Top PCB manufacturers are recognized for their quality and speed in circuit board production. This is supported by recent reports and user feedback. The table below highlights how leading manufacturers perform:

Manufacturer | Quality & Speed Highlights | User Feedback Summary |

|---|---|---|

Cirexx International | Produces high-quality boards quickly and provides excellent customer support | Customers appreciate their professionalism and fast delivery |

TTM Technologies | Specializes in various advanced PCBs with rapid turnaround | Trusted for reliable and speedy circuit board production |

All Flex | Excels in complex flex PCBs and handles urgent orders efficiently | Users report durable boards that save costs |

Sierra Circuits | Offers the fastest US service using cutting-edge technology | Praised for quick prototyping and responsive support |

GESP TECHNOLOGY | Delivers fast prototypes and high-quality flex PCBs | Engineers value their professionalism and superior products |

Nippon Mektron | Known for innovative flexible PCB designs and consistent quality | Customers favor their steady quality and new tech |

Flexium Interconnect | Produces boards rapidly and manages challenging designs | Recognized for innovative ideas and complex circuit board production |

PCBWay | Provides fast prototype production, quick delivery, and easy ordering | Users like their speedy delivery and helpful technical support |

The market for PCB manufacturers evolves rapidly.

The book-to-bill ratio and recent data show that only current trends matter.

Accurate, up-to-date information helps customers select the right manufacturer for printed circuit board and circuit board production needs.

Each manufacturer excels in different projects and services.

Key Takeaways

Leading PCB manufacturers are not all the same. They have different quality, speed, and special features. Pick one that matches your project and budget. Fast work and good quality are very important. This helps you avoid delays and finish on time. Choose companies with strong certifications. Good customer support is also important. Flexible assembly options help you get better results. Use online tools like PCBShopper to check prices and services. This helps you find the best deal. Local manufacturers can deliver faster. They are easier to talk to. This is helpful for urgent or hard projects.

Top Choices for Quality and Speed

Quick Comparison Table

The table below shows top pcb manufacturers. Each one is known for quality, speed, and being reliable in making printed circuit boards.

Manufacturer | Quality Rating | Speed Rating | Best For | Typical Turnaround |

|---|---|---|---|---|

9/10 | 9/10 | Prototypes, small batch | 2-4 days | |

JLCPCB | 8/10 | 10/10 | Mass production | 1-3 days |

Sierra Circuits | 10/10 | 8/10 | Complex US projects | 3-5 days |

ALLPCB | 8/10 | 9/10 | Fast prototyping | 2-4 days |

Advanced Circuits | 9/10 | 8/10 | North American clients | 5-7 days |

Tip: Users should look at turnaround times and quality ratings before picking a pcb manufacturer for their project.

Standout Features

Many pcb manufacturers have special features that help engineers and companies do well. Some focus on fast delivery. Others use new technology or give great customer support.

PCBWay gives instant online quotes and good technical help. Their service is great for people who need quick prototypes or small batches.

JLCPCB uses machines to make boards fast. This company is good for big orders that need to be done quickly.

Sierra Circuits works on hard printed circuit board designs. Their team helps clients with tough rules for US projects.

ALLPCB is known for fast prototyping and good prices. Many engineers pick this company for jobs that need to be finished soon.

Advanced Circuits helps North American customers with steady service and good quality. They also give helpful design tools.

Note: Picking the right pcb manufacturer depends on what your project needs, your budget, and how fast you need it. Comparing what each company offers helps users choose the best one.

Why Quality and Speed Matter

Project Outcomes

Quality and speed are important for every PCB project. Smart factories and software help make prototypes quickly. Tempo Automation can finish orders in three days. They use scanning to check for mistakes. AI helps lower errors and keeps work moving fast. This helps teams meet tight deadlines and keep making products.

