Printed circuit boards have a few main types. These are single-sided, double-sided, and multilayer designs. These types are important in electronics. You can find a pc board in almost every device. They are in things like remote-control toys and medical equipment. The table below shows how each type is used in the market:

PCB Type | Market Share / Volume Status | Key Applications / Drivers | Market Share Percentage / Projection |

|---|---|---|---|

Standard Multilayer PCBs | Largest market share | Telecommunications, automotive, consumer electronics | Biggest market share (exact % not specified) |

Rigid 1-2 sided PCBs | Largest segment by volume | Servers, desktops, industrial systems | Largest by volume (exact % not specified) |

HDI/Micro-via/Build-up PCBs | Fastest growth anticipated | Wearables, smartphones, IoT, 5G applications | Rapid growth (exact % not specified) |

Flexible PCBs | Expected highest market share growth | Foldable devices, medical wearables, IoT modules | Growing rapidly (exact % not specified) |

Rigid-Flex PCBs | Combined with flexible PCBs, >16% of sales by 2025 | Wearables, medical implants, foldable smartphones, aerospace | Projected >16% of worldwide PCB sales by 2025 |

Recent data shows printed circuit boards are very important in cars. Double-sided types are the most used in this area. They made up over 36% of global revenue in 2023. By learning about these types, you can understand the technology in many products.

Key Takeaways

Printed circuit boards have three main types. These are single-sided, double-sided, and multi-layer. Each type is used for different things in electronics.

Single-sided PCBs are easy to make and cost less. They work well in simple things like remote controls and calculators.

Double-sided PCBs can hold more parts. They let you make more complex circuits. People use them in TVs, cars, and medical machines.

Multi-layer PCBs have many layers stacked together. They are used in advanced things like smartphones, airplanes, and servers. They give strong signals and save space.

Picking the right PCB depends on what the device needs. You also need to think about the materials and where it will be used. This helps the device work well and last longer.

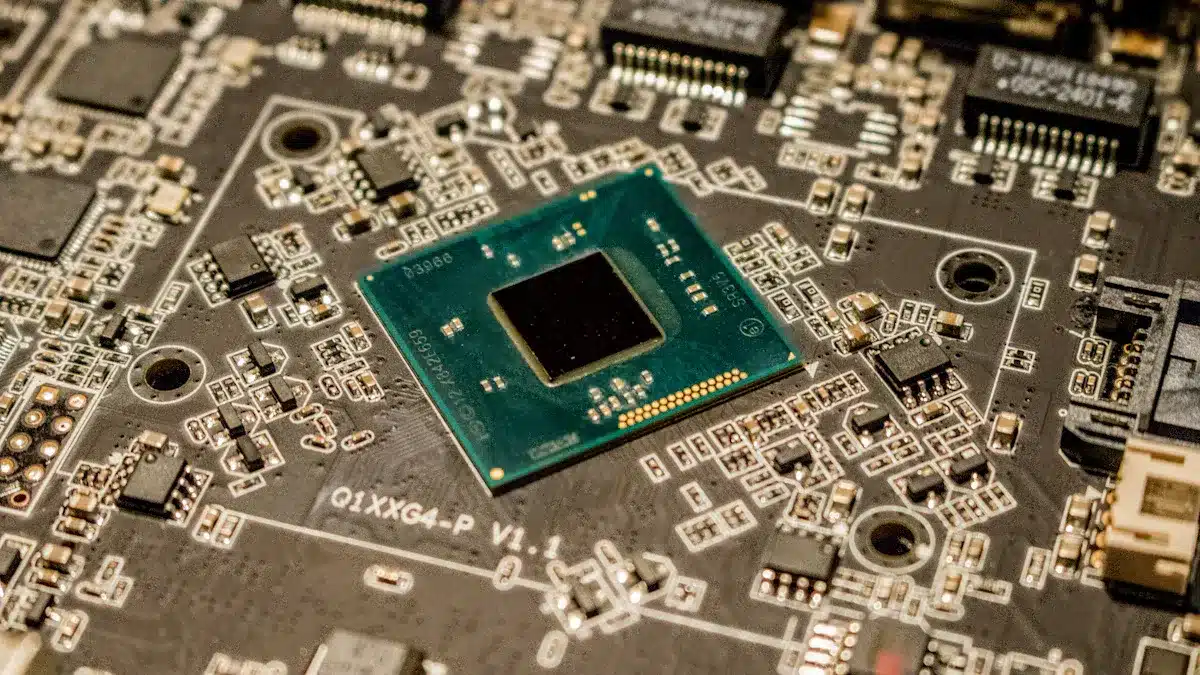

Types of printed circuit boards

Printed circuit boards have a few main types. Each type is built in a special way and has its own job. Knowing about these types helps you see why devices work as they do. The three most used types are single-sided, double-sided, and multi-layer pcbs.

