PCB manufacturing machines are very important in electronics. They make printed circuit boards for devices you use daily. In 2023, the market size for these machines was worth USD 4.2 billion. This amount is expected to rise to USD 7.2 billion by 2032. This shows a growth rate of 6.2% each year from 2024 to 2032. Such growth shows that more people want better and faster PCB manufacturing machines.

Key Takeaways

PCB manufacturing machines are important for making printed circuit boards. These boards are used in everyday electronics.

Entry-level machines are cheap and easy to use. They are great for small businesses and startups.

Mid-range machines balance cost and performance. They work well for growing companies with more complex needs.

High-end machines have advanced features and high precision. They are perfect for large-scale production and detailed designs.

When picking a PCB manufacturing machine, think about your needs, design complexity, and budget to find the best choice.

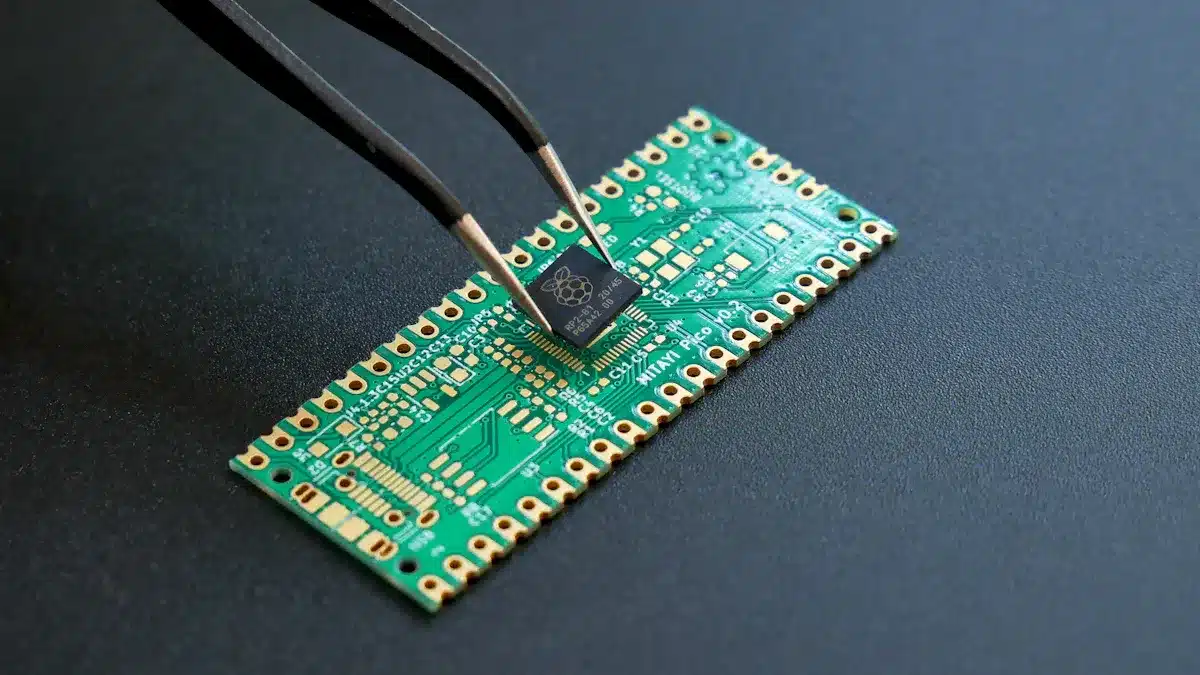

Entry-Level PCB Manufacturing Machines

Entry-level PCB manufacturing machines are very important for small businesses and startups. These machines offer a cheap way to start in the PCB making market. They let you create printed circuit boards without spending a lot of money. This helps you focus on new ideas and product growth.

Machine A: Specifications

Machine A is made for small production jobs. Here are some of its main features:

Production Speed: Can make up to 100 square meters of PCB each hour.

Layer Count: Works with up to 4 layers, good for simple designs.

Size Compatibility: Fits boards up to 300mm x 400mm.

Technology: Uses both old and new methods for PCB making.

User Interface: Has an easy touchscreen for simple use.

These features make Machine A a smart choice for beginners in PCB manufacturing.

Pros and Cons

Like any machine, Machine A has good and bad points. Here’s a quick look:

Pros:

Affordability: Costs less to start than fancy machines.

Ease of Use: Simple controls help new users learn fast.