Aspect | Description |

|---|---|

Workers check how boards look and measure them. Machines like AOI help find problems. Boards must follow IPC Class II/III rules to be safe and work well. | |

Packaging and Delivery | Boards are packed to keep out water and static. Fast shipping, like 24-hour samples, helps test and sell products sooner. |

Manufacturing Capacity | Factories can make many types of PCBs, like multilayer and flexible ones. This helps with different project needs. |

Advanced Equipment | Machines like AOI, X-ray, and flying probe testers help find mistakes. These tools make sure boards work right. |

Reliable manufacturers help engineers build things for medical, aerospace, and cars. Fast shipping and strong checks help companies sell products quickly. These steps make sure every PCB is safe and works well for important jobs.

Tip: Teams should pick PCB makers who are fast and reliable. This helps projects turn out better.

Risks of Delays or Defects

Delays or mistakes in making PCBs can mess up plans and cost more money. If a PCB does not work, engineers must fix and change it. This can take weeks or months. Fixing problems late costs even more, especially for important jobs.

Phase | Impact on Timelines | Impact on Costs |

|---|---|---|

Bad PCBs mean more fixing and testing | Changes cost more as the project goes on | |

Production | Mistakes mean fixing, repairing, or throwing away boards | More work and materials cost extra; late delivery can mean fines |

High-volume Prod | Even small mistakes make lots of bad boards | Costs go up because many boards are wasted |

Manufacturers use special checks to stop problems before they happen. Working with contract makers early helps find weak spots and avoid delays. Flexible supply lists and planning help control risks. Good quality plans with clear checks lower mistakes and costs. Picking the right contract maker helps keep projects safe and on time.

Note: Reliable PCB making helps keep projects on track and saves money, especially for important jobs.

