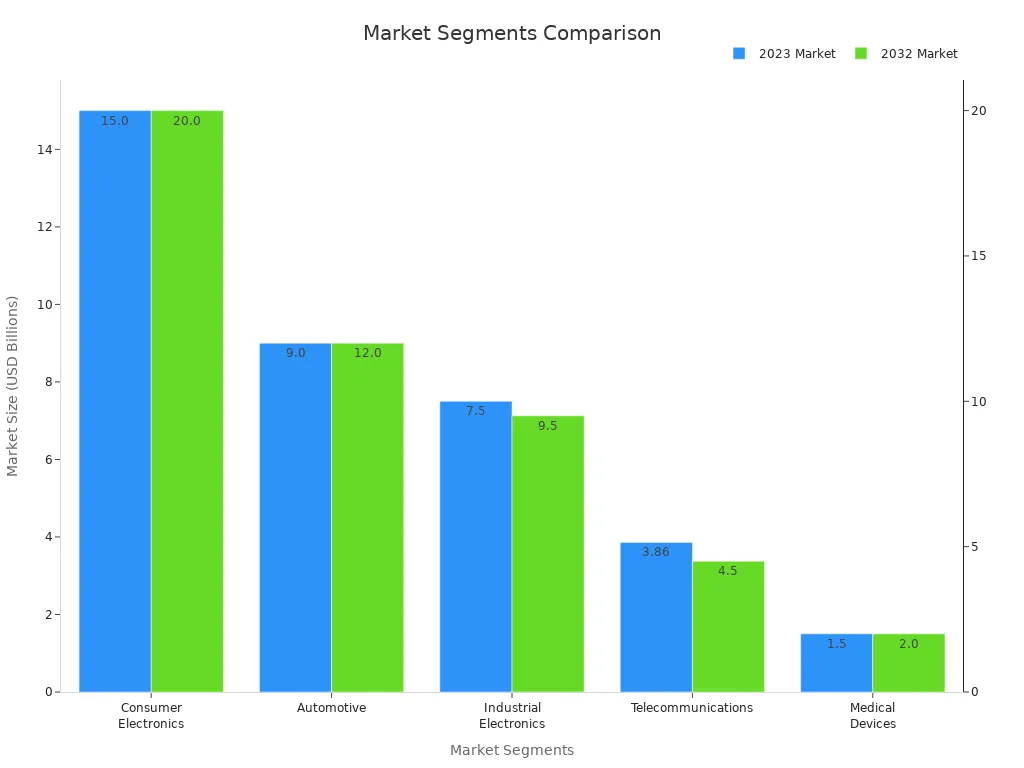

PCBA is very important in today’s electronics. It turns a simple PCB into a finished product. The printed circuit board assembly market is growing quickly. This is because more people want electronics, cars, and medical devices. In 2024, the market was $39.44 billion. By 2034, it may reach $55.33 billion. Cars, especially electric ones, help this growth. Asia-Pacific makes the most because it costs less there.

PCBA makes sure every device is high quality. Checks like AOI and X-ray find problems early. Lists of parts and trusted sellers help keep quality high and costs low. Printed circuit board assembly helps things work well, from smartwatches to medical gear.

PCB vs PCBA: Key Differences

Function

A printed circuit board and a printed circuit board assembly do different jobs. The circuit board is like the bones of a device. It gives shape and lets electricity move around. By itself, a pcb cannot do any work. It just has copper lines and spots for parts. A pcba is different because it has all the parts added. Makers put chips, resistors, and connectors on it. Now, the board can do things like send signals or turn on a device. You can think of a pcb as the frame of a house. The pcba is like a house with furniture and lights. This shows how their jobs are not the same.

