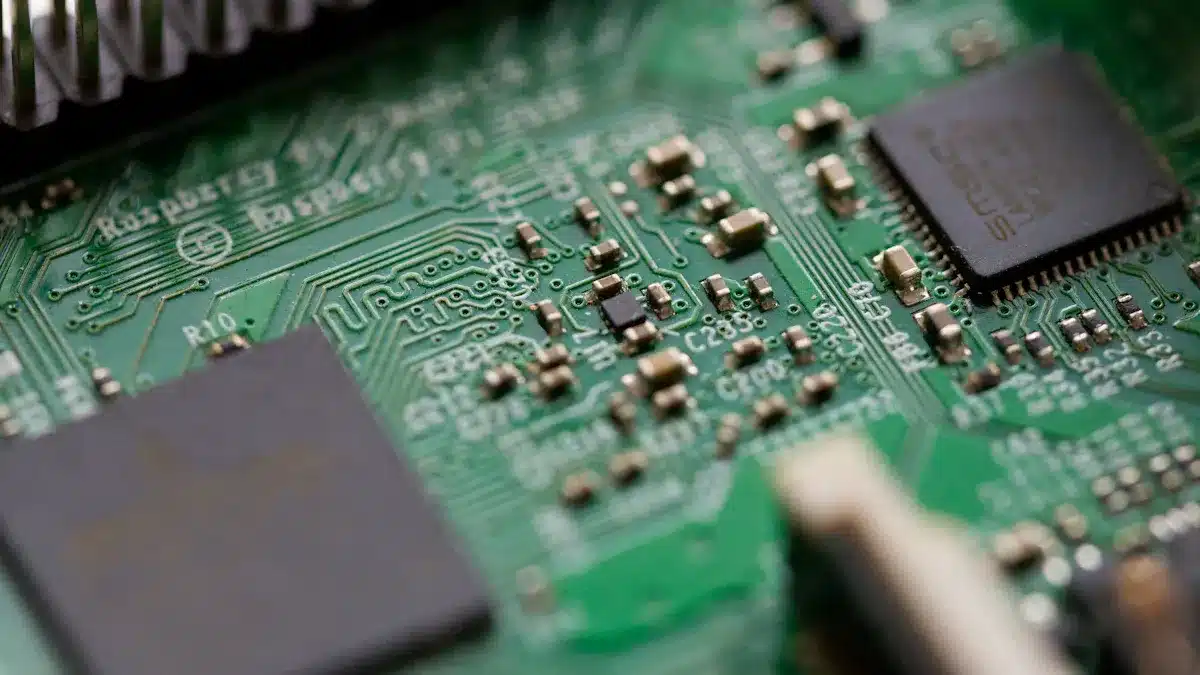

You might wonder, whats pcb and why it’s so important. A pcb, or printed circuit board, is used whenever you operate modern electronics. Its main job is to hold and connect all the electronic parts in your device so they can work together seamlessly. New advancements like surface mount technology, high-density interconnects, and flexible pcbs allow engineers to pack more features into smaller spaces. These innovations make smartphones, medical tools, and cars smaller, stronger, and more efficient. So, whats pcb? It’s the quiet helper that keeps everything running smoothly.

Key Takeaways

A printed circuit board (PCB) links and holds electronic parts inside devices. It helps them work well together.

PCBs have layers like copper paths and strong bases. These guide signals and power safely to the right spots.

Good PCB design helps devices work faster and last longer. It also keeps them safe from heat, shocks, and damage.

Different PCB types are made for different needs. Some are for simple gadgets, others for smartphones or medical tools.

Modern electronics need PCBs to be smaller, stronger, and more efficient. PCBs help power the devices you use every day.

Whats PCB

Printed Circuit Board Definition

If you ask, “whats pcb,” you want a simple answer. A printed circuit board is found in almost every electronic device. The IPC says a printed circuit board holds and connects electronic parts with copper paths on a base that does not conduct electricity. SolidWorks calls a circuit board the brain of electronic systems. It links all the parts so your device can work. You see circuit boards in things like smartphones and washing machines. Without a circuit board, electronics would not work. The printed circuit board lets signals and power move to the right places. If you open a device, you will see a circuit board holding chips, resistors, and connectors. This neat setup helps devices work well and makes them easier to put together.