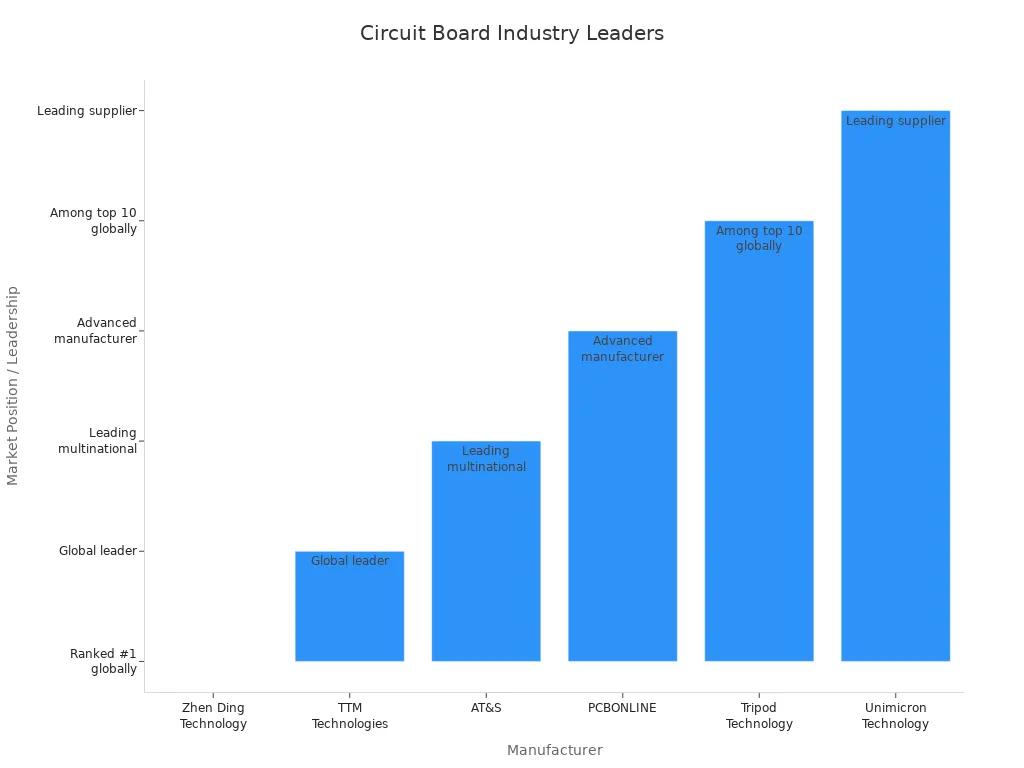

Circuit Board Production: Leading Manufacturers

The world has many pcb manufacturers. Each one is good at different things like quality, speed, assembly, and shipping. The profiles below show top companies. This helps engineers and businesses pick the best manufacturer for their needs.

JLCPCB

JLCPCB is a one-stop pcb manufacturer. They are known for making boards fast and at good prices. They follow IPC-A-600 Class 2 rules, and can do Class 3 if needed. JLCPCB can make some boards in just 24 hours. Their website makes it easy to upload pcb designs and order boards. Both professionals and hobbyists find it simple to use.

Aspect | Strengths | Weaknesses / Limitations |

|---|---|---|

Quality Standards | Meets IPC-A-600 Class 2; high manufacturing quality | May struggle with very complex pcb designs |

Turnaround Times | Rapid fabrication, some 24-hour services | Expedited assembly may cost more; lead times vary with complexity |

Pricing | Low prices for prototypes and small batches; discounts for larger orders | Limited sourcing for rare components; user may need to supply unique parts |

Ordering & Support | User-friendly online system; responsive support | Less personalized support compared to some competitors |

Component Sourcing | Efficient for basic parts; reduces assembly cost | Specialized components often require user sourcing |

JLCPCB is great for fast shipping, low prices, and easy assembly for normal projects. They may not be the best for very hard or special designs. Many people use JLCPCB for testing ideas, small orders, and when they need boards quickly.

ALLPCB

ALLPCB is popular with engineers who want fast boards and good assembly. They have good prices, quick prototyping, and an easy online quote system. ALLPCB can handle both simple and advanced pcb designs. This makes them a flexible choice for many jobs.

Strengths:

Fast turnaround, often delivering prototypes within 2-4 days.

Competitive pricing for both small and medium batch orders.

Responsive customer service and technical support.

Supports a wide range of pcb design types, including multilayer and flexible boards.

Weaknesses:

Limited options for highly specialized or high-performance pcbs.

Some users report occasional delays during peak periods.

Assembly services may not cover all rare or custom components.

ALLPCB is good for quick testing, school projects, and new companies that need fast shipping and steady assembly.

PCBWay

PCBWay is a one-stop pcb manufacturer. They offer many services for making and assembling boards. PCBWay does fast prototyping, big orders, and flexible pcb solutions. Their website helps users get price quotes easily. Their shipping network sends boards quickly all over the world.

Key Advantages:

Full assembly services, including component sourcing, soldering, inspection, and testing.

Design-for-manufacturing support to improve reliability and reduce lead times.

Holds ISO, IPC, and RoHS certifications for quality and compliance.

User-friendly online platform and global shipping options.

PCBWay is strong in flexible assembly, high reliability, and can handle both easy and hard projects. Their experience and worldwide reach help engineers move from pcb design to finished boards quickly.

Advanced Circuits

Advanced Circuits is a top North American pcb manufacturer. They are known for high-quality boards and strict rules for quality. They work with industries like aerospace, defense, and medical devices where boards must be very reliable.

Certification / Standard | Description / Relevance |

|---|---|

Advanced Quality Management Program (AQMP) for process control | |

MIL-PRF-31032 | Meets military performance specifications |

IPC 6012 Class 3 | High reliability standard for printed circuit boards |

Nadcap | Accreditation for aerospace and military quality |

RoHS Compatible | Environmentally compliant materials and processes |

Advanced Circuits can deliver boards in 5-7 days, with faster options if needed. Their assembly and technical help make it easier for customers to finish tough projects. Prices are higher than some other companies, but many people trust their quality and rule-following.