Single-sided pc board

A single-sided pc board has copper only on one side. All the parts go on the same side as the copper. This type is the easiest to make. It is good for simple circuits that do not need many paths.

You can think of a single-sided pc board like a one-way street. All the signals move in one direction. There are no bridges or tunnels to cross.

Key features of single-sided pcbs:

One copper layer only

Parts and copper on one side

Simple and cheap to make

Easy to fix and check

Common uses for single-sided pcbs include:

Radios and simple home gadgets

Power supplies and battery chargers

LED lights

Basic car systems like dashboard lights

Single-sided pcbs are good for products that need easy, steady circuits. Companies pick this type for quick and cheap making.

Double-sided pcb

A double-sided pcb has copper on both the top and bottom. Parts can go on either side. This type uses small holes called vias to link the two sides. Double-sided pcbs let you make more complex circuits and fit in more parts.

A double-sided pcb is like a two-story building. Signals can move between floors using stairs called vias. This makes it easier to fit more rooms in the same space.

Comparison Table: Single-sided vs. Double-sided PCBs

Characteristic | Single-Sided PCBs | Double-Sided PCBs |

|---|---|---|

Conductive copper layer | Only on one side of the board | On both top and bottom sides |

Component placement | Components and copper on one side only | Components and copper on both sides |

Circuit complexity | Suitable for simple, low-density circuits | Suitable for complex, high-density circuits |

Manufacturing cost | Lower cost | Higher cost |

Manufacturing speed | Faster, suitable for large volume production | Slower, lower volume production |

Space efficiency | Occupies more space | Meets space constraints |

Circuit routing flexibility | Less flexible, no overlapping traces | More flexible, traces can overlap and intersect |

Troubleshooting and repair | Easier to troubleshoot and repair | More difficult to troubleshoot and repair |

Inter-layer connections | Not applicable | Uses vias to connect top and bottom layers |

Mounting technologies | N/A | Supports through-hole and surface mount technologies |

Benefits of double-sided pcbs:

More parts can fit on the board

Easier to make tricky paths

Good for hard circuit designs

Better signal quality

Smaller board for the same job

Double-sided pcbs appear in:

Audio gear, printers, and home gadgets

LED lights and power circuits

Car control systems and engine parts

Routers, switches, and network tools

Medical machines like patient monitors

Double-sided pcbs help engineers put more features in small devices. They let you make better designs and get stronger signals.

Multi-layer printed circuit boards

Multi-layer pcbs have three or more copper layers stacked up. Layers are kept apart by special material. Vias link the layers so signals can move between them. Multi-layer pcbs are used for the hardest designs and the most parts.

Multi-layer pcbs are like a tall building. Each floor holds different circuits. Elevators called vias let signals move between floors. This saves space and lets you do more in a small area.

Manufacturing Comparison Table

PCB Type | Manufacturing Complexity | Manufacturing Cost | Key Manufacturing Processes | Typical Applications / Examples |

|---|---|---|---|---|

Single-Sided | Simplest; copper on one side only | Lowest | Copper layer on one side, solder mask, silkscreen | Cameras, audio equipment, power supplies, printers |

Double-Sided | Moderate; copper on both sides, drilling vias | Higher than single-sided | Copper on both sides, drilling and plating vias | LED lighting, vending machines, car dashboards |

Multi-layer | Most complex; 3+ copper layers laminated | Highest | Multiple copper layers laminated with prepreg, hot press curing | Smartphones, fiber optics, scientific equipment |

Why use multi-layer pcbs?

They let you make tiny paths and use microvias.

They keep signals strong in fast circuits.

They help control heat in small spaces.

They let you put more features in smaller devices.