Tip: To make your device work well, you need a strong circuit board and good pcb design.

PCB Structure

You may wonder what is inside a circuit board. A pcb has many layers and materials. Here are the main parts:

Copper Layers: These layers move signals and power. Pads hold parts and traces connect them.

Substrate: This is the base, often made from FR-4 or polyimide. It gives strength and keeps electricity from leaking.

Adhesive: Acrylic glue sticks the layers together.

Cover Layers: Polyimide covers keep copper safe from harm.

Silkscreen Layers: These layers show labels and marks for building and fixing.

Copper Pour: Big copper areas help current flow and block noise.

There are different circuit boards based on their structure. Single-layer boards have one copper layer. Double-layer boards have two copper layers with links between them. Multilayer boards have three or more copper layers for harder pcb design. Rigid-flex boards mix stiff and bendy parts for special jobs. Each type helps with different circuit design needs.

PCB Type | Layers | Common Use Cases |

|---|---|---|

Single Layer | 1 | Simple gadgets, toys |

Double Layer | 2 | Home appliances, sensors |

Multilayer | 3+ | Computers, smartphones |

Rigid-Flex | 3+ (mixed) | Wearables, medical devices |

When you pick a pcb design, you match the board’s structure to your device. Good pcb design helps electronics last longer and work better.

What Do PCBs Do

Printed circuit boards are very important in electronics. When you ask, “what do pcbs do,” you find out they help organize and connect all the parts inside a device. A circuit board uses copper conductors, traces, and pads to link electronic parts. These copper parts act like roads. They guide electrical signals and power to the right places. If there was no circuit board, your device would not work right. Let’s look at the main jobs of a pcb.

Signal Routing

Circuit boards move signals between different parts of your device. Copper traces on the board act as paths for these signals. Pads are copper spots where you solder parts, so each part connects well. Vias are tiny holes lined with metal. They let signals move between layers of the board. This setup is neater than using lots of wires. It keeps everything tidy and easy to fix. When you use a phone or computer, the circuit board inside sends signals from the processor to the memory, screen, and other parts. Trace width and spacing are important. They help keep signals clear and stop interference. By guiding signals well, printed circuit boards help all the circuits work together.

Tip: Good signal routing on a pcb helps your device work fast and well.

Power Distribution

A circuit board does more than move signals. It also sends power to every part. Wide copper traces and special power planes carry current safely across the board. Ground planes help lower noise and keep voltage steady. When you turn on a device, the circuit board makes sure each part gets the right power. Designers use special layouts to handle heat and stop problems between power and signal paths. You might see heat sinks, fans, or thermal vias to help cool things down. Protection parts like fuses and circuit breakers keep your device safe from power surges. Good power distribution helps circuits run smoothly and not get too hot.

Thermal features stop overheating.

Protection parts guard against power spikes.

Mechanical Support

Circuit boards hold all the electronic parts in place. Most boards use strong materials like fiberglass or epoxy. This makes a hard platform for the parts. It protects them from shaking, drops, and heat changes. Rigid circuit boards keep everything steady, so your device lasts longer. The board also shields parts from water, dust, and other dangers. When you use a device, the circuit board inside keeps chips, resistors, and connectors safe. This strength is important for devices you use every day.

Note: Good materials in a pcb help your electronics last longer and work in tough places.

Why Devices Need PCBs

If you take out the circuit board or use a bad one, your device will not work. Problems like short circuits, bad soldering, or wrong part placement can make things fail. Devices may shut off, get too hot, or break if the circuit board does not work right. Good pcb design and making keep your electronics safe and working.

Poor design can cause damage from heat or water.

Devices often stop working until you fix or change the circuit board.

Good circuit boards help devices last longer and break less.

Printed circuit boards connect, power, and hold every part in your electronics. They help circuits work together, keep your device safe, and make it last longer. Without a circuit board, modern electronics would not be possible.

Types of Printed Circuit Boards

Printed circuit boards come in many types for different devices. Each type has its own structure and use. You pick the right one based on how hard your device is and what it must do.