OSHPark

OSHPark is known for making high-quality prototypes and small orders. They use US factories and focus on quality, steady results, and fast shipping for US customers.

Reviewer | Prototype Quality | Delivery Speed & Service | Additional Notes |

|---|---|---|---|

Tom Price | Beautiful boards, excellent quality | Quick turnaround, free postage | ENIG as standard, highly recommended for US users |

Ryan | PCB quality unmatched | Very fast turnaround, super swift panel used for faster processing | Good customer service |

Stretchyman | Quality and consistency superb | Unbeatable turnaround time | Quick to rectify minor issues, free replacements provided |

Matthew Skala | Some holes too small, causing issues | Bought slower service, still faster than China, but delays impacted project | Refund given after dispute, but delay caused project impact |

Kelly | Holes too small, thin copper, cheap mask | Long international shipping (2+ weeks) | Excellent communication and customer support |

OSHPark is good at making boards look nice, keeping quality steady, and helping customers. They are best for prototypes and small orders, with fast shipping in the US. Some people say shipping overseas is slow and there can be small drill problems.

WellPCB

WellPCB offers many services for making and assembling boards. They work with both normal and high-performance pcbs. WellPCB can make multilayer, flexible, and rigid-flex boards. This makes them good for hard projects.

Strengths:

Fast shipping and competitive pricing for prototypes and small batches.

Comprehensive assembly services, including testing and inspection.

Good customer support and technical assistance.

Flexible manufacturing options for various pcb design needs.

Weaknesses:

Limited presence in North America and Europe may affect shipping times for some regions.

Some users report occasional communication challenges.

WellPCB is best for engineers who need boards fast, want steady assembly, and need help with advanced pcb designs.

Sunstone Circuits

Sunstone Circuits is a well-known US pcb manufacturer. They are known for fast board making and strong customer support. After joining with American Standard Circuits, they can make more boards and ship faster.

Fast prototyping and assembly, with delivery in as little as 24-48 hours.

Dynamic online quoting system for quick and accurate project estimates.

Integrated design solutions for smooth transitions from design to production.

Partnership with Screaming Circuits allows fully assembled boards with rapid assembly turn times.

Emphasis on quality and reliability, making Sunstone a trusted choice for North American customers.

Sunstone Circuits is great for urgent jobs, school projects, and when local help and fast shipping are needed.

NextPCB

NextPCB is known for advanced board making and good prices. They can make hard pcb designs, like HDI and rigid-flex. NextPCB can ship prototypes fast, sometimes in just 24 hours.

Strengths:

Advanced manufacturing for complex designs.

Global logistics network for fast shipping.

Comprehensive quality control, including AOI and X-ray inspection.

Attractive pricing for prototypes and small batches.

Weaknesses:

Inconsistent customer service, with reports of unresponsiveness and delayed orders.

Occasional quality control issues, such as incorrect copper thickness or misaligned solder masks.

Pricing transparency concerns, with some users noting hidden fees.

Limited component sourcing for rare parts, which can delay assembly.

NextPCB is good for hobbyists, new companies, and engineers who want fast, cheap prototypes and can handle some risks with assembly and shipping.

EasyEDA

EasyEDA is different because it has a cloud-based platform for pcb design, simulation, and board making. The website is easy to use and lets people work together in real time. It has a big part library and tools that help with design.

Works with partners like JLCPCB for direct ordering and fast shipping.

Freemium pricing lets many people use professional pcb design.

Cloud access helps with quick testing and small runs.

Real-time teamwork lets groups work together easily.

Best for simple to medium designs that need fast making and easy assembly.

EasyEDA is a good pick for students, hobbyists, and pros who want one place for design, assembly, and shipping for fast board making.