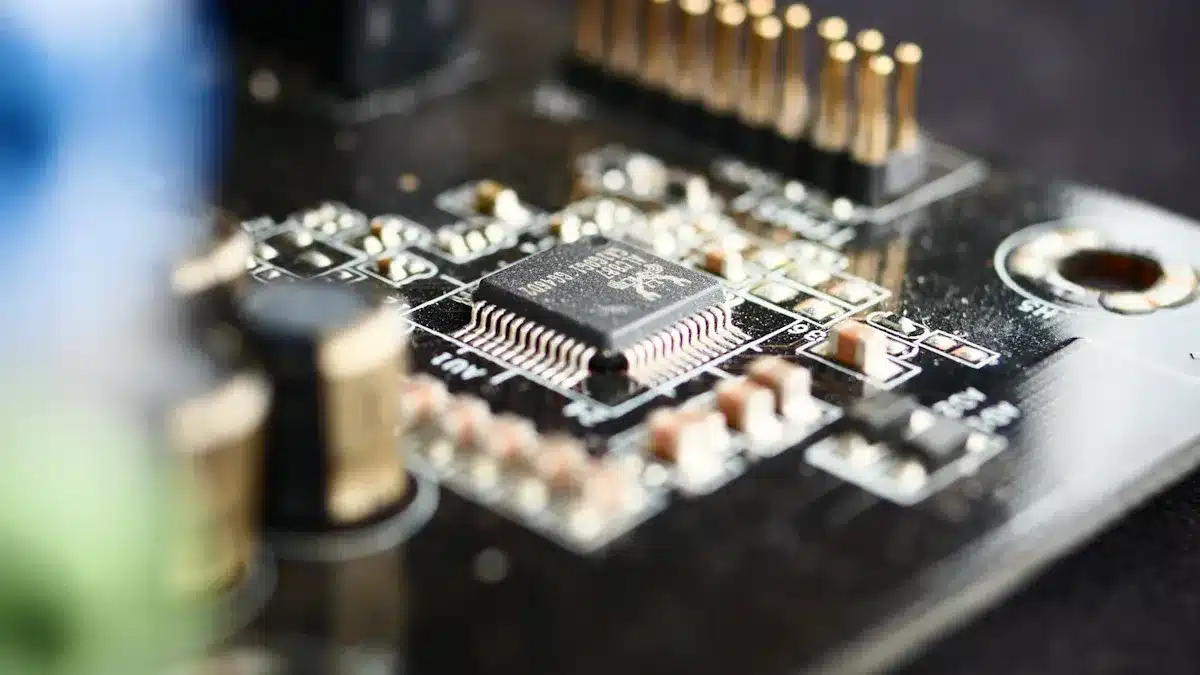

Manufacturing

Making a pcb and making a pcba are not the same. First, the pcb is made by designing it and building it from layers. Machines cut the copper to make paths. Workers add coatings and drill holes. This makes the plain board. For a pcba, more steps are needed. Makers buy all the parts. Machines or people put each part in the right spot. Soldering sticks the parts to the board. Checks like AOI and X-ray help find mistakes. Tests make sure the board works right. Some boards use surface mount or through-hole soldering, which makes things harder. Good assembly helps save money and time. Mistakes in assembly cost more because of fixing and waste. If makers follow good steps, they can make better boards faster. PCB design is about the board’s look. PCBA design adds steps for putting parts on and testing.

Cost

The price of a pcb and a pcba is not the same. A plain board costs less because it uses fewer things and steps. A pcba costs more because it needs extra work and parts. Makers must buy parts, pay for workers or machines, and pay for soldering and tests. Many things change the price of a pcba. The list of parts, setup for machines, and how many boards are made all matter. Making lots of boards makes each one cheaper. Small batches cost more. Fancy features like tiny holes can make boards cost twice as much. Where you make the board also changes the price. For example, making a six-layer pcb in China can save a lot of money compared to the U.S. Using machines can cut worker costs by 15%. But assembly still costs a lot. Tests like in-circuit testing add to the price but help with quality. Using green materials and supply problems can also make prices go up. All these things make pcbas cost more than plain boards.

Application

How people use a pcb and a pcba is also different. Engineers use plain boards for early ideas, testing, and simple things. Examples are calculators, remotes, and special boards for planes or phones. These boards are just the start for more work. A pcba is ready to use in finished things. Makers use pcbas in phones, tablets, car controls, medical tools, and defense gear. The assembly steps make sure each board is good. Tests and checks help find problems before people use the product.

Aspect | Printed Circuit Board (PCB) | Printed Circuit Board Assembly (PCBA) |

|---|---|---|

Bare board with conductive pathways, no components mounted | Fully assembled board with electronic components soldered on | |

Manufacturing Process | Design, substrate prep, etching, protective layers | Component sourcing, placement, soldering, inspection |

Functionality | Framework for circuits, non-functional alone | Functional electronic circuit ready for use |

Cost Implications | Lower cost, raw board | Higher cost due to components and assembly |

Typical Applications | Prototyping, simple devices, complex multi-layer systems | Consumer electronics, automotive, medical, aerospace |

Usage Context Examples | Early development, basic gadgets, high-frequency systems | Finished products needing full functionality |

Tip: Pick a pcb if you are just starting or testing. Choose a pcba when you need something that works right away.

Applications in Electronics

PCB Uses

Engineers use printed circuit boards at many steps in design. When they try new ideas, they use PCBs to test and fix things fast. Some companies can make double-sided boards in eight hours. This helps teams work quickly. PCBs are used for boards with copper pads and for testing circuits. These boards help stop mistakes and let people change designs often. In factories, PCBs are the base for most electronics. You can find them in phones, computers, and home gadgets. PCBs are also used in big machines that need to last a long time and work in hard places.

