Top sub PCBA companies like TTM Technologies, Sanmina, Jabil, Flex, and Zhen Ding Technology Group help you make strong electronics every day. Sub pcba is when parts are put onto a printed circuit board. This board is the main part of most electronic devices. If you pick the right sub pcba suppliers, you get better quality, faster work, and new technology. Many top manufacturers have certifications like ISO 9001. They use machines to test boards, which makes checking much faster, up to 70% less time. These things make these suppliers special in the pcba industry.

Company | Market Impact |

|---|---|

TTM Technologies | $2.4B revenue, largest US pcb manufacturer |

Unimicron | Top substrate supplier, 9 years market leader |

Tripod Technology | 2.7% global market share, 7th largest worldwide |

Key Takeaways

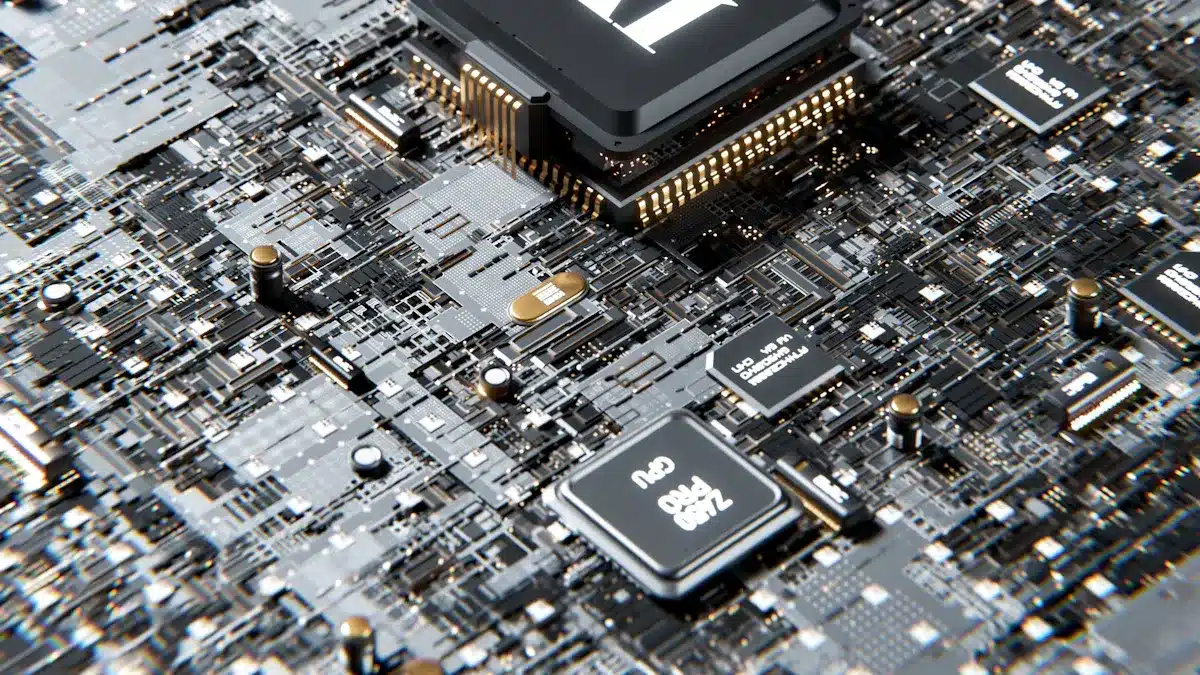

Sub PCBA is putting parts on printed circuit boards. These boards help electronic devices work well and fast.

Top companies like TTM Technologies, Sanmina, and Jabil are leaders. They offer good quality, fast service, and new technology for PCB assembly.

Automation, AI, and IoT are changing PCB assembly. They make production faster, smarter, and more connected.

Picking the right sub PCBA supplier saves time and money. It also makes quality better and helps launch new products quickly.

Making things with green materials cuts waste and pollution. This helps protect the environment while making electronics.

Sub PCBA Overview

What Is Sub PCBA

Sub pcba is found in almost every device you use. It means putting parts onto a printed circuit board. This makes a board that controls your device. First, you start with a pcb. A pcb is a flat board made from fiberglass. Next, you add chips, resistors, and other parts. This step is called pcb assembly. Sub pcba often means smaller or special boards for bigger systems.