Compact Size: Fits nicely in small shops or labs.

Versatility: Can work with different types of PCB, including flexible printed circuits.

Cons:

Limited Production Capacity: Not good for making a lot of products.

Basic Features: Does not have advanced options like more expensive machines.

Lower Precision: Might not work well for complex designs needing high-density layouts.

Mid-Range PCB Manufacturing Machines

Mid-range PCB manufacturing machines are between entry-level and high-end models. They balance cost and performance. This makes them great for growing businesses. These machines have better features that help companies increase production without spending too much money.

Machine B: Specifications

Machine B is made for medium to high production amounts. Here are its main specifications:

Production Speed: Can produce up to 200 square meters of PCB each hour.

Layer Count: Supports up to 8 layers, good for complex designs.

Size Compatibility: Fits boards up to 600mm x 800mm.

Technology: Uses advanced features like Surface Mount Technology (SMT) for better assembly.

User Interface: Has an easy touchscreen with customizable settings.

These specifications make Machine B a strong choice for businesses wanting to improve production efficiency.

Pros and Cons

Like any machine, Machine B has good and bad points. Here’s a quick overview:

Pros:

Cost-Effective: Balances price and performance, making it good for growing companies.

Advanced Features: Has automation and AI for finding defects, which helps quality control.

Scalability: Works well in different production settings, allowing for future growth.

Precision: Uses advanced tools for direct imaging, improving the accuracy of printed circuit boards.

Cons:

Higher Initial Investment: Costs more than entry-level machines, which may worry startups.

Complexity: Needs more training for operators than simpler models.

Maintenance Needs: Advanced features might need more maintenance.

When choosing a mid-range PCB manufacturing machine, think about design complexity, component choices, and assembly methods. These factors greatly affect costs and performance. For example, complex designs may need more resources, while technology choices can impact manufacturing costs and the final product’s quality.

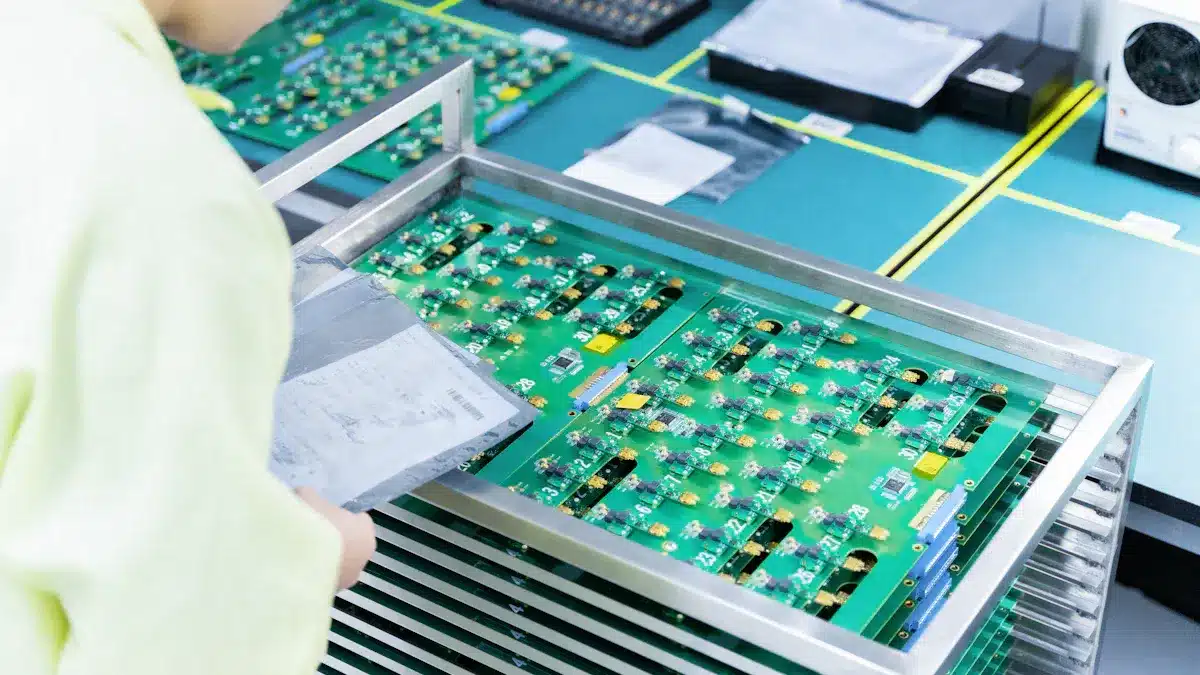

High-End PCB Manufacturing Machines

High-end PCB manufacturing machines are special because they have advanced features. These machines are made for big production and complex designs. They are very important for serious PCB makers. They help you create high-density printed circuit boards quickly and accurately.