PCB Board Assembly and Turnkey Services

Assembly Capabilities

Manufacturers give many ways to put boards together for different projects. PCBCart is special because they do everything from start to finish. They make the boards, put on the parts, and send them to you. They also buy the parts and check each step. Bay Area Circuits helps people in the US get boards made fast. They can make more boards quickly and give prices right away. RushPCB can finish a sample board in just one day. They help with both kitted and turnkey orders. American Circuits works with SMT, THT, and mixed assembly. This means they can help with many kinds of electronics. JLCPCB puts boards together quickly too. Some flex PCBs are done in only four days. These companies help engineers and businesses get good boards fast.

Turnkey Solutions

Turnkey pcb solutions make things easier for customers. They take care of everything from the idea to the finished board. PCBCart’s turnkey service makes talking easier and saves money. They do the board making, part buying, and shipping all together. PCB Trace Technologies helps with sample boards and full turnkey jobs. They have ISO certificates for good quality. Gorilla Circuits does both board making and assembly in one place. They focus on doing things well and in their own factory. These services help new and small companies make better products fast. Customers can watch their order and get prices online. This makes the whole job simple and easy to follow.

Additional Manufacturing Services

Top companies do more than just put boards together. They offer extra electronic manufacturing services like:

Conformal coating keeps boards safe from dust, water, and chemicals so they last longer.

IC programming gets chips ready before or after they go on the board.

Burn-in testing checks if boards work well by running them for up to 168 hours.

Box-build assembly puts boards in cases and adds logos so they are ready to use.

Enclosure manufacturing makes special parts that fit each board.

Module assembly puts PCBAs into bigger systems or battery packs.

Logistics and shipping use air, sea, or train with companies like DHL, FedEx, and UPS.

Sunstone Circuits and PCBWay also help with cable assembly, chip programming, and testing. These extra services help customers get finished products fast. Quick shipping and flexible ways to put boards together help projects finish on time.

High-Quality Prototypes and Small Batch Options

Prototyping Specialists

Some manufacturers are experts at making high-quality pcb prototypes. They help engineers and designers test ideas before making lots of boards. Companies like JLCPCB, Eurocircuits, PCB Train, and Osh Park are often recommended. People trust them because they work fast and do a good job. These companies have easy-to-use websites and let you pick how you want your boards delivered. They use new technology to make sure prototypes are high quality. The table below shows what users like about each company:

Manufacturer | Key Strengths and Recommendations |

|---|---|

JLCPCB | Cost-effective, high quality, fast turnaround, user-friendly platform. |

Eurocircuits | European quality standards, focused on prototyping and small batches. |

PCB Train | UK-based, flexible delivery, easy online quotation and design submission. |

Osh Park | Cost-effective prototyping, specializes in small to medium batches, American community-based service. |

PCBWay | Consistent production quality, fair pricing, fast delivery, advanced technology. |

Advanced Circuits | No minimum order for prototypes, free design check tool, handles small to large-scale production. |

These companies help engineers who need good pcb prototypes for testing and new products.

Small Batch Production

Small batch production lets companies make a small number of pcb boards quickly. This is good for testing or special projects. Some companies are experts at making low volume pcb orders. They work fast and can change things if needed. Each company is different in how many boards you must order, how flexible they are, and how much experience they have. Here are some ways top companies handle small batch production:

Low-volume PCB assembly means making less than 1,000 boards. This is best for testing and special products.

Flexible order sizes help save money.

Being flexible helps deliver on time, even if parts are hard to find or designs change.

One-stop services like making, buying parts, putting boards together, testing, and shipping help avoid mistakes.

Companies with experience know the rules and make sure boards are good quality.

Fast delivery, usually between 5 and 15 days, is important for small orders.