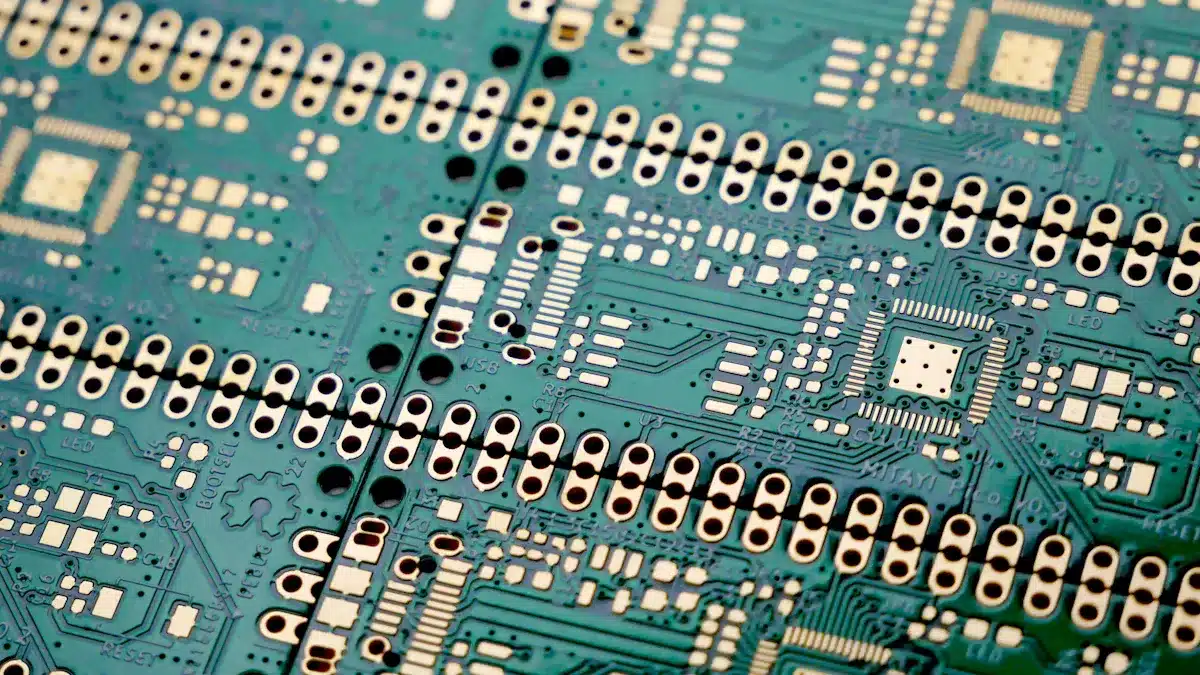

Single-Sided

A single-sided pcb has copper on only one side. All the parts go on this side. This design is simple and easy to fix. You find single-sided boards in devices with easy circuits.

Single-sided boards are in calculators, remotes, and LED lights.

Many simple home gadgets use this type because it is cheap and works well.

Car dashboards and basic power supplies also use single-sided boards.

Tip: If you want a cheap board for easy electronics, pick a single-sided pcb.

Double-Sided

A double-sided pcb has copper on both sides of the board. You can put parts on both sides, so you fit more in less space. Vias are tiny holes that link the two sides. This makes the board more useful.

Aspect | Details |

|---|---|

Structure | Two copper layers, one on each side, joined by vias. |

Functionality | Handles harder circuits and better signal paths. |

Applications | Used in phones, factory controls, power units, and car electronics. |

You see double-sided boards in devices that need to work better, like game consoles, printers, and test tools. These boards help with heat and let you add more features.