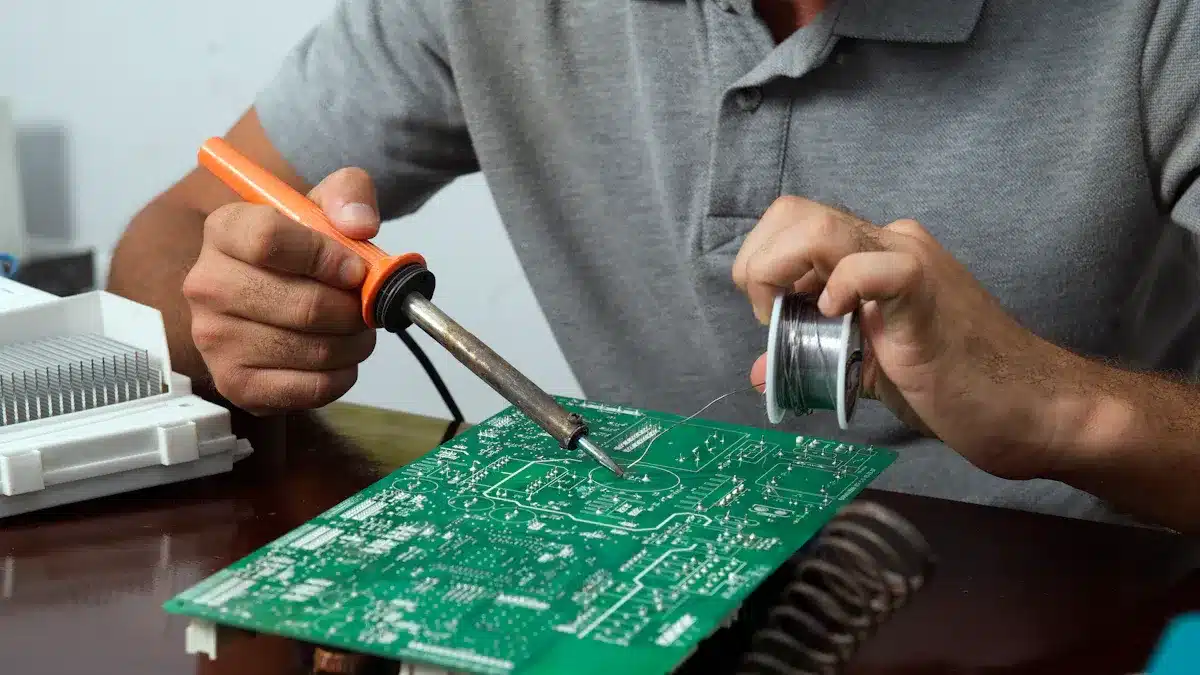

Engineers use prototype circuit board assembly to test new ideas. They check if a design works before making many boards. Sub pcba helps build these test boards fast. In pcba manufacturing, every pcb must work well and meet standards. Companies use machines and tests to check each board.

The market for pcb assembly is getting bigger. Here is a table that shows how large the pcba market is and how fast it grows:

Metric | Value |

|---|---|

$76.9 billion | |

PCBA Market Size (2034) | $129.2 billion |

PCBA CAGR (2024-2034) | ~5.3% |

PCBA Market Volume (2024) | 1.2 billion units |

PCBA Market Volume (2028) | 1.8 billion units |

Largest Segment | Consumer Electronics (45%) |

Second Largest Segment | Automotive Electronics (30%) |

Dominant Region | Asia Pacific |

Key Countries in Asia Pacific | China, Japan, South Korea |

Other Significant Regions | North America, Europe |

Why Sub PCBA Matters

Sub pcba is needed to make modern electronics work. The pcb is like the backbone for all the parts. Good pcb assembly helps your phone, car, or computer work well. Picking the right supplier gives you better quality and faster delivery. This helps you bring new products to market quickly.

Tip: Prototype circuit board assembly lets you test ideas fast and fix problems before making many boards.

In pcb manufacturing, you want to save money and avoid mistakes. Here are some ways sub pcba helps you do that:

Using fewer layers in a pcb lowers the cost.

Picking the right size and shape for your pcb makes it cheaper to build.

Choosing the best surface finish helps with soldering and keeps costs down.

A complete Bill of Materials speeds up quoting and production.

Automation and AI are now important in pcb assembly. These tools help you find problems early and keep machines running. This means fewer mistakes and less downtime. In the automotive industry, you need complex pcb assemblies. Sub pcba helps you meet high standards for performance and cost.