Multi-layer pcbs are essential in:

Smartphones and smartwatches

Car electronics, especially electric cars

Airplane systems and avionics

Servers, motherboards, and computer parts

Telecom gear and outdoor towers

Factory controls and machines

Medical tools like X-ray machines and heart monitors

Military and defense electronics

Multi-layer pcbs are needed for today’s electronics. They mix small size, strong performance, and dependability. As devices get smarter and smaller, multi-layer pcbs become even more important.

Note: Multi-layer pcbs can have 8–12 layers or more in high-tech products. This design is good for hard circuits and fast signals.

Summary Table: Types of Printed Circuit Boards

Type | Layers | Complexity | Typical Uses |

|---|---|---|---|

Single-sided | 1 | Simple | Calculators, remote controls, LED lights |

Double-sided | 2 | Moderate | TVs, printers, automotive, networking |

Multi-layer | 3 or more | High | Smartphones, aerospace, medical, computers |

Each type of printed circuit board has its own job. The choice depends on what the device needs, how hard the design is, and how well signals must work. By learning about these types, you can better understand the tech inside everyday electronics.

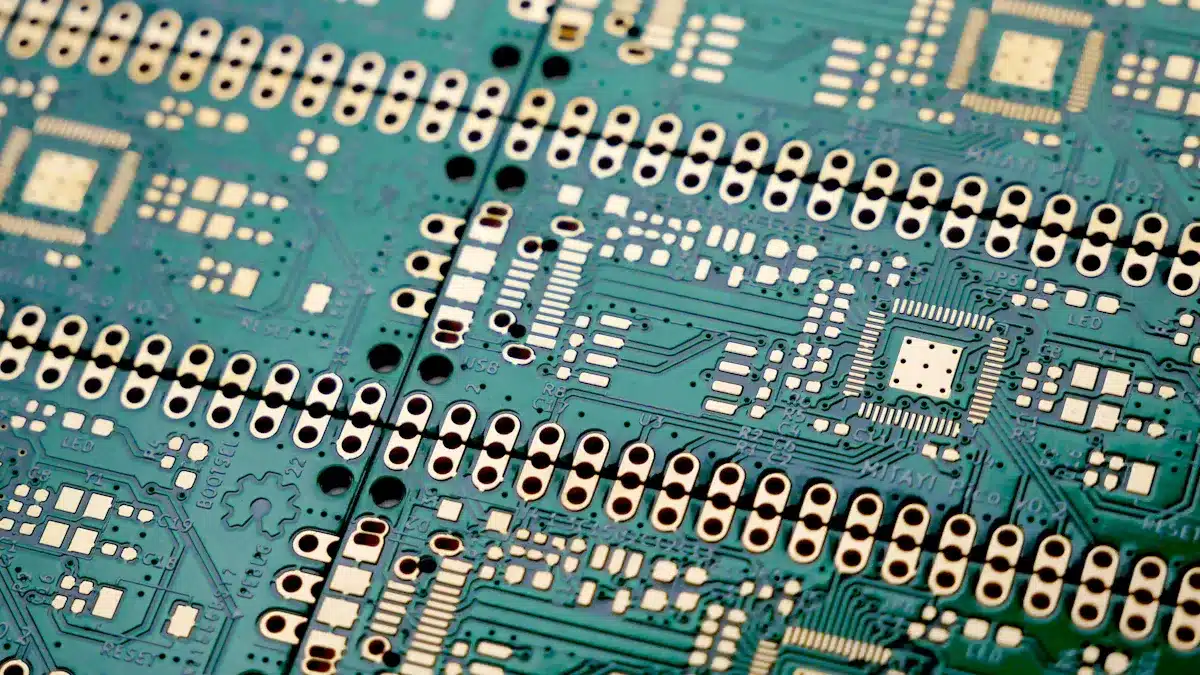

PC board materials

Common materials

PCB manufacturing uses different special materials. Each one gives the board certain strengths. Most PCBs have copper, resin, and glass fabric. Copper makes the paths for electricity. Resin holds the board together. It also affects how the board handles heat and electricity. Glass fabric makes the board strong. It helps the board keep its shape.

Tip: Using the right materials helps a pcb last longer. It also helps it work well in tough places.