Common PCB Applications and Characteristics | |

|---|---|

Medical Devices | Imaging systems, monitors, infusion pumps, implants; require high reliability and small size |

LEDs | Lighting, displays; use aluminum substrates for heat management |

Consumer Electronics | Phones, computers, entertainment systems; need small size and high connection density |

Industrial Equipment | Manufacturing tools, power equipment; use thicker boards for durability |

Automotive Components | Control systems, sensors; must endure vibration and temperature extremes |

Aerospace Components | Aircraft, satellites; require lightweight and oxidation-resistant materials |

Maritime Applications | Navigation and control systems; must withstand harsh marine environments |

Safety and Security | Security systems; reliability is critical |

PCBA Uses

Printed circuit board assemblies are needed in finished products. Makers use PCBAs in things that must work right away. PCBAs are found in fridges, coffee makers, and medical tools like heart monitors. In cars, PCBAs help control the engine and keep people safe. Phone and internet companies use PCBAs in routers and switches. Planes and satellites also use PCBAs for power and control. Robots and machines help make PCBAs faster and better. Checks like AOI and X-ray make sure each PCBA is made well.

Industry Examples

Many businesses need both PCBs and PCBAs for their products. For example, engineers use PCBs to test new phone or machine ideas. When the design is ready, they use PCBA for the final product. In hospitals, imaging tools and monitors need special PCBs and careful assembly. Cars need PCBAs that can handle heat and shaking. Planes and satellites need boards that are light and strong. More things use PCBs and PCBAs as tech gets better. Testing PCBAs is very important for safety. Good tests help stop problems and make sure things work right.

Choosing PCB or PCBA

Requirements

Picking a pcb or pcba depends on what the project needs. Engineers must check what kind of assembly is best. Surface Mount Technology is good for small and light boards. It helps make boards faster and saves money. Through Hole is better for strong boards in tough places. Some projects use both ways to build the board. Other things to think about are board size and how many layers it has. The type of material and if it meets safety rules also matter. The table below lists important technical needs:

Technical Requirement Category | Details and Considerations |

|---|---|

PCB Specifications | Board size, layers, material, thickness, copper weight, surface finish, solder mask color |

Design Rules and Constraints | Trace width, spacing, drill sizes, impedance control, critical nets |

Signal and Power Integrity | High-speed signals, analog circuits, power distribution |

Compliance and Regulatory Standards | IPC, UL, RoHS, CE certifications |

Test and Validation Requirements | Verification, in-circuit testing, diagnostics |

Timeline and Milestones | Project deadlines and delivery schedules |

Cost Factors

Cost is very important when making a choice. Reports show that buying parts and prices change the total cost. A pcb costs money for materials, making, and setup. A pcba costs more because it needs parts, workers, and tests. Not enough workers and higher pay can make it cost more. Picking the right design and materials can help save money. Buying more boards at once can lower the price. Companies also check if they will make money back before picking pcb or pcba. Talking with suppliers and smart buying can cut costs even more.

Quality

Good quality makes sure things last a long time. Engineers test boards with heat, cold, shaking, and wetness. They also check how well the board handles power and shocks. Quality checks start from the design and go to the last step. Following strict rules and picking good materials helps make better boards. Machines look for problems early with special tests. A strong system tracks each step and uses numbers to keep getting better. Using good parts and careful work stops problems in hard jobs.

Selection Tips

Experts give tips to help pick the best choice:

Think about where and how the board will be used.

Check how long the product will last and what it needs to do.

Talk with makers about design and how to put it together.

Get parts from trusted places to avoid bad ones.

Be ready to change the design if needed.

Use good ways to connect and lay out the board.

Check if the design is easy to make to stop mistakes and save money.

Use machines to build boards faster and better.

Tip: Always pick the right way and materials for your project. Plan early and talk with suppliers to get the best results.

Knowing the difference between pcb and pcba is very important for electronics projects.

PCB making gives you a board that cannot work yet, but PCBA puts on parts and checks them so the board is ready to use.

PCBA has more steps and costs more because workers must put on parts and check the board.

You should pick pcb or pcba based on your project’s step, how much money you have, and what you need it for. If you want to learn more, you can look at IPC rules, read guides from makers, and talk with experts to make sure your board is good and follows the rules.

FAQ

What is the main difference between PCB and PCBA?

A PCB is just a board with copper lines. A PCBA has all the parts put on it. The PCBA can work in a device, but the PCB cannot.

Can someone use a PCB without assembly?

No, a PCB alone cannot do anything. It needs parts like chips and resistors. The board only works after all the parts are added.

Why does PCBA cost more than PCB?

PCBA costs more because it needs more things. You pay for the board, all the parts, and the work to put them on. Testing also adds to the price.

How do engineers test PCBAs for quality?

Engineers use machines like AOI and X-ray to check the boards. These tools look for missing parts and bad solder spots.

When should a project use only a PCB?

A project uses just a PCB when testing or trying new ideas. The PCB helps engineers check the design before adding all the parts.

See Also

Key Distinctions Between PCB And PCBA In Manufacturing Electronics

Benefits And Obstacles Of Flex PCBA In Contemporary Electronics

The Importance Of Custom PCBA Production In Today’s Electronics

Understanding Functional And Structural Variations Between PCBA And PCB