Pcb manufacturing and pcb assembly are key steps for reliable electronics. Sub pcba gives you what you need to stay ahead in a fast-moving market.

Leading Sub PCBA Companies

You should know which companies are top in sub PCBA in 2025. These companies help you make electronics that work well. They give you strong pcb assembly, quick delivery, and new technology. Here is a table to show what each company does best:

Company | Headquarters | Key Strengths | Services Offered | Industry Focus |

|---|---|---|---|---|

TTM Technologies | USA | Large-scale, advanced tech | PCB, PCB assembly, prototyping | Aerospace, Automotive |

Sanmina | USA | End-to-end solutions | PCB, PCBA, EMS, design | Medical, Telecom |

Jabil | USA | Global reach, innovation | PCB, PCBA, EMS, supply chain | Consumer, Automotive |

Flex | Singapore | Flexible manufacturing | PCB, PCBA, EMS, IoT integration | Healthcare, Industrial |

Zhen Ding Technology Group | Taiwan | High-volume, HDI pcb | PCB, PCB assembly, substrates | Mobile, Wearables |

Unimicron | Taiwan | Substrate expertise | PCB, substrates, PCB assembly | Computing, Networking |

Kinwong Electronic | China | Fast turnaround, cost | PCB, PCB assembly, prototyping | Automotive, LED |

Summit Interconnect | USA | Complex, quick-turn pcb | PCB, PCB assembly, prototyping | Defense, Aerospace |

JLC PCB | China | Low-cost, rapid prototyping | PCB, PCB assembly, online orders | Hobbyist, IoT |

STHL PCBA | China | Custom solutions, support | PCB, PCB assembly, EMS | Industrial, Consumer |

Luxshare Precision | China | Integration, connectors | PCB, PCB assembly, cables | Automotive, Mobile |

PCBasic | China | Affordable, small batch | PCB, PCB assembly, prototyping | Startups, Education |

Note: You can use this table to see what each company offers. This helps you pick the best partner for your project.

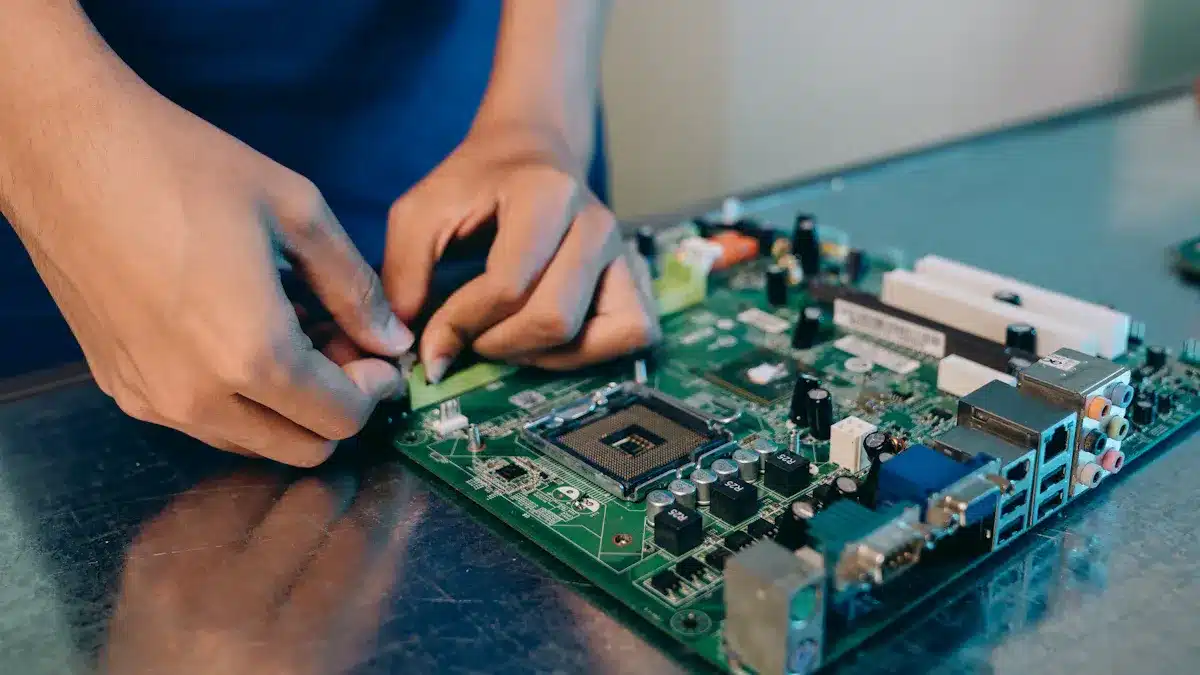

TTM Technologies

TTM Technologies is a leader in pcb and pcb assembly. They are the biggest pcb maker in the US. TTM makes boards for aerospace and cars. They help with hard designs. TTM uses new machines for fast and good work. You can count on them for big or small orders.