Here is a table with some common materials and their main properties:

Material | Typical Properties |

|---|---|

FR4 (Fiberglass-Epoxy Laminate) | Flame-resistant, strong, good electrical insulation, moisture resistant, affordable, heat resistant up to 150°C or more |

Aluminum | Great for spreading heat, slow to expand, works well at high temperatures (up to 350°C) |

Polyimide (PI) | Handles high heat, resists chemicals, keeps electrical signals strong |

PTFE (Teflon) | Flexible, stable in temperature, low signal loss |

Flex-Rigid Substrates | Mix of flexible and stiff layers, used in devices that bend or twist |

FR4 is used a lot because it is cheap and works well. Polyimide and PTFE are chosen for special boards. These boards need to handle heat or bend.

Material impact on applications

The material you pick changes how a pcb works. Some, like high-temperature FR4 and polyimide, help a pcb survive heat. These materials stop the board from breaking when it gets hot. Aluminum-backed boards spread heat fast. This keeps parts from getting too hot.

A pcb made with strong materials lasts longer. Polyimide and ceramic boards can take very high heat. They are used in cars and airplanes. PTFE boards keep signals clear. This is important in fast computers and phones. If a pcb uses weak materials, it might crack or stop working. This can happen when the weather changes or the board faces stress.

Note: Good pcb design helps with heat too. Putting parts in the right places and using extra copper can keep the board cool.

Rigid and flexible pcb

Rigid pcb features

Rigid pcbs are hard and do not bend. They keep their shape all the time. This makes them strong and dependable for electronics. Rigid pcbs have layers of copper and fiberglass pressed together. These boards can hold heavy parts and give a steady base for circuits. Many electronics use rigid pcbs because they last long and protect inside parts.

Rigid pcbs are like a backbone. They keep everything in place and keep connections safe.

Some common uses for rigid pcbs are:

Smartphones and gaming consoles

Computer motherboards

Toys and electronic gadgets

Solid-state drives

Multilayer rigid pcbs link main parts like the CPU, GPU, and RAM in computers. These boards help devices work well and do hard jobs.

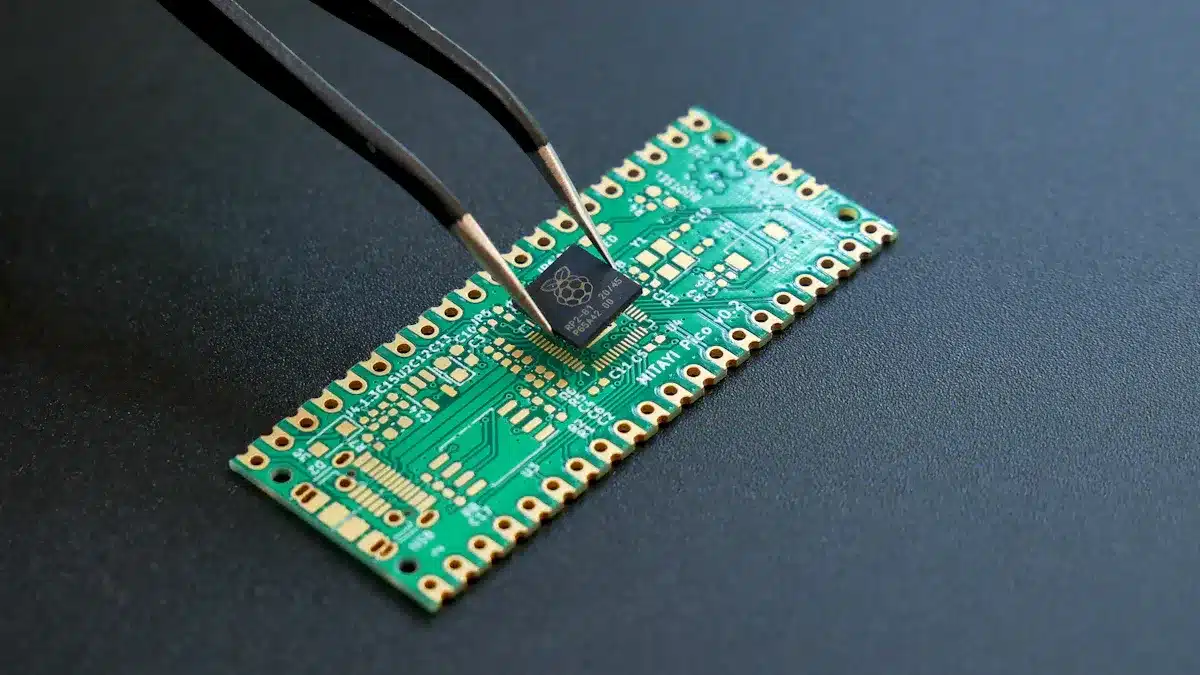

Flexible pcb features

Flexible pcbs can bend, twist, and fold without breaking. They use thin copper and special plastic films. This lets them fit into small or odd spaces. Flexible pcbs save space and make things lighter, which is good for new electronics. They also work better by needing fewer connectors and wires.