The table below compares what each company can do for small batch orders:

Manufacturer | Experience & Location | Certifications | Key Services & Technologies | MOQ & Flexibility | Turnaround Time & Special Services |

|---|---|---|---|---|---|

OurPCB | Belgium-based, units in China | ISO9001:2008 | Web-based platform, prototypes, value-added services | Flexible MOQs, suitable for small-series | Reliable, low-cost, fast delivery |

WellPCB | Australian registered, global | Not stated | SMT assembly, pick-and-place, turnkey services | Express PCB service for small batch orders | Delivery as fast as 5 days |

PCB Assembly Technology | Advanced facilities | Not stated | Turnkey SMT, low-volume expertise | Adaptable to low-volume orders | Quick delivery, quality, flexibility |

Companies that are good at assembly and can change plans easily help customers finish projects on time and meet quality needs.

Price Comparison Tools

Engineers and buyers use online tools to check prices for prototypes and small batch orders. PCBShopper.com is a popular website for comparing prices in the PCB world. Users type in their project details and see prices from many companies like JLCPCB, PCBWay, and ALLPCB. This tool helps people find the best deal for good pcb prototypes and small orders. PCBShopper makes it easy to choose and helps control spending.

Tip: Try PCBShopper to compare prices and services before you order. This helps you pick the best company for your project and budget.

Key Factors in Choosing a PCB Manufacturer

Project Complexity

PCB manufacturers work on projects that are easy or hard. For tough designs, engineers need special skills and custom options. Good supply chains and strong inventory help boards arrive on time. Risk controls keep quality steady. Companies with advanced machines and testing can handle tricky assembly and finishes like ENIG or OSP. Local suppliers may finish boards faster and talk with you more easily. This helps when projects have strict rules. Teams should check if the company can change how many boards they make. They should also see if design reviews or prototype help are offered.

Flexible ways to make and deliver boards

Strong checks and testing in the factory

Can use special materials and finishes

Clear and quick communication

Volume and Lead Time

How many boards you order and how fast you need them matters. Some companies want big orders and set a minimum number. This may not work for small jobs. The number of boards changes the price and how long it takes. Big orders cost less for each board but take longer. Small batches are ready faster but cost more for each one. Good companies can make just a few boards or many. They tell you clearly about their schedule and how much they can make. If the company is close to you, boards may arrive sooner.

Tip: Think about price, quality, how many boards, and speed. This helps your project turn out better.

Compliance and Certifications

Certifications show that PCB makers follow important rules. For some jobs, these certifications are needed:

ITAR is for military and secret technology.

MIL-STD checks boards for tough jobs and tests.

IPC Standards, like IPC-A-610, show good assembly.

ISO means the company manages quality well.

RoHS keeps boards safe for the environment.

Companies with these certifications care about safety and quality. UL certification means boards are safe before you use them.

Customer Support

Good customer support makes some PCB companies stand out. PCBONLINE and Viasion give help from engineers and are open all day and night. They help you from the first price quote to after you get your boards. Fast and smart help fixes problems quickly and keeps your project moving. Reviews say quick answers and clear talk are important.

Help any time, day or night

Engineers help you one-on-one

Each project gets its own helper

Quick answers for questions and problems

Pricing and Value

Price is important, but value means more than being cheap. PCB companies with flexible prices help you save money. They let you pick different order sizes and services. Saving money often means using normal materials, simple designs, and SMT assembly. Making more boards at once or using panelization lowers the price for each board. Working with the company early can show ways to save money and keep quality. Picking the best way to put boards together and planning ahead stops extra fees.