Multilayer

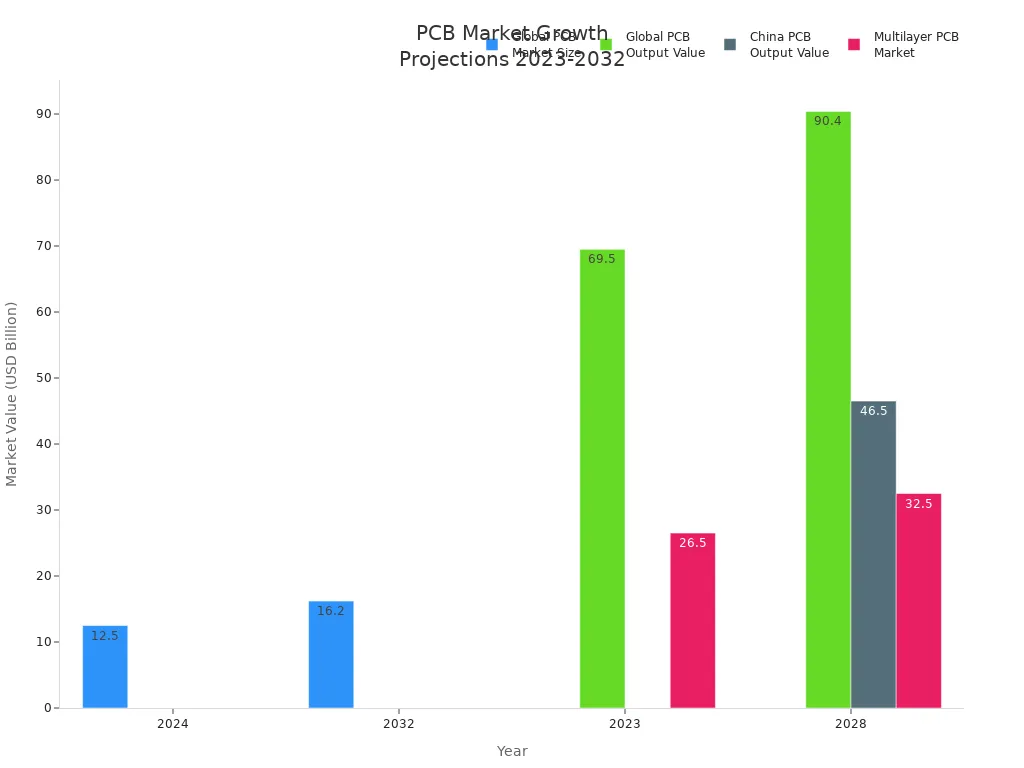

Multilayer pcbs have three or more copper layers with insulation between them. This setup lets you make very hard circuits in a small space. Multilayer pcbs handle fast signals and cut down on noise.

Multilayer pcbs let you add more parts and links in small devices.

You find multilayer pcbs in motherboards, radios, and hospital machines.

These boards are needed for new tech like 5G routers, smart factories, and planes.

Feature/Advantage | Explanation |

|---|---|

Lets you put more parts in smaller gadgets. | |

Enhanced Signal Integrity | Cuts noise and keeps signals strong. |

Electromagnetic Shielding | Stops outside signals from messing up circuits. |

Greater Functionality | Handles hard designs with power and ground layers. |

Note: Multilayer pcbs are needed for new electronics that must be fast, strong, and small.

Printed Circuit Boards in Devices

Everyday Applications

You use printed circuit boards all the time, even if you do not notice. When you grab your smartphone, open your laptop, or start your washing machine, a PCB is inside. These boards link all the parts so your device works well. In home electronics, PCBs help makers fit lots of features into tiny spaces. You can see this in tablets, smartwatches, and smart home gadgets. Because of more IoT devices and wearables, PCBs are almost everywhere at home and work.

Did you know? Almost every electronic device has a PCB. This board sends signals, gives power, and helps your device do things like computing, talking, and moving data.

Makers use special PCB types, like HDI and rigid-flex, to make small and smart products. The need for tiny, clever devices makes PCBs more common in electronics. You get faster and better gadgets because of these boards.

Importance in Modern Electronics

PCBs are very important for how well modern electronics work. You count on these boards to keep your devices working every day. The copper lines inside a PCB give strong electric links and hold parts in place. This setup saves space and is simpler than old wiring.

Makers test PCBs to make sure they last long. They check if boards can handle heat, wetness, and shaking. These tests help your devices survive drops, hot days, and water. Solder and impedance tests keep links strong and signals clear. When you use electronics in cars, hospitals, or factories, you trust PCBs to work in hard places.

Better PCB technology has helped new ideas in electronics. Old boards used simple wires, but new PCBs use better materials and designs. Surface Mount Technology and High-Density Interconnects let devices be smaller, faster, and stronger. Flexible PCBs make wearables and bendy screens possible. You get new features and better use from your devices because of these changes.