Flexible pcbs move with the device. They can handle shock and shaking, so they are great for things that need to bend. These boards help make devices smaller and lighter but still work well.

Flexible pcbs are important in:

Wearable technology like fitness trackers and smartwatches

Small medical devices and implants

Foldable phones and tablets

Cameras and hearing aids

Applications

Rigid and flexible pcbs do different jobs in electronics. Rigid boards are best for things that need to be strong and steady. Flexible pcbs are best for things that need to bend or fit in tight spots.

PCB Type | Typical Applications |

|---|---|

Rigid | Laptops, smartphones, gaming consoles, toys, SSDs |

Flexible | Wearables, medical devices, automotive electronics, cameras |

Flexible pcbs are used in many fields. Medical tools, car electronics, and telecom devices use flexible boards. Wearable tech needs flexible pcbs for comfort and strength. As devices get smaller and smarter, flexible pcbs are even more needed.

Note: Flexible pcbs first replaced big wire bundles. Now, trends like IoT and making things smaller mean they are used in many new ways.

Rigid-flex printed circuit boards

Structure

Rigid-flex pcbs have both stiff and bendable parts in one board. The stiff parts make the board strong and steady. The bendable parts let the board twist or fold. This helps engineers put circuits in small or odd spaces. Rigid-flex pcbs use layers of stiff fiberglass and bendy plastic. The bendy layers link the stiff parts together. This lets the board move without breaking. You do not need as many extra cables or connectors with this design.

Rigid-flex pcbs are like a mix of strong and bendy boards. They keep circuits safe but still let them move.

Applications

Rigid-flex pcbs are used in many high-tech devices. These boards work well when space is tight and things move a lot. Aerospace engineers use them in satellites and planes. The boards can handle shaking and fit in small spots. Medical devices, like pacemakers and hearing aids, use rigid-flex pcbs. These boards are tiny and can bend. Wearable tech, such as smartwatches and fitness bands, also uses them. The boards help these devices stay light and comfy.

Some common uses for rigid-flex pcbs are:

Controls and navigation in airplanes and space

Medical implants and test tools

Wearable gadgets and smart clothes

Military gear and radios

Cameras and small portable devices

Application Area | Why Use Rigid-Flex PCBs? |

|---|---|

Aerospace | Handles shaking, fits in small places |

Medical | Tiny, bends, safe for the body |

Wearables | Light, bends when you move |

Military | Strong, works in tough places |

Consumer Tech | Fits odd shapes, needs fewer connectors |

Rigid-flex pcbs help make things smaller, lighter, and stronger. These boards let new tech ideas use both stiff and bendy pcbs together.

Specialized pcb types

Printed circuit boards come in many kinds. Some have special features for certain jobs. These boards help devices work better in hard or advanced places.

High-frequency pcb

High-frequency pcbs move signals very fast. They use special materials to keep signals strong and clear. The design stops signals from getting weak or mixed up. Many multi-layer pcbs use high-frequency designs for fast data. These types are needed in things that send or get signals quickly.

High-frequency pcbs are used in 5G networks, radar, and RF equipment. They help cell towers, satellites, and routers send signals fast.

Engineers choose high-frequency pcbs when they need clear, quick signals. These boards keep signals steady, even at high speeds.

Aluminum-backed pcb

Aluminum-backed pcbs have a layer of aluminum under the board. This metal moves heat away from the parts. These boards help keep things cool and safe. Aluminum-backed pcbs work well where heat can hurt the board or signal.

Many LED lights, power supplies, and car electronics use aluminum-backed pcbs. These need strong boards that can handle heat.

Aluminum-backed pcbs also help keep signals steady. The metal base keeps things cool, so signals stay clear. Some multi-layer pcbs use aluminum to control heat in small spaces.