Cost-Saving Tips | Description |

|---|---|

FR-4 board, regular copper thickness | |

Make design simple | Fewer layers, smaller board |

Needs less hand work and costs less | |

Plan ahead for making | Stops rush fees and delays |

Compare companies | Find deals and discounts |

Recommendations by Project Need

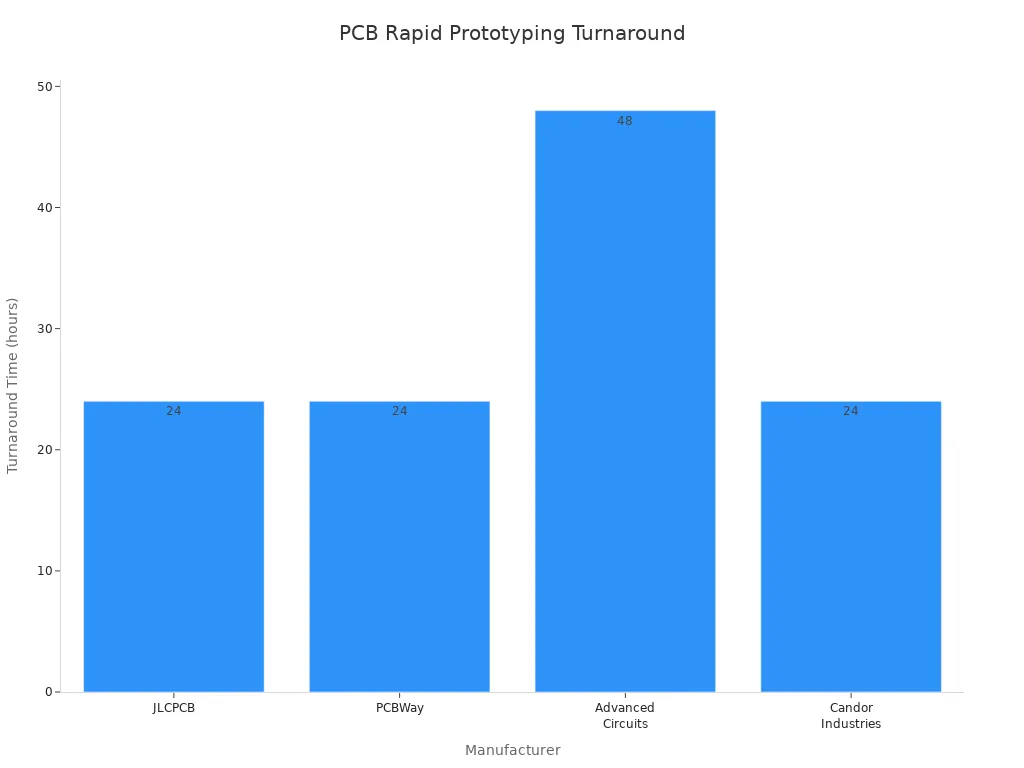

Rapid Prototyping

Engineers sometimes need pcb prototypes very fast to test ideas. Some manufacturers are experts at making boards quickly and in large amounts. These companies help teams go from an idea to a real board in just a few days. The table below lists top choices for fast service and good quality checks.

Manufacturer | Turnaround Time | Quality Certifications / Control | Pricing Details |

|---|---|---|---|

JLCPCB | Manufacturing: 24 hours; Assembly: 1-2 days | ISO 9001:2015, ISO 14001:2015, IPC-6012E | Prototype prices $0.1 to $5 for 5 pcs |

As short as 24 hours after Gerber approval | Strict quality control with comprehensive testing | Starting at $5 for 10 pcs (100mm x 100mm) | |

Advanced Circuits | 2 to 4 days | High domestic manufacturing standards | Premium pricing, competitive total cost |

Candor Industries | 24 hours for simple builds (≤8 layers) | In-house production control | Competitive domestic pricing |

JLCPCB and PCBWay make prototypes fast and check them well. Advanced Circuits and Candor Industries are good for teams who want local help and quick boards. These companies help engineers get boards sooner and start testing faster.

Tip: Pick a manufacturer known for speed and quality. Fast service helps your project stay on track.

Mass Production

Big companies need lots of boards made with steady quality. Top manufacturers check every order to make sure it is ready for mass production. They review designs and give special help with engineering. This makes sure boards meet important standards like IPC-6012 Class 2 and Mil-Spec Class 3.

Manufacturers help with big orders and give advice on board layers.

They can make thousands of boards and use machines to check them.