Sanmina

Sanmina gives you help from start to finish. They work on design and final assembly. Sanmina helps with medical, telecom, and industry projects. Their pcb assembly is high quality. You get fast shipping and good support. Sanmina is known for its worldwide service and strong supply chain.

Jabil

Jabil helps you launch new products fast. They offer pcb, pcb assembly, and full services. Jabil uses smart factories and robots. You get flexible help for consumer and car electronics. Jabil’s network lets you make more as your business grows.

Flex

Flex gives you flexible pcb assembly and making. You can use them for health, industry, and IoT. Flex helps with design, testing, and big orders. They use digital tools to lower mistakes. Flex also cares about green pcb making.

Zhen Ding Technology Group

Zhen Ding Technology Group is great at high-density pcb and substrates. You can use their boards in phones and wearables. Zhen Ding makes lots of boards quickly. Their pcb assembly works with tiny chips and thin lines. You get good quality for tough electronics.

Unimicron

Unimicron is known for substrate and pcb skills. You can use their boards in computers and networks. Unimicron makes advanced pcb assembly for fast and high-frequency needs. Their research team brings new tech. Unimicron takes both big and small jobs.

Kinwong Electronic

Kinwong Electronic gives you quick and cheap pcb solutions. You can use their pcb assembly for cars, LEDs, and home products. Kinwong is fast and saves you money. Their factories use new machines for good results. You get help with samples and big orders.

Summit Interconnect

Summit Interconnect helps with hard and fast pcb jobs. You can trust them for defense and space electronics. Summit does advanced pcb assembly and testing. Their engineers help fix hard design problems. Summit is a top pick for fast and quality work.

JLC PCB

JLC PCB gives you cheap and quick pcb samples. You can order online and watch your pcb assembly. JLC PCB helps hobbyists, new companies, and IoT makers. Their factories use robots for speed. You get good prices for small or big orders.

STHL PCBA

STHL PCBA gives custom pcb assembly and strong support. You can use them for industry and home electronics. STHL PCBA helps with design, buying parts, and testing. Their team works with you for special needs. You get good quality and flexible help.

Luxshare Precision

Luxshare Precision is a leader in pcb and connector solutions. You can use their products in cars and phones. Luxshare makes advanced pcb assembly and cables. Their focus on integration saves space and boosts performance. Luxshare helps with big and custom jobs.

PCBasic

PCBasic gives you cheap pcb and pcb assembly for small orders. You can use them for school, new ideas, and samples. PCBasic lets you order online and get fast shipping. Their team helps with design and tech questions. You get good value and support for new projects.

Tip: Pick a sub PCBA partner with strengths that fit your needs. Use this guide to compare and find the best company.

PCBA Industry Trends 2025

Automation and AI

Automation and artificial intelligence are changing electronics. In 2025, factories use more robots and smart tools. These help make pcb and pcb assembly faster and better. Asia and the Pacific are leading this change. AI spending there may reach $175 billion by 2028. Companies use AI platforms to control design, testing, and making products. This helps find problems early and fix them fast.

The AI server pcb market grows about 12% each year from 2025 to 2033.

High-performance computing and AI need better pcb designs.

The US, China, Japan, South Korea, and Taiwan lead the market.

Factories use more 24-layer and 28-layer pcb for AI work.

Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

2023 | 2.44 | N/A |

2024 | 2.53 | 3.82 |

2032 | 3.42 | N/A |

These changes help you get faster and smarter pcb assembly. Your products also become more reliable.

IoT Integration

More devices connect to the internet every year. This is called the Internet of Things (IoT). Your phone, car, and fridge can now talk to each other. Each device needs small and strong pcb to work. Companies make pcb that fit tiny spaces and use less power. IoT makes you use new materials and layouts in pcb assembly. You see more sensors and wireless chips on each board. This lets your devices share data all the time.

Tip: Ask your pcba partner if they have IoT experience. This helps your products stay smart and connected.