Machine C: Specifications

Machine C is built for high-volume production and complex PCB making. Here are its main specifications:

Production Speed: Can produce over 300 square meters of PCB each hour.

Layer Count: Supports up to 32 layers, perfect for detailed electronic circuits.

Size Compatibility: Fits boards up to 1,200mm x 1,500mm.

Technology: Has advanced automation, including AI for spotting defects and multi-angle lighting for better visibility.

User Interface: Features a smart touchscreen that allows remote access and monitoring.

These specifications make Machine C a great choice for manufacturers who need to meet high demands and complex needs.

Pros and Cons

Like any machine, Machine C has good and bad points. Here’s a closer look:

Pros:

Superior Accuracy: High-end machines provide excellent precision, which is important for high-density designs.

Fast Production: With high-speed abilities, you can quickly fulfill large orders.

Advanced Features: Uses AI and machine learning to improve defect detection and cut down programming time.

Scalability: Easily adjusts to higher production needs without losing quality.

Cons:

High Cost: The starting price can be high, which may scare off smaller businesses.

Complex Operation: Needs skilled operators for best use, which can lead to training costs.

Maintenance Needs: Advanced features might need more regular maintenance and support.

High-end PCB manufacturing machines are great at making multilayer PCBs. These are important for modern electronics. They ensure good insulation and precise electrical connections through careful layering and well-placed holes. For example, one manufacturer says they can produce 40,000㎡ each month, allowing them to handle big industrial orders easily.

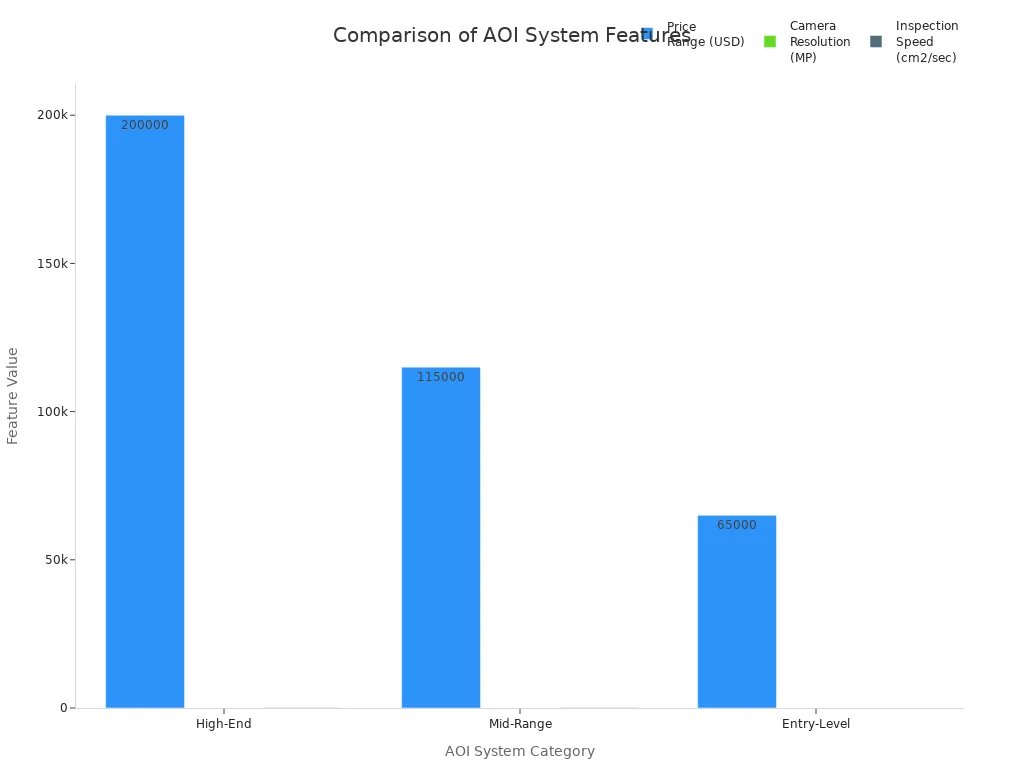

Here’s a comparison of features that set high-end machines apart from mid-range and entry-level models:

Feature | Mid-Range AOI Systems | Entry-Level AOI Systems | |

|---|---|---|---|

Price Range | $150,000 – $250,000+ | $80,000 – $150,000 | $50,000 – $80,000 |

Camera Resolution | 20+ megapixels | 10-20 megapixels | 5-10 megapixels |

Inspection Speed | 80-100+ cm²/sec | 50-80 cm²/sec | 30-50 cm²/sec |

Inspection Type | Full 3D with advanced AI | 2D with optional 3D add-ons | Primarily 2D |

Use Case | High-volume, complex PCBs | Medium to high production | Small to medium production |

Pros | Superior accuracy, fast | Balanced cost and performance | Affordable, easy to use |

Cons | High cost, complex operation | May require more training | Limited accuracy for tiny |

Comparison of PCB Manufacturing Machines

When you look at PCB manufacturing machines, think about some important features and how well they work. These things help you choose what fits your needs best.

Key Specifications Overview

Here are some key points to think about when comparing machines at different price levels:

Customization and Flexibility: More customization usually means higher prices because it’s more complex.

Quality and Reliability: Cheaper prices might lower quality, which can cost more later.

Lead Times and Responsiveness: Faster lead times might cost more but can be very valuable.

Post-Sale Support and Warranty: Good support can make higher prices worth it because of long-term savings.

Lifecycle Costs: The total cost of ownership, including upkeep, is important for checking efficiency.

Scalability and Future-proofing: Scalable options may cost more upfront but save money as needs change.

Environmental Compliance and Sustainability: Following rules can affect prices but might save money on waste management.

Performance Metrics

Performance metrics are very important when judging PCB manufacturing machines. Here’s a comparison of different testing methods based on speed, accuracy, and reliability:

Testing Method | Speed | Accuracy | Reliability |

|---|---|---|---|

AOI | Fast | Limited to surface issues | Good for early detection |

ICT | Moderate | Highly accurate | High, requires fixtures |

Functional Testing | Slow | Ensures overall performance | Critical for final validation |

Flying Probe Testing | Slower | Good coverage | Flexible, but less practical for high volume |

Advanced equipment boosts manufacturing for high-frequency, high-speed, and high-density boards. Complete inspection and testing tools greatly improve quality checks before shipping. Automation and smart systems help with efficiency and keep product quality steady.

For cost analysis, think about both the initial investment and running costs. Most of the initial investment goes to machine costs, plus land and site development. First-year running costs include raw materials, utilities, and maintenance, with big increases expected by the fifth year due to inflation and market changes.

In 2025, picking the right PCB manufacturing machine is important. You need to think about different things. First, look at your needs, like how much you will produce and how complex the designs are. Check how each machine handles materials, what surface finishes it offers, and its quality standards.

Tips for Choosing the Right Machine:

Figure out what finishing services you need.

Find manufacturers that provide steady quality and quick schedules.

Make a list of possible manufacturers based on advice and certifications.

By paying attention to these points, you can choose a machine that fits your needs for high-quality production and effective PCB assembly services.

FAQ

What is a PCB manufacturing machine?

A PCB manufacturing machine makes printed circuit boards. It uses different steps to etch, drill, and put together electronic parts on a board. These machines are very important for making reliable electronics.

How do I choose the right PCB manufacturing machine?

Think about what you need for production, how complex your designs are, and your budget. Check the machine’s details, like speed, layer count, and technology. This helps you find a machine that meets your needs.

What are the benefits of using high-end PCB manufacturing machines?

High-end machines provide better accuracy, faster production speeds, and advanced features. They can handle complex designs and large production amounts well, making them great for serious manufacturers.

Can entry-level machines handle complex designs?

Entry-level machines usually have trouble with complex designs. They work best for simpler projects with fewer layers. For detailed designs, think about moving up to mid-range or high-end machines.

How often should I maintain my PCB manufacturing machine?

Regular maintenance is very important for good performance. Plan maintenance every few months, or as the manufacturer suggests. This helps avoid breakdowns and makes the machine last longer.

See Also

Essential Steps In The PCBA Manufacturing Process Explained

Choosing The Right PCBA Manufacturer For Your Business

Finding PCBA Manufacturing Services With Superior Capabilities