Specialized applications

Some jobs need special pcb types. These types fix problems like heat, space, or weak signals. The table below shows how each type helps with special needs:

PCB Type | Applications | Why Use This Type? |

|---|---|---|

High-frequency | 5G networks, RF equipment, radar, telecom | Keeps signals strong and fast; supports high-speed data |

Aluminum-backed | LED lighting, automotive electronics, power supplies | Moves heat away; protects signals; works in hot places |

Multi-layer pcbs | Smartphones, servers, advanced computing | Handles many signals; fits in small spaces; good for hard jobs |

Flexible | Wearables, tablets, car dashboards | Bends and twists; fits in tight spots; keeps signals steady |

Rigid-flex | Aerospace, medical devices, military gear | Mixes stiff and bendy layers; saves space; keeps signals safe in tough places |

Many advanced jobs use multi-layer pcbs to handle lots of signals. High-frequency and aluminum-backed types help devices work in special places. These boards keep signals strong, even when the job is hard.

Choosing the right pc board

Application needs

Picking the right printed circuit board starts with knowing what the product needs. Each device needs a certain size, level of complexity, and performance. Some things only need simple circuits. Others need more advanced features. For example, a remote control uses a single-sided board. A smartphone needs a multi-layer board to handle many signals in a small space.

Engineers think about many things before they choose a pcb design. They look at how much space there is. They check how many parts the board must hold. They also think about how strong the signal should be. Flexible boards are good for wearables and foldable devices. These boards can bend and fit into small spaces. Rigid boards are strong and work well in computers and TVs. Rigid-flex boards mix both features. These are used when a product needs to save space and move.

The table below lists important things to think about when picking a board:

Factor Category | Details | Examples / Notes |

|---|---|---|

Different constructions for different applications | Single-sided (simple), Double-sided (medium), Multi-layer (complex), Rigid, Flexible, Rigid-Flex | |

Materials Used | Materials affect heat, strength, and signal quality | FR-4 (common), Polyimide (flexible), Rogers (high-frequency), Aluminum (heat) |

Cost Considerations | Balance between quality and price | Higher quality improves performance and reliability |

PCB manufacturing teams use these things to match the board to the product. Good pcb design helps the device work well and last longer.

Environmental factors

Where a device is used changes what board you need. Temperature, humidity, and vibration can affect how a board works. High temperatures make materials grow bigger. This can cause cracks or bending. Humidity lets water get into the board. This can weaken signals and cause rust. Vibration can shake parts loose or make small cracks.

Temperature changes can make the board grow or shrink, which can cause damage.

Humidity can cause rust and make signals weaker.

Vibration can break solder joints or traces.

Engineers pick materials and designs to protect against these problems. Polyimide boards can handle heat and water. This makes them good for cars and airplanes. Aluminum-backed boards help move heat away in LED lights. Careful pcb design and making keep signals strong and devices working, even in tough places.

Tip: Picking the right board for the job and place helps electronics work better and last longer.

Printed circuit boards are very important in today’s electronics. You can find them in things like toys, cell phones, and medical devices. People can tell the type of printed circuit board by counting the layers or seeing where the parts are placed. Sometimes, you can also read the silkscreen labels to help. Printed circuit boards started out simple, with just flat paths for electricity. Now, they have many layers and are much more complex. This change has helped companies make better products and smaller, smarter devices.

How to tell PCB types in devices:

Single-sided: parts are only on one side

Double-sided: parts are on both sides

Multi-layer: has more than two copper layers inside

When you learn about printed circuit boards, you can see how important they are in things you use every day.

FAQ

What does PCB stand for?

PCB stands for “Printed Circuit Board.” People use PCBs to connect electronic parts in almost every device, from toys to computers.

Why do some PCBs bend while others stay stiff?

Flexible PCBs use special plastic films. These films let the board bend and twist. Rigid PCBs use hard fiberglass, so they stay stiff and strong.

How can someone tell if a PCB is single-sided or double-sided?

Look for copper traces and parts. A single-sided PCB has them only on one side. A double-sided PCB has traces and parts on both sides.

Where do engineers use aluminum-backed PCBs?

Application | Reason for Use |

|---|---|

LED lighting | Moves heat away quickly |

Car electronics | Handles high heat |

Power supplies | Keeps parts cool |

Aluminum-backed PCBs help devices stay cool and safe.

See Also

Essential PCBA Parts And Their Primary Functions Explained

The Functionality Of PCBA Motherboards And Their Importance

Exploring The Applications Of PCBA In Consumer Devices

Defining PCBA And Its Major Uses Within Electronics Industry