Sustainable Manufacturing

You care about the planet, and so do many companies. In 2025, more factories use green materials and recycle old pcb. New boards use banana fiber and biodegradable resin. These meet strict rules. Some companies add special nanoparticles to make pcb stronger and safer. These changes help you cut waste and pollution.

Aspect | Evidence Summary |

|---|---|

Sustainable Material Development | Banana fiber and biodegradable resin are used as PCB substrate. They meet IPC 4101 A/24 standards. |

Mechanical & Thermal Properties | Special nanoparticles make pcb stronger and safer from fire. |

Electrical Performance | A test board with a rectifier circuit works well for low-power use. |

Environmental Impact | Old pcb are 42% of e-waste. New materials help lower this number. |

Circular Economy Alignment | Recycling saves rare metals and helps the earth. |

Empirical Validation | Tests show green pcb can replace plastic boards. |

You help the earth by picking suppliers who use these new ways. Green pcb assembly means less e-waste and a cleaner world.

Choosing a Sub PCBA Partner

Matching Capabilities to Needs

You want your project to do well, so you need a supplier who fits your needs. First, think about what your project needs most. Some projects need high-quality pcb assembly for things like medical devices. Other projects need fast pcb production for gadgets people use every day. If you pick a supplier with the right skills, you save both time and money.

Here is a table that shows how top companies got better results by matching what they can do to what their projects needed:

Company | Challenges | Solutions Implemented | Results / Numerical Improvements |

|---|---|---|---|

Boeing | Reduce assembly time and waste | Automation and lean manufacturing | 25% less assembly time, less waste |

Intel | Boost chip performance and efficiency | Advanced fabrication and automation | More powerful, energy-efficient chips |

Samsung | Need for speed and precision | Smart Factory with AI and IoT | Faster production, better quality, lower costs |

Caterpillar | Variable demand and cost reduction | Automation, IoT, machine learning | More agility, lower labor costs, better safety |

When you match what your supplier does best to your project, you get better results. You also avoid delays and expensive mistakes. Top suppliers use machines, smart tools, and strong checks for quality. This helps you get good pcb assembly every time.

Supplier Evaluation Tips

You need to check each supplier before you choose one. Look at their size, where they are, and what people say about them. Make sure they have worked in your industry before. Ask if they have certifications like ISO 9001, and see if they support your type of pcb.

Use these key things to compare suppliers:

Defect density: Check how often problems happen in their pcb assembly.

Rate of return: See how many products customers send back.

Right first time percentage: Find out how often they get it right the first time.

Machine downtime rate: Learn how much time their machines are not working.

Planned maintenance percentage: Ask about how often they do machine care.

Unit costs: Compare how much it costs to make each pcb.

You should also check your suppliers by doing audits. Use trusted sources and customer reviews to see if their claims are true. Regular audits help you know if a supplier keeps up with quality and follows the rules. Top suppliers help you come up with new ideas, improve quality, and work better. When you pick the right partner, you get reliable pcb assembly and strong support for your business.

You learned that companies like TTM Technologies, Sanmina, and Jabil are leaders. They give great service and use new technology. Picking the best supplier changes how good your project is. It also affects how much it costs and how fast you get it. Research shows working with suppliers closely gives better results. It also helps your business get bigger. Find partners who have the right skills and certifications for your field. Make sure they can support your needs. Use the chart in this guide to help you choose wisely and make better electronics.

FAQ

What does “sub PCBA” mean?

You find “sub PCBA” when companies make small or special circuit boards. These boards go inside bigger systems. They help your devices work by linking and controlling parts.

How do you choose the best sub PCBA supplier?

You want a supplier with good quality, quick delivery, and helpful support. Look at their certifications and what customers say. Make sure they have done your kind of project before.

Why do certifications like ISO 9001 matter?

Certifications mean a company follows strict rules for quality. This gives you safer and more dependable products. Many top suppliers have these certifications.

Can you order small batches from top sub PCBA companies?

Yes, you can order small batches from many top companies. They offer small batch or prototype services. This lets you try new ideas before making lots of boards.

What trends should you watch in PCBA for 2025?

Look for more robots, smarter factories, and eco-friendly materials. These trends help you get electronics that are better, faster, and safer.

See Also

The Role Of PCBA In Advancing Modern Electronics

The Significance Of Custom PCBA In Electronics Today

Why PCBA Production Skills Are Vital For Electronics Design

Factors Behind China’s Dominance In PCBA Contract Manufacturing