Tip: Next time you use your favorite gadget, remember a PCB makes it work. It holds, links, and powers every part inside.

You use printed circuit boards whenever you use electronics. PCBs link and hold all the parts in your devices. They make sure signals and power go to the right places. Their tough design lets you have smaller and quicker gadgets that work well.

PCBs help smartphones, cars, and medical tools work safely and easily.

Think of these boards as the main support for modern technology. When you use your favorite device, a PCB is what makes it work.

FAQ

What materials make up a PCB?

You find most PCBs made from fiberglass (FR-4), copper, and special plastics. The copper forms the paths for electricity. The fiberglass or plastic gives the board strength and keeps electricity from leaking.

Can you repair a broken PCB?

You can fix some PCB problems, like broken traces or loose parts. Use a soldering iron to reconnect parts or patch traces. For big damage, you may need to replace the whole board.

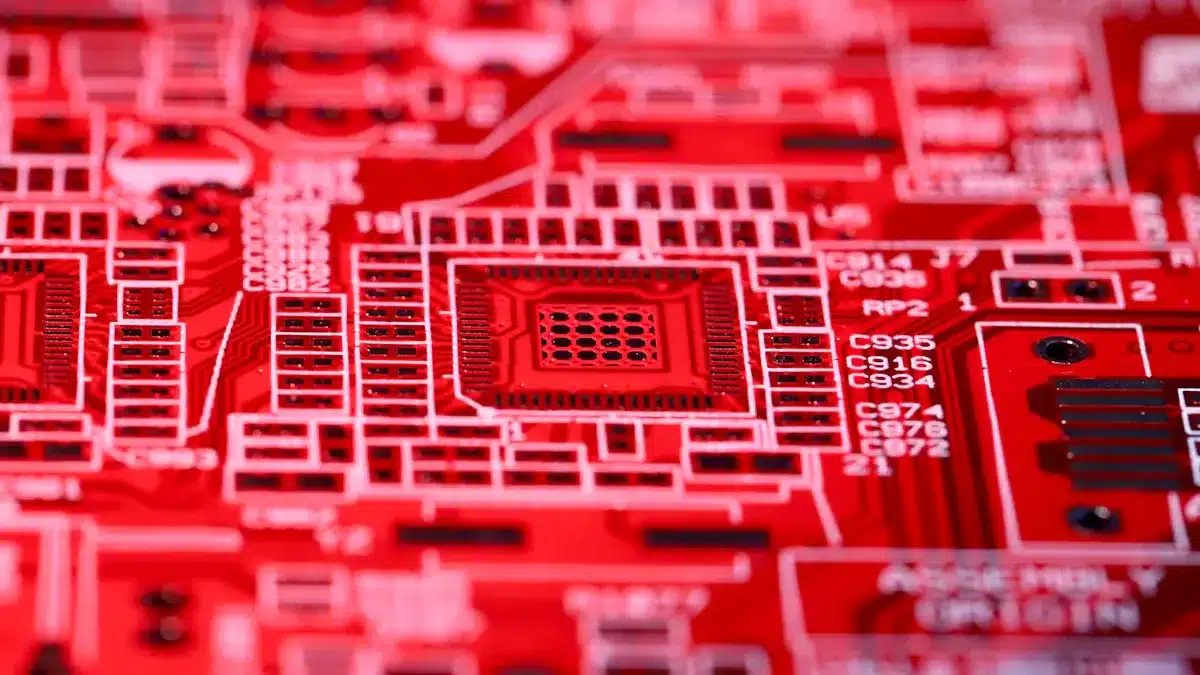

Why do PCBs have green color?

You see green on most PCBs because of the solder mask. This layer protects copper traces and stops short circuits. Green is common, but you can find other colors like blue, red, or black.

How do you keep a PCB safe from damage?

Store your PCB in a dry, clean place. Avoid bending or dropping it. Use anti-static bags to stop static electricity. Handle the board by the edges to keep it clean and safe.

See Also

Understanding PCB Design And Its Importance In Electronics

Exploring PCBA And Its Significance In Electronic Systems

Defining PCBA And Its Function Within Electronic Devices

What PCBA Means And How It Supports Electronic Equipment

The Importance Of PCBA Services In Electronics Manufacturing