Mass production uses special features like blind vias, HDI, and flex-rigid boards.

PCBWay, JLCPCB, and Advanced Circuits are great at making many boards from a small start.

These companies have strong assembly lines and ship products all over the world. They keep quality high for every batch and help save money.

Note: For big projects, pick a manufacturer with lots of experience and strong assembly skills.

Complex or Custom Boards

Some projects need boards with special designs or hard features. These manufacturers can make boards with things like HDI, blind vias, and rigid-flex shapes. They help with custom layers and give advice for tricky layouts.

CAM engineers check each design to make sure it can be built.

Assembly teams work with special parts and finishes.

PCBWay and Advanced Circuits help with tough jobs for cars, planes, and hospitals.

JLCPCB and NextPCB offer choices for custom boards and extra testing.

These companies use advanced machines and skilled workers to help engineers get good results on hard projects.

Tip: For tricky boards, work with a manufacturer who gives engineering help and advanced assembly.

Budget-Friendly Options

Small teams and new companies often need cheap ways to make boards. JLCPCB and PCBWay have low prices for fast prototypes and assembly. EasyEDA lets people design and order boards online to save money.

Manufacturer | Typical Pricing | Services Included | Best For |

|---|---|---|---|

JLCPCB | $0.1 to $5 for 5 pcs | Assembly, prototyping, online quotes | Students, startups |

PCBWay | $5 for 10 pcs | Assembly, prototyping, DFM checks | Hobbyists, engineers |

EasyEDA | Free design tools, low-cost boards | Assembly, simulation, direct ordering | Designers, educators |

These budget-friendly companies help teams try ideas without spending a lot. They offer assembly and quick shipping for small orders.

Tip: Use online tools to compare prices and find the best deal.

Local Support

Some projects need boards made close by and delivered fast. US companies like Advanced Circuits and Sunstone Circuits make boards in the country and give local help. They offer quick prototypes, big orders, and technical support for North America.

Local companies deliver boards faster and talk with you directly.

They follow strict rules and have important certifications.

Sunstone Circuits works with Screaming Circuits for fast assembly and full service.

Local support helps teams fix problems quickly and meet tight deadlines.

Note: For urgent jobs or when talking is important, pick a manufacturer with local help and assembly.

Top PCB manufacturers are known for quick delivery and good quality. They also have strong assembly services. Before picking a company, readers should look at different assembly choices. They should check how helpful the customer support is. It is smart to compare prices too. Tools like PCBShopper help people find the best company for their needs. Asking for quotes or samples can help make better choices. Talking to experts can also help projects turn out well. Picking the right assembly for each project helps avoid problems and delays. Good planning and smart choices help every project succeed.

FAQ

What factors affect PCB manufacturing turnaround time?

How fast boards are made depends on a few things. Board complexity matters. Big orders take longer. Factories get busy and that can slow things down. Using machines and making boards nearby helps speed up work. Customers should always check how long it will take before ordering.

How do manufacturers ensure PCB quality?

Manufacturers use AOI and X-ray testing. They follow IPC standards. Quality teams look at every board. Certifications like ISO9001 and RoHS mean the company cares about good quality.

Can customers order both prototypes and mass production from the same manufacturer?

Most top manufacturers let you order both types. You can get a few boards for testing. You can also order lots of boards for big jobs. This helps keep quality steady and makes talking with the company easier.

What should buyers look for in PCB assembly services?

Buyers should look for turnkey options and flexible assembly. Good companies help with testing and finding parts. Fast shipping is important. Strong technical support helps fix problems quickly. Good communication makes everything easier.

See Also

In-Depth Comparison Between PCBWay And Other PCB Makers

Choosing PCBA Manufacturing Services With Cutting-Edge Features

Tips For Picking The Ideal PCB Prototype Manufacturer

Best Practices To Guarantee Quality And Efficiency In PCBA

Selecting The Right PCBA Manufacturer To Meet Business Goals